Abstract

Selective laser melting (SLM), as one of the additive manufacturing technologies, is widely investigated to fabricate metal parts. In SLM, parts are manufactured directly from powders in a layer-by-layer fashion; SLM also provides several advantages, such as production of complex parts with high three-dimensional accuracy, compared with other additive manufacturing technologies. Therefore, SLM can be applied in aeronautics, astronautics, medicine, and die and mould industry. However, this technique differs from traditional methods, such as casting and forging; for instance, the former greatly differs in terms of microstructure and properties of products. This paper summarizes relevant studies on metal material fabrication through SLM. Based on a work completed in Huazhong Univ. Sci Tech., Rapid Manuf. Center (HUST-RMC) and compared with characteristics described in other reported studies, microstructure, properties, dimensional accuracy, and application of SLM are presented.

Similar content being viewed by others

References

Ahn D G. Applications of laser assisted metal rapid tooling process to manufacture of molding & forming tools-state of the art. International Journal of Precision Engineering and Manufacturing, 2011, 12(5): 925–938

Wen S, Li S, Wei Q, et al. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. Journal of Materials Science and Technology, 2014, 214(11): 2660–2667

Song B, Dong S J, Liao H, et al. Morphology evolution mechanism of single tracks of FeAl intermetallics in selective laser melting. Materials Research Innovations, 2012, 16(5): 321–325

Loh L E, Chua C K, Yeong W Y, et al. Numerical investigation and an effective modelling on the selective laser melting (SLM) process with aluminium alloy 6061. International Journal of Heat and Mass Transfer, 2015, 80: 288–300

Huang W, Lin X, Chen J, et al. Laser Solid Forming: Rapid Fabrication of Dense Metal Parts with High Performance. Xi’an: Publishing House of Northwestern Polytechnical University, 2007 (in Chinese)

Zhou X, Li K, Zhang D, et al. Textures formed in a CoCrMo alloy by selective laser melting. Journal of Alloys and Compounds, 2015, 631: 153–164

Li R. Basic researches on the materials formation directly from powders using selective laser melting. Dissertation for the Doctoral Degree. Wuhan: Huazhong University of Science and Technology, 2010 (in Chinese)

Gu D, Shen Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Materials & Design, 2009, 30(8): 2903–2910

Hall E O. Yield Point Phenomena in Metals and Alloys. New York: Plenum Press, 1970

Guan K, Wang Z, Gao M, et al. Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Materials & Design, 2013, 50: 581–586

Edwards P, Ramulu M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Materials Science and Engineering A, 2014, 598: 327–337

Simonelli M, Tse Y Y, Tuck C. The formation of alpha plus beta microstructure in as-fabricated selective laser melting of Ti-6Al-4V. Journal of Materials Research, 2014, 29(17): 2028–2035

Vrancken B, Thijs L, Kruth J P, et al. Microstructure and mechanical properties of a novel beta titanium metallic composite by selective laser melting. Acta Materialia, 2014, 68(15): 150–158

Song B, Dong S, Deng S, et al. Microstructure and tensile properties of iron parts fabricated by selective laser melting. Optics & Laser Technology, 2014, 56: 451–460

Song B, Dong S, Coddet C. Rapid in situ fabrication of Fe/SiC bulk nanocomposites by selective laser melting directly from a mixed powder of microsized Fe and SiC. Scripta Materialia, 2014, 75: 90–93

Song B, Dong S, Coddet P, et al. Microstructure and tensile behavior of hybrid nano-micro SiC reinforced iron matrix composites produced by selective laser melting. Journal of Alloys and Compounds, 2013, 579: 415–421

Li S, Wei Q, Zhang D, et al. Microstructures and texture of Inconel 718 alloy fabricated by selective laser melting. In: Proceedings of 1st International Conference on Progress in Additive Manufacturing. Singapore, 2014

Song B, Dong S, Coddet P, et al. Fabrication of NiCr alloy parts by selective laser melting: Columnar microstructure and anisotropic mechanical behavior. Materials & Design, 2014, 53: 1–7

Gu D, Meiners W, Hagedorn Y C, et al. Bulk-form TiCx/Ti nanocomposites with controlled nanostructure prepared by a new method: Selective laser melting. Journal of Physics D: Applied Physics, 2010, 43(29): 295402–295407

Gu D, Wang H, Zhang G. Selective laser melting additive manufacturing of Ti-based nanocomposites: The role of nanopowder. Metallurgical and Materials Transactions. A, Physical Metallurgy and Materials Science, 2014, 45(1): 464–476

Dadbakhsh S, Hao L. Effect of layer thickness in selective laser melting on microstructure of Al/5 wt.%Fe2O3 powder consolidated parts. The Scientific World Journal, 2014: 106129–106138

