Abstract

Landfill leachate, which is a complicated organic sewage water, presents substantial dangers to human health and the environment if not properly handled. Electrochemical technology has arisen as a promising strategy for effectively mitigating contaminants in landfill leachate. In this comprehensive review, we explore various theoretical and practical aspects of methods for treating landfill leachate. This exploration includes examining their performance, mechanisms, applications, associated challenges, existing issues, and potential strategies for enhancement, particularly in terms of cost-effectiveness. In addition, this critique provides a comparative investigation between these treatment approaches and the utilization of diverse kinds of microbial fuel cells (MFCs) in terms of their effectiveness in treating landfill leachate and generating power. The examination of these technologies also extends to their use in diverse global contexts, providing insights into operational parameters and regional variations. This extensive assessment serves the primary goal of assisting researchers in understanding the optimal methods for treating landfill leachate and comparing them to different types of MFCs. It offers a valuable resource for the large-scale design and implementation of processes that ensure both the safe treatment of landfill leachate and the generation of electricity. The review not only provides an overview of the current state of landfill leachate treatment but also identifies key challenges and sets the stage for future research directions, ultimately contributing to more sustainable and effective solutions in the management of this critical environmental issue.

Similar content being viewed by others

Introduction

Landfill leachate is formed when sanitary landfills are utilised to dispose of solid waste from urban areas (Abu-Daabes et al. 2013; Ishaq et al. 2023). Leachate is created by chemical and biological interactions of solid rubbish in landfills, as stated by Abu-Daabes et al. (2013). Leachate from landfills has been shown to include various contaminants, including dissolved organic waste, ammonium, inorganic salt, and other suspended particles (Lu et al. 2009). According to Bhalla et al. (2013), municipal solid wastes dumped on land significantly impact the ecosystem and ecology due to their age, content, and yearly weather fluctuations. Numerous studies have demonstrated that active and decommissioned unlined landfills affect groundwater and surface water by leachate dissipation via soil (Naveen et al. 2018). Landfill leachate contains various contaminants, including toxic metals (Tao et al. 2014) and organic molecules (ammonia nitrogen; Huang et al. 2018). Substrates in microbial fuel cell (MFC) power plants can include everything from organic molecules to living organisms to xenobiotics to heavy metals to inorganic salts and ammonia (Keyikoglu et al. 2021). Activated sludge, oxidation ditches, adsorption processes, trickling filters, lagoon-based treatments, and aerobic-anaerobic digestions are all examples of conventional biological wastewater treatment methods that have run into problems over the past few decades due to issues like high costs, limited space, and high energy requirements (Verma et al. 2021). Using many chemicals and high costs make this approach unfeasible for most situations. While heavy leachate may be deoxygenated via anaerobic treatment, the process has a bad reputation due to its smell. In order to treat leachate and recover energy, anaerobic digestion is one of the most widely employed biological treatment procedures. Instability in the digestion processes and fluctuations in gas output are the main connected issues that might arise from sudden changes in operating parameters (such as organic overloads, over-acidification, ammonia inhibition, etc.). (Wu et al. 2019; Elmaadawy et al. 2020a).

MFC can overcome current technologies’ limitations due to its inexpensive design and construction. For its potential environmental friendliness, MFC is being researched to clean up landfill leachate (Gálvez et al. 2009; Ishaq et al. 2023). MFCs employ microorganisms that clean wastewater while converting organic resources into energy, which might reduce the cost of running an effluent treatment plant (Lu et al. 2009). In recent years, MFCs have emerged as a potential energy-collecting approach. Cost-effective, low-maintenance, powered solely by air, etc. Chemical energy from a wide range of organics (found in landfill leachate) is converted directly into electrical energy by exoelectrogenic bacteria in MFCs (Özkaya et al. 2013; Sebastià Puig et al. 2011; Ishaq et al. 2023). MFCs may be utilised to generate power and treat many forms of wastewater (Logan 2010). The MFC framework has made considerable progress in energy recovery and wastewater treatment operations, two of the many shortcomings of traditional treatment systems. The current state of knowledge about MFCs as a treatment tool for leachate and their potential energy-generating applications is the focus of this paper. Since most existing literature deals with wastewater treatment rather than landfill leachate treatment. In light of these problems with traditional treatment methods, innovative treatment methods, such as MFCs, are energetically preferred. Many reviews, as far as we’re aware, have shed light on landfill leachate’s essentials, removal efficiency, and resource recovery (Kelly and He 2014; Pant et al. 2010; Iskander et al. 2016; Mandal et al. 2017; Elmaadawy et al. 2020a). However, modern MFC technology in landfill leachate treatment calls for careful examination.

