Abstract

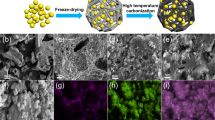

The structural characteristics of litchi shell-derived carbon are conducive to regulation and modification. Using biomass waste litchi shells as carbon source and nano-silicon particles to prepare silicon-carbon composite materials to relieve the volume effect of silicon in the charge and discharge process, litchi shell-derived activated carbon (LAC) with high specific surface area (1011.115 m2 g−1) and high porosity was obtained from litchi shell as silicon buffer matrix by simple high-temperature calcination and activation of ZnCl2. A silicon-carbon composite material (3D LAC@Si) with an embedded cladding structure was prepared with a high-energy ball milling process. In the electrochemical performance test, 3D LAC@Si as the negative electrode of a lithium-ion battery showed a high lithium storage capacity of 834.4 mAh g−1 and a high coulombic efficiency of 98.34% after cycling 100 cycles at a current density of 0.2A g−1.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author: Zhao Fang fangzhao@xauat.edu.cn, upon reasonable request.

Code availability

Not applicable.

References

Scrosati B (2000) Recent advances in lithium ion battery materials. Electrochim Acta 45:2461–2466

Peng J, Yu J, Meng B, Wang L, Zhang X, Cheng W, Wen P, Zhao J, Li L, Fang Z (2020) Hierarchical porous biomass activated carbon for hybrid battery capacitors derived from persimmon branches. 20: 523-530

Yu J, Wang L, Peng J, Jia X, Zhou L, Yang N, Li L (2021) O-doped porous carbon derived from biomass waste for high-performance zinc-ion hybrid supercapacitors. Ionics 27:4495–4505

Tran M K, Panchal S, Chauhan V, Brahmbhatt N, Mevawalla A, Fraser R, Fowler M (2021) Python‐based scikit‐learn machine learning models for thermal and electrical performance prediction of high‐capacity lithium‐ion battery. International Journal of Energy Research

Tran M-K, DaCosta A, Mevawalla A, Panchal S, Fowler M (2021) Comparative study of equivalent circuit models performance in four common lithium-ion batteries: LFP, NMC, LMO. NCA Batteries 7:51

Duan J, Zhao J, Li X, Panchal S, Yuan J, Fraser R, Fowler M (2021) Modeling and analysis of heat dissipation for liquid cooling lithium-ion batteries. Energies 14:4187

Akhoundzadeh MH, Panchal S, Samadani E, Raahemifar K, Fowler M, Fraser R (2021) Investigation and simulation of electric train utilizing hydrogen fuel cell and lithium-ion battery. Sustainable Energy Technologies and Assessments 46:101234

Yi T-F, Qu J-P, Lai X, Han X, Chang H, Zhu Y-R (2021) Toward high-performance Li storage anodes: design and construction of spherical carbon-coated CoNiO2 materials. Materials Today Chemistry 19:100407

Yi T-F, Xie Y, Zhu Y-R, Zhu R-S, Shen H (2013) Structural and thermodynamic stability of Li4Ti5O12 anode material for lithium-ion battery. J Power Sources 222:448–454

Yi T-F, Mei J, Peng P-P, Luo S (2019) Facile synthesis of polypyrrole-modified Li5Cr7Ti6O25 with improved rate performance as negative electrode material for Li-ion batteries. Compos B Eng 167:566–572

Yi T-F, Sari H M K, Li X, Wang F, Zhu Y-R, Hu J, Zhang J, Li X (2021) A review of niobium oxides based nanocomposites for lithium-ion batteries, sodium-ion batteries and supercapacitors. Nano Energy 105955

Fuchsbichler B, Stangl C, Kren H, Uhlig F, Koller S (2011) High capacity graphite–silicon composite anode material for lithium-ion batteries. J Power Sources 196:2889–2892

Zhang H, Hu R, Liu Y, Cheng X, Liu J, Lu Z, Zeng M, Yang L, Liu J, Zhu M (2018) Highly reversible conversion reaction in Sn2Fe@SiOx nanocomposite: a high initial Coulombic efficiency and long lifetime anode for lithium storage. Energy Storage Materials 13:257–266

Lee G, Kim S, Kim S, Choi J (2017) SiO2/TiO2 composite film for high capacity and excellent cycling stability in lithium-ion battery anodes. Adv Func Mater 27:1703538

Du F-H, Ni Y, Wang Y, Wang D, Ge Q, Chen S, Yang HY (2017) Green fabrication of silkworm cocoon-like silicon-based composite for high-performance Li-ion batteries. ACS Nano 11:8628–8635

Lin N, Han Y, Zhou J, Zhang K, Xu T, Zhu Y, Qian Y (2015) A low temperature molten salt process for aluminothermic reduction of silicon oxides to crystalline Si for Li-ion batteries. Energy Environ Sci 8:3187–3191

Magasinski A, Dixon P, Hertzberg B, Kvit A, Ayala J, Yushin G (2010) High-performance lithium-ion anodes using a hierarchical bottom-up approach. Nat Mater 9:353–358