Mercelis P, Kruth J P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyping Journal, 2006, 12(5): 254–265

Kruth J P, Mercelis P, van Vaerenbergh J V, et al. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyping Journal, 2005, 11(1): 26–36

Thijs L, Verhaeghe F, Craeghs T, et al. A study of the microstructural evolution during selective laser melting of Ti-6Al- 4V. Acta Materialia, 2010, 58(9): 3303–3312

Yadroitsev I, Bertrand P H, Smurov I. Parametric analysis of the selective laser melting process. Applied Surface Science, 2007, 253 (19): 8064–8069

Gu D, Shen Y. Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Materials & Design, 2009, 30(8): 2903–2910

Rombouts M, Kruth J P, Froyen L, et al. Fundamentals of selective laser melting of alloyed steel powders. CIRP Annals-Manufacturing Technology, 2006, 55(1): 187–192

Yadroitsev I, Gusarov A, Yadroitsava I, et al. Single track formation in selective laser melting of metal powders. Journal of Materials Processing Technology, 2010, 210(12): 1624–1631

Li R, Liu J, Shi Y, et al. Balling behavior of stainless steel and nickel powder during selective laser melting process. The International Journal of Advanced Manufacturing Technology, 2012, 59(9–12): 1025–1035

Wei K, Gao M, Wang Z, et al. Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy. Materials Science and Engineering A, 2014, 611: 212–222

Yasa E, Deckers J, Kruth J P. The investigation of the influence of laser re-melting on density, surface quality and microstructure of selective laser melting parts. Rapid Prototyping Journal, 2011, 17 (5): 312–327

Song M, Lin X, Yang G, et al. Influence of forming atmosphere on the deposition characteristics of 2Cr13 stainless steel during laser solid forming. Journal of Materials Processing and Technology, 2014, 214(3): 701–709

Zhang B, Liao H, Coddet C. Selective laser melting commercially pure Ti under vacuum. Vacuum, 2013, 95: 25–29

Hussein A, Hao L, Yan C, et al. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Materials & Design, 2013, 52: 638–647

Kruth J P, Deckers J, Yasa E, et al. Assessing and comparing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture. 2012, 226: 980–991

Tong X, Dai M, Zhang Z. Thermal fatigue resistance of H13 steel treated by selective laser surface melting and CrNi alloying. Applied Surface Science, 2013, 271: 373–380

Amato K N, Gaytan S M, Murr L E, et al. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Materialia, 2012, 60(5): 2229–2239

Gu D, Meiners W, Wissenbach K, et al. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. International Materials Reviews, 2012, 57(3): 133–164

Kruth J P, Froyen L, van Vaerenbergh J, et al. Selective laser melting of iron-based powder. Journal of Materials Processing Technology, 2004, 149(1–3): 616–622

Carter L N, Martin C, Withers P J, et al. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. Journal of Alloys and Compounds, 2014, 615: 338–347

Gusarov A V, Pavlov M, Smurov I. Residual stresses at laser surface remelting and additive manufacturing. Physics Procedia, 2011, 12: 248–254

Shishkovskii I V, Yadroitsev I A, Smurov I Y. Selective laser sintering/melting of nitinol-hydroxyapatite composite for medical applications. Powder Metallurgy Metal Ceramics, 2011, 50(5–6): 275–283

Abe F, Osakada K, Shiomi M, et al. The manufacturing of hard tools from metallic powders by selective laser melting. Journal of Materials Processing Technology, 2001, 111(1–3): 210–213

Zhang S, Gui R, Wei Q, et al. Cracking behavior and mechanism of TC4 titanium by selective laser melting. Mechanical Engineering, 2013, 49: 21–27

Prashanth K G, Scudino S, Klauss H J, et al. Microstructure and mechanical properties of Al-12Si produced by selective laser melting: Effect of heat treatment. Materials Science and Engineering A, 2014, 590: 153–160

Monroy K P, Delgado J, Sereno L, et al. Effects of the selective laser melting manufacturing process on the properties of CoCrMo single tracks. Metals and Materials International, 2014, 20(5): 873–884

Vrancken B, Cain V, Knutsen R, et al. Residual stress via the contour method in compact tension specimens produced via selective laser melting. Scripta Materialia, 2014, 87: 29–32

Leuders S, Lieneke T, Lammers S, et al. On the fatigue properties of metals manufactured by selective laser melting—The role of ductility. Journal of Materials Research, 2014, 29(17): 1911–1919

Riemer A, Leuders S, Thöne M, et al. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Engineering Fracture Mechanics, 2014, 120: 15–25