This article’s goals are to offer a comprehensive analysis of microbial fuel cell technology for nutrient removals in landfill leachate treatment, electricity generation, and water purification. Analyse the synergistic advantages of MFC technology with conventional leachate treatment in terms of boosting treatment and energy recovery, and talk about the prospects for future research and development of MFC technology for efficient treatment (Elmaadawy et al. 2020a).

Classes of leachate

According to the age of the landfill, there are three types of leachate: young leachate, intermediate leachate, and old leachate (Miao et al. 2014). Landfill leachate can be classified as “young” if it is less than 5 years old, “middle-aged” if it is between five and 10 years old, or “old” if it is more than 10 years old (Jagaba et al. 2021).

Leachate from a young landfill (acid-phase landfills) is often a high-strength effluent with various negative properties. These include a high concentration of volatile fatty acids (VFA) (Neczaj et al. 2005), a high concentration of organic chemicals, a moderate quantity of ammonia (400 mg/L), a low pH, and the presence of various dangerous substances. Leachate from a mature landfill (methanogenic-phase landfills) causes environmental problems despite its low biodegradable organic substance concentration (COD 3000 mg/L), high ammonia concentration (>1000 mg/L), low BOD5/COD ratio (0.1), and high BOD/TKN ratio (Saleem et al. 2018). Landfill leachate aged 30 to 60 years has a COD/TN ratio of 3 to 6 and high biodegradability (Li et al. 2014). Anaerobic decomposition may be to blame for the fall in the proportion of organic pollutants in leachate that can be broken down biologically as landfills age. According to studies (Aziz et al. 2011), refractory organics are less abundant in fresh leachate than in older leachate.

Leachate degradations

Leachate is an aqueous effluent that results from the breakdown of organic components in waste by bacteria and physicochemical processes. It is an extremely contaminated wastewater that varies depending on the quantity of garbage it contains and how much of it has degraded and broken down. Seasonal variation, waste properties, moisture content, acidity, and temperature all have an impact on leachate deterioration and stabilization (Renou et al. 2008; Schiopu and Gavrilescu 2010). The decomposition of garbage is affected by a plethora of chemical and biological reactions that take place in landfills (Jagun et al. 2022). Leachate’s physical properties are affected by the concentration of inorganic particles like iron and lead and their temperature and colour (Slack et al. 2005). Landfills degrade garbage via at least five different phases, each of which is followed by the emission of a specific combination of chemicals and gases. Aerobic: Water and carbon dioxide are the two most abundant byproducts, with the latter either being released as a gas or dissolved in water to form carbonic acid, the acidic component of leachate. Carbon dioxide, hydrogen, ammonia, and organic acids are all examples of acidogenic chemicals, whereas acetic acid and its derivatives and carbon dioxide and hydrogen are all examples of acetogenic substances. Methanogenic: the typical composition of landfill gas is 60–40% methane and carbon dioxide. Carbon dioxide and water are the key ingredients in an aerobic environment (Flimban et al. 2019).

