Abstract

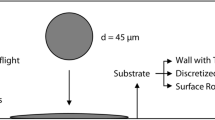

A mathematical model, incorporating the thermal component of sticking efficiency (SE t) into the calculation of shape evolution, is formulated to predict the evolution and final geometry of plates. The plates are spray formed using a moving substrate displaced in a two-dimensional (i.e., X-Y) plane. By using this model, the effects of the substrate movement parameters, such as the acceleration, time required to complete a stroke in the reciprocal movement direction (X-axis), and the velocity in the uniform movement direction (Y-axis), on the shapes of the plates are investigated. The processing parameters are evaluated by minimizing the values of the mean-squared (MS) surface roughness. On the basis of the evaluation, the optimal combinations of processing parameters are found.

Similar content being viewed by others

References

E.J. Lavernia and Y. Wu:Spray Atomization and Deposition, John Wiley & Sons, Inc., New York, NY, 1996.

P.S. Grant:Progr. Mater. Sci., 1995, vol. 39, pp. 497–545.

C.Y. Tsao and N.J. Grant:Int. J. Powder Metall., 1994, vol. 30, pp. 323–33.

S. Annavarapu, D. Apelian, and A. Lawley:Metall. Trans. A, 1990, 21A, pp. 3237–56.

G. Hartmann, P.N. Hansen, and P.R. Sahm: inModeling and Control of Casting and Welding Processes IV, A.F. Giamei and G.J. Abbaschian, eds., TMS, Warrendale, PA, 1988, pp. 915–21.

B.W. Oh and Z.H. Lee:Proc. Modeling of Casting and Solidification Process, Yonsei University, Yonsei, Korea, 1991, pp. 13–22.

H.K. Seok, D.H. Yeo, K.H. Oh, H.I. Lee, and H.Y. Ra:Metall. Mater. Trans. B, 1998, vol. 29B, pp. 699–708.

P. Mathur, D. Apelian, and A. Lawley:Mater. Sci. Eng., 1991, vol. A142, pp. 261–76.

Y.J. Lin, J.E. Bobrow, D.R. White, and E.J. Lavernia:Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2917–29.

H.K. Seok, D.H. Yeo, K.H. Oh, H.Y. Ra, D.S. Shin, and H.I. Lee:Proc. 3rd Int. Conf. on Spray Forming, Wales, United Kingdom, 1996, pp. 287–95.

B.C. Moon, Z.H. Lee, and E.J. Lavernia:J. Mater. Res., 2000, vol. 15.

E.A. Brandes and G.B. Brook:Smithells Metals Reference Book, Butterworths-Heinemann, Oxford, United Kingdom, 1992.

D.R. Lide:The CRC Chemistry and Physics Handbook, CRC Press, Ann Arbor, MI, 1995.

W. Cai and E.J. Lavernia:Metall. Mater. Trans. B, 1998, vol. 29B, pp. 1085–96.

E.L. Crow and K. Shimizu:Lognormal Distributions: Theory and Applications, Marcel Dekker, New York, NY, 1988, p. 2.

J.E. Smith and M.L. Jordan:J. Colloid. Sci., 1964, vol. 19, pp. 549–59.

A.H. Lefebvre:Atomizations and Spray, Taylor & Francis, Bristol, PA, 1989, p. 85.

A. Lawley:Atomization: the Production of Metal Powders, MPIF, Princeton, NJ, 1992, p. 74.

K. Lubanska:J. Met., 1970, vol. 22, pp. 45–49

Q. Xu, V.V. Gupta, and E.J. Lavernia:Metall. Mater. Trans. B, 1999, vol. 30B, pp. 527–39.

Q. Xu, V.V. Gupta, and E.J. Lavernia:Acta Metall., 2000, vol. 48, pp. 835–49.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, Y.J., Feng, W., Bobrow, J.E. et al. Modeling of spray-formed plates using anX-Y moving substrate. Metall Mater Trans A 32, 831–840 (2001). https://doi.org/10.1007/s11661-001-1018-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-1018-5