Abstract

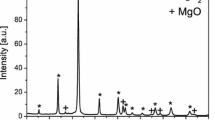

Using commercial amorphous B powder (92% in purity) and Mg powder (99% in purity) as starting materials, 19-filament Fe/Cu clad MgB2 wires were fabricated by an in situ powder-in-tube method. Heat treatment was performed at 700°C for 1 h under an argon gas atmosphere. The influence of Mg/B ratio on the microstructure and superconducting properties of the wires was investigated. It was found that the major phases of MgB2 wires were MgB2 accompanied with relatively small amounts of MgO and Fe2B impurities. With 5% excess Mg addition, the onset T C slightly decreased. However, the transport J C at 4.2 K and 4 T reached 1.07×104 A·cm−2, increasing by a factor of 1.4 compared to the stoichiometric sample. Moreover, the Mg1.05B2 sample showed an improved field dependence of J C, suggesting that less voids and smaller grain size of the Mg1.05B2 core lead to better grain connectivity and stronger flux pinning.

Similar content being viewed by others

References

Nagamatsu J, Nakagawa N, Zenitani Y, et al. Superconductivity at 39 K in magnesium diboride. Nature, 2001, 410: 63–64

Larbalestier D C, Rikel M O, Cooley M D. Strongly linked current flow in polycrystalline forms of the superconductor MgB2. Nature, 2001, 410: 186–193

Flukiger R, Suo H L, Musolino N, et al. Superconducting properties of MgB2 tapes and wires. Physica C, 2003, 385: 286–305

Iwasa Y, Larbalestier D C, Okada M, et al. A round table discussion on toward a wide market or a niche production? —A summary. IEEE Trans Appl Supercond, 2006, 16(2): 1457–1464

Alessandrini M, Fang H, Hanna M, et al. The potential application of superconducting magnets in space. IEEE Trans Appl Supercond, 2006, 16(2): 1442–1444

Musenich R, Fabbricatore P, Farinon S, et al. Behavior of MgB2 react & wind coils above 10 K. IEEE Trans Appl Supercond, 2005, 15(2): 1452–1456

Tanaka K, Kitaguchi H, Kumakura H, et al. Fabrication and transport properties of an MgB2 solenoid coil. Supercond Sci Technol, 2005, 18: 678–681

Birajdar B, Braccini V, Tumino A, et al. MgB2 multifilamentary tapes:microstructure chemical composition and superconducting properties. Supercond Sci Technol, 2006, 19: 916–923

Modica M, Grasso G, Greco M, et al. Behavior of reacted and wound coils from 14 K to 32 K in a cryogen free apparatus. IEEE Trans Appl Supercond, 2006, 16(2): 1449–1452

Collings E W, Lee E, Sumption M D, et al. Continuous-and batch-processed MgB2/Fe strands—Transport and magnetic properties. Physica C, 2003, 386: 555–559

Jiang J, Senkowicz B J, Larbalestier D C, et al. Influence of boron powder purification on the connectivity of bulk MgB2. Supercond Sci Technol, 2006, 19: L33–L36

Xu X, Qin M J, Konstantinov K, et al. Effect of boron powder purity on superconducting properties of MgB2. Supercond Sci Technol, 2006, 19: 466–469

Ribeiro R A, BudKo S L, Petrovic C, et al. Effects of stoichiometry, purity, etching and distilling on resistance of MgB2 pellets and wire segments. Physica C, 2002, 382: 194–202

Susner M A, Sumption M D, Bhatia M, et al. Influence of Mg/B ratio and SiC doping on microstructure and high field transport J c in MgB2 strands. Physica C, 2007, 465: 180–187

Liu Z K, Schlom D G, Li Q, et al. Thermodynamics of the Mg-B system: Implications for the deposition of MgB2 thin films. Appl Phys Lett, 2001, 78: 3678–3680

Zhang X P, Gao Z S, Wang D L, et al. Improved critical current densities in MgB2 tapes with ZrB2 doping. Appl Phys Lett, 2006, 89: 132510

Jiang C H, Nakane T, Kumakura H. Enhanced J-B performance in MgB2/Fe tapes with nanometre Si3N4 addition. Supercond Sci Technol, 2005, 18: 902–906

Xu H L, Feng Y, Yan G, et al. Investigation of MgB2/Fe wires with different diameters. Supercond Sci Technol, 2006, 19: 1169–1172

Hinks D G, Jorgensen J D, Zheng H, et al. Synthesis and stoichiometry of MgB2. Physica C, 2002, 382: 166–176

Dew-Hughes D. The role of grain boundaries in determining J c in high-field high-current superconductors. Phil. Mag. B, 1987, 55: 459–479

Pu M H, Feng Y, Zhang P X, et al. Investigating the flux pinning in high temperature superconductors more accurately. Physica C, 2003, 386: 47–51

Haruta M, Fujiyoshi T, Sueyoshi T, et al. Critical current density of mgb2 thin film with pinning centres introduced by deposition in Oxygen atmosphere. Supercond Sci Technol, 2005, 18: 1460–1463

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the Beijing Municipal Science and Technology Commission (Grant No. Z07000300703), the State Key Development Program for Basic Research of China (Grant No. 2006CB601004) and the National High Technology Research and Development Program for Advanced Materials of China (Grant No. 2006AA03Z203)

About this article

Cite this article

Yu, Z., Ma, Y., Wang, D. et al. Fabrication of the 19-filament Fe/Cu clad MgB2 wire via in situ powder-in-tube method. CHINESE SCI BULL 52, 2621–2625 (2007). https://doi.org/10.1007/s11434-007-0383-x

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11434-007-0383-x