Abstract

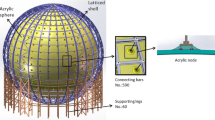

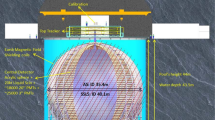

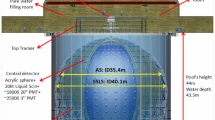

After the success of the Daya Bay experiment, the Jiangmen Underground Neutrino Observatory (JUNO) was launched to measure neutrino-mass hierarchy and oscillation parameters and to study other neutrino physics. Its central detector is set for antineutrinos from reactors, the Earth, the atmosphere, and the Sun. The main requirements of the central detector are containment of 20 kt of liquid scintillator, as the target mass, and 3% energy resolution. It is about a ball-shape detector of 38.5 m with ∼75% coverage of PMT on its inner surface. The design of such a huge detector is a big challenge because it must meet the requirements for several different types of physics measurement and possess the feasibility and reliability in its structure and engineering, all at reasonable time and cost. One option for the JUNO central detector is a hyper-scale acrylic ball submerged in the water to shield the background. This paper proposes a structural scheme for such an acrylic ball that is supported by a stainless-steel truss, inspired by point-supported glass-curtain walls in civil engineering. The preliminary design of the scheme is completed and verified by finite element (FE) method using ABAQUS. FE analysis shows that the scheme can control the stress level of the acrylic ball within the limit of 5 to 10 MPa, in accordance with the demand of the design objective of the central detector. The scheme is of outstanding global stability and allows various choices on local connections. We prove that the scheme is of good feasibility and should be a reasonable option for the central detector.

Similar content being viewed by others

References

An F P, Bai J Z, Balantekin A B, et al. Observation of electron-anti-neutrino disappearance at Daya Bay. Phys Rev Lett, 2012, 108: 171803

Adrian C. Key neutrino measurement signals China’s rise. Science, 2012, 335: 1287–1288

Reich E S. Neutrino oscillations measured with record precision. Nature News, 2012, doi: 10.1038/nature.2012.10202

Hirsch M, Päs H, Porod W. Ghostly beacons of new physics. Sci Amer, 2013, 308: 40–47

Feder T. news notes: Daya Bay experiment revs up. Phys Today, 2011, 64: 30

Wang Y F. A neutrino experiment using the Daya Bay reactor (in Chinese). Physics, 2007, 36: 207–214

Chen X H, Luo X L, Heng Y K, et al. Leakage tests of the stainless steel vessels of the antineutrino detectors in the Daya Bay reactor neutrino experiment. Sci China Tech Sci, 2013, 56: 148–151

Collaboration S N O. Electron Energy Spectra, Fluxes, and Day-Night Asymmetries of Solar Neutrinos from the 391-Day Salt Phase SNO Data Set. arXiv preprint nucl-ex/0502021, 2005

Eguchi K, Enomoto S, Furuno K, et al. First results from KamLAND: Evidence for reactor antineutrino disappearance. Phys Rev Lett, 2003, 90: 021802

Alimonti G, Arpesella C, Back H, et al. Science and technology of Borexino: A real-time detector for low energy solar neutrino. Astropart Physics, 2002, 16: 205–234

Chen J, Fu M F, Lin Z P. Mechanical and photoplasticity research of polymethyl methacrylate (in Chinese). J Tianjin Univ, 2000, 33: 85–87

Wang Y Q, Shi Y J, Wu L L. Research on Application Technology of Point-supporting Glass Building (in Chinese). Beijing: Science Press, 2009. 8

Wang Y Q, Wu L L, Shi Y J, et al. FEM analysis and experimental study on monolayer cable net for glass facades: Static performance. Adv Struct Eng, 2007, 10: 371–382

JGJ7-2010. Technical specification for space frame structures. 2010

CEN. Eurocode 3: Design of steel structures-Part 1–4: General-Structures in stainless steel. 2003

Wang X C. Finite Element Method (in Chinese). Beijing: Tsinghua University Press, 2003

Wang Y Q, Yuan H X, Shi Y J, et al. Bearing capacity of non-linear metallic spiders used in point supported glass facades. Int J Steel Struct, 2012, 12: 191–204

Wang Y Q, Yuan H X, Shi Y J, et al. A review of current application and research of stainless steel structure (in Chinese). Steel Structures, 2010, 25: 1–13

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Zong, L., Heng, Y. et al. Application of an acrylic vessel supported by a stainless-steel truss for the JUNO central detector. Sci. China Technol. Sci. 57, 2523–2529 (2014). https://doi.org/10.1007/s11431-014-5715-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5715-x