Abstract

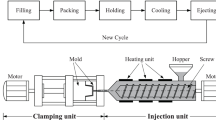

Injection molding is one of the most widely used material processing methods in producing plastic products with complex geometries and high precision. The determination of process parameters is important in obtaining qualified products and maintaining product quality. This article reviews the recent studies and developments of the intelligent methods applied in the process parameter determination of injection molding. These intelligent methods are classified into three categories: Case-based reasoning methods, expert system- based methods, and data fitting and optimization methods. A framework of process parameter determination is proposed after comprehensive discussions. Finally, the conclusions and future research topics are discussed.

Similar content being viewed by others

References

Yang D, Danai K, Kazmer D. A knowledge-based tuning method for injection molding machines. Journal of Manufacturing Science and Engineering, 2000, 123(4): 682–691

Kolodner J L. An introduction to case-based reasoning. Artificial Intelligence Review, 1992, 6(1): 3–34

Mok S L, Kwong C K, Lau W S. Review of research in the determination of process parameters for plastic injection molding. Advances in Polymer Technology, 1999, 18(3): 225–236

Kwong C K, Smith G F, Lau W S. Application of case based reasoning injection moulding. Journal of Materials Processing Technology, 1997, 63(1–3): 463–467

Kwong C K, Smith G F. A computational system for process design of injection moulding: Combining blackboard-based expert system and case-based reasoning approach. International Journal of Advanced Manufacturing Technology, 1998, 14(4): 239–246

Mok S L, Kwong C K, Lau W S. An intelligent hybrid system for initial process parameter setting of injection moulding. International Journal of Production Research, 2000, 38(17): 4565–4576

Mok S L, Kwong C K. Application of artificial neural network and fuzzy logic in a case-based system for initial process parameter setting of injection molding. Journal of Intelligent Manufacturing, 2002, 13(3): 165–176

Shelesh-Nezhad K, Siores E. An intelligent system for plastic injection molding process design. Journal of Materials Processing Technology, 1997, 63(1–3): 458–462

Zhou H M, Zhao P, Feng W. An integrated intelligent system for injection molding process determination. Advances in Polymer Technology, 2007, 26(3): 191–205

Kim S G, Suh N P. Knowledge-based synthesis system for injection molding. Robotics and Computer-Integrated Manufacturing, 1987, 3(2): 181–186

Pandelidis I, Kao J F. DETECTOR: A knowledge-based system for injection molding diagnostics. Journal of Intelligent Manufacturing, 1990, 1(1): 49–58

Jan T C, O’Brien K. A user-friendly, interactive expert system for the injection moulding of engineering thermoplastics. International Journal of Advanced Manufacturing Technology, 1993, 8(1): 42–51

Kameoka S, Haramoto N, Sakai T. Development of an expert system for injection molding operations. Advances in Polymer Technology, 1993, 12(4): 403–418

He W, Zhang Y F, Lee K S, et al. Automated process parameter resetting for injection moulding: A fuzzy-neuro approach. Journal of Intelligent Manufacturing, 1998, 9(1): 17–27

He W, Zhang Y F, Lee K S, et al. Development of a fuzzy-neuro system for parameter resetting of injection molding. Journal of Manufacturing Science and Engineering, 2001, 123(1): 110–118

Tan K, Yuen M. An expert system for injection molding defect correction. In: Proceedings of the 3rd International Conference, Computer Integrated Manufacturing. 1995, 11–14

Chen M Y, Tzeng H W, Chen Y C, et al. The application of fuzzy theory for the control of weld line positions in injection-molded part. ISA Transactions, 2008, 47(1): 119–126

Li D Q, Zhou H M, Zhao P, et al. A real-time process optimization system for injection molding. Polymer Engineering and Science, 2009, 49(10): 2031–2040

Dhaliwal J S, Benbasat I. The use and effects of knowledge-based system explanations: Theoretical foundations and a framework for empirical evaluation. Information Systems Research, 1996, 7(3): 342–362

