Abstract

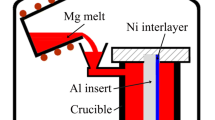

The lost foam casting (LFC) process was used to prepare the A356 aluminum and AZ91D magnesium bimetallic castings, and the interface characteristics of the reaction layer between aluminum and magnesium obtained by the LFC process were investigated in the present work. The results indicate that a uniform and compact interface between the aluminum and magnesium was formed. The reaction layer of the interface with an average thickness of approximately 1000 μm was mainly composed of Al3Mg2 and Al12Mg17 intermetallic compounds, including the Al3Mg2 layer adjacent to the aluminum insert, the Al12Mg17 middle layer, and the Al12Mg17 + δ eutectic layer adjacent to the magnesium base. Meanwhile, the Mg2Si intermetallic compound was also detected in the reaction layer. An oxide film mainly containing C, O, and Mg elements generated at the interface between the aluminum and magnesium, due to the decomposed residue of the foam pattern, the oxidations of magnesium and aluminum alloys as well as the reaction between the magnesium melt and the aluminum insert. The microhardness tests show that the microhardnesses at the interface were obviously higher than those of the magnesium and aluminum base metals, and the Al3Mg2 layer at the interface had a high microhardness compared with the Al12Mg17 and Al12Mg17 + δ eutectic layers, especially the eutectic layer.

Similar content being viewed by others

References

1. W.M. Jiang, Z.T. Fan, X. Chen, B.J. Wang, and H.B. Wu: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 1776-88.

Z.M. Li, Q.G. Wang, A.A. Luo, P.H. Fu, L.M. Peng, Y.X. Wang, and G.H. Wu: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5202-15.

3. H. Springer, A. Kostka, E.J. Payton, D. Raabe, A. Kaysser-Pyzalla, and G. Eggeler: Acta Mater., 2011, vol. 59, pp. 1586-600.

4. M. Marzouk, M. Jain, and S. Shankar: Mater. Sci. Eng. A, 2014, vol. 598, pp. 277-87.

5. K.J.M. Papis, B. Hallstedt, J.F. Loffler, and P.J. Uggowitzer: Acta Mater., 2008, vol. 56, pp. 3036-43.

6. M. Paramsothy, N. Srikanth, and M. Gupta: J. Alloys Compd., 2008, vol. 461, pp. 200-8.

7. M. Thirumurugan, S.A. Rao, S. Kumaran, and T.S. Rao: J. Mater. Process. Technol., 2011, vol. 211, pp. 1637-42.

8. E. Hajjari, M. Divandari, S. H. Razavi, S. M. Emami, T. Homma, and S. Kamado: J. Mater. Sci., 2011, vol. 46, pp. 6491-99.

9. W.M. Jiang, Z.T. Fan, D.J. Liu, D.F. Liao, X.P. Dong, and X.M. Zong: Mater. Sci. Eng. A, 2013, vol. 560, pp. 396-403.

10. P.M. Geffroy, M. Lakehal, J. Goni, E. Beaugnon, J.M. Heintz, and J.F. Silvain: Metall. Mater. Trans. A, 2006, vol. 37, pp. 441-47.

11. X.J. Liu, S.H. Bhavnani, and R.A. Overfelt: J. Mater. Process. Technol., 2007, vol. 182, pp. 333-42.

12. W.M. Jiang, Z.T. Fan, D.J. Liu, D.F. Liao, Z. Zhao, X.P. Dong, and H.B. Wu: Int. J. Cast Met. Res., 2012, vol. 25, pp. 47-52.

13. Z.L. Liu, J.Y. Hu, Q.D. Wang, W.J. Ding, Y.P. Zhu, Y.Z. Lu, and W.Z. Chen: J. Mater. Process. Technol., 2002, vol. 120, pp. 94-100.

14. M.R. Barone and D.A. Caulk: Int. J. Heat Mass Transfer, 2005, vol. 48, pp. 4132-49.

15. M.M. Hejazi, M. Divandari, and E. Taghaddos: Mater. Des., 2009, vol. 30, pp. 1085-92.

16. M. Divandari and A.R. Vahid Golpayegani: Mater. Des., 2009, vol. 30, pp. 3279-85.

17. K.H. Choe, K.S. Park, B.H. Kang, G.S. Cho, K.Y. Kim, K.W. Lee, M.H. Kim, A. Ikenaga, and S. Koroyasu: J. Mater. Sci. Technol., 2008, vol. 24, pp. 60-64.

