Abstract

Purpose

Food production is set to double by 2050 to feed the increasing world population. This poses a global challenge to minimise environmental impacts from intensified production and use of chemical fertilisers. The study investigates whether basalt rock dust fertiliser can be an environmentally sustainable close substitute to expensive conventional rock-derived P and K fertilisers.

Method

The study uses the attributional life cycle assessment method to estimate and compare 15 environmental impacts between basalt rock dust fertiliser, a potential source of phosphorus (P) and potassium (K), and five widely used industrial P and K fertilisers. In addition, we model hypothetical basalt substitution rates for PK fertilisers to highlight potential ecological savings in terms of carbon capture.

Results

Basalt rock dust fertiliser has minimal embodied environmental impacts across all 15 impact categories, including global warming, compared to industrial P and K fertilisers.

Conclusion

Our results suggest that transitioning to milled basalt as a natural geo-fertiliser to support food production may help address several UN Sustainable Development Goals such as ‘Responsible consumption and production’ and ‘Climate Action and Zero Hunger’.

Similar content being viewed by others

1 Introduction

Global demand for food is continually increasing, fuelled mainly by population growth. A recent report released by Food and Agriculture Organisation, World Food Programme, and World Health Organisation (FAO, IFAD, UNICEF, WFP and WHO 2021) indicates that the threat of food insecurity and hunger is ascending, especially in Asia and Africa. At the same time, the constant cultivation and harvesting of food crops lead to rapid depletion of soil nutrients at levels that cannot be considered sustainable for future production. As a solution, industrial synthetic fertilisers, particularly NPK fertilisers, have become popular in replenishing lost nutrients and increasing crop yields (Roberts 2009; Stewart and Roberts 2012).

However, the environmental and economic sustainability of using these fertilisers have been questioned. Fertiliser cost to local farmers, especially in poor regions of the world, is relatively high, yet such places have been known to have highly weathered soils in need of replenishment (Sanchez 2002; Chianu et al. 2012). In addition to the high prices, evidence in previous research suggests the continuous production and use of these fertilisers presents environmental challenges such as greenhouse gas emissions and eutrophication (Carpenter et al. 1998; Tilman et al. 2002; Wood and Cowie 2004; Atafar et al. 2010; Gan et al. 2014; Goucher et al. 2017). Because of this, several studies have sought to compare the environmental performance of chemical fertilisers with other sources, including human, plant, animal, and food waste recovery and recirculation as substitutes for conventional fertilisers (Moore et al. 2017; Brod et al. 2015; Bøen and Haraldsen 2013; Franzosi et al. 2014; Helsel 1992).

This study investigates whether basalt rock dust fertiliser can be an environmentally sustainable close substitute to expensive conventional rock-derived P and K fertilisers (Van Straaten 2002). We use the phrase ‘close substitute’ to signify that basalt rock dust fertiliser cannot supply nitrogen (N) but can supply phosphorus (P) and potassium (K). Potential benefits of basalt dust for croplands include increased yields (Leonardos et al. 1987; Harley and Gilkes 2000), possibly by reversing soil acidification, thereby increasing plant nutrient uptake and increasing root-associating mycorrhizal abundance and provision of trace elements to the crop plants, especially on highly weathered tropical soils (Gillman et al. 2001, 2002; Anda et al. 2009). Basalt also contains silica, which is not present in industrial fertilisers, released by weathering in a plant-available form (silicic acid). Although not an essential plant nutrient, silica can protect plants from abiotic stresses and pests and diseases (Beerling et al. 2018).

Furthermore, basalt rock dust is amongst the few fertilisers acceptable to the growing organic agricultural sector (Van Straaten 2006). In emerging economies like Brazil, the government supports using silicate rocks such as basalt as soil remineralisers for crop nutrition. It has also been proposed to developing countries as a feasible solution to reduce their reliance on expensive imported fertilisers (Manning and Theodoro 2020). Large-scale spreading of basalt rock dust on croplands may also represent a carbon dioxide removal (CDR) strategy through the chemical breakdown of silicate rocks, a process known as enhanced weathering (Renforth 2012; Moosdorf et al. 2014; Taylor et al. 2016).

However, there is a need to understand the potential embodied environmental impacts during the production of milled basalt (also referred to here as basalt rock dust fertiliser) and compare them with industrial fertilisers across a wide range of environmental indicators to provide a robust basis for decision-making. Previous studies, for instance, have highlighted the health challenges associated with the particle size distribution of basalt waste dust which may present different health challenges than those faced by industrial fertilisers (Dalmora et al. 2016). However, a full environmental impact assessment of both fertiliser types (in this case, basalt and industrial fertilisers) is required before a meaningful conclusion is made on which option is environmentally sustainable.

The life cycle assessment (LCA) method is used in estimating potential environmental impacts of products and processes and has been applied in studies on fertilisers but mostly on their application or usage (Brentrup et al. 2004; Skowrońska and Filipek 2014; Quirós et al. 2015) with few assessing impacts from their production (Mirlean and Roisenberg 2006; Ledgard et al. 2011; Hasler et al. 2015). Against this backdrop, we present a comparative life cycle assessment of basalt rock dust fertiliser and five industrially used P and K fertilisers: single superphosphate (SSP), triple superphosphate (TSP), potassium chloride (KCI), potassium carbonate (K2CO3), and potassium hydroxide (KOH). We estimate and compare 15 potential environmental impact indicators, including climate change impact (global warming potential), acidification potential, eutrophication potential, land use, ionising radiation, malodours air, and six variants of toxicological footprints associated with the production of basalt rock dust fertiliser and industrial fertilisers. The specific objective is to assess the production side of the fertiliser supply chain by tracing the impacts of producing different fertiliser types from the start of the supply chain, i.e., the production phase, to address the ‘hidden’ impacts. Such an assessment provides a holistic view of fertiliser production and compares environmentally sustainable options based on estimated environmental impacts.

