Abstract

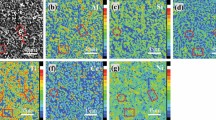

A trimodal metal matrix composite (MMC) based on AA (Al alloy) 5083 (Al-4.4Mg-0.7Mn-0.15Cr wt pct) was synthesized by cryomilling powders followed by compaction of blended powders and ceramic particles using two successive dual mode dynamic forgings. The microstructure consisted of 66.5 vol pct ultrafine grain (UFG) region, 30 vol pct coarse grain (CG) region and 3.5 vol pct reinforcing boron carbide particles. The microstructure imparted high-tensile yield strength (581 MPa) compared to a conventional AA 5083 (242 MPa) and enhanced ductility compared to 100 pct UFG Al MMC. The deformation behavior of the heterogeneous structure and the effects of CG regions on crack propagation were investigated using in situ scanning electron microscopy micro-tensile tests. The micro-strain evolution measured using digital image correlation showed early plastic strain localization in CG regions. Micro-voids due to the strain mismatch at CG/UFG interfaces were responsible for crack initiation. CG region toughening was realized by plasticity-induced crack closure and zone shielding of disconnected micro-cracks. However, these toughening mechanisms did not effectively suppress its brittle behavior. Further optimization of the CG distribution (spacing and morphology) is required to achieve toughness levels required for structural applications.

Similar content being viewed by others

References

H. Gleiter, “Nanocrystalline materials,” Progess Mater. Sci., vol. 33, pp. 223–315, 1990.

R. Birringer, “Nanocrystalline materials,” Mater. Sci. Eng. A, vol. 117, pp. 33–43, Sep. 1989.

C. Suryanarayana, “Nanocrystalline materials,” Int. Mater. Rev., vol. 40, no. 2, pp. 41–64, Jan. 1995.

K. Lu, “Nanocrystalline metals crystallized from amorphous solids: nanocrystallization, structure, and properties,” Mater. Sci. Eng. R, no. 16, pp. 161–221, 1996.

H. Gleiter, “Nanostructured materials:Basic concepts and microstructure,” Acta Mater., vol. 48, pp. 1–29, 2000.

M. A. Meyers, A. Mishra, and D. J. Benson, “Mechanical properties of nanocrystalline materials,” Prog. Mater. Sci., vol. 51, no. 4, pp. 427–556, May 2006.

R. . Valiev, R. . Islamgaliev, and I. . Alexandrov, “Bulk nanostructured materials from severe plastic deformation,” Prog. Mater. Sci., vol. 45, no. 2, pp. 103–189, Mar. 2000.

V. L. Tellkamp, A. Melmed, and E. J. Lavernia, “Mechanical behavior and microstructure of a thermally stable bulk nanostructured Al alloy,” Metall. Mater. Trans. A, vol. 32A, no. September, pp. 2335–2343, 2001.

D. B. Witkin and E. J. Lavernia, “Synthesis and mechanical behavior of nanostructured materials via cryomilling,” Prog. Mater. Sci., vol. 51, no. 1, pp. 1–60, Jan. 2006.

A. P. Newbery, B. Ahn, T. D. Topping, P. S. Pao, S. R. Nutt and E. J. Lavernia, “Large UFG Al alloy plates from cryomilling”, J. Mater. Proc. Tech., vol. 203 (1-3), pp. 37-45, 2008.

G. Hardenbergstr, “Mechanical formation by mechanical attrition,” Nanostructured Mater., vol. 6, no. 95, pp. 33–42, 1995.

R. W. Hayes, P. B. Berbon, and R. S. Mishra, “Microstructure characterization and creep deformation of an Al-10 wt pct Ti-2 wt pct Cu nanocomposite,” Metall. Mater. Trans. A, vol. 35, pp. 3855–3861, 2004.

T.J. Van Daam and C.C. Bampton: US Patent, The Boeing Company, Chicago, IL, 2008.

O. Susegg, E. Hellum, A. Olsen and M. Luton, “An electron microscopy study of dispersoids in cryomilled ODS-materials,” Micron Microsc. Acta, vol. 23, no. 1/2, pp. 223–224, 1992.

Y. Li, W. Liu, V. Ortalan, W. F. Li, Z. Zhang, R. Vogt, N. D. Browning, E. J. Lavernia, and J. M. Schoenung, “HRTEM and EELS study of aluminum nitride in nanostructured Al 5083/B4C processed via cryomilling,” Acta Mater., vol. 58, no. 5, pp. 1732–1740, Mar. 2010.