Various landfill regions may be in differing states of decomposition at any given time. These processes may continue even after the landfill has been covered or closed (Christensen et al. 2001; Kjeldsen et al. 2002). There are four distinct phases in the decomposition of organic waste, as shown in Fig. 1, each with unique properties and factors (Schiopu and Gavrilescu 2010). The resultant leachate can be categorized based on these factors. (1) Chemical oxygen demand (measured as COD), which includes:

Schematic diagram of leachate biological Degradation processes (Adhikari 2015)

-

i)

Ammonia nitrogen (\({\textrm{NH}}_4^{+}\)–N).

-

ii)

Dissolved solids.

-

iii)

Suspended solid.

-

iv)

Xenobiotic organic compounds (XOCs).

-

v)

Heavy metals.

-

vi)

Salts.

Different parts of a landfill are at various stages of decay at any given moment. These processes may persist even after the landfill has been covered or closed (Christensen et al. 2001; Kjeldsen et al. 2002). According to Schiopu and Gavrilescu (2010), the breakdown of organic waste may be broken down into four separate stages, each with its own characteristics and contributing variables. Based on these characteristics, the resulting leachate may be sorted. Which is comprised of the following:

-

a)

Leachate from landfills typically contains larger amounts of inorganic macro-compounds than surface water does, while the concentration of specific macro-components can vary with landfill age. Some of the most common inorganic compounds include: \({NH}_4^{+}\), \(nitric\ and\ nitrate\ oxides\ \left({NO}_3^{-}\right)\), \(nitrate\ ions\ \left({NO}_2^{-}\right)\), \({SO}_4^{2-}\), Cl-, \({PO}_4^{3-}\), sodium (Na+), potassium (K+), calcium (Ca2+), magnesium (Mg2+), iron (Fe2+) and hydrogen carbonate (HCO3-) (Robinson 2007). Some cations (including calcium, magnesium, and iron) are absorbed by organic molecules and precipitated out with anions due to the high pH in methanogenic leachate. This results in a leachate with a decreased cation content. Asadi (2008) notes, leaching washes away several macro-components, including Cl-, Na+, and K+, leaving them with little time to undergo sorption, precipitation, or complexation into other compounds. Due to the lack of alternative ammonia degradation processes, leaching has been proposed as a potential mechanism for ammonia reduction in the methanogenic phase. Therefore, ammonia has been found to be the major component of leachate over the long term, according to various studies. The range of 50–200 mg/L of ammonia has positive effects on anaerobic processes at higher pH levels, whereas concentrations of 1500–3000 mg/L are inhibitory, according to research by Kale et al. (2010). Microorganisms are killed off at ammonia concentrations exceeding 3000 mg/L (Kale et al. 2010). In addition, leachate with a nitrate origin (such as sewage, fertilizer, farm, animal waste, food waste, etc.) is readily observable. Microbial conversion of sulfate to sulfide occurs during the methanogenic phase (Bhalla et al. 2012), leading to reduced sulfate concentrations.

-

b)

Contaminants of emerging concern (CEC): The category of rising concern includes primarily unregulated substances, including micropollutants, pharmaceuticals, and personal care products (PPCPs), as well as endocrine-disrupting compounds (EDCs). These substances have been observed in the natural environment (Qi et al. 2018). Propp et al. (2021) have documented many forms of cation exchange capacity (CEC) in leachate derived from a historical landfill. These include polyfluroalkyl substances (PFAS), perfluorooctanoic acid (PFOA), organophosphate esters (OPE), substituted phenols, bisphenols, perchlorate, and pharmaceutical compounds. The study conducted by Propp et al. (2021) reported the highest observed value of 12.7 μg/L for per- and polyfluoroalkyl substances (PFAS). Additionally, the investigation found considerably elevated concentrations of other substances, including OPE, sulfamic acid, cotinine, and bisphenols. In a similar vein, a total of fifty-eight CEC (Contaminants of Emerging Concern) compounds were identified in samples of landfill leachate collected from Greece. Notably, the substances Bisphenol A, valsartan, and 2− OH-benzothiazole exhibited the highest average concentrations among the observed CEC compounds. The study conducted by Nika et al. (2020) found that pharmaceuticals, industrial chemicals, and agrochemicals were the primary types of contaminants of emerging concern (CEC) that were observed. Qi et al. (2018) have shown that the kinds of CECs most commonly studied in Chinese landfill leachate include phthalate esters and PPCPs. Nine different contaminants of emerging concern (CEC) have been seen to exhibit a wide range of concentrations, spanning from 0.03 to 4500 μg/L.