In addition, the study attempts to model potential basalt that can be substituted or complemented with PK fertiliser production based on different hypothetical scenarios. Based on this, we can estimate the potential ecological savings, particularly the reduction in climate change impact that can be made by substituting a certain amount of PK fertilisers with basalt. This analysis is included in the study due to the growing evidence of CO2 removal through silicate rock weathering, including basalt (Renforth 2012; Moosdorf et al. 2014; Taylor et al. 2016).

2 Method

This study deploys the life cycle assessment (LCA) method according to the standards of ISO 14040 (2006). LCA is a widely-accepted method used in identifying and quantifying the environmental impacts of products and processes across their life cycle stages (Guinée, 2002). The technique is commonly advocated as a valuable tool for achieving sustainable production and consumption (Parent et al. 2013). We use this method, therefore, to calculate and compare the environmental profile of basalt rock dust fertiliser and five industrial fertilisers using the Supply Chain Environmental Analysis Tool (SCEnAT), a life cycle assessment software tool that captures both direct and indirect impacts along supply chains (Koh et al. 2013). As per ISO 14040, typical LCA is carried out in four phases.

2.1 Phase I: goal and scope definition

First, the LCA goal and scope of the production systems to be studied is defined, including setting an appropriate system boundary. There are different kinds of LCA system boundaries, including cradle-to-gate (raw material extraction to the factory gate), cradle-to-grave (raw material extraction, use, and end-of-life stages), and cradle-to-cradle (from raw material extraction to recycling stages). The type of system boundary is influenced mainly by the goal of the LCA (Tillman et al. 1994) and as outlined in the ISO 14040 (2006) standards; “the selection of the system boundary shall be consistent with the goal of the study”. As stated earlier in the introduction, in studies relating to fertilisers, LCA has predominantly been employed in examining impacts at their application or use phase (Brentrup et al. 2004; Skowrońska and Filipek 2014; Quirós et al. 2015). A few studies have evaluated impacts stemming from their production (Mirlean and Roisenberg 2006; Ledgard et al. 2011; Hasler et al. 2015). This LCA study aims to estimate and compare the environmental impacts associated with basalt rock dust fertiliser and industrial fertiliser production. Since the emphasis is to highlight potential environmental impacts related to production, the cradle-to-gate system boundary is considered appropriate.

A cradle-to-gate system boundary has been used to include raw material extraction and product processing. The functional unit of the production of fertilisers is set at 1 kg each. The environmental impacts estimated are therefore measured relating to the functional unit. For example, for every 1 kg produced, there is a climate change impact of 0.007 kg CO2-e and ~ 1.4 kg CO2-e for basalt rock dust and SSP fertiliser, respectively (Table 1). The same applies to all the other impact categories.

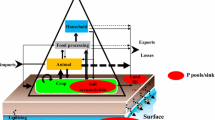

Production routes for each fertiliser may differ, but their production has basic similarities. For instance, phosphate and potash rock are raw materials used to produce most of the industrial fertilisers considered in this study. The system boundary of the study’s LCA (Fig. 1) includes extraction of such raw materials, transportation of extracted raw materials to the processing site, and the energy and emissions associated with processing these inputs. In the case of basalt rock fertiliser, the primary raw material needed is the basalt rock produced in basalt quarry operations which involves mining, crushing, grinding, and classification.

The system boundary considered in the LCA shows some relevant material and energy input inventory and processes involved in producing basalt rock fertiliser and industrial synthetic fertiliser. See supplementary information for a detailed breakdown of quantities and inputs needed to produce 1 kg of each fertiliser type. For simplicity, the diagram does not show each industrial fertiliser’s unique production route or technique. The sustainability metric ‘Toxicity’ includes freshwater aquatic, freshwater sediment, marine aquatic, marine sediment, terrestrial, and human toxicity

2.2 Phase II: life cycle inventory

In Phase II, the life cycle inventory (LCI) phase, the inputs into the system (energy and raw material requirements), and system outputs are quantified. We obtained data on the material and energy input needed per kilogramme of output fertiliser from Ecoinvent version 3.4 (Wernet et al. 2016) for each fertiliser product (See Supplementary Information). The production inventory from the Ecoinvent data is based on comprehensive literature and manufacturer specifications specifically tailored to European production. The data is calculated based on the mean values of multiple European fertiliser plants. The inventory for the unit process considers the transportation of raw materials and intermediate products to the fertiliser processing plant. The inventory does not account for the production and waste treatment of catalyst, coating, and packaging for the final fertiliser products. As our study is a cradle-to-gate system, impacts from waste (waste associated with disposal after the use phase) were excluded. The data used for the production of basalt rock fertiliser were from basalt quarry operations obtained from Ecoinvent, which is based on open-quarry pit operations that use German quarries as a proxy for Europe. Production activities for basalt rock dust fertiliser start with the mining stage, and the subsequent beneficiation stage involves crushing, washing, and classification.

Energy for mining used in the study is ~ 6 kWh per tonne (see supplementary information Table S1), which closely compares to ~ 5.23 kWh estimated by Hangx and Spiers (2009). Various particle sizes of the rocks are produced during the crushing and grinding process. The classification step allows the varying grain sizes to be screened and grouped. Ideally, small grain sizes are more suitable for use as fertilisers as they have a faster dissolution rate (Harley and Gilkes 2000; Anda et al. 2009).

