Abstract

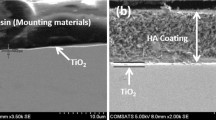

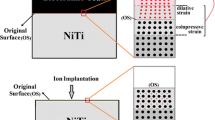

A uniform and dense TiO2 film was grown on the surface of porous NiTi shape memory alloys (SMAs) successfully by RF magnetron sputtering. The morphology and composition of the surface film were analyzed by using scanning electron microscopy and X-ray photoelectron spectroscopy. The corrosion resistance measurement proved that the surface modified porous NiTi SMAs exhibit better corrosion resistance and over 25% reduction of Ni ion release in the blood of the rabbits in comparing with the samples without surface modification. Moreover, the biocompatibility, as demonstrated by cell adherence and implant surgery, revealed that the cell adherence and bone tissue inducing capability are respectively enhanced over 1.1–1.2 and 9–10 times by sputtering a uniform TiO2 film on the surfaces of porous NiTi SMAs.

Similar content being viewed by others

References

Abkowitz S, Siergiej J M, Regan R R. Titanium-nickel alloy manufacturing methods. United States Patent Office Patent 3, 700, 434, 1969

Martynova I, Skorohod V, Solonin S. Shape memory and superelasticity behavior of porous Ti-Ni material. J Phys IV, 1991, C4: 421–426

Brett L. A new era in porous metals: Applications in orthopaedics. Adv Eng Mater, 2008, 215: 788–792

Jiang H C, Rong L J. Effect of hydroxyapatite coating on nickel release of the porous NiTi shape memory alloy fabricated by SHS method. Surf Coat Technol, 2006, 201: 1017–1021

Bansiddhi A, Sargeant T D, Stupp S I, et al. Porous NiTi for bone implants: A review. Acta Biomater, 2008, 4: 773–782

Itin V, Nalsenik O, Magel O, et al. Corrosion behavior of TiNi based alloys in the HCl water solutions. Metal Protection, 1999, 35: 373–375

Yuan B, Li H, Gao Y, et al. Passivation and oxygen ion implantation double surface treatment on porous NiTi shape memory alloys and its Ni suppression performance. Surf Coat Technol, 2009, 204: 58–63

Ho J P Y, Wu S L, Poon R W Y, et al. Oxygen plasma treatment to restrain nickel outdiffusion from porous nickel titanium orthopedic materials. Surf Coat Technol, 2007, 201: 4893–4896

Wu S L, Liu X, Chan Y L, et al. Nickel release behavior, cytocompatibility, and superelasticity of oxidized porous single-phase NiTi. J Biomed Mat Res A, 2007, 81A: 948–955

Lemaire V, Sicotte B, Allard S. Surface modification treatments to reduce Ni leaching from porous nitinol. In: Metfoam Conference, 2007

Gu Y W, Li H, Tay B Y, et al. In vitro bioactivity and osteoblast response of porous NiTi synthesized by SHS using nanocrystalline Ni-Ti reaction agent. J Biomed Mat Res A, 2006, 78A: 316–323

Li H, Yuan B, Gao Y, et al. Remarkable biocompatibility enhancement of porous NiTi alloys by a new surface modification approach: in-situ nitriding and in vitro and in vivo evaluation. J Biomedical Mater Res-Part A, 2011

Huang N, Yang P, Chen X, et al. Blood compatibility of amorphous titanium oxide films synthesized by ion beam enhanced deposition. Biomater, 1998, 19: 771–776

Li H, Yuan B, Yan G, et al. High porosity NiTi superelastic alloys fabricated by low-pressure sintering using titanium hydride as pore-forming agent. J Mater Sci, 2009, 44: 875–881

Ayers R A, Simske S J, Bateman T A, et al. Effect of nitinol implant porosity on cranial bone ingrowth and apposition after 6 weeks. J Biomed Mater Res, 1999, 45: 42–47

Thierry B, Tabrizian M, Savadogo O, et al. Effects of sterilization processes on NiTi alloy: Surface characterization. J Biomed Mater Res, 2000, 49: 88–98

Firstov G S, Vitchev R G, Kumar H, et al. Surface oxidation of NiTi shape memory alloy. Biomater, 2002, 23: 4863–4871

Kapanen A, Danilov A, Lehenkari P, et al. Effect of metal alloy surface stresses on the viability of ROS-17/2.8 osteoblastic cells. Biomater, 2002, 23: 3733–3740

Quarto R, Bianchi G, Derubeis A, et al. Bone marrow stromal cells: Cell biology & clinical applications. European Cells Mater, 2002, 4: 28–33

Es-Souni M, Es-Souni M, Fischer-Brandies H. On the properties of two binary NiTi shape memory alloys. Effects of surface finish on the corrosion behaviour and in vitro biocompatibility. Biomaterials, 2002, 23(14): 2887–2894

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, B., Li, H., Gao, Y. et al. In vitro and in vivo evaluation of porous NiTi alloy modified by sputtering a surface TiO2 film. Sci. China Technol. Sci. 55, 437–444 (2012). https://doi.org/10.1007/s11431-011-4683-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4683-7