Wang D. Characteristics and technology of stainless steel parts research by selective laser melting. Dissertation for the Doctoral Degree. Guangzhou: South China University of Technology, 2011 (in Chinese)

Frazier W E. Metal additive manufacturing: A review. Journal of Materials Engineering and Performance, 2014, 23(6): 1917–1928

SAE Aerospace. AMS 4991D-2010: Titanium Alloy Casting, Investment Ti6Al-4V Hot Isostatic Pressed, Anneal Optional. 2010

Facchini L, Magalini E, Robotti P, et al. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyping Journal, 2010, 16(6): 450–459

Rengers S. Electron Beam Melting [EBM] vs. Direct Metal Laser Sintering [DMLS]. Presented at SAMPE Midwest Chapter, Direct Part Manufacturing Workshop, Wright State University, 2012

Zhang S. Medical alloy fabricated by selective laser melting. Dissertation for the Doctoral Degree. Wuhan: Huazhong University of Science and Technology, 2014 (in Chinese)

Murr L E, Martinez E, Gaytan S M, et al. Microstructural architecture, microstructures, and mechanical properties of a nickel-base super-alloy fabricated by electron beam melting. Metallurgical and Materials Transactions A, 2011, 42(11): 3491–3508

Yadroitsev I, Pavlov M, Bertrand P, et al. Mechanical properties of samples fabricated by selective laser melting. In: Proceedings of 14èmes Assises Européennes du Prototypage & Fabrication Rapide. Paris, 2009

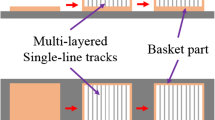

Yadroitsev I, Thivillion L, Bertrand P, et al. Strategy of manufacturing components with designed internal structure by selective laser melting of metallic powder. Applied Surface Science, 2007, 254(4): 980–983

Zhao X, Chen J, Lin X, et al. Study on microstructure and mechanical properties of laser rapid forming Inconel 718. Materials Science and Engineering A, 2008, 478(1–2): 119–124

Wang Z, Guan K, Gao M, et al. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. Journal of Alloys and Compounds, 2012, 513: 518–523

Amato K N, Gaytan S M, Murr L E, et al. Microstructure and mechanical behaviour of Inconel 718 fabricated by selective laser melting. Acta Materialia, 2012, 60(5): 2229–2239

Wang L. Study on the properties of parts fabricated by selective laser melting. Dissertation for the Doctoral Degree. Wuhan: Huazhong University of Science and Technology, 2012 (in Chinese)

Mertens A, Reginster S, Paydas H, et al. Mechanical properties of alloy Ti-6Al-4V and of stainless steel 316L processed by selective laser melting: Influence of out-of-equilibrium microstructures. Powder Metallurgy, 2014, 57(3): 184–189

Zhang B, Dembinski L, Coddet C. The study of the laser parameters and environment variables effect on mechanical properties of high compact parts elaborated by selective laser melting 316L powder. Materials Science and Engineering A, 2013, 584: 21–31

Spierings A B, Starr T L, Wegener K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyping Journal, 2013, 19(2): 88–94

Yan C, Hao L, Hussein A, et al. Advanced lightweight 316L stainless steel cellular lattice structures fabricated via selective laser melting. Materials & Design, 2014, 55: 533–541

Mumtaz K, Hopkinson N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyping Journal, 2009, 15(2): 96–103

Alrbaey K, Wimpenny D, Tosi R, et al. On optimization of surface roughness of selective laser melted stainless steel parts: A statistical study. Journal of Materials Engineering and Performance, 2014, 23 (6): 2139–2148

Dalgarno K. Materials research to support high performance RM parts. In: Proceedings of 2nd International Conference on Rapid Manufacturing. 2007, 147–156

Zhang S, Wei Q, Cheng L, et al. Effects of scan line spacing on pore characteristics and mechanical properties of porous Ti6Al4V implants fabricated by selective laser melting. Materials & Design, 2014, 63: 185–193

Zhang S, Li Y, Hao L, et al. Metal-ceramic bond mechanism of the Co-Cr alloy denture with original rough surface produced by selective laser melting. Chinese Journal of Mechanical Engineering, 2014, 27(1): 69–78

Toth-Tascau M, Stoia D I. Analysis of dimensional accuracy of two models of customized hip prostheses made of Polyamide powder by selective laser melting technology. Optoelectronics and Advanced Materials—Rapid Communications, 2011, 5(12): 1356–1363

Buchbinder D, Meiners W, Pirch N, et al. Investigation on reducing distortion by preheating during manufacture of aluminum components using selective laser melting. Journal of Laser Applications, 2014, 26(1): 012004