-

c)

Xenobiotic organic compounds (XOCs): Xenobiotic organic chemicals (XOCs) are often found in low amounts, typically below 1 mg/L for specific substances. Benzene, toluene, phenols, chlorinated aliphatics, phthalates, and halogenated hydrocarbons such as tetrachloroethylene and trichloroethylene are among the XOCs that have been identified (Propp et al. 2021). The main sources of these pollutants consist of home and industrial chemicals, as well as pesticides and fertilizers. The level of contaminants in leachate is influenced by waste mix, landfill technique, and age. The extensive investigation of monoaromatic hydrocarbons, including benzene, toluene, xylenes, and halogenated hydrocarbons, has been conducted due to their detrimental effects on both the environment and human health (Adhikari 2015). The analysis of monoaromatic hydrocarbons is straightforward.

-

d)

Heavy metals, salts: leachate commonly contains a range of heavy metals, including zinc (Zn), nickel (Ni), lead (Pb), copper (Cu), chromium (Cr), and cadmium (Cd). Additionally, there are metalloids such as arsenic (As), selenium (Se), mercury (Hg), and cobalt (Co), but these are typically found in minimal quantities. According to Ishak et al. (2016), the extended persistence of heavy metals in leachate can be attributed to their non-biodegradable and soluble characteristics. Consequently, these substances can undergo bio-magnification as they accumulate progressively along the food chains, resulting in many detrimental consequences for both humans and other organisms (Wijesekara et al. 2014). The primary sources of heavy metal discharge into leachate are batteries, automobile components, electrical wire, alloys, paints, lamp filaments, and ceramics (Trabelsi et al. 2013). The concentration of heavy metals in landfill leachate is typically minimal. However, there may be modest variations in concentration according to the degradation phase of the landfill.

-

e)

Dissolved organic matter (DOM): DOM constitutes a significant constituent within landfill leachate, and it exhibits interactions with various inorganic and organic contaminants, including heavy metals, as demonstrated by Huo et al. (2008). DOM refers to the proportion of organic material that is capable of traversing a filtration membrane with a pore size of 0.45 μm, including a diverse array of molecular weights and sizes. A study conducted by He et al. (2006) identified many major DOM components that are found in landfill leachate at significantly elevated levels. These components include amino acids, volatile fatty acids (VFA), hydrophilic acids, as well as fulvic-like and humic-like chemicals. The presence of many functional groups in DOM, such as carboxylic, phenolic, alcoholic, hydroxyquinone, and carbonyl groups, contributes to its high functional capacity in the environment. These functional groups enable DOM to interact with other compounds present in leachate (Kjeldsen et al. 2002; Vithanage et al. 2017). According to Vithanage et al. (2017), a greater presence of humic-like compounds indicates that the leachate is in an intermediate state of degradation.

-

f)

Conversely, a significant concentration of volatile fatty acids suggests an earlier acetogenic phase. DOM has the potential to impact the transit and evolution of heavy metals such as cadmium (Cd), copper (Cu), mercury (Hg), lead (Pb), manganese (Mn), nickel (Ni), and zinc (Zn) through the formation of complex species (Robinson 2007). Significantly, the phenomenon of the dark brown colour of leachate can be attributed to the presence of humic and fulvic chemicals, which can form complexes with ferric hydroxide colloids (Wijesekara et al. 2014). Hence, the determination of DOM is commonly conducted by the measurement of several bulk properties, including biological, biochemical oxygen demand (BOD), chemical oxygen demand (COD), total organic carbon (TOC), volatile fatty acids (VFA), and specific chemicals like as methane (Kjeldsen et al. 2002). In general, elevated levels of biochemical oxygen demand (BOD) and chemical oxygen demand (COD) in leachate are indicative of a substantial presence of DOM. Conversely, a low BOD/COD ratio suggests lower concentrations of volatile fatty acids and larger quantities of humic and fulvic-like compounds (Adhikari 2015).

