Abstract

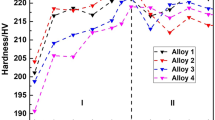

The effect of Sc additions on precipitation strengthening in a direct chill (DC) cast Al-Zn-Mg-Cu alloy was studied after natural and artificial aging. The microhardness, room temperature (RT) mechanical properties, and phase composition of the alloys were determined after different steps of aging. The strengthening mechanisms were discussed. It was shown that minor additions of Sc increased the strength of the Al-Zn-Mg-Cu alloy after casting and solution heat treatment, due to the precipitation of fine coherent Al3(Sc,Zr) particles. An analysis of the aging kinetics revealed that Sc had no effect on the natural aging, which was controlled by the formation and growth of Guinier–Preston (GP) I zones. On the other hand, the Sc additions accelerated the aging process at 120 °C and 150 °C within a period of time of the formation and growth of GP II zones and η′ particles. It was concluded that the presence of Sc accelerated the formation and growth of GP II zones in the Al-Zn-Mg-Cu alloys, which led to the earlier precipitation of the η′ phase. However, at longer aging times at 120 °C and 150 °C, the aging response of the Sc-containing alloys slowed down, due to faster coarsening of the η′ particles and their transformation into η particles. A model of the formation of vacancy-rich clusters (VRCs), precursors to GP zones, in the Al-Zn-Mg–based alloys was proposed. According to this model, the observed effects of Sc on aging are the result of the Sc-induced increase in the number density of the GP II clusters and the concentration of quenched-in solute-bound excess vacancies.

Similar content being viewed by others

Notes

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

PANDAT is a trademark of CompuTherm, LLC, Madison, WI

Here and thereafter, the vacancy concentration is identified as the fraction of the empty atom sites in the unit volume of the crystal matrix.

References

Properties of Aluminum Alloys: Tensile, Creep, and Fatigue Data at High and Low Temperatures, J.G. Kaufman, ed., ASM INTERNATIONAL, Materials Park, OH, 1999

Aluminum and Aluminum Alloys, J.R. Davis, ed., ASM INTERNATIONAL, Materials Park, OH, 1993

J.H. Auld, S.McK. Cousland: J. Austr. Inst. Met., 1974, vol. 19, pp. 194–99

F.A. Costello, J.D. Robson, P.B. Pragnell: Mater. Sci. Forum, 2002, vols. 396–402, pp. 757–62

P. Villars and L.D. Calvert: Pearson’s Handbook of Crystallographic Data for Intermetallic Phases, ASM INTERNATIONAL, Materials Park, OH, 1991, vols. 1–4

K. Stiller, P.J. Warren, V. Hansen, J. Angenete, J. Gjonnes: Mater. Sci. Eng., A, 1999, vol. A270, pp. 55–63

L.K. Berg, J. Gjonnes, V. Hansen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, L.R. Wallenberg: Acta Mater., 2001, vol. 49, pp. 3443–51

T. Engdahl, V. Hansen, P.J. Warren, K. Stiller: Mater. Sci. Eng., A, 2002, vol. A327, pp. 59–64

V. Hansen, O.B. Karlsen, Y. Langsrud, J. Gjønnes: Mater. Sci. Technol., 2004, vol. 20, pp. 185–93

G. Sha, A. Cerezo: Acta Mater., 2004, vol. 52, pp. 4503–16

A. Dupasquier, R. Ferragut, M.M. Iglesias, M. Massazza, R. Riontino, P. Mengucci, G. Barucca, C.E. Macchi, A. Somoza: Philos. Mag., 2007, vol. 87, pp. 3297–3323

H. Löffler, I. Kovács, J. Lendvai: J. Mater. Sci., 1993, vol. 18, pp. 2215–40

X.Z. Li, V. Hansen, J. Gjønnes, R. Wallenderg: Acta Mater. 1999, vol. 47, pp. 2651–59

Handbook of Aluminum, G.E. Totten and D.S. MacKenzie, eds., Marcel Dekker, Inc., New York, NY, 2003, vol. 1, pp. 284–89 and 916–20

X.J. Jiang, B. Noble, V. Hansen, J. Tafto: Metall. Mater. Trans. A, 2001, vol. 32, pp. 1063–73

A.K. Mukhopadhyay, G.J. Shiflet, S.R. Starke: Scripta Mater., 1990, vol. 24, pp. 307–12

A.K. Mukhopadhyay, Q.B. Yang, S.B. Singh: Acta Metall. Mater., 1994, vol. 42, pp. 3083–91

V.I. Elagin: Technology of Light Alloys, Tekhnologiya Legkikh Splavov, USSR, 1994, No. 9, pp. 5–14

V.I. Elagin, V.V. Zakharova, T.D. Rostova: Met. Sci. Heat Treat., 1995, vol. 36 (7–8), pp. 375–80

O.N. Senkov, R.B. Bhat, S.V. Senkova: in Metallic Materials with High Structural Efficiency, O.N. Senkov, D.B. Miracle, S.A. Firstov, eds., Kluwer Academic Publishers, Dordrecht, The Netherlands, 2004, pp. 151–62

