Abstract

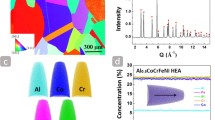

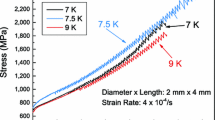

High-entropy alloys (HEAs) have attracted considerable attention in recent years because of their unique mechanical properties. In this work, the mechanism of dynamic shear banding (also called adiabatic shear bands, ASBs) in a BCC HEA HfNbZrTi was investigated combining dynamic experiments and numerical simulations. The temperature evolution during dynamic shear banding, which has been believed to play a dominant role during ASB formation in the literature, was measured using high-speed infrared thermal detectors synchronized with a split Hopkinson pressure bar system. The dynamic mechanical behavior of the BCC HEA was described using the Johnson-Cook model accompanied by damage accumulation. The process of ASB formation, considering potential contributions from thermal softening and damage softening, was numerically investigated by controlling the activation of each softening mechanism separately. Based on the results of experimental observation and numerical analysis, dynamic shear banding in this BCC HEA is proposed to be dominated by damage softening, and thermal softening only plays a secondary role, which differs from the thermal-softening-dominated ASB formation in typical FCC HEAs such as the Cantor alloy.

Similar content being viewed by others

References

Meyers M A. Dynamic Behavior of Materials. New York: John Wiley, 1994

Magness Jr. L S. High strain rate deformation behaviors of kinetic energy penetrator materials during ballistic impact. Mech Mater, 1994, 17: 147–154

Bai Y L. Adiabatic shear banding. Res Mech, 1990, 31: 133–203

Cai W D, Li Y, Dowding R J, et al. A review of tungsten-based alloys as kinetic energy penetrator materials. Rev Particul Mater, 1995, 3: 71–132

Yan X H, Li J S, Zhang W R, et al. A brief review of high-entropy films. Mater Chem Phys, 2018, 210: 12–19

Cantor B. Multicomponent and high entropy alloys. Entropy, 2014, 16: 4749–4768

Zener C, Hollomon J H. Effect of strain rate upon plastic flow of steel. J Appl Phys, 1944, 15: 22–32

Wright T W, Batra R C. The initiation and growth of adiabatic shear bands. Int J Plast, 1985, 1: 205–212

Bai Y L. Thermo-plastic instability in simple shear. J Mech Phys Solids, 1982, 30: 195–207

Clifton R J, Duffy J, Hartley K A, et al. On critical conditions for shear band formation at high strain rates. Scripta Metall, 1984, 18: 443–448

Molinari A, Clifton R J. Analytical characterization of shear localization in thermoviscoplastic materials. J Appl Mech, 1987, 54: 806–812

Dodd B, Atkins A G. Flow localization in shear deformation of void-containing and void-free solids. Acta Metall, 1983, 31: 9–15

Rittel D, Landau P, Venkert A. Dynamic recrystallization as a potential cause for adiabatic shear failure. Phys Rev Lett, 2008, 101: 165501

Guo Y Z, Li Y L, Pan Z, et al. A numerical study of microstructure effect on adiabatic shear instability: Application to nanostructured/ultrafine grained materials. Mech Mater, 2010, 42: 1020–1029

Zhu S, Guo Y, Ruan Q, et al. Formation of adiabatic shear band within Ti−6Al−4V: An in-situ study with high-speed photography and temperature measurement. Int J Mech Sci, 2020, 171: 105401

Zhu S, Guo Y, Chen H, et al. Formation of adiabatic shear band within Ti−6Al−4V: Effects of stress state. Mech Mater, 2019, 137: 103102

Li Z, Zhao S, Ritchie R O, et al. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog Mater Sci, 2019, 102: 296–345

George E P, Raabe D, Ritchie R O. High-entropy alloys. Nat Rev Mater, 2019, 4: 515–534

Li Z, Pradeep K G, Deng Y, et al. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature, 2016, 534: 227–230

