Abstract

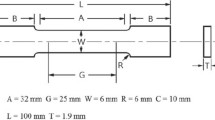

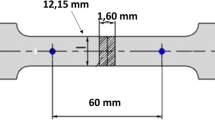

In this study, the stress corrosion cracking (SCC) resistance of AA5083 is intentionally degraded by a series of progressively longer annealing treatments at 448 K (175 °C) that create a two-phase microstructure. Precipitation of strongly anodic Mg2Al3, known as β-phase, occurs heterogeneously with substantial precipitation along the grain boundaries, as observed by differential interference microscopy. Ultimate tensile strength, yield strength, and strain to failure of AA5083 alloy were found to be independent of the amount of β-phase precipitates, making AA5083 an ideal system to study the relative contributions of anodic dissolution and hydrogen embrittlement. Open circuit dropwise exposure SCC tests with precracked double cantilever beam (DCB) specimens made from the AA5083 alloy with different heat treatment conditions were conducted using 3.5 pct NaCl solution at an initial stress intensity factor (K I ) of \( 1 5\,{\text{ksi}}\sqrt {\text{in}} .\;\left( { 1 6. 5\,{\text{MPa}}\sqrt {\text{m}} } \right). \) Two SCC characteristics, initial crack growth rate and incubation time, were found to be strongly dependent on the amount of β-phase precipitates. Initial crack growth rate increased sigmoidally as a function of heat treatment time with an inflection point between 120 and 240 hours of sensitization time, while the incubation time decreases monotonically with sensitization time. Additionally, fracture surfaces investigated by scanning electron microscopy demonstrated characteristics of intergranular cracking with multiple crack tips. Discussion centers on the evidence supporting anodic dissolution of β-phase grain boundary precipitates as a primary mechanism of SCC in severely sensitized AA5083 alloy and the potential contribution of hydrogen embrittlement in the failure of grain boundary ligaments between β-phase grain boundary precipitates in less severely sensitized conditions.

Similar content being viewed by others

References

J.E. Hatch: Aluminum: Properties and Physical Metallurgy, ASM INTERNATIONAL, Metals Park, OH, 1984, pp. 351–78.

D.O. Sprowls and R.H. Brown: in Fundamental Aspects of Stress Corrosion Cracking, Conf. Proc., R.W. Staehle and A.J. Froty, eds., NACE, Houston, TX, 1969, pp. 466–512.

R.H. Jones, D.R. Baer, M.J. Danielson, and J.S. Vetrano: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1699–1711.

R.H. Jones, J.S. Vetrano, and C.F. Windisch, Jr.: Corrosion, 2004, vol. 60, pp. 1144–54.

R.H. Jones, V.Y. Gertsman, J.S. Vetrano, and C.F. Windisch, Jr.: Scripta Mater., 2004, vol. 50, pp. 1355–59.

T.B. Massalski, J.L. Murray, L.H. Bennett, and H. Baker: Binary Alloy Phase Diagrams, ASM INTERNATIONAL, Metals Park, OH, 1984, vol. 1, pp. 129–31.

E.H. Dix, Jr., W.A. Anderson, and M.B. Shumaker: Corrosion, 1959, vol. 15, pp. 19–26.

R. Braun and T. Hack: Mater. Sci. Forum, 1996, vols. 217–222, pp. 1635–40.

J.C. Chang and T.H. Chuang: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3191–99.

M.C. Carroll, P.I. Gouma, M.J. Mills, G.S. Daehn, and B.R. Dunbar: Scripta Mater., 2000, vol. 42, pp. 335–40.

R.G. Buchheit, R.K. Boger, M.C. Carroll, R.M. Leard, C. Paglia, and J.L. Searles: J. Miner. Met. Mater. Soc., 2001, vol. 53, pp. 29–36.

J.L. Searles, P.I. Gouma, and R.G. Buchheit: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2859–67.

J.L. Searles, P.I. Gouma, and R.G. Buchheit: Mater. Sci. Forum, 2002, vols. 396–402, pp. 1437–42.

A. Barbucci, P.L. Cabot, G. Bruzzone, and G. Cerisola: J. Alloys Compd., 1998, vol. 268, pp. 295–301.

F.S. Bovard: Corrosion in Marine and Saltwater Environments II, Electrochemical Society Proc., D.A. Shifler, T. Tsuru, P.M. Natishan, and S. Ito, eds., The Electrochemical Society, Inc., Pennington, NJ, 2005, vols. 2004–2014, pp. 232–43.

I.N.A. Oguocha, O.J. Adigun, and S. Yannacopoulos: J. Mater. Sci., 2008, vol. 43, pp. 4208–14.

S. Badirujjaman, X.W. Li, and M. Winning: Mater. Sci. Eng. A, 2007, vol. 448, pp. 242–48.

R. Goswami, G. Spanos, P.S. Pao, and R.L. Holtz: Mater. Sci. Eng. A, 2010, vol. 527, pp. 1089–95.

M. Francon: Progress in Microscopy, Row, Peterson, and Company, New York, 1961, pp. 94–128.

M. Spencer: Fundamentals of Light Microscopy, Cambridge University Press, New York, NY, 1982, pp. 54–60.

M. Popovic and E. Romhanji: Mater. Sci. Eng. A, 2008, vol. 492, pp. 460–67.

Annual Book of ASTM Standards 2006, vol. 03.02, ASTM International, Philadelphia, PA, 2006, pp. 684–93.

Annual Book of ASTM Standards 2006, vol. 03.01, ASTM International, Philadelphia, PA, 2006, pp. 64–87.

Metals Handbook, vol. 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, ASM INTERNATIONAL, Metals Park, OH, 1990, pp. 29–61.

Acknowledgments

The technical skills of Mr. Stephen R. Robinson, who prepared samples and took the photographs, are very much appreciated. The research was supported by the Office of Naval Research under Grant No. N00014–07–1-0554, Dr. A.K. Vasudevan, Scientific Officer.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 23, 2009.

Rights and permissions

About this article

Cite this article

Gao, J., Quesnel, D.J. Enhancement of the Stress Corrosion Sensitivity of AA5083 by Heat Treatment. Metall Mater Trans A 42, 356–364 (2011). https://doi.org/10.1007/s11661-010-0375-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0375-3