18. E. Hajjari, M. Divandari, S.H. Razavi, T. Homma, and S. Kamado: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4667-77.

19. A. Kostka, R.S. Coelho, J. dos Santos, and A.R. Pyzalla: Scripta Mater., 2009, vol. 60, pp. 953-56.

20. H. Zhang, Y.Q. Chen, and A.A. Luo: Scripta Mater., 2014, vol. 86, pp. 52-55.

21. J. Wang, Y.J. Li, P. Liu, and H.R. Geng: J. Mater. Process. Technol., 2008, vol. 205, pp. 146-50.

22. M. Gao, S.W. Mei, X.Y. Li, and X.Y. Zeng: Scripta Mater., 2012, vol. 67, pp. 193-96.

23. S.M. Emami, M. Divandari, E. Hajjari, and H. Arabi: Int. J. Cast Met. Res., 2013, vol. 26, pp. 43-50.

24. K.A. Guler, A. Kisasoz, and A. Karaaslan: Mater. Test., 2014, vol. 56, pp. 700-2.

25. U.R. Kattner and T.B. Massalski: Binary Alloy Phase Diagrams, ASM International, Material Park, OH, 1990.

26. E. Hajjari, M. Divandari, S.H. Razavi, T. Homma, and S. Kamado: Intermetallics, 2012, vol. 23, pp. 182-86.

27. D. Singh, C. Suryanarayana, L. Mertus, and R.H. Chen: Intermetallics, 2003, 11, 373-76.

28. W.M. Jiang, Z.T. Fan, D.F. Liao, D.J. Liu, Z. Zhao, and X.P. Dong: Mater. Des., 2011, vol. 32, pp. 926-34.

29. J. Campbell: Casting, 2nd ed., Butterworth-Heinemann, Oxford, United Kingdom, 2003.

30. A.R. Mirak, M. Divandari, S.M.A. Boutorabi, and J. Campbell: Int. J. Cast. Met. Res., 2007, vol. 20, pp. 215-20.

31. C.R. Werrett, D.R. Pyke, and A.K. Bhattacharya: Surf. Interface Anal., 1997, vol. 25, pp. 809-16.

32. P. Liu, Y. Li, H. Geng, and J. Wang: Mater. Lett., 2007, vol. 61, pp. 1288-91.

33. Y. S. Sato, S. Hwan, C. Park, M. Michiuchi, and H. Kokawa: Scripta Mater., 2004, vol. 50, pp. 1233-36.

34. D. Dietrich, D. Nickel, M. Krause, T. Lampke, M.P. Coleman, and V. Randle: J. Mater. Sci., 2011, vol. 46, pp. 357-64.

35. Y.Y. Wang, G.Q. Luo, J. Zhang, Q. Shen, and L.M. Zhang: J. Alloys Compd., 2012, vol. 541, pp. 458-61.

36. L.M. Zhao and Z.D. Zhang: Scripta Mater., 2008, vol. 58, pp. 283-86.

37. L.M. Liu, X.J. Liu, and S.H. Liu: Scripta Mater., 2006, vol. 55, pp. 383-86.

38. Y.Y. Wang, G.Q. Luo, J. Zhang, Q. Shen, and L.M. Zhang: Mater. Sci. Eng. A, 2013, vol. 559, pp. 868-74.

Acknowledgments

This work was funded by Project 51204124 supported by the National Natural Science Foundation of China, Project P2015-09 supported by State Key Laboratory of Materials Processing and Die & Mould Technology, HUST, and Project 2012M511610 & 2014T70694 supported by the China Postdoctoral Science Foundation. The authors would also like to thank the support of the Research Project of State Key Laboratory of Materials Processing and Die & Mould Technology and the Analytical and Testing Center, HUST.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 8, 2015.

Rights and permissions

About this article

Cite this article

Jiang, W., Li, G., Fan, Z. et al. Investigation on the Interface Characteristics of Al/Mg Bimetallic Castings Processed by Lost Foam Casting. Metall Mater Trans A 47, 2462–2470 (2016). https://doi.org/10.1007/s11661-016-3395-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3395-9