Inaba Y, Sakakibara S, Taira T, et al. Expert system for injection molding machine to support stable condition during long time production. In: Proceedings of International Conference on Artificial Intelligent in the Pacific Rim. 1991, 909–914

Liao S H. Expert system methodologies and applications—A decade review from 1995 to 2004. Expert Systems with Applications, 2005, 28(1): 93–103

Pardo S A. Fractional factorial designs. In: Pardo S A, ed. Empirical Modeling and Data Analysis for Engineers and Applied Scientists. Cham: Springer}, 2016, 59–93

Liu T F, Zhang C L, Yang G S, et al. Central composite design-based analysis of specific leaf area and related agronomic factors in cultivars of rapeseed (Brassica napus L.). Field Crops Research, 2009, 111(1–2): 92–96

Roy R K. A Primer on Taguchi Method. New York: Van Nostrand Reinhold, 1990

Helton J C, Davis F J. Latin hypercube sampling and the propagation of uncertainty in analyses of complex systems. Reliability Engineering & System Safety, 2003, 81(1): 23–69

Fang K T, Lin D K J, Winker P, et al. Uniform design: Theory and application. Technometrics, 2000, 42(3): 237–248

Chen W C, Nguyen M H, Chiu W H, et al. Optimization of the plastic injection molding process using the Taguchi method, RSM, and hybrid GA-PSO. International Journal of Advanced Manufacturing Technology, 2016, 83(9–12): 1873–1886

Zhao J, Cheng G. An innovative surrogate-based searching method for reducing warpage and cycle time in injection molding. Advances in Polymer Technology, 2015, 35(3): 288–297

Wang Y, Kim J, Song J I. Optimization of plastic injection molding process parameters for manufacturing a brake booster valve body. Materials & Design, 2014, 56: 313–317

Jou Y T, Lin W T, Lee W C, et al. Integrating the Taguchi method and response surface methodology for process parameter optimization of the injection molding. Applied Mathematics & Information Sciences, 2014, 8(3): 1277–1285

Wen T, Chen X, Yang C, et al. Optimization of processing parameters for minimizing warpage of large thin-walled parts in whole stages of injection molding. Chinese Journal of Polymer Science, 2014, 32(11): 1535–1543

Chen W C, Liou P H, Chou S C. An integrated parameter optimization system for MIMO plastic injection molding using soft computing. International Journal of Advanced Manufacturing Technology, 2014, 73(9–12): 1465–1474

Chen W C, Kurniawan D. Process parameters optimization for multiple quality characteristics in plastic injection molding using Taguchi method, BPNN, GA, and hybrid PSO-GA. International Journal of Precision Engineering and Manufacturing, 2014, 15(8): 1583–1593

Azaman M D, Sapuan S M, Sulaiman S, et al. Optimization and numerical simulation analysis for molded thin-walled parts fabricated using wood-filled polypropylene composites via plastic injection molding. Polymer Engineering & Science, 2015, 5(5): 1082–1095

Chen W C, Wang L Y, Huang C C, et al. Parameter optimization of the injection molding process for a LED lighting lens using soft computing. Advanced Materials Research, 2013, 690–693: 2344–2351

Tzeng C J, Yang Y K, Lin Y H, et al. A study of optimization of injection molding process parameters for SGF and PTFE reinforced PC composites using neural network and response surface methodology. International Journal of Advanced Manufacturing Technology, 2012, 63(5–8): 691–704

Lu N, Gong G, Yang Y, et al. Multi-objective process parameter optimization for energy saving in injection molding process. Journal of Zhejiang University. Science A, 2012, 13(5): 382–394

Yin F, Mao H, Hua L. A hybrid of back propagation neural network and genetic algorithm for optimization of injection molding process parameters. Materials & Design, 2011, 32(6): 3457–3464

Mehat N M, Kamaruddin S. Multi-response optimization of injection moulding processing parameters using the Taguchi method. Polymer-Plastics Technology and Engineering, 2011, 50 (15): 1519–1526

Chen WL, Huang C Y, Hung CW. Optimization of plastic injection molding process by dual response surface method with non-linear programming. Engineering Computations, 2010, 27(8): 951–966

