Abstract

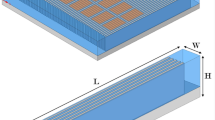

Based on constructal theory, the constructs of three “volume-point” heat conduction models with three-dimensional cylindrical element and rectangular and triangular elements on microscale and nanoscale are optimized by taking minimum entransy dissipation rate as optimization objective. The optimal constructs of the three “volume-point” heat conduction models with minimum dimensionless equivalent thermal resistance are obtained. The results show that the optimal constructs of the three-dimensional cylindrical assembly based on the minimizations of dimensionless equivalent thermal resistance and dimensionless maximum thermal resistance are different, which is obviously different from the comparison between those of the corresponding two-dimensional rectangular assembly based on the minimizations of these two objectives. The optimal constructs based on rectangular and triangular elements on microscale and nanoscale when the size effect takes effect are obviously different from those when the size effect does not take effect. Because the thermal current density in the high conductivity channel of the rectangular and triangular second order assemblies are not linear with the length, the optimal constructs of these assemblies based on the minimization of entransy dissipation rate are different from those based on the minimization of maximum temperature difference. The dimensionless equivalent thermal resistance defined based on entransy dissipation rate reflects the average heat transfer performance of the construct. The studies on “volume-point” heat conduction constructal problems at three-dimensional conditions and microscale and nanoscale by taking minimum entransy dissipation rate as optimization objective extend the application range of the entransy dissipation extremum principle.

Similar content being viewed by others

References

Bejan A. Shape and Structure, from Engineering to Nature. Cambridge: Cambridge University Press, 2000

Bejan A, Lorente S. Thermodynamic optimization of flow geometry in mechanical and civil engineering. J Non-Equilib Thermodyn, 2001, 26(4): 305–354

Bejan A, Lorente S. Constructal theory of generation of configuration in nature and engineering. J Appl Phys, 2006, 100(4): 041301

Bejan A, Merkx G W. Constructal Theory of Social Dynamics. New York: Springer, 2007

Bejan A, Lorente S. Design with Constructal Theory. New Jersey: Wiley, 2008

Bejan A, Lorente S, Miguel A F, et al. Constructal Human Dynamics, Security & Sustainability. Amsterdam: IOS Press, 2009

Bejan A. Constructal-theory network of conducting paths for cooling a heat generating volume, Trans ASME, J Heat Transfer, 1997, 40(4): 799–816

Ledezma G, Bejan A, Errera M. Constructal tree networks for heat transfer. J Appl Phys, 1997, 82(1): 89–100

Almogbel M, Bejan A. Constructal optimization of nonuniformly distributed tree-shaped flow structures for conduction. Int J Heat Mass Transfer, 2001, 44(22): 4185–4194

Ghodoossi L, Egrican N. Exact solution for cooling of electronics using constructal theory. J Appl Phys, 2003, 93(8), 4922–4929

Wu W, Chen L, Sun F. On the “area to point” flow problem based on constructal theory. Energy Convers Mgmt, 2007, 48(1): 101–105

Wu W, Chen L, Sun F. Improvement of tree-like network constructal method for heat conduction optimization. Sci China Ser-E: Tech Sci, 2006, 49(3): 332–341

Ghodoossi S, Egrican N. Conductive cooling of triangular shaped electronics using constructal theory. Energy Convers Mgmt, 2004, 45(6): 811–828

Wei S, Chen L, Sun F. The volume-point constructal optimization for discrete variable cross-section conducting path. Appl Energy, 2009, 86(7/8): 1111–1118

Zhou S, Chen L, Sun F. Optimization of constructal volume-point conduction with variable cross-section conducting path. Energy Convers Mgmt, 2007, 48(1): 106–111

Neagu M, Bejan A. Constructal-theory tree networks of’ constant’ thermal resistance. J Appl Phys, 1999, 86(2): 1136–1144

Xiao Q, Chen L, Sun F. Constructal entransy dissipation rate minimization for heat conduction based on variable-shaped element. Chin Sci Bull, 2011, 56(22): 2400–2410

Karakas A, Camdali U, Tunc M. Constructal optimization of heat generating volumes. Int J Exergy, 2009, 6(5): 637–654

Ledezma G A, Bejan A. Constructal three-dimensional trees for conduction between a volume and one point. Trans ASME, J Heat Transfer, 1998, 120(4): 977–984