In instances when landfill leachate is not appropriately managed via collection, treatment, and safe release, it can give rise to many environmental concerns, including soil contamination, surface water pollution, groundwater contamination, and potential risks to human health (Jagun et al. 2022). The potential adverse impacts of landfill leachate on ecosystems and human health, as illustrated in Fig. 2, can be attributed to the elevated concentrations of ammonia, heavy metals, and certain organic compounds (Volatile Organic Compounds (VOCs)). Therefore, leachate is seen as possessing the capacity to induce eco-toxic effects that exert stress on many components of the ecosystem. The presence of significant quantities of xenobiotic organic compounds (XOCs) and heavy metals in leachate has the potential to result in the accumulation and bio-magnification of these substances in the tissues of animals across different trophic levels within food chains. This accumulation can lead to the development of carcinogenic effects, as well as acute and genotoxicity outcomes (Mukherjee et al. 2015; Toufexi et al. 2013). The illustrations of the pollutants are clearly shown in Fig. 2.

Impacts of landfill leachate components. (Wijekoon et al. 2022)

Composition of landfills

The composition of leachate is affected by many factors, such as the waste’s type and quantity, the grinding level, the compaction level, the degradation processes (hydrolysis, adsorption, biodegradation, speciation, dissolution, dilution, ion exchange, redox, contact time, partitioning, precipitation gas, heat generation, and transport), the humidity of the waste, the climate, the hydrology of the storage site, the temperature of the waste while stored, and the le (Jagaba et al. 2021). Other features of the system include liquid waste co-disposal, water recirculation for irrigation and trash processing (Jagaba et al. 2021b). Leachate from landfills is influenced by a number of factors, including landfill age, solid waste components, rainfall rate, and landfilling technique (Remmas et al. 2018). Factors such as the waste’s substance, age, and size impact the quantity of leachate generated, while the landfill’s geology and weather conditions determine the degree to which rubbish is compacted (Choudhury et al. 2021). Alcohols, humic and fulvic acids, and volatile fatty acids are all examples of organic compounds, inorganic compounds (e.g., Ca2+, Na2+, K2+, Mg2+, Fe2+, Mn2+, \({\textrm{NH}}_4^{+}\)-N, \({\textrm{SO}}_4^{2-}\), Cl and HCO3 ), heavy metals (e.g., Cd, Pb, Cr, Ni, Hg, Cu, and Zn), and persistent organic compounds, pathogens, medicines, cyanides, total dissolved salts, NH3-N, total alkalinity, COD, total hardness, solvent, and carcinogens with an unpleasant odour are all present in leachate (Aziz et al. 2011; Neczaj et al. 2005; Yong et al. 2018; Jagaba et al. 2021).