F. Tang, C.P. Liao, B. Ahn, S.R. Nutt and J.M. Schoenung: Powder Metall., 2007, vol. 50(4), pp. 307–12.

K. M. Youssef, R. O. Scattergood, K. Linga Murty, and C. C. Koch, “Ultratough nanocrystalline copper with a narrow grain size distribution,” Appl. Phys. Lett., vol. 85, no. 6, p. 929, 2004.

K. . Kumar, H. Van Swygenhoven, and S. Suresh, “Mechanical behavior of nanocrystalline metals and alloys,” Acta Mater., vol. 51, no. 19, pp. 5743–5774, Nov. 2003.

E. Ma, “Instabilities and ductility of nanocrystalline and ultrafine-grained metals,” Scr. Mater., vol. 49, no. 7, pp. 663–668, Oct. 2003.

P.G. Sanders, J.A. Eastman, and J.R. Weertman: Acta Mater., 1997, vol. 45(10), pp. 4019–25.

Y. Wang, M. Chen, F. Zhou, and E. Ma, “High tensile ductility in a nanostructured metal.,” Nature, vol. 419, no. 6910, pp. 912–5, Oct. 2002.

G. J. Fan, H. Choo, P. K. Liaw, and E. J. Lavernia, “Plastic deformation and fracture of ultrafine-grained Al–Mg alloys with a bimodal grain size distribution,” Acta Mater., vol. 54, no. 7, pp. 1759–1766, Apr. 2006.

Z. Lee, V. Radmilovic, B. Ahn, E. J. Lavernia, and S. R. Nutt, “Tensile deformation and fracture mechanism of bulk bimodal ultrafine-grained Al-Mg alloy,” Metall. Mater. Trans. A, vol. 41, no. 4, pp. 795–801, Oct. 2009.

L. Jiang, K. Ma, H. Yang, M. Li, E. J. Lavernia, and J. M. Schoenung, “The microstructural design of trimodal aluminum composites”, JOM, vol. 66, no. 6, pp. 898-908, 2014.

Y. Li, Y. H. Zhao, V. Ortalan, W. Liu, Z. H. Zhang, R. G. Vogt, N. D. Browning, E. J. Lavernia, and J. M. Schoenung, “Investigation of aluminum-based nanocomposites with ultra-high strength,” Mater. Sci. Eng. A, vol. 527, no. 1–2, pp. 305–316, Dec. 2009.

K.M. Reddy, P. Liu, A. Hirata, T. Fujita, and M.W. Chen: Nat. Commun., 2013, vol. 4, p. 2483.

Z. Zhang, T. Topping, Y. Li, R. Vogt, Y. Zhou, C. Haines, J. Paras, D. Kapoor, J. M. Schoenung, and E. J. Lavernia, “Mechanical behavior of ultrafine-grained Al composites reinforced with B4C nanoparticles,” Scr. Mater., vol. 65, no. 8, pp. 652–655, Oct. 2011.

Z. Zhang, S. Dallek, R. Vogt, Y. Li, T. D. Topping, Y. Zhou, J. M. Schoenung, and E. J. Lavernia, “Degassing behavior of nanostructured Al and its composites,” Metall. Mater. Trans. A, vol. 41, no. 2, pp. 532–541, Nov. 2009.

J.R. Davis: Properties and Selection: Nonferrous Alloys and Special Purpose Materials, 1990, ASM International, Metals Park, vol. 2.

P. W. Trimby, “Orientation mapping of nanostructured materials using transmission Kikuchi diffraction in the scanning electron microscope.,” Ultramicroscopy, vol. 120, pp. 16–24, Sep. 2012.

P. W. Trimby, Y. Cao, Z. Chen, S. Han, K. J. Hemker, J. Lian, X. Liao, P. Rottmann, S. Samudrala, J. Sun, J. T. Wang, J. Wheeler, and J. M. Cairney, “Characterizing deformed ultrafine-grained and nanocrystalline materials using transmission Kikuchi diffraction in a scanning electron microscope,” Acta Mater., vol. 62, pp. 69–80, Jan. 2014.

Y. Zhang, T. D. Topping, E. J. Lavernia, and S. R. Nutt, “Dynamic micro-Strain analysis of ultrafine-grained aluminum magnesium alloy using digital image correlation,” Metall. Mater. Trans. A, vol. 45, no. 1, pp. 47–54, May 2013.

Y. J. Li, W. Z. Zhang, and K. Marthinsen, “Precipitation crystallography of plate-shaped Al6(Mn,Fe) dispersoids in AA5182 alloy,” Acta Mater., vol. 60, no. 17, pp. 5963–5974, Oct. 2012.

