Abstract

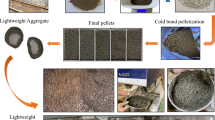

We aimed to reuse the propylene oxide sludge (POS). Propylene oxide sludge shell-aggregate (POSS-A) and propylene oxide sludge gradient shell-aggregate (POSGS-A) whose main hydrated phase is tobermorite were successfully manufactured by the hydrothermal synthesis of POS and silica materials under the condition of autoclaved (180 °C, 1.0 MPa) curing. Influences of pre-wetting time of coarse aggregate and pressure application mode on the different concretes were investigated. The experimental results show that the concrete with POSS-A as coarse aggregate (POSS-A concrete), the concrete with POS gradient shell-aggregate as coarse aggregate (POSGS-A concrete), sintered aggregate concrete and common concrete, all have excellent impermeability performance whatever the pre-wetting time of coarse aggregate is 0.5 h or 24 h, and the pre-wetting time of coarse aggregate has a negligible influence on the concrete. The influence degree of pressure application mode on the impermeability performance of the sintered aggregate concrete is the greatest among three kinds of concrete, which has a negligible influence on impermeability performance of the other concretes. POSGS-A can be used as a green building light aggregate in hydraulic concrete.

Similar content being viewed by others

References

Seong TY, Tae YH, Jin KK. The Effects of Hydraulic Pressure and Crack Width on Water Permeability of Penetration Crack-induced Concrete[J]. Constr. Build. Mater., 2011, 25(5): 2576–2583

Basheer L, Kropp J, Cleland DJ. Assessment of the Durability of Concrete from Its Permeation Properties: A Review[J]. Constr. Build. Mater., 2001, 15: 93–103

Hoseini M, Bindiganavile V, Banthia N. The Effect of Mechanical Stress on Permeability of Concrete: A Review[J]. Cem. Concr. Compos., 2009, 31(4): 213–220

Chen SH, He Z. Status Quo and Prospects for Simulation Analysis of Service Life for Concrete Dam[J]. Eng. J. Wuhan Univ., 2011, 3: 273–280 (in Chinese)

Hall C, Hoff WD. Water Transport in Brick, Stone and Concrete[M]. Spon Press, London, 2012

Kameche Z, Ghomari F, Choinska M, et al. Assessment of Liquid Water and Gas Permeabilities of Partially Saturated Ordinary Concrete[J]. Constr. Build. Mater., 2014, 65: 551–565

Li X, Li D, Xu Y. Modeling the Effects of Microcracks on Water Permeability of Concrete Using 3D Discrete Crack Network[J]. Compos. Struct., 2019, 210: 262–273

Li D, Liu Sh. The Influence of Steel Fiber on Water Permeability of Concrete under Sustained Compressive Load[J]. Constr. Build. Mater., 2020, 242: 1–9

Wang FM, Li MQ, Zhang W. Analysis of the Production Status and Development Prospect of Propylene Oxide in China[J]. Technology & Economics in Petrochemicals, 2020, 36(2): 20–25

Ma HL, Cui Ch, Li X, et al. Study of High Performance Autoclaved Shell-aggregate from Propylene Oxide Sludge[J]. Constr. Build. Mater., 2011, 25: 3030–3037

Ma HL, Cui Ch, Li X. Mechanical Properties of Autoclaved Shell-aggregate[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2011, 4: 719–725

Ma HL, Cui Ch, Li X. Study on Mechanical Properties of Steel Fiber Reinforced Autoclaved Lightweight Shell-Aggregate Concrete[J]. Mater Design, 2013, 52: 565–571

Ma HL, Cui Ch, Zhang BX. Effect of Autoclaved Aggregate Structure on Strength of Concrete[J]. Applied Mechanics and Materials, 2011, 44–47: 2438–2442

GB/T 17431.2-1998. Lightweight Aggregates and Its Test Methods-Part 2: Test Methods for Lightweight Aggregates[S]. (in Chinese)

GB/T 50082-2009. Standard Test Methods for Long-term Performance and Durability of Ordinary Concrete[S]. (in Chinese)

Mu LF, Li SQ, Feng JJ, et al. Experimental Study on the Influence of Prewetted Aggregate on the Properties of Ceramsite Concrete[J]. China Concrete and Cement Products, 2019, 11: 66–69 (in Chinese)

Chen Y, Han TY. Influence of Pre-wetted Light-weight Aggregates on Workability of Combined Aggregate Concrete[J]. Bulletin of the Chinese Ceramic Society, 2015, 34(11): 3377–3382 (in Chinese)

Ma HL, Cui Ch, Ma WT, et al. Enhancement Mechanism of New Type Autoclave-d Calcium Carbide Residue Shell-aggregate on Concrete[J]. Cem. Concr. Compos., 2016, 72: 146–154

Wang DY, Cui Ch, Chen XF, et al. Characteristics of Autoclaved Lightweight Aggregates with Quartz Tailingsand Its Effect on the Mechanical Properties of Concrete[J]. Constr. Build. Mater., 2020, 262: 1–10

Hossain KMA, Ahmed S, Lachemi M. Lightweight Concrete Incorporating Pumice Based Blended Cement and Aggregate: Mechanical and Durability Characteristics[J]. Constr. Build. Mater., 2011, 25: 1186–1195

Shen PL, Lu LN, Wang ZF, et al. Water Desorption Characteristics of Saturated Lightweight Fine Aggregate in Ultra-high Performance Concrete[J]. Cem. Concr.Compos., 2020, 106: 1–13

Winslow DN, Cohen MD, Bentz DP, et al. Percolation and Pore Structure in Mortars and Concrete[J]. Cem. Concr. Res., 1994, 24: 25–37

Scrivener KL, Nemati KM. The Percolation of Pore Space in the Cement Paste/Aggregate Interfacial Zone of Concrete[J]. Cem. Concr. Res., 1996, 26(1): 35–40

Ollivier JP, Maso JC, Bourdette B. Interfacial Transition Zone in Concrete[J]. Adv. Cem. Based Mater., 1995, 2: 30–38

Wang LC, Ueda T. Mesoscale Modeling of Water Penetration into Concrete by Capillary Absorption[J]. Ocean Eng., 2011, 38: 519–528

Funding

Funded by the National Nature Science Foundation of China (Nos. 51468053, 51772153, 11662015, and 51769026)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, H., Cui, C., Yang, Y. et al. Impermeability Research of Autoclaved Propylene Oxide Sludge Shell-aggregate Concrete. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 241–247 (2022). https://doi.org/10.1007/s11595-022-2523-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2523-1