Characteristics of landfill leachate

The properties and composition of leachate can be affected by several factors, such as the waste’s type and quantity, the degree to which it was crushed and compressed, the decomposition process (hydrolysis, adsorption, decay, speciation, refreezing, dilution, ion exchange, redox, contact time, separating, precipitation gas, heat dissipation, and transport), and the decomposition time (Aluko and Sridhar 2014; Mojiri et al. 2016). This is due to the fact that leachate varies greatly in terms of its composition and features as a result of the dynamic and complex nature of these elements. Therefore, it is difficult to manage and treat leachate without taking into account these aspects in order to lessen the negative effects on the environment and guarantee efficient treatment. When cleaning up leachate, it’s common to use a combination of physical, chemical, and biological methods, depending on the nature of the pollutants in question. Leachate undergoes fast alterations after its production, the nature of which is determined by its source and how old it is. Leachate strength changes as landfill disposal time progresses after closure. After only 2 days in the waste holding cell, leachate from incinerators and transfer stations can still preserve its quality (Remmas et al. 2018; Jagaba et al. 2021). The final composition of landfill leachate is made up of dissolved organic molecules (alcohols, humic, fulvic, and VFA), inorganic compounds (e.g., Ca2+, Na+, K+, Mg2+, Fe2+, Mn2+, \({\textrm{NH}}_4^{+}\)-N, SO42−, Cl−, and HCO3), and heavy metals (e.g., Cd, Pb, Cr, Ni, Hg). Due to specific waste qualities, leachate may produce NH3 − N, total alkalinity, COD, total hardness, solvent, malignancy, and a terrible odour. The environment, climate, landfill operation, landfilling technology, waste age, and weather conditions significantly influence each quality (Remmas et al. 2018). The leachate is classified as young (less than 5 years old), intermediate (5 to 10 years old), or old (more than 10 years old), depending on how long it has been lying in a landfill (Jagaba et al. 2021). Leachate often contains significant quantities of ammoniacal nitrogen (NH3 − N), chloride, and sulphate, as well as trace levels of heavy metals and other organic components (Lebron et al. 2021). Young landfill leachate (acid-phase landfills) has a lower BOD5/COD ratio and a lower concentration of biodegradable organic components (COD 3000 mg/L) than older landfills (Ying et al. 2012). In mature landfill leachate (methanogenic phase landfill), which has a high proportion of molecular weight organics, there is a low percentage of biodegradable organic compounds, rubbish, and so on (Ying et al. 2012). The middle-aged landfill, on the other hand, has both a very low concentration of ammonia (0.10) and a very high concentration of ammonia (>1000 mg/L), both of which are global concerns due to their fertilising and destructive impacts. The fraction of biodegradable organic pollutants in leachate decreases with landfill age, which may be connected to anaerobic decomposition (Ying et al. 2012). Organic compounds, both biodegradable and nonbiodegradable, and heavy metals, phenols, NH3 − N, sulphide, and phosphate are abundant. The landfill leachate characteristics with emerging contaminants are described in Table 1.

The negative impact of leachate on groundwater contamination

Groundwater contamination from landfill leachates is a lengthy and progressive process. Leachates from landfills account for 10% of all municipal waste (Aluko and Sridhar 2014), and about 70% of all rubbish is biodegradable. While the leachate treatment plant may handle some leachate, some may leak out of the landfill and into the surrounding soil and groundwater. If not properly managed, leachate can contaminate the surface and groundwater (Aluko and Sridhar 2014). Due to its components' harmful and persistent nature, heavy metals and ammonia produce a continual shift in input and toxicity (Trabelsi et al. 2013). The transport mechanisms and persistence of leachate compounds in groundwater create long-term contamination issues, making remediation costly and challenging. Groundwater contamination not only endangers human health but also jeopardizes aquatic ecosystems and drinking water sources (Hussein et al. 2021). The release of leachate into soil and aquifers seriously threatens human health and the environment (Remmas et al. 2018). When dumped in a natural setting, raw leachate can seep into the earth and surrounding water sources, severely contaminating both (Longe and Balogun 2010). This negatively affects the soil and the entire biological system, including humans(Yong et al. 2018). The rate of leachate leakage differs significantly between the landfilling phase, the covering phase, and the entirely covered phase because the leachate depth varies with penetrating rainfall. Most developed countries, therefore, have legislation for treating hazardous elements of leachate before disposal (Ishaq et al. 2022) to prevent contamination of water resources and major and chronic toxicity intrusion. Ammonia, metals, colour, dissolved solids, organic chemicals, and inorganic compounds are the most common contaminants in landfill leachate. Due to its high concentration in landfill leachate, ammonia has become a critical issue among many contaminants, posing significant environmental risks and negatively impacting human health. The leachate plume impacts hydrogeological processes in the aquifer, extending hundreds of meters when mixed with the unconfined aquifer (Mor et al. 2016). Therefore, it’s important to study concentrations and find the best treatment method. This review article relied on a narrative literature search to identify the current findings on the topic.