Luo X, Zhang H, Pan W, Gong J, Khalid B, Zhong M, Wu H (2015) SiOx nanodandelion by laser ablation for anode of lithium-ion battery. Small 11:6009–6012

Kim JS, Pfleging W, Kohler R, Seifert HJ, Kim TY, Byun D, Jung H-G, Choi W, Lee JK (2015) Three-dimensional silicon/carbon core–shell electrode as an anode material for lithium-ion batteries. J Power Sources 279:13–20

Zhu X, Chen H, Wang Y, Xia L, Tan Q, Li H, Zhong Z, Su F, Zhao X (2013) Growth of silicon/carbon microrods on graphite microspheres as improved anodes for lithium-ion batteries. Journal of Materials Chemistry A 1:4483–4489

Du FH, Li B, Fu W, Xiong YJ, Wang KX, Chen JS (2014) Surface binding of polypyrrole on porous silicon hollow nanospheres for Li-ion battery anodes with high structure stability. Adv Mater 26:6145–6150

Wu H, Chan G, Choi JW, Ryu I, Yao Y, McDowell MT, Lee SW, Jackson A, Yang Y, Hu L (2012) Stable cycling of double-walled silicon nanotube battery anodes through solid–electrolyte interphase control. Nat Nanotechnol 7:310–315

Chan CK, Peng H, Liu G, McIlwrath K, Zhang XF, Huggins RA, Cui Y (2008) High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol 3:31–35

Liu N, Lu Z, Zhao J, McDowell MT, Lee H-W, Zhao W, Cui Y (2014) A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat Nanotechnol 9:187–192

Liu XH, Zhong L, Huang S, Mao SX, Zhu T, Huang JY (2012) Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6:1522–1531

Su X, Wu Q, Li J, Xiao X, Lott A, Lu W, Sheldon BW, Wu J (2014) Silicon-based nanomaterials for lithium-ion batteries: a review. Adv Energy Mater 4:1300882

Kasavajjula U, Wang C, Appleby AJ (2007) Nano-and bulk-silicon-based insertion anodes for lithium-ion secondary cells. J Power Sources 163:1003–1039

Hassan FM, Chabot V, Elsayed AR, Xiao X, Chen Z (2014) Engineered Si electrode nanoarchitecture: a scalable postfabrication treatment for the production of next-generation Li-ion batteries. Nano Lett 14:277–283

Wilson A, Dahn J (1995) Lithium insertion in carbons containing nanodispersed silicon. J Electrochem Soc 142:326

Gao P, Fu J, Yang J, Lv R, Wang J, Nuli Y, Tang X (2009) Microporous carbon coated silicon core/shell nanocomposite via in situ polymerization for advanced Li-ion battery anode material. Phys Chem Chem Phys 11:11101–11105

Hu YS, Demir-Cakan R, Titirici MM, Müller JO, Schlögl R, Antonietti M, Maier J (2008) Superior storage performance of a Si@SiOx/C nanocomposite as anode material for lithium-ion batteries. Angew Chem Int Ed 47:1645–1649

Cakan R D, Titirici M-M, Antonietti M, Cui G, Maier J, Hu Y-S (2008) Hydrothermal carbon spheres containing silicon nanoparticles: synthesis and lithium storage performance. Chemical Communications 3759–3761

Ng SH, Wang J, Wexler D, Konstantinov K, Guo ZP, Liu HK (2006) Highly reversible lithium storage in spheroidal carbon-coated silicon nanocomposites as anodes for lithium-ion batteries. Angew Chem Int Ed 45:6896–6899

Chen C-Y, Liang A-H, Huang C-L, Hsu T-H, Li Y-Y (2020) The pitch-based silicon-carbon composites fabricated by electrospraying technique as the anode material of lithium ion battery. Journal of Alloys and Compounds 844:156025

Hwa Y, Kim W-S, Hong S-H, Sohn H-J (2012) High capacity and rate capability of core–shell structured nano-Si/C anode for Li-ion batteries. Electrochim Acta 71:201–205

Liu N, Wu H, McDowell MT, Yao Y, Wang C, Cui Y (2012) A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett 12:3315–3321

Sun Z, Wang S, Yan L, Xiao M, Han D, Meng Y (2016) Mesoporous carbon materials prepared from litchi shell as sulfur encapsulator for lithium-sulfur battery application. J Power Sources 324:547–555

Zhu Z, Zeng X, Wu H, Wang Y, Cheng H, Dong P, Li X, Zhang Y, Liu H (2021) Green energy application technology of litchi pericarp-derived carbon material with high performance. Journal of Cleaner Production 286: 124960

Hayashi J, i, Kazehaya A, Muroyama K, Watkinson A P, (2000) Preparation of activated carbon from lignin by chemical activation. Carbon 38:1873–1878

Ge M, Fang X, Rong J, Zhou C (2013) Review of porous silicon preparation and its application for lithium-ion battery anodes. Nanotechnology 24: 422001

Lee SJ, Kim HJ, Hwang TH, Choi S, Park SH, Deniz E, Jung DS, Choi JW (2017) Delicate structural control of Si–SiOx–C composite via high-speed spray pyrolysis for Li-ion battery anodes. Nano Lett 17:1870–1876