Neagu M, Bejan A. Three-dimensional tree constructs of ‘constant’ thermal resistance. J Appl Phys, 1999, 86(12): 7107–7115

Alebrahim A, Bejan A. Constructal trees of circular fins for conductive and convective heat transfer. Int J Heat Mass Transfer, 1999, 42(19): 3585–3597

Majumdar A. Microscale heat conduction in dielectric thin films. J Heat Transfer, 1993, 115, 7–16

Goodson K E, Flik M K. Electron and phonon thermal conduction in epitaxial high-Tc superconducting films. J Heat Transfer, 1993, 115, 17–25

Guo Z. Frontier of heat transfer-microscale heat transfer (in Chinese). Adv Mech, 2000, 30(1): 1–6

Duncan A B, Peterson G P. Review of microscale heat transfer. Appl Mech Rev, 1994, 47(9): 397–428

Gao P, Le Person S, Favre-Marinet M. Scale effects on hydrodynamics and heat transfer in two-dimensional mini and microchannels. Int J Therm Sci, 2002, 41(11), 1017–1027

Guo Z, Li Z. Size effect on microscale single-phase flow and heat transfer. Int J heat Mass Transfer, 2003, 46(1): 149–159

Guo Z, Li Z. Size effect on single-phase channel flow and heat transfer at microscale. Int J Heat Fluid Flow, 2003, 24(3), 284–298

Liu T, Ji J, Guo Z, et al. Achievements of major project “microscale heat transfer in astronautic technology and microeletronic devices” (in Chinese). Chin Sci fund, 2004, 6: 349–351

Hu X, Jain A, Goodson K E. Investigation of the natural convection boundary condition in microfabricated structures. Int J Therm Sci, 2008, 47(7): 820–824

Gosselin L, Bejan A. Constructal heat trees at micro and nanoscales. J Appl Phys, 2004, 96(10): 5852–5859

Guo Z, Zhu H, Liang X. Entransy — A physical quantity describing heat transfer ability. Int J Heat Mass Transfer, 2007, 50(13/14): 2545–2556

Li Z, Guo Z. Field Synergy Principle of Heat Convection Optimization. Beijing: Science Press, 2010

Guo Z, Cheng X, Xia Z. Least dissipation principle of heat transport potential capacity and its application in heat conduction optimization. Chin Sci Bull, 2003, 48(4): 406–410

Han G, Zhu H, Cheng X, et al. Transfer similarity among heat conduction, elastic motion and electric conduction (in Chinese). J Eng Thermophys, 2005, 26(6): 1022–1024

Han G, Guo Z. Physical mechanism of heat conduction ability dissipation and its analytical expression (in Chinese). Proc CSEE, 2007, 27(17): 98–102

Zhu H, Chen J, Guo Z. Electricity and thermal analogous experimental study for entransy dissipation extreme principle (in Chinese). Prog Natural Sci, 2007, 17(12): 1692–1698

Chen Q, Ren J. Generalized thermal resistance for convective heat transfer and its relation to entransy dissipation. Chin Sci Bull, 2008, 53(23): 3753–3761

Chen Q, Ren J, Guo Z. The extremum principle of mass entransy dissipation and its application to decontamination ventilation designs in space station cabins. Chin Sci Bull, 2009, 54(16): 2862–2870

Xia S, Chen L, Sun F. Optimization for entransy dissipation minimi zation in heat exchanger. Chin Sci Bull, 2009, 54(19): 3587–3595

Wang S, Chen Q, Zhang B. An equation of entransy and its application. Chin Sci Bull, 2009, 54(19): 3572–3578

Guo J, Cheng L, Xu M. Entransy dissipation number and its application to heat exchanger performance evaluation. Chin Sci Bull, 2009, 54(15): 2708–2713

Chen Q, Wang M, Pan N, et al. Optimization principles for convective heat transfer. Energy, 2009, 34(9): 1199–1206

Chen L, Chen Q, Li Z, et al. Optimization for a heat exchanger couple based on the minimum thermal resistance principle. Int J Heat Mass Transfer, 2009, 52(21/22): 4778–4784

Guo Z, Liu X, Tao W, et al. Effectiveness-thermal resistance method for heat exchanger design and analysis. Int J Heat Mass Transfer, 2010, 53(13/14): 2877–2884

