Abstract

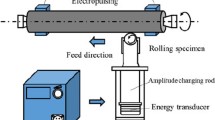

The effect of high-energy electropulsing-ultrasonic surface treatment (EUST) on the surface properties and the microstructure evolution of C45E4 steel was investigated. Refined microstructure and reduced surface roughness were obtained owing to the surface nanocrystallization process. Compared with the ultrasonic surface treatment (UST), the impact depth of the surface strengthened layer was increased by 40% to 700 μm after EUST. The average grain size of the surface nanocrystallization layer was reduced to 30-50 nm. The surface roughness of the C45E4 steel was reduced to 0.25 μm, and the surface microhardness was dramatically enhanced to 460 HV. The improvement of microstructure and micro-hardness at ambient temperature was likely attributed to the acceleration of atomic diffusion and the enhancement of plastic deformation ability in the surface strengthened layer under the influence of electropulsing. Due to the electropulsing-assisted ultrasonic strengthening effect, the surface nanocrystallization in this ultrafast procedure was noticeably enhanced.

Similar content being viewed by others

References

Han H, Gao Y, Zhang Y, et al. Effect of Magnetic Field Distribution of Friction Surface on Friction and Wear Properties of 45 Steel in DC Magnetic Field[J]. Wear, 2015, 328: 422–435

Goel S, Rashid WB, Luo X, et al. A Theoretical Assessment of Surface Defect Machining and Hot Machining of Nanocrystalline Silicon Carbide[J]. J. Manu. Sci. Eng., 2014, 136(2): 325–325

Li Y, Sun K, Liu P, et al. Surface Nanocrystallization Induced by Fast Multiple Rotation Rolling on Ti-6Al-4V and Its Effect on Microstructure and Properties[J]. Vac., 2014, 101: 102–106

Marteau J, Bigerelle M, Mazeran PE, et al. Relation between Roughness and Processing Conditions of AISI 316L Stainless Steel Treated by Ultrasonic Shot Peening[J]. Tribol. Int., 2015, 82: 319–329

Maawad E, Brokmeier HG, Wagner L, et al. Investigation on the Surface and Near-surface Characteristics of Ti-2.5 Cu After Various Mechanical Surface Treatments[J]. Surf. Coat. Technol., 2011, 205(12): 3 644–3 650

Wang T, Yu J, Dong B. Surface Nanocrystallization Induced by Shot Peening and Its Effect on Corrosion Resistance of 1Cr18Ni9Ti Stainless Steel[J]. Surf. Coat. Technol., 2006, 200(16): 4 777–4 781

Villegas JC, Dai K, Shaw LL, et al. Nanocrystallization of a Nickel Alloy Subjected to Surface Severe Plastic Deformation[J]. Mater. Sci. Eng., A, 2005, 410: 257–260

Lin Y, Lu J, Wang L, et al. Surface Nanocrystallization by Surface Mechanical Attrition Treatment and Its Effect on Structure and Properties of Plasma Nitrided AISI 321 Stainless Steel[J]. Acta Mater., 2006, 54(20): 5 599–5 605

Huang L, Lu J, Troyon M. Nanomechanical Properties of Nanostructured Titanium Prepared by SMAT[J]. Surf. Coat. Technol., 2006, 201(1): 208–213

Lu K, Lu J. Nanostructured Surface Layer on Metallic Materials Induced by Surface Mechanical Attrition Treatment[J]. Mater. Sci. Eng. A, 2004, 375: 38–45

Dai K, Shaw L. Comparison Between Shot Peening and Surface Nanocrystallization and Hardening Processes[J]. Mater. Sci. Eng. A, 2007, 463(1): 46–53

Tang GY, Xu Z, Tang M, et al. Effect of a Pulsed Magnetic Treatment on the Dislocation Substructure of a Commercial High Strength Steel[J]. Mater. Sci. Eng. A, 2005, 398(1): 108–112

Qin RS. Critical Assessment 8: Outstanding Issues in Electropulsing Processing[J]. Mater. Sci. Technol., 2015, 31(2): 203–206

Rahnama A, Qin RS. Electropulse-induced Microstructural Evolution in a Ferritic-pearlitic 0.14% C Steel[J]. Scr. Mater., 2015, 96: 17–20

Gromov VE, Ivanov YF, Sizov VV, et al. Increase in the Fatigue Durability of Stainless Steel by Electron-beam Surface Treatment[J]. J. Surf. Inves. X-ray, Syn. Neu. Techni., 2013, 7(1): 94–98

Ye X, Liu T, Ye Y, et al. Enhanced Grain Refinement and Microhardness of Ti-Al-V Alloy by Electropulsing Ultrasonic Shock[J]. J. Alloys Compd., 2015, 621: 66–70

Jang D, Greer JR. Size-induced Weakening and Grain Boundaryassisted Deformation in 60 nm Grained Ni Nanopillars[J]. Scr. Mater., 2011, 64(1): 77–80

Pagnoux G, Fouvry S, Peigney M, et al. Influence of Scratches on the Wear Behavior of DLC Coatings[J]. Wear, 2014, 330–331: 380–389

Zhu YH, To S, Lee WB, et al. Effects of Dynamic Electropulsing on Microstructure and Elongation of a Zn-Al Alloy[J]. Mater. Sci. Eng. A, 2009, 501(1): 125–132

Zhou Y, Zhang W, Wang B, et al. Grain Refinement and Formation of Ultrafine-grained Microstructure in a Low-carbon Steel Under Electropulsing[J]. J. Mater. Res., 2002, 17(08): 2 105–2 111

Ting W, Dongpo W, Gang L, et al. Investigations on the Nanocrystallization of 40Cr Using Ultrasonic Surface Rolling Processing[J]. Appl. Surf. Sci., 2008, 255(5): 1 824–1 829

Wu Y, Liu Y. Surface Topography of Fine-grained ZrO2 Ceramic by Two-dimensional Ultrasonic Vibration Grinding[J]. J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2011, 26(6): 1 162–1 165

Xu Q, Guan L, Jiang Y, et al. Improved Plasticity of Mg-Al-Zn Alloy by Electropulsing Tension[J]. Mater. Lett., 2010, 64(9): 1 085–1 087

Nikulin I, Kipelova A, Malopheyev S, et al. Effect of Second Phase Particles on Grain Refinement during Equal-channel Angular Pressing of an Al-Mg-Mn Alloy[J]. Acta Mater., 2012, 60(2): 487–497

Li J, Qu Z, Wu R, et al. Microstructure, Mechanical Properties and Aging Behaviors of As-extruded Mg-5Li-3Al-2Zn-1.5 Cu Alloy[J]. Mater. Sci. Eng., A, 2011, 528(10): 3 915–3 920

Du Y, Wang Y, Hao Z. Quick Surface Treatment of AZ31B by AC Micro-arc Oxidation[J]. J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2014, 29(4): 773–77

Acknowledgements

This project is supported by Natural Science Foundation of China (50571048) and Research & Development Funding Project of Shenzhen (JCYJ20120619152539900). The authors would like to thank Tsinghua University for supporting this work. The authors would also like to thank the editors and reviewers for their valuable comments and for making the paper more readable.

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Natural Science Foundation of China (No.50571048) and the Research & Development Funding Project of Shenzhen (No.JCYJ20120619152539900)

Rights and permissions

About this article

Cite this article

Chen, L., Wang, H., Liu, D. et al. Surface nanocrystallization of C45E4 steel by ultrafast electropulsing-ultrasonic surface treatment. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 1426–1432 (2017). https://doi.org/10.1007/s11595-017-1764-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1764-x