Tang H, Zhang Y, Xiong Q, Cheng J, Zhang Q, Wang X, Gu C, Tu J (2015) Self-assembly silicon/porous reduced graphene oxide composite film as a binder-free and flexible anode for lithium-ion batteries. Electrochim Acta 156:86–93

Li Z-F, Zhang H, Liu Q, Liu Y, Stanciu L, Xie J (2014) Novel pyrolyzed polyaniline-grafted silicon nanoparticles encapsulated in graphene sheets as Li-ion battery anodes. ACS Appl Mater Interfaces 6:5996–6002

Dmitriev P, Makarov S, Milichko V, Mukhin I, Gudovskikh A, Sitnikova A, Samusev A, Krasnok A, Belov P (2016) Laser fabrication of crystalline silicon nanoresonators from an amorphous film for low-loss all-dielectric nanophotonics. Nanoscale 8:5043–5048

Su A, Li J, Dong J, Yang D, Chen G, Wei Y (2020) An amorphous/crystalline incorporated Si/SiOx anode material derived from biomass corn leaves for lithium-ion batteries. Small 16:2001714

Kim H, Seo M, Park MH, Cho J (2010) A critical size of silicon nano-anodes for lithium rechargeable batteries. Angew Chem Int Ed 49:2146–2149

Guo C, Wang D, Liu T, Zhu J, Lang X (2014) A three dimensional SiOx/C@ RGO nanocomposite as a high energy anode material for lithium-ion batteries. Journal of Materials Chemistry A 2:3521–3527

Barr TL (1983) An XPS study of Si as it occurs in adsorbents, catalysts, and thin films. Applications of Surface Science 15:1–35

Dunn B, Kamath H, Tarascon J-M (2011) Electrical energy storage for the grid: a battery of choices. Science 334:928–935

Wong DP, Suriyaprabha R, Yuvakumar R, Rajendran V, Chen Y-T, Hwang B-J, Chen L-C, Chen K-H (2014) Binder-free rice husk-based silicon–graphene composite as energy efficient Li-ion battery anodes. Journal of Materials Chemistry A 2:13437–13441

Pinson MB, Bazant MZ (2012) Theory of SEI formation in rechargeable batteries: capacity fade, accelerated aging and lifetime prediction. J Electrochem Soc 160:A243

Liu J, Zhang Q, Wu ZY, Li JT, Huang L, Sun SG (2015) Nano-/microstructured Si/C composite with high tap density as an anode material for lithium-ion batteries. ChemElectroChem 2:611–616

Wu J J, Bennett W R In Fundamental investigation of Si anode in Li-ion cells (2012) IEEE Energytech. IEEE 2012:1–5

Peng J-x, Zhong K-n, Huang W-l, Hou X-y, Gao H-q, Fang Z, Li L-b (2021) Regulation of an inner helmholtz plane by hierarchical porous biomass activated carbon for stable cathode electrolyte interphase films. Vacuum 191: 110331

Ko S, Lee CW, Im JS (2016) Petrochemical-waste-derived high-performance anode material for Li-ion batteries. J Ind Eng Chem 36:125–131

Tan G, Wu F, Li L, Chen R, Chen S (2013) Coralline glassy lithium phosphate-coated LiFePO4 cathodes with improved power capability for lithium ion batteries. The Journal of Physical Chemistry C 117:6013–6021

Pawbake A, Mayabadi A, Waykar R, Kulkarni R, Jadhavar A, Waman V, Parmar J, Bhattacharyya S, Ma YR, Devan R (2016) Growth of boron doped hydrogenated nanocrystalline cubic silicon carbide (3C-SiC) films by hot wire-CVD. Mater Res Bull 76:205–215

Yu J, Peng J, Huang W, Wang L, Wei Y, Yang N, Li L (2021) Inhibition of excessive SEI-forming and improvement of structure stability for LiNi0.8Co0.1Mn0.1O2 by Li2MoO4 coating. Ionics

Fang Z, Peng J, Ma N, Liang L, Gao H, Zhou H, Jin X, Yang J, Liu M, Du J, Li Q, Li X, Li L (2018) Preparation and optimization of new high-power nanoscale Li4Ti5O12 full-cell system. J Nanosci Nanotechnol 18:8232–8239

Liu H, Chen Y, Jiang B, Zhao Y, Guo X, Ma T (2020) Hollow-structure engineering of a silicon carbon anode for ultra-stable lithium-ion batteries. Dalton Trans 49:5669–5676

Funding

This work was supported by the National Natural Science Foundation of China (51974219, 52034011), National Key Research and Development Project (2018YFE0203400), and Natural Science Basic Research Plan in Shaanxi Province (2018JM5135).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, L., Luo, S., Zheng, Z. et al. Litchi shell-derived porous carbon for enhanced stability of silicon-based lithium-ion battery anode materials. Ionics 28, 161–172 (2022). https://doi.org/10.1007/s11581-021-04337-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-021-04337-x