Ting P H, Hsu C I, Hwang J R. Optimization of the wear properties of polyoxymethylene components under injection process conditions. Polymer-Plastics Technology and Engineering, 2010, 49(9): 892–899

Altan M. Reducing shrinkage in injection moldings via the Taguchi, ANOVA and neural network methods. Materials & Design, 2010, 31 (1): 599–604

Chen W C, Fu G L, Tai P H, et al. Process parameter optimization for MIMO plastic injection molding via soft computing. Expert Systems with Applications, 2009, 36(2): 1114–1122

Chen C P, Chuang M T, Hsiao Y H, et al. Simulation and experimental study in determining injection molding process parameters for thin-shell plastic parts via design of experiments analysis. Expert Systems with Applications, 2009, 36(7): 10752–10759

Chen W C, Wang M W, Chen C T, et al. An integrated parameter optimization system for MISO plastic injection molding. International Journal of Advanced Manufacturing Technology, 2009, 44(5–6): 501–511

Deng W J, Chen C T, Sun C H, et al. An effective approach for process parameter optimization in injection molding of plastic housing components. Polymer-Plastics Technology and Engineering, 2008, 47(9): 910–919

Cheng W S, Chen C S, Chen S C, et al. Investigation of the effects of injection molding processing parameters on conductive polymeric composites for electromagnetic interference shielding effectiveness. Polymer-Plastics Technology and Engineering, 2009, 48 (2): 216–220

Tsai K M, Hsieh C Y, Lo W C. A study of the effects of process parameters for injection molding on surface quality of optical lenses. Journal of Materials Processing Technology, 2009, 209(7): 3469–3477

Yang Y K, Shie J R, Liao H T, et al. A study of Taguchi and design of experiments method in injection molding process for polypropylene components. Journal of Reinforced Plastics and Composites, 2008, 27(8): 819–834

Huang M S, Lin T Y. An innovative regression model-based searching method for setting the robust injection molding parameters. Journal of Materials Processing Technology, 2008, 198(1–3): 436–444

Shie J R. Optimization of injection molding process for contour distortions of polypropylene composite components by a radial basis neural network. International Journal of Advanced Manufacturing Technology, 2008, 36(11–12): 1091–1103

Chen W C, Fu G L, Tai P H, et al. ANN and GA-based process parameter optimization for MIMO plastic injection molding. In: Proceedings of International Conference on Machine Learning and Cybernetics. Hong Kong: IEEE, 2007, 1909–1917

Wang L, Li Q, Shen C, et al. Effects of process parameters and twoway interactions on sink mark depth of injection molded parts by using the design of experiment method. Polymer-Plastics Technology and Engineering, 2007, 47(1): 30–35

Song M C, Liu Z, Wang M J, et al. Research on effects of injection process parameters on the molding process for ultra-thin wall plastic parts. Journal of Materials Processing Technology, 2007, 187–188: 668–671

Oktem H, Erzurumlu T, Uzman I. Application of Taguchi optimization technique in determining plastic injection molding process parameters for a thin-shell part. Materials & Design, 2007, 28(4): 1271–1278

Kuo C F, Su T L. Optimization of injection molding processing parameters for LCD light-guide plates. Journal of Materials Engineering and Performance, 2007, 16(5): 539–548

Kemal Karasu M, Cakmakci M, Cakiroglu M B, et al. Improvement of changeover times via Taguchi empowered SMED/case study on injection molding production. Measurement, 2014, 47: 741–748

Liu F, Zeng S Q, Zhou H M, et al. A study on the distinguishing responses of shrinkage and warpage to processing conditions in injection molding. Journal of Applied Polymer Science, 2012, 125 (1): 731–744

AlKaabneh F A, Barghash M, Mishael I. A combined analytical hierarchical process (AHP) and Taguchi experimental design (TED) for plastic injection molding process settings. International Journal of Advanced Manufacturing Technology, 2012, 66(5): 679–694

Kitayama S, Natsume S. Multi-objective optimization of volume shrinkage and clamping force for plastic injection molding via sequential approximate optimization. Simulation Modelling Practice and Theory, 2014, 48: 35–44