Xia S, Chen L, Sun F. Entransy dissipation minimization for liquid-solid phase processes. Sci China Tech Sci, 2010, 53(4): 960–968

Xia S, Chen L, Sun F. Entransy dissipation minimization for a class of one-way isothermal mass transfer processes. Sci China Tech Sci, 2011, 54(2): 352–361

Guo J, Xu M, Cheng L. Principle of equipartition of entransy dissipation for heat exchanger design. Sci China Tech Sci, 2010, 53(5): 1309–1314

Guo J, Xu M, Chen L. The influence of viscous heating on the entransy in two-fluid heat exchangers. Sci China: Tech Sci, 2011, 54(5): 1267–1274

Cheng X, Xu X, Liang X. Application of entransy to optimization design of parallel thermal network of thermal control system in spacecraft. Sci China Tech Sci, 2011, 54(4): 964–971

Cheng X, Liang X, Guo Z. Entransy decrease principle of heat transfer in an isolated system. Chin Sci Bull, 2011, 56(9): 847–854

Li X, Guo J, Xu M, et al. Entransy dissipation minimization for optimization of heat exchanger design. Chin Sci Bull, 2011, 56(20), 2174–2178

Wei S, Chen L, Sun F. “Volume-point” heat conduction constructal optimization with entransy dissipation minimization objective based on rectangular element. Sci China Ser E-Tech Sci, 2008, 51(8): 1283–1295

Wei S, Chen L, Sun F. Constructal entransy dissipation minimization for “volume-point” heat conduction without the premise of optimized last-order construct. Int J Exergy, 2010, 7(5): 627–639

Wei S, Chen L, Sun F. Constructal optimization of discrete and continuous-variable cross-section conducting path based on entransy dissipation rate minimization. Sci China Tech Sci, 2010, 53(6): 1666–1677

Wei S, Chen L, Sun F. “Volume-point” heat conduction constructal optimization with entransy dissipation minimization objective based on triangular element. Therm Sci, 2010, 14(4): 1075–1088

Wei S, Chen L, Sun F. Constructal multidisciplinary optimization of electromagnet based on entransy dissipation minimization. Sci China Ser E-Tech Sci, 2009, 52(10): 2981–2989

Xie Z, Chen L, Sun F. Constructal optimization for geometry of cavity by taking entransy dissipation minimization as objective. Sci China Ser E-Tech Sci, 2009, 52(12): 3504–3513

Xie Z, Chen L, Sun F. Constructal optimization on T-shaped cavity based on entransy dissipation minimization. Chin Sci Bull, 2009, 54(23): 4418–4427

Xiao Q Chen L, Sun F. Constructal entransy dissipation rate minimization for “disc-to-point” heat conduction. Chin Sci Bull, 2011, 56(1): 102–112

Chen L, Wei S, Sun F. Constructal entransy dissipation rate minimization of a disc. Int J Heat Mass Transfer, 2011, 54(1–3): 210–216

Xiao Q, Chen L, Sun F. Constructal entransy dissipation rate minimization for umbrella-shaped assembly of cylindrical fins. Sci China Tech Sci, 2011, 54(1): 211–219

Xie Z, Chen L, Sun F. Comparative study on constructal optimizations of T-shaped fin based on entransy dissipation rate minimization and maximum thermal resistance minimization. Sci China Tech Sci, 2011, 41(7): 962–970

Xiao Q, Chen L, Sun F. Constructal entransy dissipation rate and flow-resistance minimizations for cooling channels. Sci China Tech Sci, 2010, 53(9): 2458–2468

Wei S, Chen L, Sun F. Constructal entransy dissipation rate minimization of round tube heat exchanger cross-section. Int J Therm Sci, 2011, 50(7), 1285–1292

Xiao Q, Chen L, Sun F. Constructal design for a steam generator based on entransy dissipation extremum principle. Sci China Tech Sci, 2011, 54(6): 1462–1468

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, H., Chen, L. & Sun, F. “Volume-point” heat conduction constructal optimization based on entransy dissipation rate minimization with three-dimensional cylindrical element and rectangular and triangular elements on microscale and nanoscale. Sci. China Technol. Sci. 55, 779–794 (2012). https://doi.org/10.1007/s11431-011-4690-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4690-8