Abstract

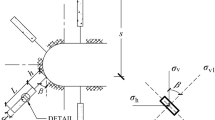

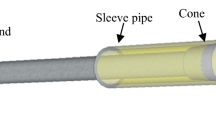

As an effective energy-absorbing cable, constant resistance large deformation (CRLD) cables have been widely applied in rock engineering projects; however, to the best of our knowledge, its interaction mechanism with the surrounding rock has never been studied. According to previous practical projects, the CRLD cable–rock interaction differs from that of conventional cables because of the tubular expansion during the CRLD process, and it influences the performance of the cable reinforcement system. Therefore, an attempt was made to investigate the characteristics of the CRLD cable–rock interaction under static pull-out loading by using a coupled numerical method. The structure of the CRLD cable was modelled via the finite-difference method, and the surrounding rock was modelled via the discrete-element method. The micro-parameters of the surrounding rock were carefully calibrated, and the macro-parameters of the CRLD cable were verified by comparing them with a corresponding experimental test in the laboratory. The numerical results were carefully analysed. The constant resistance forces of a single CRLD cable and a CRLD cable reinforcement system were compared. The distribution of the normal and shearing stresses on the cable–rock interface was obtained, and the evolution mode of the pull-out strength was examined. In addition, the failure mode of the grouting material and surrounding rock was studied on a micro-scale. The findings describe the interaction of the CRLD cable against the surrounding rock, reveal its special anchorage mechanism, and can be used to predict and improve the performance of the CRLD cable reinforcement system.

Similar content being viewed by others

References

Blanco Martín L, Tijani M, Hadj-Hassen F, Noiret A (2013) Assessment of the bolt-grout interface behaviour of fully grouted rockbolts from laboratory experiments under axial loads. Int J Rock Mech Min Sci 63:50–61. https://doi.org/10.1016/j.ijrmms.2013.06.007

Cai Y, Esaki T, Jiang Y (2004) A rock bolt and rock mass interaction model. Int J Rock Mech Min Sci 41:1055–1067

Charette F, Plouffe M (2008) A new rock bolt concept for underground excavations under high stress conditions. Johannesburg, pp 225–240

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geothechnique 29:331–336

Fairhurst C (1989) General report: deformation, yield, rupture and stability of excavations at depth in rock. Am J Gastroenterol 98:S40–S40

Farmer I (1975) Stress distribution along a resin grouted rock anchor. Int J Rock Mech Min Sci Geomech Abstr 12:347–351

Fuller PG, Hume BG, Hume RG (1996) Bolt load simulation and its practical application. Balkema, Rotterdam, pp 187–193

He MC (2009) Real-time remote monitoring and foresting system for geological disasters and its engineeringapplication. Chin J Rock Mech Eng 28:1081–1090 (in Chinese)

He MC, Guo Z (2014) Mechanical property and engineering application of anchor bolt with constant resistance and large deformation. Chin J Rock Mech Eng 33:1297–1308 (in Chinese)

He MC, Sousa LR (2014) Experiments on rock burst and its control. In: Australasian Ground Control in Mining Conference, Sidney

He MC, Sun XM (2004) China coal mine soft rock engineering supporting design and construction guide. Science Press, Beijing, p 109

He M, Gong W, Wang J et al (2014) Development of a novel energy-absorbing bolt with extraordinarily large elongation and constant resistance. Int J Rock Mech Min Sci 67:29–42

He MC, Li C, Gong W et al (2016) Support principles of NPR bolts/cables and control techniques of large deformation. Chin J Rock Mech Eng 35:1513–1529 (in Chinese)

He MC, Li C, Gong W et al (2017) Dynamic tests for a Constant-Resistance-Large-Deformation bolt using a modified SHTB system. Tunn Undergr Space Technol 64:103–116. https://doi.org/10.1016/j.tust.2016.12.007

Itasca (2012) PFC3D user manual, Version 5.0. Itasca Consulting Group Inc., Minneapolis

Itasca (2012) FLAC3D user manual, Version 6.0. Itasca Consulting Group Inc., Minneapolis

Jager AJ (1992) Two new support units for the control of rockburst damage. In: Kais PK, McCreath DR (eds) Rock Support Min Undergr Constr, pp 621–631

Jalalifar H, Aziz N (2012) Numerical simulation of fully grouted rock bolts. In: Numer Simul Theory Ind, pp 607–640