Shi H Z, Xie S M, Wang X C. A warpage optimization method for injection molding using artificial neural network with parametric sampling evaluation strategy. International Journal of Advanced Manufacturing Technology, 2013, 65(1–4): 343–353

Xia W, Luo B, Liao X. An enhanced optimization approach based on Gaussian process surrogate model for process control in injection molding. International Journal of Advanced Manufacturing Technology, 2011, 56(9–12): 929–942

Shi H Z, Gao Y H, Wang X C. Optimization of injection molding process parameters using integrated artificial neural network model and expected improvement function method. International Journal of Advanced Manufacturing Technology, 2010, 48(9–12): 955–962

Chen W, Zhou X, Wang H, et al. Multi-objective optimal approach for injection molding based on surrogate model and particle swarm optimization algorithm. Journal of Shanghai Jiaotong University (Science), 2010, 15(1): 88–93

Liao X, Long F. Gaussian process modeling of process optimization and parameter correlation for injection molding. Journal of Marine Science and Engineering, 2010, 4(10): 90–97

Li C, Wang F L, Chang Y Q, et al. A modified global optimization method based on surrogate model and its application in packing profile optimization of injection molding process. International Journal of Advanced Manufacturing Technology, 2010, 48(5–8): 505–511

Gao Y, Turng L S, Wang X. Adaptive geometry and process optimization for injection molding using the kriging surrogate model trained by numerical simulation. Advances in Polymer Technology, 2008, 27(1): 1–16

Zhou J, Turng L S. Process optimization of injection molding using an adaptive surrogate model with Gaussian process approach. Polymer Engineering and Science, 2007, 47(5): 684–694

Sun B S, Chen Z, Gu B Q, et al. Injection molding process parameter optimization for warpage minimization based on uniform design of experiment. Applied Mechanics and Materials, 2011, 37–38: 570–575

Deng Y M, Wang L Z. Applying a uniform design of experiment approach for reducing injection moulding warpage deflection. Key Engineering Materials, 2010, 443: 57–62

Guo W, Hua L, Mao H J. Minimization of sink mark depth in injection-molded thermoplastic through design of experiments and genetic algorithm. International Journal of Advanced Manufacturing Technology, 2014, 72(1–4): 365–375

Chen C C, Su P L, Chiou C B, et al. Experimental investigation of designed parameters on dimension shrinkage of injection molded thin-wall part by integrated response surface methodology and genetic algorithm: A case study. Materials and Manufacturing Processes, 2011, 26(3): 534–540

Chen C C, Su P L, Lin Y C. Analysis and modeling of effective parameters for dimension shrinkage variation of injection molded part with thin shell feature using response surface methodology. International Journal of Advanced Manufacturing Technology, 2009, 45(11–12): 1087–1095

Spina R. Optimisation of injection moulded parts by using ANNPSO approach. Journal of Achievements in Materials and Manufacturing Engineering, 2006, 15(1–2): 146–152

Kurtaran H, Erzurumlu T. Efficient warpage optimization of thin shell plastic parts using response surface methodology and genetic algorithm. International Journal of Advanced Manufacturing Technology, 2006, 27(5–6): 468–472

Deng Y M, Zhang Y, Lam Y C. A hybrid of mode-pursuing sampling method and genetic algorithm for minimization of injection molding warpage. Materials & Design, 2010, 31(4): 2118–2123

Cheng J, Liu Z, Tan J. Multiobjective optimization of injection molding parameters based on soft computing and variable complexity method. International Journal of Advanced Manufacturing Technology, 2013, 66(5–8): 907–916

Iniesta A A, Alcaraz J L G, Borbon MI R. Optimization of injection molding process parameters by a hybrid of artificial neural network and artificial bee colony algorithm. Revista Facultad De Ingenieria-Universidad De Antioquia, 2013, (67): 43–51

Wang R J, Feng X X, Xia Y J, et al. A back propagation artificial neural network prediction model of the gate freeze time for injection molded polypropylenes. Journal of Macromolecular Science, Part B: Physics, 2013, 52(10): 1414–1426

