Abstract

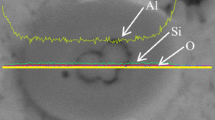

To optimize the braze composition design route for aluminum matrix composite, the feasibility of in situ producing reinforcing phase within the transient liquid phase bond seam matrix, by adding active melting point increaser (MPI, e.g., Ti) together with general melting point depressant (MPD, e.g., Cu) into the interlayer, was demonstrated. For SiC p /A356 composite, by comparing the wettability, joint microstructure, joint shear strength, and fracture path for the developed Al-19Cu-1Ti, Al-19Cu, Al-33Cu-1Ti, Al-33Cu (wt pct), and commercial Cu foils as interlayer, the feasibility of in situ producing reinforcing phase within the bond seam by adding Ti was demonstrated. Especially for Al-19Cu-1Ti active braze, small and dispersed ternary aluminide of Al-Si-Ti phase was obtained within the bond seam as in situ reinforcement, leading to a favorable fracture path within SiC p /A356, not along the initial interface or within the bond seam. For the formation mechanism of the in situ reinforcing phase of MPI-containing intermetallic compound within the bond seam, a model of repeating concentration-precipitation-termination-engulfment during isothermal solidification is proposed.

Similar content being viewed by others

References

M.B.D. Ellis: Int. Mater. Rev., 1996, vol. 41, pp. 41–58.

D. Storjohann, O.M. Barabash, S.S. Babu, S.A. David, P.S. Sklad, and E.E. Bloom: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 3237–47.

A. Urena, M.D. Escalera, and L. Gil: Compos. Sci. Technol., 2000, vol. 60, pp. 613–22.

X.P. Zhang, G.F. Quan, and W. Wei: Compos. Part A, 1999, vol. 30A, pp. 823–27.

W.P. Weng and T.H. Chuang: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 2673–82.

A. Suzumura and Y.J. Xing: Prepr. Nat. Meet. JWS, 1994, vol. 55, pp. 282–83.

A. Suzumura, M. Matsumoto, and Y.J. Xing: Prepr. Nat. Meet. JWS, 1996, vol. 59, pp. 262–63.

T. Enjo, K. Ikeuchi, Y. Murakami, and N. Suzuki: Trans. JWRI, 1987, vol. 16, pp. 285–92.

R. Klehn and T.W. Eagar: WRC Bull., 1993, vol. 385, pp. 1–26.

Z. Li, Y. Zhou, and T.H. North: J. Mater. Sci., 1995, vol. 30, pp. 1075–82.

A.A. Shirzadi and E.R. Wallach: Mater. Sci. Technol., 1997, vol. 13, pp. 135–42.

A. Suzumura and Y.J. Xing: Mater. Trans. JIM, 1996, vol. 37, pp. 1109–15.

J.R. Askew, J.F. Wilde, and T.I. Khan: Mater. Sci. Technol., 1998, vol. 14, pp. 920–24.

W.F. Gale and D.A. Butts: Sci. Technol. Weld. Join., 2004, vol. 9, pp. 283–300.

Y. Shen, W.F. Gale, J.W. Fergus and X. Wen: Mater. Sci. Technol., 2001, vol. 17, pp. 1293–98.

Z.W. Xu, J.C. Yan, B.Y. Zhang, X.L. Kong, and S.Q. Yang: Mater. Sci. Eng., 2006, vol. 415, pp. 80–86.

G.O. Cook III and C.D. Sorensen: J. Mater. Sci., 2011, vol. 46, pp. 5305–23.

I. Tuah-poku, M. Dollar, and T.B. Massalski: Metall. Trans. A, 1988, vol. 19A, pp. 675–86.

W.H. Liu, D.Q. Sun, S.S. Jia, and X.M. Qiu: Trans. China Weld. Inst., 2003, vol. 24, pp. 13–16 (in Chinese).

G. Zhang, J. Zhang, Y. Pei, S. Li, and D. Chai: Mater. Sci. Eng. A, 2008, vol. 488A, pp. 146–56.

G. Zhang, W. Su, J. Zhang, and A. Suzumura: J. Mater. Eng. Perform., 2013, vol. 22, pp. 1982–94.

W.P. Weng and T.H. Chuang: Mater. Manuf. Process., 1997, vol. 12, pp. 1107–32.