High-energy input is required to produce grind rocks to small grain sizes (Renforth 2012; Moosdorf et al. 2014). Renforth (2012) estimates between 15 and 100 kWh t−1 to grind towards grain sizes between 5 mm and 0.01 mm. Moosdorf et al. (2014) estimate optimistic and pessimistic energy requirements as 0.06 GJ t−1 and 2 GJ t−1 for grain sizes between 0.03 mm and 0.001 mm, respectively. Hangx and Spiers (2009) estimate production grain sizes of 100 μm and 37 μm, corresponding to the energy input of approximately 13 kWh t−1 and 24 kWh t−1, respectively. In our study, the total energy input for crushing and grinding is 0.04 MJ per kg from the Ecoinvent database (see supplementary information). This implies an energy input of approximately 11.1 kWh per tonne of rock. Using grain size/energy calculations by Hangx and Spiers (2009) as the basis, we assume this energy input may correspond to potential grain sizes of 100 μm and 117 μm.

2.3 Phase III and IV: life cycle impact assessment and interpretation

In the impact assessment stage of the LCA (Phase III), the environmental impacts identified in the inventory analysis phase on human health and the environment across various indicators are evaluated before the results are presented and interpreted (Phase IV). The environmental profiles of the fertilisers are compared based on fifteen environmental impact categories which provide a broad assessment of the impacts of their production supply chain on air, water, and land. There is an extensive range of LCA environmental indicators, but generally, these can be grouped under impacts underwater, air, and solid emissions (waste). Therefore, the selection of indicators for the study considered impact categories that reflect these general groups of environmental impacts. In addition, the choice of indicators for LCA must reflect implications relevant to the research and be closely associated with the product’s sector (ISO 2006; Chevalier et al. 2011). A complete description of selected impacts is shown in the supplementary information.

The CML 2001 (Guinée 2002) categorisation model available in Ecoinvent was used for all impact categories except those on the ecosystem, human health, and resources. These are from Eco-indicator 99, also taken from the Ecoinvent database. Ecosystem quality affects species such as vascular plants and lower organisms based on four indicators: ecotoxicity, acidification, eutrophication, and land use. Resources are a measure of the surplus or extra energy required in the future to extract lower-quality minerals and fossil resources. Human health includes the number and duration of diseases and life years lost. The other environmental impacts have acidification potential (kg SO2e), climate change (kg CO2e, GWP 100a), and eutrophication potential (kg NOxe). In addition, six variants of toxicological footprint with the reference unit, kg of 1, 4-dichlorobenzene equivalent (1, 4-DCB-eq) are included; freshwater sediment ecotoxicity, freshwater aquatic ecotoxicity, marine aquatic ecotoxicity, marine sediment ecotoxicity terrestrial ecotoxicity, and human toxicity. These measure the potential impact of toxic substances on the environment, mainly aquatic, sediment, and terrestrial ecosystems. Malodours air (m3 air), ionisation radiation (DALYs), and land use (m2a) are also included. In total, 15 environmental impacts are estimated, forming the basis for comparison for 1 kg each of basalt rock fertiliser and five industrial fertilisers produced. Complete data on individual contributions of each input to each environmental impact indicator in the various fertilisers are shown in the Supplementary Information.

2.4 Limitations of the study

A limitation of the study is centred on the data type. The use of primary data, in general, improves data precision compared to secondary data from LCA databases. Ecoinvent is a secondary database using primary data collected from manufacturing plants. The challenge with using such a database is that some of the data may not be recent with every updated version of the database. We encourage future research to incorporate more recent data as it becomes available.

Preliminary data collection for LCA modelling is a very time-consuming process. Therefore, the use of easily assessable and widely accepted databases such as the Ecoinvent was relied upon, which is also deemed appropriate given the scale of the analyses in this study. The Ecoinvent database has been used extensively in most studies on environmental impact assessment using LCA. The transparency of the data makes it possible for results to be replicated.

We acknowledge, however, that results may slightly differ if actual site-specific primary data was collected from quarry industries (basalt fertiliser) and fertiliser manufacturing plants (industrial fertiliser). However, we doubt the difference would be enough to completely change the outcome of the study’s conclusions and results. We can come to this conclusion because we compared the general findings with other similar studies, especially of fertiliser production; and in each instance, it confirms the narrative that high-energy use in production is a source of negative environmental impacts such as GHGs emissions (Jenssen and Kongshaug 2003; Brentrup et al. 2004; Hasler et al. 2015). Uncertainty analysis was also carried out to improve the robustness of the findings (see supplementary information).

One key difference in our study is that we conduct a comparative environmental impact assessment based on various indicators, making our findings robust and comprehensive. Comparing our results with similar studies increase the reliability of our results. Our study is the first to demonstrate the novel potential of sustainable fertiliser (basalt rock dust) compared to industrial fertilisers, giving thought-provoking insights into the embedded environmental impacts in their production.

3 Results

3.1 Comparing primary energy input

A key difference in potential environmental impacts between basalt rock fertiliser and industrial fertiliser is the high-primary energy inputs (electrical and thermal) in the latter’s production (Fig. 2). The production of SSP and KOH, in particular, has the highest electrical energy input of approximately 6.8 MJ per kg produced each. Thermal energy is also very high in KOH production, which is 4.8 MJ per kg compared to TSP, KCI, and K2CO3, which require thermal energy input of 2.8 MJ, 0.8 MJ, and 0.2 MJ per kg, respectively. Results show that, overall, basalt has a very minimal energy input requirement per kg produced compared to the rest of the P and K fertilisers. The findings support the discourse that the production of industrial fertilisers is energy-intensive (Helsel 1992; Swaminathan and Sukalac 2004).

Thermal and electrical energy input for fertiliser production. Data from Ecoinvent. Data on thermal energy input was not provided in Ecoinvent for SSP fertiliser. The assumption here is that the electrical energy input for this fertiliser is similar to that of the other listed industrial fertilisers

3.2 Comparing environmental impacts

We find significant differences in the environmental impacts associated with the production of basalt rock fertiliser compared with industrial fertilisers. The estimated value for each effect per kg produced for a given fertiliser type is shown in Table 1. We also show the relative percentage contribution of each fertiliser type to the total impact of all six fertilisers in a given environmental impact category (Fig. 3).