Standard regulations for leachate management and discharge

Landfill can become an underlying source of pollution due to the danger of leachate penetration into the soil and groundwater if it is not disposed of effectively. As a result, the created leachate must be gathered and handled carefully before being released into the natural habitat. According to Tsilogeorgis et al. (2008), proper management of a landfill site may significantly cut down on the amount of leachate created as well as the volume of it. However, leachate cannot be removed entirely. According to Aftab et al. (2020); Deng et al. (2020), if untreated raw leachate is disposed of, it can become a major source of water pollution. Because leachate may create major environmental problems, it must be collected and appropriately treated before being released into the environment (Deng et al. 2020). Environmental and economic considerations (Jagaba et al. 2021) and the technology applied to remove leachate may explain the variation in standard limit values across locations. To meet discharge standards, leachate treatment becomes a significant challenge (Trabelsi et al. 2013). The regulations governing the management and discharge of leachate vary across different countries and regions, being typically under the jurisdiction of local environmental agencies and authorities. Nevertheless, there exist certain shared principles and standards that often serve as guidelines for the management and discharge of leachate from landfill sites. Several general aspects and standards pertaining to leachate management include the following:

-

1)

Effluent standards: Regulations frequently stipulate the maximum permissible concentrations of various contaminants in leachate effluent. These pollutants include factors like Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), pH levels, heavy metals, and specific organic and inorganic compounds. These standards are established to safeguard the quality of surface water and groundwater.

-

2)

Discharge permits: Landfill operators typically must obtain permits for the discharge of leachate. These licenses outline specific circumstances, monitoring prerequisites, and release limits that must be followed to comply with environmental regulations.

-

3)

Monitoring and reporting: Regular monitoring of the quality and quantity of leachate is often mandated. Landfill operators are obligated to submit reports to regulatory authorities that provide detailed accounts of the results obtained from monitoring efforts. This information aids in ensuring compliance with discharge standards.

-

4)

Treatment requirements: Depending on the characteristics of the leachate and its potential impact on the environment, treatment may be necessary prior to discharge. Treatment techniques may involve physical-chemical treatment, biological treatment, or a combination of these approaches.

-

5)

Landfill design and liner systems: Regulations frequently establish design requirements for landfill liners and leachate collection systems with the aim of minimizing the migration of contaminants into groundwater. Proper construction and maintenance of liners are of paramount importance in preventing leachate leakage.

-

6)

Buffer zones and setbacks: Regulations may necessitate the implementation of buffer zones or setbacks between landfills and vulnerable receptors, such as drinking water wells, rivers, or residential areas, in order to safeguard against contamination.

-

7)

Closure and post-closure care: Regulations may also govern the closure and post-closure care of landfills, including the management of leachate during and after the operational phase of a landfill.

-

8)

Environmental impact assessments: In the case of new landfill projects or expansions, it may be required to conduct environmental impact assessments to evaluate potential impacts on the surrounding environment and to devise appropriate mitigation measures.

-

9)

Public notification: Certain regulations may mandate public notification and consultation regarding landfill operations and leachate management, particularly when there is a potential for environmental or health impacts.

-

10)

Emergency response plans: Landfill operators may be obligated to develop and maintain emergency response plans in the event of accidents or unexpected releases of leachate.

