Abstract

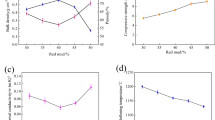

Low-cost thermal insulation porous ceramics with uniform pore diameter and low bulk density were prepared with soda-ash dregs and felsic tailings. We investigated the effect of temperature, foaming agent, fluxing agent, Al2O3 and CaO content on the pore structure and crystal phase of porous ceramics. The effect of Ca2+ in soda-ash dregs on the preparation of quartz-feldspar based porous ceramics was studied. The results showed that the contribution of Ca2+ to the preparation of porous ceramics in this system was mainly to accelerate the Si-O bond fracture and reduce the sintering temperature at the initial stage of sintering, which destroyed the needle-like feldspar in the high temperature melt and reduced the melt viscosity, thus reduced the foaming resistance and promoted the porous products with uniform pore size distribution. The Ca2+ content on the high side can participate in the formation of crystals in sintering. The generated needle-like diopside and augite, which have small length-diameter ratio, will negligibly change in the viscosity of melt at high temperatures, and their inhibition effect on pores is not as good as that of feldspar with large length-diameter ratio, resulting in the merger and collapse of pores. But the increase of diopside and augite can improve the compressive strength of porous products to some extent. Porous ceramic products containing needle-like feldspar phase can be prepared by using two kinds of solid waste, which can improve the compressive strength of the products and reduce the raw material cost and energy consumption while comprehensively utilizing the double solid waste. The optimal product has a bulk density of 0.45 g/cm3, a compressive strength of 3.17 MPa, and a thermal conductivity of 0.11 W/(m·K).

Similar content being viewed by others

References

Khalid R, Moataz NS, Kody MP. Real-time Optimization of a Solar-natural Gas Hybrid Power Plant to Enhance Solar Power Utilization[C]. 2018 Annual American Control Conference (ACC) IEEE, 2018: 3 002–3 007

Papadopoulos AM. State of the Art in Thermal Insulation Materials and Aims for Future Developments[J]. Energy and Buildings, 2005, 37(1): 77–86

Hammel EC, Ighodaro OLR, Okoli OI. Processing and Properties of Advanced Porous Ceramics: An Application Based Review[J]. Ceramics International, 2014, 40(10): 15 351–15 370

Yang H, Jiang Y, Liu H, et al. Mechanical, Thermal and Fire Performance of an Inorganic-organic Insulation Material Composed of Hollow Glass Microspheres and Phenolic Resin[J]. J. Colloid Interface Sci., 2018, 530: 163–170

Aditya L, Mahlia TMI, Rismanchi B, et al. A Review on Insulation Materials for Energy Conservation in Buildings[J]. Renewable and Sustainable Energy Reviews, 2017, 73: 1 352–1 365

Jiang CC, Huang SF, Li GZ, et al. Formation of Closed-pore Foam Ceramic from Granite Scraps[J]. Ceramics International, 2018, 44(3): 3 469–3 471

Liu TY, Zhang JS, Wu JQ, et al. The Utilization of Electrical Insulators Waste and Red Mud for Fabrication of Partially Vitrified Ceramic Materials with High Porosity and High Strength[J]. Journal of Cleaner Production, 2019, 223: 790–800

Gao HT, Liu XH, Chen JQ, et al. Preparation of Glass-ceramics with Low Density and High Strength Using Blast Furnace Slag, Glass Fiber and Water Glass[J]. Ceramics International, 2018, 44(6): 6 044–6 053

Wang H, Chen ZW, Ji R, et al. Integrated Utilization of High Alumina Fly Ash for Synthesis of Foam Glass Ceramic[J]. Ceramics International, 2018, 44(12): 13 681–13 688

Bai JG, Yang XH, Xu SC, et al. Preparation of Foam Glass from Waste Glass and Fly Ash[J]. Materials Letters, 2014, 136: 52–54

Boltakova, NV, Faseeva GR, Kabirov RR, et al. Utilization of Inorganic Industrial Wastes in Producing Construction Ceramics. Review of Russian Experience for the Years 2000–2015[J]. Waste Management, 2017, 60: 230–246

Gorokhovsky AV, Escalante-Garcia JI, Sanchez-Valdes E, et al. Synthesis and Characterization of High-strength Ceramic Composites in the System of Potassium Titanate — Metallurgical Slag[J]. Ceramics International, 2015, 41(10): 13 294–13 303

Du GJ. The Advantage of Using Industrial Solid Waste to Prepare Ceramic Materials is Obvious[N]. China Building Materials News, May 9, 2018

Shao Y, Liu XL, Zhu JJ. Experimental Study on the Improvement of Marine Soft Soil by Alkali Residue[J]. Water Power, 2019, (2): 1–7

Uçal GO, Mahdi M, Mustafa T. Hydration of Alinite Cement Produced from Soda Waste Sludge[J]. Construction and Building Materials, 2018, 164: 178–184