Comparison between basalt fertiliser and industrial PK fertilisers across 15 environmental sustainability metrics based on relative percentages. The potential sustainability metrics relate to the functional unit of producing 1kg each of fertiliser type. A breakdown of the contribution of individual material and energy input for each fertiliser to the total impact across indicators is provided in the supplementary information

Triple superphosphate fertiliser production has the highest impact, followed by single superphosphate and potassium hydroxide. In the climate change impact category, these three fertilisers (KOH, TSP, and SSP) contribute over 80% to climate change impact per kg produced, the highest potential impact associated with KOH and TSP production, that is ~ 1.5 kg CO2-e each, followed by TSP which has ~ 1.4 kg CO2-e). On the other hand, the potash-based fertilisers KCl and K2CO3 have relatively lower impacts across all environmental effects than the phosphorus-based fertilisers (TSP and SSP).

However, the toxicological footprint of KOH is very high regarding marine sediment ecotoxicity, contributing to an average of 70%, corresponding to 2.5 kg of 1–4-DCB-eq. For freshwater aquatic, freshwater ecotoxicity, and marine aquatic ecotoxicity, the dominant impacts come from SSP and TSP. In addition, the effects of these phosphorus-based fertilisers in acidification potential, eutrophication potential, land use, ionising radiation, ecosystem quality, human health, and resource are relatively very high, with over 50% of the total impacts attributed to their production. On the other hand, the production of basalt fertiliser has minimal contribution to the total effects, with less than an average of 1% contribution across all impacts estimated mainly due to the relatively low energy requirement in processing, which is discussed further in the study.

3.3 Potential ecological savings from substituting PK with basalt

We present hypothetical scenarios where PK fertilisers produced globally are substituted with basalt rock dust fertiliser. The hypothetical scenarios under different basalt fertiliser substitution rates are 5%, 10%, 15%, and 20%. The potential ecological savings from substituting PK fertiliser production with basalt rock dust fertiliser are three-fold. First, the reduction in PK fertiliser production would consequently lead to a fall in the associated environmental impacts (climate change impact, toxicological impacts, etc.) analysed in the study. Second, basalt rock dust fertiliser production for substitution would be relatively minimal, as shown by its low environmental footprint compared to PK industrial fertilisers. Finally, the carbon capture potential of the applied basalt rock dust fertiliser would reduce greenhouse gas emissions.

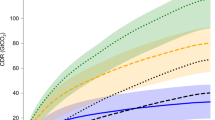

To demonstrate these ecological savings, we estimate and compare the associated potential global warming impact (GWP) of both industrial PK fertilisers. Global PK fertiliser production is taken to be approximately 83 Mt (million tonnes) based on a 5-year annual average supply capacity (2016–2020) from the recent FAO fertiliser outlook summary report (FAO 2019). This corresponds to a potential GWP of 83Mt CO2, with a higher proportion of the impacts occurring in Asia. In Fig. 4a and b, we see how this impact can be reduced through the different basalt substitution rates. At a higher % substitution rate of 20%, the potential GWP impact from PK fertiliser production reduces significantly from approximately 83Mt CO2-e to 67Mt CO2-e. In addition, the associated global warming impact from producing the basalt fertiliser needed to substitute the 20% production of the industrial PK fertiliser would be relatively low.

Due to the large difference in GWP between both fertiliser categories, significant environmental impact reduction can be achieved by reducing industrial fertilisers produced and substituting the reduction with rock dust fertilisers. The results suggest that basalt rock dust fertiliser is more sustainable in terms of avoided GHG emissions (from a decline in industrial fertiliser production) as well as the carbon capture from its enhanced weathering potential upon application (Fig. 4). We estimate the carbon capture potential of such global and regional basalt rock fertiliser application.

is based on the average GWP impact (climate change impact) of industrial PK fertilisers from the study (1kgCO2-e/kg) and data from FAO on industrial PK fertiliser annual production (FAO 2019). As more basalt is substituted for PK fertiliser production, the associated global and regional GWP impact of PK industrial fertilisers is expected to reduce

The substitution scenarios considered above are only hypothetical. In real-life application scenarios, we expect other factors to be considered to ascertain the effectiveness of substituting PK fertilisers with basalt. For instance, the location of the basalt rocks and the amount of P-K available in the rock and weathering rate could potentially affect the substitution rate. Unless referring to a specific basalt rock dust sample from a designated location, it is difficult to determine the precise phosphorus (P) and potassium (K) content, as basalt rock exhibits variations in chemical composition and mineralogy (Luchese et al. 2023; Van Straaten 2006; Harley and Gilkes 2000). Consequently, the macronutrient P and K, along with other essential elements like calcium (Ca), magnesium (Mg), and silicon (Si), may differ in two separate 1 kg samples of basalt rock dust (Dalmora et al. 2016; Gilman et al. 2002). Various studies in the literature, including laboratory and field applications, have demonstrated differing geochemical compositions of applied basalt rock fertilisers (Swoboda et al. 2022; Manning and Theodoro 2018; Gilman et al. 2002). These factors are, however, beyond the scope of this research. Future ongoing research may be able to address these equally important factors.

4 Discussion and conclusion

We have shown that accounting for embodied environmental impacts from the production phase is a critical missing element for the sustainability assessment of fertilisers in the food production chain. The production-related effects of fertilisers must be considered a crucial factor that needs to be on the global environmental agenda and negotiations. As population growth continues to fuel increasing production and consumption, it is vital to ensure that fertiliser resources are efficiently sourced to meet food security challenges that will arise with the most minimal impacts possible. This may require broadening rock-based fertilisers to include basalt fertiliser, which, as discovered in the study, has relatively low production impacts. Our findings, therefore, have policy relevance and potential contribution to several Sustainable Development Goals, as identified in Table 2.