Jiang Y, Wu X, Wang G et al (2015) Interaction mechanism of yielding rock bolt and matrix mass. In: 13th International Congress of Rock Mechanics, Montreal, Canada

Li CC (2010) A new energy-absorbing bolt for rock support in high stress rock masses. Int J Rock Mech Min Sci 47:396–404

Li CC (2010) Field observations of rock bolts in high stress rock masses. Rock Mech Rock Eng 43:491–496. https://doi.org/10.1007/s00603-009-0067-8

Li C, Stillborg B (1999) Analytical models for rock bolts. Int J Rock Mech Min Sci 36:1013–1029

Li Y, Han X, Ji J, Wang H (2014) Research of rigid-pile composite foundation with crushed stone cushion based on FDM–PFC coupling method. In: Geomechanics from Micro to Macro, pp 927–932

Li ZH, Jiang Y, Tao Z, He M (2018) Monitoring prediction of a rockslide in an open-pit mine and numerical analysis using a material instability criterion. Bull Eng Geol Environ. https://doi.org/10.1007/s10064-017-1224-z

Li ZH, Lv Q, Zhu HX et al (2019) Laboratory testing and modeling of a high-displacement cable bolt. Int J Geomech ASCE. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001472

Lv Q, Tao ZG, Li ZH, He MC, An WB (2018) Elasto-plastic mechanics analysis of large deformation anchor. Chin J Rock Mech Eng 37(4):792–800 (in Chinese)

Martin LB, Hassen FH, Tijani M, Noiret A (2011) A new experimental and analytical study of fully grouted rockbolts. In: 45th Us Rock Mech, vol 20, pp 119–128

Ministry of Construction of People’s Republic of China (2002) Technical Code for Building Slope Engineering GB 50330-2002

Ministry of Construction of People’s Republic of China (2010) Technical Code for Design of Concrete Structures GB 50010-2010

Moosavi M, Grayeli R (2006) A model for cable bolt-rock mass interaction: integration with discontinuous deformation analysis (DDA) algorithm. Int J Rock Mech Min Sci 43:661–670

Nemcik J, Ma S, Aziz N et al (2014) Numerical modelling of failure propagation in fully grouted rock bolts subjected to tensile load. Int J Rock Mech Min Sci 71:293–300. https://doi.org/10.1016/j.ijrmms.2014.07.007

Ortlepp WD, Read JJ (1970) Yieldable rock bolts for shock loading and grouted bolts for faster rock stabilization. Min Eng 60:12–17

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Simser B, Parrott T, Turcotte P et al (2006) Field behaviour and failure modes of modified conebolts at the Craig, LaRonde and Brunswick Mines in Canada. In: Deep and high stress mining. Perth, pp 347–354

St-Pierre L, Hassani FP, Radziszewski PH, Ouellet J (2009) Development of a dynamic model for a cone bolt. Int J Rock Mech Min Sci 46:107–114

Sun X, Dong W, Cong W et al (2014) Tensile properties and application of constant resistance and large deformation bolts. Chin J Rock Mech Eng 33:1765–1771 (in Chinese)

Tao ZG, Li HP, Sun GL et al (2015) Development of monitoring and early warning system for landslides based on constant resistance and large deformation anchor cable and its application. Rock Soil Mech 10:3032–3040

Timoshenko S, Goodier JN (1970) Theory of elasticity, 3rd. McGraw-Hill, New York

Windsor CR (1996) Rock reinforcement systems. Int J Rock Mech Min Sci 34:919–951

Windsor CR, Thompson AG (1992) A new friction stabilizer assembly for rock and soil reinforcement applications. In: Kais PK, McCreath DR (eds) Rock Support Min Undergr Constr, pp 523–529

Windsor CR, Thompson AG (1993) Rock reinforcement-technology, testing, design and evaluation. Pergamon Press, Oxford, pp 451–484

Zhang Y, Wang D, Yang J et al (2017) Mechanical properties and supporting effect of CRLD bolts under static pull test conditions. Int J Miner Metall Mater 24:1–9

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Z.H., Hu, J., Zhu, H.X. et al. Numerical study on the CRLD cable–rock interaction under static pull-out loading using coupled DEM–FDM method. Acta Geotech. 15, 2137–2158 (2020). https://doi.org/10.1007/s11440-019-00888-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-019-00888-6