G. Lucadamo, N. Y. C. Yang, C. S. Marchi, and E. J. Lavernia, “Microstructure characterization in cryomilled Al 5083,” Mater. Sci. Eng. A, vol. 430, no. 1–2, pp. 230–241, Aug. 2006.

T. D. Topping, B. Ahn, Y. Li, S. R. Nutt, and E. J. Lavernia, “Influence of process parameters on the mechanical behavior of an ultrafine-grained Al alloy,” Metall. Mater. Trans. A, vol. 43, no. 2, pp. 505–519, Aug. 2011.

J. Ye, B. Q. Han, Z. Lee, B. Ahn, S. R. Nutt, and J. M. Schoenung, “A tri-modal aluminum based composite with super-high strength,” Scr. Mater., vol. 53, no. 5, pp. 481–486, Sep. 2005.

E. O. Hall, “The deformation and ageing of mild steel: III discussion of results,” Proc. Phys. Soc. London, vol. 64, no. 381, pp. 747–753, 1951.

Petch, N.J., “The cleavage Strength of Polycrystals,” Journal of the Iron and Steel Institute, 1953. 174(1): p. 25-28.

K. Peng, W. Chen, H. Zhang, and K.-W. Qian, “Features of dynamic strain aging in high strength Al-Zn-Mg-Cu alloy,” Mater. Sci. Eng. A, vol. 234–236, pp. 138–141, Aug. 1997.

F. Tang and J. M. Schoenung, “Strain softening in nanocrystalline or ultrafine-grained metals: A mechanistic explanation,” Mater. Sci. Eng. A, vol. 493, no. 1–2, pp. 101–103, Oct. 2008.

T.D. Topping and E.J. Lavernia: 13th International Conference on Aluminum Alloys, John Wiley & Sons, Inc., Hoboken, NJ, 2012.

H. Yang, T.D. Topping, K. Wehage, L. Jiang, E.J. Lavernia, and J.M. Schoenung: Mater. Sci. Eng. A. DOI:10.1016/j.msea.2014.07.079.

S. R. Nutt and J. M. Duva, “Failure in Al-SiC composites,” Scr. Metall., vol. 20, no. 7, p. 1055, 1986.

Y.H. Zhao, Y.Z. Guo, Q. Wei, T.D. Topping, A.M. Dangelewicz, Y.T. Zhu, T.G. Langdon, and E.J. Lavernia: Mater. Sci. Eng. A, 2009, vol. 525(1–2), pp. 68–77.

B. Ahn, E.J. Lavernia, and S.R. Nutt, “Dynamic observations of deformation in an ultrafine-grained Al-Mg alloy with bimodal grain structure”, J. Mater. Sci., vol. 43, pp. 7403, 2008.

Z. Lee, D. B. Witkin, V. Radmilovic, E. J. Lavernia, and S. R. Nutt, “Bimodal microstructure and deformation of cryomilled bulk nanocrystalline Al–7.5Mg alloy,” Mater. Sci. Eng. A, vol. 410–411, pp. 462–467, Nov. 2005.

A.P. Newbery, S.R. Nutt, and E.J. Lavernia: J. Miner. Met. Mater. Soc., 2006, vol. 58, pp. 56–61.

D. C. Hofmann, J.-Y. Suh, A. Wiest, G. Duan, M.-L. Lind, M. D. Demetriou, and W. L. Johnson, “Designing metallic glass matrix composites with high toughness and tensile ductility,” Nature, vol. 451, no. 7182, pp. 1085–9, Feb. 2008.

R.W. Hertzberg: Deformation and Fracture Mechanics of Engineering Materials, Chapter 8. Wiley, New York, 1996.

P.S. Pao, H.N. Jones, and C.R. Feng: Mater. Res. Soc. Symp. Proc., 2004, vol. 791, p. Q1.8.1.

Acknowledgments

The authors gratefully acknowledge J. Curulli and M. Mecklenburg for their valuable advice. The images and data used in this article were generated at the Center for Electron Microscopy and Microanalysis (CEMMA), University of Southern California. The authors wish to acknowledge the financial support provided by the Office of Naval Research under the guidance of Rod Peterson and Bill Golumbfskie (ONR Contract N00014-12-C-0241).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 27, 2014.

Rights and permissions

About this article

Cite this article

Zhang, Y., Topping, T.D., Yang, H. et al. Micro-strain Evolution and Toughening Mechanisms in a Trimodal Al-Based Metal Matrix Composite. Metall Mater Trans A 46, 1196–1204 (2015). https://doi.org/10.1007/s11661-014-2729-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2729-8