The International Fertiliser Association (IFA) projects that global phosphoric and potassium capacity will increase by 11% and 16% by 2024 (IFA 2020). The environmental impacts associated with such production capacity growth in the fertiliser industry can be disastrous in the long term in terms of negative climate and toxicological footprint. In addition, continuous over-exploitation of natural resources such as rock-based fertiliser may lead to decreased economic growth (Lampert 2019). Transitioning to milled basalt as a natural geo-fertiliser to support food production may help address the UN Sustainable Development Goal of ‘Responsible consumption and production’. This can be achieved by the reduction in the large quantities of PK fertiliser production, which is evidenced in the study indicates have relatively high negative environmental impacts. The reduction can be complemented with basalt fertiliser, considered more environmentally sustainable than PK fertiliser production.

Our findings have implications for the environmental costs of current and future global fertiliser production. Plans to expand fertiliser production to meet consumption without addressing emission intensities could significantly increase toxicological footprints and climate change (Lampert 2019). The potential environmental impacts of such an expansion in the fertiliser industry can be estimated by extrapolation of our results.

The results suggest that phosphate and potash-based fertilisers have relatively high potential production-related environmental impacts beyond those associated with their application on croplands. These impacts mainly occur in the more comprehensive and upstream fertiliser supply chain. They are related to the extraction of the material inputs, such as phosphate rock and potash, before their use in fertiliser production. Furthermore, the production of phosphoric acid from phosphate rock involves the release of potentially harmful substances into the air and water. An example is phosphogypsum, a gypsum formed as a by-product of processing phosphate ore into fertiliser with sulphuric acid. It is radioactive due to naturally occurring uranium and radium in the phosphate ore (Pérez-López et al. 2007). Both UNEP and IFA recognise the potentially harmful impacts of phosphate rock and potash mining (IFA 2001).

Approximately 1.2% of the world’s total energy each year is consumed by global fertiliser production (Jenssen and Kongshaug 2003), and this percentage is proportional to the overall contribution of the fertiliser industry to global GHG emissions. Therefore, energy-related impacts from industrial fertilisers consider all the energy inputs needed for producing the individual raw material inputs (such as phosphoric acid and potash salts) and give an accurate picture of the industrial fertilisers’ relatively high production environmental footprint. Processing of basalt rock dust fertiliser, the grinding of rocks is also an energy-intensive process (Renforth 2012; Moosdorf et al. 2014), but in our analyses, this has minor consumption of both electrical and thermal energy per kg produced compared to all of the industrial fertilisers analysed (Fig. 5).

Carbon capture potential from basalt rock fertiliser production is calculated based on the application of produced basalt fertiliser where a tonne of basalt can potentially sequester 0.3tCO2 per tonne of rock (Renforth 2012)

Prices of conventional fertilisers produced from finite rock-derived phosphorus and potassium (potash) have doubled in the past decade (Amundson et al. 2015). Rock fertilisers represent inexpensive and environmentally sound fertiliser options for farmers in areas with infertile soils and suitable climates. With the right choice of locally available rock materials for the appropriate soils, these materials have significantly benefitted local agriculture when modified or blended with locally available organic materials (Van Straaten 2006).

In addition, the agricultural sector is identified as a critical sector in terms of its contribution to GHG emissions and where the effects of climate change are harshly felt. A third of human-induced greenhouse emissions globally are attributed to agricultural food systems (Crippa et al. 2021). It is important to note that in developing climate change mitigation strategies in this sector, the best solutions may not necessarily be to find entirely new technologies but to find ways to integrate existing practises with ‘green’ solutions such as crop farming with basalt rocks for carbon sequestration via the enhanced weathering process. Consequently, agricultural practises through a contributor to climate change could also present mitigation options and co-benefits (Vermeulen et al. 2012; Cohen et al. 2021). In this regard, we identify that enhanced weathering with basalt can serve as a credible carbon dioxide removal strategy to contribute to the UN Sustainable Development Goal of climate change action. As a co-benefit of enhanced weathering with basalt on croplands, the rate of ocean acidification can be slowed via run-off water of weathered by-products into the ocean (Taylor et al. 2016).

Beyond the benefits of crop yield associated with industrial fertilisers, it is crucial to find ways of achieving similar or comparable results; however, with a fertiliser type that has minimal impacts on ecology during production and application. From this perspective, sustainable fertilisers, such as basalt rock dust, could be a suitable partial substitute for industrial P and K fertilisers. Increasing evidence of its positive impact on crop yield suggests a potential contribution to the Zero Hunger Sustainable Development Goal (Van Strateen 2002; Beerling et al. 2018; Smith et al. 2019). Due to the relatively fast reaction of conventional fertilisers to soil solution, it may not be possible for multi-nutrient silicate rock fertilisers such as basalt to replace conventional fertilisers in the short term. Nevertheless, research suggests a significant potential for combining the application of rock and mineral fertilisers to highly weathered and degraded soils in the long term (Van Straaten 2006).

Basalt fertiliser in the study is the by-product of existing mining and quarrying sites, and so essentially, it is not mined as a separate product on its own. Currently, companies are specifically using this waste resource piled up on these mining and quarry sites as fertiliser, supplying to farms, and as a carbon removal strategy through enhanced weathering. One such company is UNDO in the UK, which sources the basalt dust fertiliser from local quarry sites in Scotland, the United States, and Northern England and supplies it at no cost to nearby farms in these countries (Mann 2023). It will be good to compare the demand for PK and the availability of mine waste resources, such as basalt rock dust, to evaluate the potential opportunity where farmers can use the latter to subsidise their fertiliser cost whilst contributing to carbon sequestration. Data from FAO estimates global annual demand for P and K fertilisers as approximately 48 million tonnes and 37 million tonnes, respectively (FAO 2019).