Pacurar R, Balc N, Prem F. Research on how to improve the accuracy of the SLM metallic parts. In: Proceedings of 14th International ESAFORM Conference on Material Forming. AIP Publishing, 2011, 1353(1): 1385–1390

Kumar S, Kruth J P. Wear performance of SLS/SLM materials. Advanced Engineering Materials, 2008, 10(8): 750–753

Gu D, Hagedorn Y C, Meiners W, et al. Selective laser melting of insitu TiC/Ti5Si3 composites with novel reinforcement architecture and elevated performance. Surface and Coatings Technology, 2011, 205(10): 3285–3292

Hedberg Y S, Qian B, Shen Z, et al. In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting. Dental Materials, 2014, 30(5): 525–534

De Wild M, Meier F, Bormann T, et al. Damping of selective-lasermelted NiTi for medical implants. Journal of Materials Engineering and Performance, 2014, 23(7): 2614–2619

Zhou X, Wei Q, Zhu W, et al. Forming processes of near a titanium alloy powder by selective laser melting. Journal of Hubei University of Technology, 2014, 29: 14–17 (in Chinese)

Amato K N, Gaytan S M, Murr L E, et al. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Materialia, 2012, 60(5): 2229–2239

Mumtaz K, Hopkinson N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyping Journal, 2009, 15(2): 96–103

NASA. http://www.nasa.gov/exploration/systems/sls/selective_- melting.html?ie = UTF8&tag = hardwaresoftw-20&LinkCode = asn&CreativeASIN

Balla V K, Bodhak S, Bose S, et al. Porous tantalum structures for bone implants: Fabrication, mechanical and in vitro biological properties. Acta Biomaterialia, 2010, 6(8): 3349–3359

Mullen L, Stamp R C, Brooks W K, et al. Selective laser melting: A regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. Journal of Biomedical Materials Research. Part B, Applied Biomaterials, 2009, 89B(2): 325–334

Macchetta A, Turner I G, Bowen C R. Fabrication of HA/TCP scaffolds with a graded and porous structure using a camphenebased freeze-casting method. Acta Biomaterialia, 2009, 5(4): 1319–1327

Bobyn J D, Stackpool G J, Hacking S A, et al. Characteristics of bone ingrowth and interface mechanics of a new porous tantalum biomaterial. The Journal of Bone and Joint Surgery. British Volume, 1999, 81(5): 907–914

Salito A, van Osten U, Brime F. Gentle coating technique. Sulzer Technical Review, 1998, 1: 34–37

Taylor N, Dunand D C, Mortensen A. Initial stage hot pressing of monosized Ti and 90% Ti-10% TiC powders. Acta Metallurgica et Materialia, 1993, 41(3): 955–965

Ahmadi S M, Campoli G, Amin Yavari S, et al. Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells. Journal of the Mechanical Behavior of Biomedical Materials, 2014, 34: 106–115

Zhang Z, Jones D, Yue S, et al. Hierarchical tailoring of strut architecture to control permeability of additive manufactured titanium implants. Materials Science and Engineering: C, 2013, 33 (7): 4055–4062

Fukuda A, Takemoto M, Saito T, et al. Osteoinduction of porous Ti implants with a channel structure fabricated by selective laser melting. Acta Biomaterialia, 2011, 7(5): 2327–2336

Balla V K, Bodhak S, Bose S, et al. Porous tantalum structures for bone implants: Fabrication, mechanical and in vitro biological properties. Acta Biomaterialia, 2010, 6(8): 3349–3359

Spoerke E D, Murray N G, Li H, et al. Titanium with aligned, elongated pores for orthopedic tissue engineering applications. Journal of Biomedical Materials Research. Part A, 2008, 84A(2): 402–412

Van Bael S, Chai Y C, Truscello S, et al. The effect of pore geometry on the in vitro biological behavior of human periosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds. Acta Biomaterialia, 2012, 8(7): 2824–2834

Liu Y, Wang Z, Gao B, et al. Evaluation of mechanical properties and porcelain bonded strength of nickel-chromium dental alloy fabricated by laser rapid forming. Lasers in Medical Science, 2010, 25(6): 799–804

Takaichi A, Suyalatu, Nakamoto T, et al. Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications. Journal of the Mechanical Behavior of Biomedical Materials, 2013, 21: 67–76

Huang Q, Gao Y, Luo P, et al. Preliminary study on some properties of Co-Cr dental alloy formed by selective laser melting technique. Journal of Wuhan University of Technology-Material Science Edition, 2012, 27(4): 665–668

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, B., Zhao, X., Li, S. et al. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 10, 111–125 (2015). https://doi.org/10.1007/s11465-015-0341-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-015-0341-2