Araya N, Andrzej K, Luis AC. Towards Mine Tailings Valorization: Recovery of Critical Materials from Chilean Mine Tailings[J]. Journal of Cleaner Production, 2020, 263: 121 555

Guo XY, Qin H, Tian QH, et al. The Efficacy of a New Iodination Roasting Technology to Recover Gold and Silver from Refractory Gold Tailing[J]. Journal of Cleaner Production, 2020, 261: 121 147

Yang SW, Liu ZR, Yuan GN. The Resource Utilization of Gold Tailing Sand in Concrete[J]. New Progress in Research and Application of Chemical Admixtures And Mineral Admixtures in China, 2016: 400–403

Huang ZQ, Cheng C, Liu, ZW, et al. Utilization of a New Gemini Surfactant as the Collector for the Reverse Froth Flotation of Phosphate Ore in Sustainable Production of Phosphate Fertilizer[J]. Journal of Cleaner Production, 2019, 221: 108–112

He SY, Song M, Peng JJ, et al. Study on Sintering Mechanism of High Content Gold Tailings Sintering Brick[J]. Birck&Tile, 2012, (12): 23–25

Wang BM, Wang WL, Liang XX, et al. Development of Cementitious Materials Utilizing Alkali-activated Yellow River Silt[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2021, 36(4): 364–373

Zhan JY, Yang FH, Li WM, et al. Hydration Characteristics and Humidity Control Performance of Calcium Silicate Board Prepared from Mine Tailing and Diatomite[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2020, 35(2): 147–154

Lin WQ, Luo WJ, Zhang GH, et al. Preparation of Phlogopite-based Geopolymer and Its Surface Nonpolar Modification[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2021, 36(4): 433–438

Liu HX, Wang RS, Pan YM, et al. A New Material of Sericite Powder Was Extracted from Gold Tailings[J]. Gold, 2020, 32(1): 61–63

Kim Y, Kim M, Sohn J, et al. Applicability of Gold Tailings, Waste Limestone, Red Mud, and Ferronickel Slag for Producing Glass Fibers[J]. Journal of Cleaner Production, 2018, 203: 957–965

Shao H, Liang K, Peng F, et al. Production and Properties of Cordierite-based Glass-ceramics from Gold Tailings[J]. Minerals Engineering, 2005, 18(6): 635–637

Ivanets AI, Azarova TA, Agabekov VE, et al. Effect of Phase Composition of Natural Quartz Raw Material on Characterization of Microfiltration Ceramic Membranes[J]. Ceramics International, 2016, 42(15): 16 571–16 578

RILEY CM. Relation of Chemical Properties to the Bloating of Clays[J]. Journal of The American Ceramic Society-Riley, 1951, 34(4): 121–128

Zhao LB, Xu B, Li GF, et al. Development Status in Comprehensive Utilization of Alkaline Residues[J]. Industrial Minerals & Processing, 2017, 6: 73–76

Gao CZ, Dong Y, Zhang HJ, et al. Utilization of Distiller Waste and Residual Mother Liquor to Prepare Precipitated Calcium Carbonate[J]. Journal of Cleaner Production, 2007, 15(15): 1 419–1 425

Wang Q, Li JJ, Yao G, et al. Characterization of the Mechanical Properties and Microcosmic Mechanism of Portland Cement Prepared with Soda-ash Dregs[J]. Construction and Building Materials, 2020, 241: 117 994

Ke YS. Study on Farming Use about Soda-ash Dregss and Polybasic Compound Fertilizer Containing Calcium and Magnesium[J]. Soda Ash Industry, 2001, (4): 3–7

Ponsot I, Bernardo E, Bontempi E, et al. Recycling of Pre-stabilized Municipal Waste incinerator Fly Ash and Soda-lime Glass into Sintered Glass-ceramics[J]. Journal of Cleaner Production, 2015, 89: 224–230

Shen WG, Liu Y, Yan BL, et al. Cement Industry of China: Driving Force, Environment Impact and Sustainable Development[J]. Renewable and Sustainable Energy Reviews, 2017, 75: 618–628

Zhao XH, Liu CY, Wang L, et al. Physical and Mechanical Properties and Micro Characteristics of Fly Ash-based Geopolymers Incorporating Soda-ash Dregs[J]. Cement and Concrete Composites, 2019, 98: 125–136

Zhou MK, Ge XX, Wang HD, et al. Effect of the CaO Content and Decomposition of Calcium-containing Minerals on Properties and Microstructure of Ceramic Foams from Fly Ash[J]. Ceramics International, 2017, 43(12): 9 451–9 457

Zeng L, Sun H, Peng T, et al. Preparation of Porous Glass-ceramics from Coal Fly Ash and Asbestos Tailings by High-temperature Pore-forming[J]. Waste Manag., 2020, 106: 184–192