However, it is difficult to provide an accurate global estimate of the quantity of basalt dust specifically. It is best to refer to literature, including industry reports and mining associations, that compile such data on mining operations in active and non-active quarries to obtain such accurate and up-to-date information. Research by Renforth et al. (2011) makes an excellent contribution to filling this research gap by providing a global account of the quantity of silicate material waste produced. Their study estimates that approximately 2 to 6.5 billion tonnes of mine waste are produced yearly.

Questions remain, however, on the overall sustainability of basalt rock dust fertiliser which must be answered to increase its embedment in sustainable agriculture policies and the global environment agenda. Whilst our research reveals that basalt rock dust fertiliser is a more ecologically sound choice in production when compared to industrial fertilisers, it is crucial to acknowledge that certain conditions or factors must be considered in making it a viable option. These factors encompass the basalt’s type and source, the rock’s mineralogy and chemistry, and grain size and surface area for direct application (Dalmora et al. 2016; Van Straaten 2006). According to Harley and Gilkes (2000), the limited dissolution rates of silicate minerals present in rocks such as basalt may hinder the agricultural use of rocks dust fertilisers unless appropriate soils are identified and optimal rock dust is developed.

Although our study considers malodorous air impact (a measure of air pollution) associated with basalt dust production, we recommend conducting further research into the potential risk to human health when spreading these on farms. It is imperative to establish some cleaning protocols on farms to minimise potential exposure to natural basalt dust due to their nano-particle size (Dalmora et al. 2016). Further assessment of the economic and social risks or challenges associated with large-scale basalt rock dust fertiliser adoption must be investigated nationally.

Data availability

The data supporting the findings of this study are available in the manuscript and its supporting analysis.

References

Amundson R, Berhe AA, Hopmans JW, Olson C, Sztein AE, Sparks DL (2015) Soil and human security in the 21st century. Science 348(6235). https://doi.org/10.1126/science.1261

Anda M, Shamshuddin J, Fauziah CI, Omar SRS (2009) Dissolution of ground basalt and its effect on oxisol chemical properties and cocoa growth. Soil Sci 174(5):264–271. https://doi.org/10.1097/SS.0b013e3181a56928

Atafar Z, Mesdaghinia A, Nouri J, Homaee M, Yunesian M, Ahmadimoghaddam M, Mahvi AH (2010) Effect of fertiliser application on soil heavy metal concentration. Environ Monit Assess 160(1):83–89. https://doi.org/10.1007/s10661-008-0659-x

Beerling DJ, Leake JR, Long SP, Scholes JD, Ton J, Nelson PN, Bird M, Kantzas E, Taylor LL, Sarkar B, Kelland M (2018) Farming with crops and rocks to address global climate, food and soil security. Nat Plants 4(3):138–147. https://doi.org/10.1038/s41477-018-0108-y

Bøen A, Haraldsen TK (2013) Meat and bone meal and biosolids as slow-release phosphorus fertilisers. Agric Food Sci 22(2):235–246. https://doi.org/10.23986/afsci.7498

Brentrup F, Küsters J, Lammel J, Barraclough P, Kuhlmann H (2004) Environmental impact assessment of agricultural production systems using the life cycle assessment (LCA) methodology II. The application to N fertiliser use in winter wheat production systems. Eur J Agron 20(3):265–279. https://doi.org/10.1016/S1161-0301(03)00039-X

Brod E, Øgaard AF, Haraldsen TK, Krogstad T (2015) Waste products as alternative phosphorus fertilisers part II: predicting P fertilisation effects by chemical extraction. Nutr Cycl in Agroe 103(2):187–199. https://doi.org/10.1007/s10705-015-9731-4

Carpenter SR, Caraco NF, Correll DL, Howarth RW, Sharpley AN, Smith VH (1998) Nonpoint pollution of surface waters with phosphorus and nitrogen. Ecol Applic 8(3):559–568. https://doi.org/10.1890/1051-0761(1998)008[0559:NPOSWW]2.0.CO;2

Chevalier B, Reyes T, Laratte B (2011) Methodology for choosing life cycle impact assessment sector-specific indicators. In DS 68–5 Proc of the 18th Intl Conf on Eng Design (ICED 11)15.-19.08. (pp. 312–323). https://www.designsociety.org/publication/30604/METHODOLOGY+FOR+CHOOSING+LIFE+CYCLE+IMPACT+ASSESSMENT+SECTOR-SPECIFIC+INDICATORS

Chianu JN, Chianu JN, Mairura F (2012) Mineral fertilisers in the farming systems of sub-Saharan Africa. A Review Agro for Sustain Dev’t 32(2):545–566. https://doi.org/10.1007/s13593-011-0050-0

Cohen B, Cowie A, Babiker M, Leip A, Smith P (2021) Co-benefits and trade-offs of climate change mitigation actions and the Sustainable Development Goals. Sustain Prod Consum 26:805–813. https://doi.org/10.1016/j.spc.2020.12.034

Crippa M, Solazzo E, Guizzardi D, Monforti-Ferrario F, Tubiello FN, Leip AJNF (2021) Food systems are responsible for a third of global anthropogenic GHG emissions. Nat Food 2(3):198–209. https://doi.org/10.1038/s43016-021-00225-9

Dalmora AC, Ramos CG, Oliveira ML, Teixeira EC, Kautzmann RM, Taffarel SR, de Brum IA, Silva LF (2016) Chemical characterisation, nano-particle mineralogy and particle size distribution of basalt dust wastes. Sci Total Env 539:560–565. https://doi.org/10.1016/j.scitotenv.2015.08.141

FAO, Ifad, UNICEF, WFP, WHO (2021) The State of Food Security and Nutrition in the World (2021) Transforming food systems for food security, improved nutrition and affordable healthy diets for all. Rome, FAO. https://doi.org/10.4060/cb4474en

FAO (2019) World fertiliser trends and outlook to 2022. Rome. https://www.fao.org/3/ca6746en/ca6746en.pdf