E. Lugscheider, S. Ferrara, H. Janssen, A. Reimann, and B. Wildpanner: Microsystem Technol., 2004, vol. 10, pp. 233–36.

J.C. Yan, H.B. Xu, L. Shi, X.H. Wang, and S.Q. Yang: Sci. Technol. Weld. Join., 2008, vol. 13, pp. 760–764.

B. Wielage, I. Hoyer and S. Weis: Weld. J., 2007, vol. 86, pp. 67–70.

S. Weis, I. Hoyer and B. Wielage: Weld. J., 2008, vol. 87, pp. 35–37.

J.C. Yan, Z.W. Xu, L. Shi, X. Ma, and S.Q. Yang: Mater. Des., 2011, vol. 32, pp. 343–47.

K.O. Cooke, T.I. Khan, and G.D. Oliver: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 2271–77.

J.H. Huang, Y.L. Dong, and Y. Wan: J. Mater. Process. Technol., 2007, vol. 190, pp. 312–16.

J.H. Huang, Y.L. Dong, Y. Wan, J.G. Zhang, and G.A. Zhou: Mater. Sci. Technol., 2005, vol. 21, pp. 1217–21.

S.C. Tjong and Z.Y. Ma: Mater. Sci. Eng. R, 2000, vol. 29R, pp. 49–113.

B.S.B. Reddy, K. Das, and S. Das: J. Mater. Sci., 2007, vol. 42, pp. 9366–78.

J.T. Niemann and G.W. Wille: Weld. J., 1978, vol. 57, pp. 285s–94s.

C.J. Hsu, C.Y. Chang, P.W. Kao, N.J. Ho, and C.P. Chang: Acta Mater., 2006, vol. 54, pp. 5241–49.

H. Sato, T. Murase, T. Fujii, S. Onaka, Y. Watanabe, and M. Koto: Acta Mater., 2008, vol. 56, pp. 4549–58.

Y. Watanabe, H. Eryu, and K. Matsuura: Acta Mater., 2001, vol. 49, pp. 775–83.

Y. Watanabe, N. Yamanaka, and Y. Fukui: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3253–61.

Y. Watanabe and T. Nakamura: Intermetallics, 2001, vol. 9, pp. 33–43.

S. El-Hadad, H. Sato, and Y. Watanabe: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 3249–56.

Z.Y. Ma and S.C. Tjong: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 1931–42.

S.C. Tjong, G.S. Wang, and Y.W. Mai: Compos. Sci. Technol., 2005, vol. 65, pp. 1537–46.

S.C. Tjong and G.S. Wang: Mater. Sci. Eng. A, 2004, vol. 386A, pp. 48–53.

P. Yu, Z. Mei, and S.C. Tjong: Mater. Chem. Phys., 2005, vol. 93, pp. 109–16.

C.F. Feng and L. Froyen: Compos. Part A, 2000, vol. 31A, pp. 385–90.

S. Yu, H. Feng, and Y. Li: J. Alloys Compd., 2008, vol. 457, pp. 404–07.

X. Wang, A. Jha, and R. Brydson: Mater. Sci. Eng. A, 2004, vol. 364A, pp. 339–45.

S.H. Wang and P.W. Kao: Acta Mater., 1998, vol. 46, pp. 2675–82.

Q. Zhang, B.L. Xiao, D. Wang, and Z.Y. Ma: Mater. Chem. Phys., 2011, vol. 130, pp. 1109–17.

M. Nofar, H.R. Madaah Hosseini, and N. Kolagar-Daroonkolaie: Mater. Des., 2009, vol. 30, pp. 280–86.

V. Abbasi Chianeh, H.R. Madaah Hosseini, and M. Nofar: J. Alloys Compd., 2009, vol. 473, pp. 127–32.

M. Zeren and E. Karakulak: J. Alloys Compd., 2008, vol. 450, pp. 255–59.

Y. Watanabe and S. Oike: Acta Mater., 2005, vol. 53, pp. 1631–41.

ACKNOWLEDGMENT

The present research was supported by the National Science Foundation of China (Grant Nos. 51275390 and 50875199).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 14, 2014.

Rights and permissions

About this article

Cite this article

Zhang, G., Liao, X., Chen, B. et al. Approach to In-Situ Producing Reinforcing Phase Within an Active-Transient Liquid Phase Bond Seam for Aluminum Matrix Composite. Metall Mater Trans A 46, 2568–2578 (2015). https://doi.org/10.1007/s11661-015-2821-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2821-8