Tabit K, Hajjou H, Waqif M, et al. Effect of CaO/SiO2 Ratio on Phase Transformation and Properties of Snorthite-based Ceramics from Coal Fly Ash and Steel Slag[J]. Ceramics International, 2020, 46(6): 7 550–7 558

Wang ZJ, Il S. Effect of the Al2O3/SiO2 Mass Ratio on the Crystallization Behavior of CaO-SiO2-MgO-Al2O3 Slags Using Confocal Laser Scanning Microscopy[J]. Ceramics International, 2018, 44(16): 19 268–19 277

Ge XX, Zhou MK, Wang HD, et al. Effects of Flux Components on the Properties and Pore Structure of Ceramic Foams Produced from Coal Bottom Ash[J]. Ceramics International, 2019, 45(9): 12 528–12 534

Jia RD, Deng LB, Yun F, et al. Effects of SiO2/CaO Ratio on Viscosity, Structure, and Mechanical Properties of Blast Furnace Slag Glass Ceramics[J]. Materials Chemistry and Physics, 2019, 233: 155–162

Stebbins, Jonathan F. “Free” Oxide Ions in Silicate Melts: Thermodynamic Considerations and Probable Effects of Temperature[J]. Chemical Geology, 2017, 461: 2–12

Kang JF, Wang J, Zhou XY, et al. Effects of Alkali Metal Oxides on Crystallization Behavior and Acid Corrosion Resistance of Cordierite-based Glass-ceramics[J]. Journal of Non-Crystalline Solids, 2018, 481: 184–190

Liu ZB, Zong YB, Ma HY, et al. Effect of (CaO+MgO)/SiO2 Ratio on Crystallisation and Properties of Slag Glass-ceramics[J]. Advances in Applied Ceramics, 2014, 113(7): 411–418

Orts MJ, Amorós JL, Escardino A, et al. Kinetic Model for the Isothermal Sintering of Low Porosity Floor Tiles[J]. Appl. Clay Sci., 1993, 8: 231–245

Bernardo E, Cedro R, Florean M, et al. Reutilization and Stabilization of Wastes by the Production of Glass Foams[J]. Ceramics International, 2007, 33(6): 963–968

Doweidar H. Density-structure Correlations in Na2O-Al2O3-SiO2 Glasses[J]. Journal of Non-Crystalline Solids, 1998(240): 55–65

GAROFALINI, David MZ, Stephen H. Reactions on Modified Silica Surfaces[J]. Journal of Non-Crystalline Solids, 1990(120): 111–120

Park JH, Min DJ. Effect of Fluorspar and Alumina on the Viscous Flow of Calcium Silicate Melts Containing MgO[J]. Journal of Non-Crystalline Solids, 2004, 337(2): 150–156

Ding LF, Ning W, Wang QW, et al. Preparation and Characterization of Glass-ceramic Foams from Blast Furnace Slag and Waste Glass[J]. Materials Letters, 2015, 141: 327–329

Tarragó M, Esteves H, Garcia-Valles M, et al. Effect of Ca in P-doped Basaltic Glass-ceramics: Application to Waste Inertization[J]. Materials Letters, 2018, 220: 266–268

Deng LB, Yun Fei, Jia RD, et al. Effect of SiO2/MgO Ratio on the Crystallization Behavior, Structure, and Properties of Wollastonite-augite Glass-ceramics Derived from Stainless Steel Slag[J]. Materials Chemistry and Physics, 2020, 239: 122 039

Kingery WD, Bowen HK, Uhlmann DR. Introduction to Ceramics[M], New York: John Wiley and Sons, 1976

Lamkin MA, Riley FL. Oxygen Mobility in Silicon Dioxide and Silicate Glass: A Review[J]. Journal of the European Ceramic Society, 1992, (10): 347–367

Kachanov M, Behrouz A. On the Isotropic and Anisotropic Viscosity of Suspensions Containing Particles of Diverse Shapes and Orientations[J]. International Journal of Engineering Science, 2015, 94: 71–85

Bhogi S, Mukherjee M. Foam Stabilization by Magnesium[J]. Materials Letters, 2017, 200: 118–120

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China(No.51674161), Major Basic Research Projects of Shandong Province Natural Science Foundation (No.ZR2017ZC0735), Open Topic of Key Laboratory of Gold Mineralization Processes and Resource Utilization Subordinated to the Ministry of Land and Resources, and Key Laboratory of Metallogenic Geological Process and Resources Utilization in Shandong Province (No.Kfkt201812), Research on Precious Metal Mineral Achievement Integration and Tailings Comprehensive Utilization in Shandong Province (Shandong Geological Exploration Document:[2018]No.10)

Rights and permissions

About this article

Cite this article

Wang, Z., Yao, G., Wang, Q. et al. Preparation of Thermal Insulation Ceramics Using Felsic Tailings as Main Raw Material and Soda-ash Dregs as Flux. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 38, 31–41 (2023). https://doi.org/10.1007/s11595-023-2664-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-023-2664-1