Franzosi C, Castro LN, Celeda AM (2014) Technical evaluation of glauconies as alternative potassium fertiliser from the Salamanca Formation, Patagonia. Southwest Argentina Nat Resour Res 23(3):311–320. https://doi.org/10.1007/s11053-014-9232-1

Gan Y, Liang C, Chai Q, Lemke RL, Campbell CA, Zentner RP (2014) Improving farming practices reduces the carbon footprint of spring wheat production. Nat Commun 5(1):1–13. https://doi.org/10.1038/ncomms6012

Gasser T, Guivarch C, Tachiiri K, Jones CD, Ciais P (2015) Negative emissions physically needed to keep global warming below 2 C. Nat Commun 6:7958. https://doi.org/10.1038/ncomms8958

Gillman GP, Burkett DC, Coventry RJ (2001) A laboratory study of application of basalt dust to highly weathered soils: effect on soil cation chemistry. Soil Res 39(4):799–811. https://doi.org/10.1071/SR00073

Gillman GP, Burkett DC, Coventry RJ (2002) Amending highly weathered soils with finely ground basalt rock. Appl Geochem 17(8):987–1001. https://doi.org/10.1016/S0883-2927(02)00078-1

Goucher L, Bruce R, Cameron DD, Koh SCL, Horton P (2017) The environmental impact of fertiliser embodied in a wheat-to-bread supply chain. Nat Plants 3(3):17012. https://doi.org/10.1038/nplants.2017.12

Guinée JB (2002) Handbook on life cycle assessment operational guide to the ISO standards. Int J Life Cycle Assess 7(5):311. https://doi.org/10.1007/BF02978897

Hangx SJ, Spiers CJ (2009) Coastal spreading of olivine to control atmospheric CO2 concentrations: a critical analysis of viability. Int J Greenhouse Gas Cont 3(6):757–767. https://doi.org/10.1016/j.ijggc.2009.07.001

Harley AD, Gilkes RJ (2000) Factors influencing the release of plant nutrient elements from silicate rock powders: a geochemical overview. Nutr Cycling AgroEcosyst 56(1):11–36. https://doi.org/10.1023/A:1009859309453

Hasler K, Bröring S, Omta SWF, Olfs HW (2015) Life cycle assessment (LCA) of different fertiliser product types. Eur J Agronomy 69:41–51. https://doi.org/10.1016/j.eja.2015.06.001

Helsel ZR (1992) Energy and alternatives for fertiliser and pesticide use. Energ Farm Prod 6:177–201. https://books.google.co.uk/books?hl=en&lr=&id=RRkQx-5PcEgC&oi=fnd&pg=PA177&dq=25.%09Helsel,+Z.R.,+1992.+Energy+and+alternatives+for+fertilizer+and+pesticide+use.+&ots=j5PZM3DoJO&sig=rCeaN7AvyuEwMB4TcxzEto4eNzU&redir_esc=y#v=onepage&q&f=false

International Fertilizer Association (IFA) (2020) Global medium-term outlook for fertilizers and raw materials 2020–2024. https://api.ifastat.org/reports/download/13005

International Fertilizer Industry Association (IFA) and UNEP (2001) Environmental aspects of phosphate and potash mining. https://wedocs.unep.org/bitstream/handle/20.500.11822/8071/-Environmental%20Aspects%20of%20Phosphate%20and%20Potash%20Mining-20011385.pdf

International Organization for Standardization (ISO) (2006) Environmental Management Life Cycle Assessment - Principles Framework (No. 2006). http://www.cscses.com/uploads/2016328/20160328110518251825.pdf

Jenssen TK, Kongshaug G (2003) Energy Consumption and Greenhouse Gas Emissions in Fertiliser Production. Proceedings No. 509, The International Fertiliser Society, York. https://cir.nii.ac.jp/crid/1130000797429081088

Koh SL, Genovese A, Acquaye AA, Barratt P, Rana N, Kuylenstierna J, Gibbs D (2013) Decarbonising product supply chains: design and development of an integrated, evidence-based decision support system–the supply chain environmental analysis tool (SCEnAT). Int J Prod Res 51(7):2092–2109. https://doi.org/10.1080/00207543.2012.705042

Lampert A (2019) Over-exploitation of natural resources is followed by inevitable declines in economic growth and discount rate. Nat Commun 10(1):1419. https://doi.org/10.1038/s41467-019-09246-2

Lawrence MG, Schäfer S, Muri H, Scott V, Oschlies A, Vaughan NE, Boucher O, Schmidt H, Haywood J, Scheffran J (2018) Evaluating climate geoengineering proposals in the context of the Paris Agreement temperature goals. Nat Commun 9(1):3734. https://doi.org/10.1038/s41467-018-05938-3

Ledgard SF, Boyes M, Brentrup F (2011) Life cycle assessment of local and imported fertilisers used on New Zealand farms. Ministry Agricul Forest 1–13. http://tur-www1.massey.ac.nz/~flrc/workshops/11/Manuscripts/Ledgard_2011.pdf

Leonardos OH, Fyfe WS, Kronberg BI (1987) The use of ground rocks in laterite systems: an improvement to the use of conventional soluble fertilisers? Chem Geol 60(1–4):361–370. https://doi.org/10.1016/0009-2541(87)90143-4

Luchese AV, de Castro Leite IJG, da Silva Giaretta AP, Alves ML, Pivetta LA, Missio RF (2023) Use of quarry waste basalt rock powder as a soil remineralizer to grow soybean and maize. Heliyon 9(3). https://doi.org/10.1016/j.heliyon.2023.e14050

Mann J (2023) Enhanced rock weathering: the fastest-scaling carbon removal technology. Available at : https://un-do.com/2023/05/22/enhanced-rock-weathering-the-fastest-scaling-carbon-removal-technology/.Accessed 24 May 2023

Manning DA, Theodoro SH (2020) Enabling food security through use of local rocks and minerals. Extr Ind Soc. https://doi.org/10.1016/j.exis.2018.11.002