Taghizadeh S, Ozdemir A, Uluer O. Warpage prediction in plastic injection molded part using artificial neural network. Iranian Journal of Science and Technology. Transaction of Mechanical Engineering, 2013, 37(M2): 149–160

Wang H S, Wang Y N, Wang Y C. Cost estimation of plastic injection molding parts through integration of PSO and BP neural network. Expert Systems with Applications, 2013, 40(2): 418–428

Shi H, Wang X, Xie S. A warpage optimization method for injection molding using artificial neural network combined weighted expected improvement. International Polymer Processing, 2012, 27(3): 341–347

Patel G C M, Krishna P. Prediction and optimization of dimensionalshrinkage variations in injection molded parts using forward and reverse mapping of artificial neural networks. Advanced Materials Research, 2012, 463–464: 674–678

Chen W J, Lin J R. Application and design of artificial neural network for multi-cavity injection molding process conditions. In: Jin D, Lin S, eds. Advances in Future Computer and Control Systems: Volume 2. Berlin: Springer, 2012, 33–38

Yin F, Mao H J, Hua L, et al. Back propagation neural network modeling for warpage prediction and optimization of plastic products during injection molding. Materials & Design, 2011, 32 (4): 1844–1850

Sun X F, Zhu P F, Lu Y J, et al. Prediction of quality index of injection-molded parts by using artificial neural networks. Advanced Materials Research, 2011, 291–294: 432–439

Li X, Hu B, Du R. Predicting the parts weight in plastic injection molding using least squares support vector regression. IEEE Transactions on Systems, Man, and Cybernetics, Part C (Applications and Reviews), 2008, 38(6): 827–833

Yang J L, Yin Z Q, Guan C L, et al. Process parameter optimization of micro-injection molding based on support vector machine. China Plastics Industry, 2009, 37(5): 27–30 (in Chinese)

Wang G G, Shan S. Review of metamodeling techniques in support of engineering design optimization. Journal of Mechanical Design, 2007, 129(4): 370–380

Simpson T W, Poplinski J D, Koch N P, et al. Metamodels for computer-based engineering design: Survey and recommendations. Engineering with Computers, 2001, 17(2): 129–150

Oberkampf W L, Trucano T G. Validation methodology in computational fluid dynamics. In: Proceedings of Fluids 2000 Conference and Exhibit, Fluid Dynamics and Co-Located Conferences. AIAA, 2000, 2549: 19–22

Goldberg D E. Genetic Algorithm in Search, Optimization, and Machine Learning. Reading: Addison-Wesley, 1989, 2104–2116

Norman B A, Bean J C. A genetic algorithm methodology for complex scheduling problems. Naval Research Logistics, 1999, 46 (2): 199–211

Lin M H, Tsai J F, Yu C S. A review of deterministic optimization methods in engineering and management. Mathematical Problems in Engineering, 2012, 756023

Dang X P. General frameworks for optimization of plastic injection molding process parameters. Simulation Modelling Practice and Theory, 2014, 41: 15–27

Lam Y C, Deng Y M, Au C K. A GA/gradient hybrid approach for injection moulding conditions optimisation. Engineering with Computers, 2006, 21(3): 193–202

Zhang J, Wang J, Lin J, et al. Multiobjective optimization of injection molding process parameters based on Opt LHD, EBFNN, and MOPSO. International Journal of Advanced Manufacturing Technology, 2016, 85(9–12): 2857–2872

Kashyap S, Datta D. Process parameter optimization of plastic injection molding: A review. International Journal of Plastics Technology, 2015, 19(1): 1–18

Acknowledgements

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (Grant Nos. 51675199 and 51635006) and the National Program on Key Basic Research Project (Grant No. 2013CB035805).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, H., Zhang, Y., Zhou, X. et al. Intelligent methods for the process parameter determination of plastic injection molding. Front. Mech. Eng. 13, 85–95 (2018). https://doi.org/10.1007/s11465-018-0491-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-018-0491-0