Li C H, Wang M L, Zhang H Z, et al. A novel as-cast precipitation-strengthened Al0.5V0.1FeCrMnNi0.9 high-entropy alloy with high strength and plasticity. Sci China Tech Sci, 2021, 64: 1920–1926

Raman L, Anupam A, Karthick G, et al. Strengthening mechanisms in CrMoNbTiW refractory high entropy alloy. Mater Sci Eng-A, 2021, 819: 141503

Jia B, Liu X J, Wang H, et al. Microstructure and mechanical properties of FeCoNiCr high-entropy alloy strengthened by nano-Y2O3 dispersion. Sci China Tech Sci, 2018, 61: 179–183

Senkov O N, Couzinie J P, Rao S I, et al. Temperature dependent deformation behavior and strengthening mechanisms in a low density refractory high entropy alloy Al10Nb15Ta5Ti30Zr40. Materialia, 2020, 9: 100627

Wang B, Fu A, Huang X, et al. Mechanical properties and microstructure of the CoCrFeMnNi high entropy alloy under high strain rate compression. J Materi Eng Perform, 2016, 25: 2985–2992

Li Z, Zhao S, Diao H, et al. High-velocity deformation of Al0.3−CoCrFeNi high-entropy alloy: Remarkable resistance to shear failure. Sci Rep, 2017, 7: 42742

Li Z, Zhao S, Alotaibi S M, et al. Adiabatic shear localization in the CrMnFeCoNi high-entropy alloy. Acta Mater, 2018, 151: 424–431

Park J M, Moon J, Bae J W, et al. Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy. Mater Sci Eng-A, 2018, 719: 155–163

Soares G C, Patnamsetty M, Peura P, et al. Effects of adiabatic heating and strain rate on the dynamic response of a CoCrFeMnNi high-entropy alloy. J Dyn Behav Mater, 2019, 5: 320–330

Liu X F, Tian Z L, Zhang X F, et al. “Self-sharpening” tungsten high-entropy alloy. Acta Mater, 2020, 186: 257–266

Zhou S, Jian R, Liang Y J, et al. High susceptibility to adiabatic shear banding and high dynamic strength in tungsten heavy alloys with a high-entropy alloy matrix. J Alloys Compd, 2021, 859: 157796

Wu Y D, Cai Y H, Wang T, et al. A refractory Hf25Nb25Ti25Zr25 high-entropy alloy with excellent structural stability and tensile properties. Mater Lett, 2014, 130: 277–280

Peng S, Jin K, Yi X, et al. Mechanical behavior of the HfNbZrTi high entropy alloy after ion irradiation based on micro-pillar compression tests. J Alloys Compd, 2022, 892: 162043

Senkov O N, Scott J M, Senkova S V, et al. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J Alloys Compd, 2011, 509: 6043–6048

Chen W W, Song B. Split Hopkinson (Kolsky) Bar: Design, Testing and Applications. Berlin: Springer, 2010

Kubilay R E, Ghafarollahi A, Maresca F, et al. High energy barriers for edge dislocation motion in body-centered cubic high entropy alloys. Npj Comput Mater, 2021, 7: 112

Maresca F, Curtin W A. Mechanistic origin of high strength in refractory BCC high entropy alloys up to 1900K. Acta Mater, 2020, 182: 235–249

Maresca F, Curtin W A. Theory of screw dislocation strengthening in random BCC alloys from dilute to “high-entropy” alloys. Acta Mater, 2020, 182: 144–162

Johnson G R, Cook W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech, 1985, 21: 31–48

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11922202, 12002050, and 11802029), the National Key Laboratory Foundation of Science and Technology on Materials under Shock and Impact (Grant No. 6142902200401), and the Beijing Institute of Technology Research Fund Program for Young Scholars.

Rights and permissions

About this article

Cite this article

Song, WL., Ma, Q., Zeng, Q. et al. Experimental and numerical study on the dynamic shear banding mechanism of HfNbZrTi high entropy alloy. Sci. China Technol. Sci. 65, 1808–1818 (2022). https://doi.org/10.1007/s11431-022-2086-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-022-2086-9