Abstract

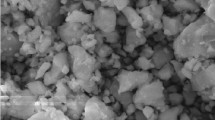

In order to understand the influence of nano-sized B4C additive on ZA27 alloy, mechanical and physical properties of ZA27-B4C nanocomposites were investigated in terms of B4C content. While physical properties were determined in terms of microstructural studies, density and porosity tests, mechanical properties were determined in terms of ultimate tensile strength (UTS) and hardness experiments. Morphological and microstructural studies were carried out with scanning electron microscopy (SEM). The experimental results indicate that nano-sized B4C can be used to enhance the mechanical properties of ZA27 alloy effectively. The highest mechanical performance can be obtained at ZA27-0.5% B4C (in weight) nanocomposite with values of tensile strength (247 MPa) and hardness (141,18 BH) and low partial porosity (0.5%). After a pick point, increasing B4C ratio may cause the formation of agglomeration in grain boundaries, that’s why density, tensile strength, and hardness values are declined.

Similar content being viewed by others

References

Zhang Z, Topping T, Li Y, et al. Mechanical Behavior of Ultrafine-grained Al Composites Reinforced with B4C Nanoparticles[J]. Scripta Materialia, 2011, 65: 652–625

Srivatsana TSU, Narendrab N, Troxellc JD. Tensile Deformation and Fracture Behavior of an Oxidedispersion Strengthened Copper Alloy[J]. Materials and Design, 1999

Zhou DS, Zhang DL, Kong C, et al. Factors Controlling the Tensile Properties of Ultrafine Structured Cu-5vol%Al2O3 Nanocomposite Prepared by High Energy Mechanical Milling and Powder Compact Extrusion[J]. Materials Science and Engineering: A., 2013, 584: 67–72

Bian GE, Wang LL, Wu J, et al. Effects of Electrolytes on the Growth Behavior, Microstructure and Tribological Properties of Plasma Electrolytic Oxidation Coatings on a ZA27 Alloy[J]. Surf. Coat Tech., 2015, 277: 251–257

Sahu S, Goel MD, Mondal DP, et al. High Temperature Compressive Deformation Behavior of ZA27-SiC Foam[J]. Mat. Sci. Eng. a-Struct., 2014, 607: 162–172

Mondal DP, Goel MD, Bagde N, et al. Closed Cell ZA27-SiC Foam Made Through Stir-casting Technique[J]. Materials & Design, 2014, 57: 315–324

Zhu YH, Lee WB, Mei Z, et al. Structural Evolution in Films of Alloy Zn70Al27Cu3 (ZA27) [J]. Appl. Surf. Sci., 2005, 242: 236–244

Bobic B, Bajat J, Acimovic-Pavlovic Z, et al. Corrosion Behaviour of Thixoformed and Heat-treated ZA27 Alloys in NaCl Solution[J]. T. Nonferr. Metal. Soc., 2013, 23: 931–941

Gervais E, Barnhurst RJ, Loong CA. An Analysis of Selected Properties of Za Alloys[J]. Jom-J. Min. Met. Mat. S., 1985, 37: 43–47

Kubel EJ. Expanding Horizons for Za Alloys[J]. Adv. Mater. Process., 1987, 132: 51–57

Zhu YH, Hernandez RM, Banos L. Phase Decomposition in Extruded Zn-Al Based Alloy[J]. J Mater Sci. 1999, 34: 3653–3658

Lehuy H, Lesperance G. Aging Characteristics of Dendritic and Non-Dentritic (Stir-Cast) Zn-Al Alloys (Za-27) [J]. Cim. Bull., 1988, 81: 76–87

Liu Y, Li HY, Jiang HF, et al. Effects of Heat Treatment on Microstructure and Mechanical Properties of ZA27 Alloy[J]. T. Nonferr. Metal Soc., 2013, 23: 642–649

Abou El-khair MT, Lotfy A, Daoud A, et al. Microstructure, Thermal Behavior and Mechanical Properties of Squeeze Cast SiC, ZrO2 or C Reinforced ZA27 Composites[J]. Mat. Sci. Eng. a-Struct., 2011, 528: 2353–2362

Sharma SC, Girish BM, Somashekar DR, et al. Mechanical Properties and Fractography of Zircon-particle-reinforced ZA-27 Alloy Composite Materials[J]. Compos Sci Technol. 1999, 59: 1805–1812

Torralba JM, da Costa CE, Velasco F. P/M Aluminum Matrix Composites: An Overview[J]. J. Mater. Process Tech., 2003,133:203–206

Fogagnolo JB, Ruiz-Navas EM, Robert MH, et al. The Effects of Mechanical Alloying on the Compressibility of Aluminium Matrix Composite Powder[J]. Mat. Sci. Eng. a-Struct., 2003, 355: 50–55

Liu CH. Structure and Properties of Boron Carbide with Aluminum Incorporation[J]. Mat. Sci. Eng. B-Solid., 2000, 72: 23–26

Afizadeh M, Paydar MH, Jazi FS. Structural Evaluation and Mechanical Properties of Nanostructured Al/B4C Composite Fabricated by ARB Process[J]. Compos. Part B-Eng., 2013, 44: 339–343

Tjong SC. Novel Nanoparticle-reinforced Metal Matrix Composites with Enhanced Mechanical Properties[J]. Adv. Eng. Mater., 2007, 9: 639–652

Varol T, Canakci A. Effect of Weight Percentage and Particle Size of B4C Reinforcement on Physical and Mechanical Properties of Powder Metallurgy Al2024-B4C Composites[J]. Met. Mater. Int., 2013; 19: 1227–1234

Gupta M, Lai MO, Saravanaranganathan D. Synthesis, Microstructure and Properties Characterization of Disintegrated Melt Deposited Mg/SiC Composites[J]. J. Mater. Sci., 2000, 35: 2155–2165

Hassan SF, Gupta A. Development of High Performance Magnesium Nano-composites using Nano-Al2O3 as Reinforcement[J]. Mat. Sci. Eng. a-Struct., 2005, 392: 163–168

Chawla N, Shen YL. Mechanical Behavior of Particle Reinforced Metal Matrix Composites[J]. Adv. Eng. Mater., 2001, 3: 357–370

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Research Projects Unit of Karadeniz Technical (Number: 12040) and TUBITAK ( Number: 213M276)

Rights and permissions

About this article

Cite this article

Dalmis, R., Cuvalci, H., Canakci, A. et al. Effect of nano-sized B4C addition on the mechanical properties of ZA27 composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 747–752 (2017). https://doi.org/10.1007/s11595-017-1662-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1662-2