Mirlean N, Roisenberg A (2006) The effect of emissions of fertiliser production on the environment contamination by cadmium and arsenic in southern Brazil. Environ Pollution 143(2):335–340. https://doi.org/10.1016/j.envpol.2005.11.022

Moore CCS, Nogueira AR, Kulay L (2017) Environmental and energy assessment of the substitution of chemical fertilisers for industrial wastes of ethanol production in sugarcane cultivation in Brazil. Int J Life Cycle Assess 22(4):628–643. https://doi.org/10.1007/s11367-016-1074-0

Moosdorf N, Renforth P, Hartmann J (2014) Carbon dioxide efficiency of terrestrial enhanced weathering. Environ Sci Technol 48(9):4809–4816. https://doi.org/10.1021/es4052022

Parent J, Cucuzzella C, Revéret JP (2013) Revisiting the role of LCA and SLCA in the transition towards sustainable production and consumption. Int J Life Cycle Assess 18(9):1642–1652. https://doi.org/10.1007/s11367-012-0485-9

Pérez-López R, Alvarez-Valero AM, Nieto JM (2007) Changes in mobility of toxic elements during the production of phosphoric acid in the fertiliser industry of Huelva (SW Spain) and environmental impact of phosphogypsum wastes. J Hazard Mater 148(3):745–750. https://doi.org/10.1016/j.jhazmat.2007.06.068

Quirós R, Villalba G, Gabarrell X, Muñoz P (2015) Life cycle assessment of organic and mineral fertilisers in a crop sequence of cauliflower and tomato. Int J Environ Sci and Technol 12(10):3299–3316. https://doi.org/10.1007/s13762-015-0756-7

Renforth P (2012) The potential of enhanced weathering in the UK. Int J Green Gas Control 10:229–243. https://doi.org/10.1016/j.ijggc.2012.06.011

Renforth P, Washbourne CL, Taylder J, Manning DAC (2011) Environ Scie Technol 45(6):2035–2041. https://doi.org/10.1021/es103241w

Roberts TL (2009) The role of fertiliser in growing the world’s food. Better Crops 93(2):12–15 http://ipni.net/publication/bettercrops.nsf/0/d21dbc864569368d85257980006fc3db/$file/better%20crops%202009-2%20p12.pdf

Sanchez PA (2002) Soil fertility and hunger in Africa. Sci 295(5562):2019–2020. https://doi.org/10.1126/science.1065256

Skowrońska M, Filipek T (2014) Life cycle assessment of fertilisers: a review. Int Agrophys 28(1):101–110. https://doi.org/10.2478/intag-2013-0032

Smith P, Adams J, Beerling DJ, Beringer T, Calvin KV, Fuss S, Griscom B, Hagemann N, Kammann C, Kraxner F, Minx JC (2019) Impacts of land-based greenhouse gas removal options on ecosystem services and the United Nations Sustainable Development Goals. Ann Rev Environ Resour 44. https://doi.org/10.1146/annurev-environ-101718-033129

Stewart WM, Roberts TL (2012) Food security and the role of fertiliser in supporting it. Proced Eng 46:76–82. https://doi.org/10.1016/j.proeng.2012.09.448

Swaminathan B, Sukalac KE (2004) Technology transfer and mitigation of climate change: the fertiliser industry perspective. IPCC Expert Meeting on Ind Technol Dev Trans Diff Tokyo Japan 2123

Swoboda P, Döring TF, Hamer M (2022) Remineralising soils? The agricultural usage of silicate rock powders: a review. Sci Total Environ 807:150976

Taylor LL, Quirk J, Thorley RM, Kharecha PA, Hansen J, Ridgwell A, Lomas MR, Banwart SA, Beerling DJ (2016) Enhanced weathering strategies for stabilising climate and averting ocean acidification. Nat Clim Change 6(4):402–406. https://doi.org/10.1038/nclimate2882

Tilman D, Cassman KG, Matson PA, Naylor R, Polasky S (2002) Agricultural sustainability and intensive production practices. Nat 418(6898):671–677. https://doi.org/10.1038/nature01014

Tillman AM, Ekvall T, Baumann H, Rydberg T (1994) Choice of system boundaries in life cycle assessment. J Clean Prod 2(1):21–29

Van Straaten P (2006) Farming with rocks and minerals: challenges and opportunities. Anais da Academia Brasileira de Ciências 78(4):731–747. https://doi.org/10.1590/S0001-37652006000400009

Van Straaten P (2002) Rocks for crops: agrominerals of sub-Saharan Africa. http://apps.worldagroforestry.org/Units/Library/Books/PDFs/11_Rocks_for_crops.pdf

Vermeulen SJ, Aggarwal PK, Ainslie A, Angelone C, Campbell BM, Challinor AJ, Hansen JW, Ingram JSI, Jarvis A, Kristjanson P, Lau C (2012) Options for support to agriculture and food security under climate change. Environ Sci Polic 15(1):136–144. https://doi.org/10.1016/j.envsci.2011.09.003

Wernet G, Bauer C, Steubing B, Reinhard J, Moreno-Ruiz E, Weidema B (2016) The ecoinvent database version 3 (part I): overview and methodology. The International J Life Cycle Assess 21:1218–1230

Wood SW, Cowie A (2004) A review of greenhouse gas emission factors for fertiliser production. http://www.sciencetheearth.com/uploads/2/4/6/5/24658156/2004_wood_a_review_of_greenhouse_gas_emission_factors.pdf

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by Camillo De Camillis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Oppon, E., Koh, S., Eufrasio, R. et al. Towards sustainable food production and climate change mitigation: an attributional life cycle assessment comparing industrial and basalt rock dust fertilisers. Int J Life Cycle Assess (2023). https://doi.org/10.1007/s11367-023-02196-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11367-023-02196-4