Y.V. Milman, A.I. Sirko, D.V. Lotsko, D.B. Miracle, O.N. Senkov: Mater. Sci. Forum, 2002, vols. 396–402, pp. 1217–22

A.F. Norman, K. Hyde, F. Costello, S. Thompson, S. Birley, P.B. Pragnell: Mater. Sci. Eng., A, 2003, vol. 354, pp. 188–98

O.N. Senkov, R.B. Bhat, S.V. Senkova, J.D. Schloz: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 2115–26

J. Royset, N. Ryum: Int. Mater. Rev., 2005, vol. 50, pp. 19–44

O.N. Senkov: Advanced Aluminum Materials for Rocket Turbopump Rotors, SBIR Phase II Final Report, AFRL-PR-ED-TR-2006-0073, U.S. Air Force Research Laboratory, Edwards Air Force Base, CA, 2006, pp. 205–30

O.N. Senkov, S.V. Senkova, M.G. Mendiratta, and D.B. Miracle: U.S. Patent 7,048,815, 2006

O.N. Senkov, S.V. Senkova, M.G. Mendiratta, D.B. Miracle, Y.V. Milman, D.V. Lotsko, and A.I. Sirko: U.S. Patent 7,060,139, 2006

L.I. Kaigorodova, E.I. Selnikhina, E.A. Tkachenko, O.G. Senatorova: Phys. Met. Metall., 1996, vol. 81, pp. 513–19

Y.L. Wu, F.H. Froes, C. Li, A. Alvarez: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1017–24

D.B. Williams, C.B. Carter: Transmission Electron Microscopy, Plenum Press, New York, NY, 1996, pp. 629–30

S. Iwamura, Y. Miura: Acta Mater., 2004, vol. 52, pp. 591–600

R. DeIasi, P.N. Adler: Metall. Trans. A, 1977, vol. 8A, pp. 1177–83

P.H. Adler, R. DeIasi: Metall. Trans. A, 1977, vol. 8A, pp. 1185–90

J.M. Papazian, R.J. DeIasi, P.N. Adler: Metall. Trans. A, 1980, vol. 11A, pp. 135–40

J.M. Papazian: Metall. Trans. A, 1982, vol. 13A, pp. 761–69

A. Deschamps, F. Livet, Y. Brechet: Acta Mater., 1999, vol. 47, pp. 281–92

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, Y.T. Zhu: Acta Mater., 2004, vol. 51, pp. 4589–99

PANDAT™, Version 5.0, CompuTherm, LLC, Madison, WI

O.N. Senkov and M.R. Shaghiev: UES, Inc., Dayton, Ohio, unpublished research, 2006

B.L. Ou, J.G. Yang, M.Y. Wei: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1760–73

S. Iwamura, Y. Miura: Acta Mater., 2004, vol. 52, pp. 591–600

J. Murray, A. Peruzzi, J.P Abriata: J. Phase Equilib., 1992, vol. 13, pp. 277–91

H.H. Jo, S.I. Fujikawa: Mater. Sci. Eng. 1993, vol. A171, pp. 151–61

J. Burke: J. Less Common Met., 1972, vol. 28, pp. 441–56

S. Özbilen, H.M. Flower: Acta Metall., 1989, vol. 37, pp. 2993–3000

R.O. Simmons, R.W. Balluffi: Phys. Rev., 1960, vol. 117, pp. 52–61

Y. Miura, C. Joh, T. Katsube: Mater. Sci. Forum, 2000, vols. 331–337, pp. 1031–36

O. Kubaschewski, C.B. Alcock, P.J. Spencer: Materials Thermochemistry, 6th ed., Pergamon Press, Oxford, United Kingdom, 1993

J.D. Eshelby: in Solid State Physics, F. Seitz and D. Turnbull, eds., Academic Press, New York, NY, 1956, vol. 3, pp. 77–144

S.K. Maloney, K. Hono, I.J. Polmear, S.P. Ringer: Scripta Mater. 1999, vol. 41, pp. 1031–38

Acknowledgments

The authors thank Drs. D.B. Miracle and C.F. Woodward, United States Air Force Research Laboratory (Wright–Patterson Air Force Base, OH), Dr. R. Wheeler, UES, Inc. (Dayton, OH), and Prof. M. Mills, Ohio State University (Columbus, OH), for useful technical help and discussions. This work was financially supported through the United States Air Force Contracts Nos. F04611-02-C-0014 (Capt. William Allen, Program Manager) and FA8650-04-D-5233 (Dr. Joan Fuller, Program Manager).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 4, 2007.

Rights and permissions

About this article

Cite this article

Senkov, O., Senkova, S. & Shagiev, M. Effect of Sc on Aging Kinetics in a Direct Chill Cast Al-Zn-Mg-Cu Alloy. Metall Mater Trans A 39, 1034–1053 (2008). https://doi.org/10.1007/s11661-008-9485-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9485-6