Several methods of landfill leachate treatment worldwide

Several methods exist for treating landfill leachate, each aiming to be effective and compliant with relevant regulations. Physical-chemical (flotation, coagulation/flocculation, adsorption, chemical precipitation, air stripping, pH adjustment, chemical oxidation, ion exchange, and electrochemical treatment) and biological (activated sludge, aerobic and anaerobic stabilisation lagoons, and biological filters) methods are all used. There are advantages and disadvantages to these treatments and their effectiveness. The success of leachate remediation is increased when multiple approaches are combined, as proven in several studies (Biki et al. 2021; Jagaba et al. 2021). Combining leachate treatment methods has increased the amount of COD, NH3, organic matter, and other pollutants that may be removed. The leachate recovered and collected from a landfill must be managed appropriately, utilizing one or more of the three applicable procedures listed: Treatment on-site, dumping into sewage systems, and transport away from the site for treatment offsite are all choices. These three treatment approaches can be subdivided into sub-methods, as shown in Fig. 3. These methods are discussed extensively in the subsection.

Different methods of Leachate recovery, reuse and degradation. Source: (Jagaba et al. 2021)

Leachate transfer processes

Recycling: Partial treatment and disposal of leachate-by-leachate recycling looks to be one of the cheapest options at well-designed and -operated landfill sites. During recycling, pollutants and impurities are often removed through a series of treatment procedures, rendering the leachate appropriate for uses like irrigation, industrial activities, and even as a water supply. The two main components of this recycling strategy are collection and pre-treatment. Recycling leachate is an effective strategy for dealing with landfill leachate, reducing adverse environmental effects, and protecting scarce water supplies. To promote a more sustainable and circular waste management system, leachate may be converted into a resource using suitable treatment technologies (Tatsi et al. 2016). Leachate recirculation has been shown to increase the moisture contents within a reactor system, providing sufficient distribution of nutrient elements and enzymes among methanogens and solids/liquids, leading to a notable decrease in methane yield and COD (Carvajal-Flórez and Cardona-Gallo 2019; Abdel-Shafy et al. 2023). Landfill leachate: Sources, nature, organic composition, and treatment: An environmental overview. Ain Shams Engineering Journal, 102293.). After recirculation, Ghosh et al. (2017) found that the COD in an anaerobic pilot plant dropped by 63 to 70%. The stabilisation time required was also shown to be reduced to two to three years via recirculation. However, significant recirculation rates may have a harmful effect on anaerobic degradation. It was also determined that methanogenesis inhibition due to high levels of organic acids (pH less than 5), which poison the methanogens, may result from leachate recirculation (Ghosh et al. 2017). Acidic conditions, saturation, and ponding can all result from excessive leachate recirculation.

Co-treatment with municipal wastewater: Low biodegradability and heavy metals of the organic inhibitory compounds in the leachate have long cast doubt on the usefulness of such a process, suggesting instead that treatment efficiency would suffer and effluent concentrations would rise (Carvajal-Flórez and Cardona-Gallo 2019; Abdel-Shafy et al. 2023). The presence of nitrogen in leachate and phosphorus in sewage necessitated urgent volumetric optimisation of leachate’s part within the overall wastewater. Filling, anaerobic, aerobic, and settling comprise a sequencing batch reactor (SBR), which is proposed as a combined treatment approach (Contrera et al. 2014). With a sewage-to-leachate ratio of 9:1, roughly 95% of BOD and 50% of nitrogen on a cycle basis were removed. An increase in the proportion of landfill leachate to municipal wastewater was determined to decrease COD and BOD concentrations. Meanwhile, adding powdered activated carbon (PAC) can considerably improve effluent quality (Deng et al. 2018).

Leachate evaporation: The liquid produced by landfills may be treated by exposing it to solar radiation in evaporation ponds or basins under strict supervision. Solar light warms the leachate as it spreads across a broad region, and this, in turn, causes water to evaporate into the air. Although it can release harmful gases and odours into the atmosphere, in addition to weather-dependence affects its effectiveness, and disposing of the residue is problematic. Pollutants and dissolved solids in the leftover leachate are concentrated by this procedure, making it more manageable for further treatment or disposal. As a result of faster evaporation rates in areas with high temperatures and low humidity, the amount of leachate may be reduced, and the environmental implications of uncontrolled leachate discharge can be mitigated. However, to comply with local rules and environmental requirements for responsible waste management, it is crucial to consider the possibility of extra treatment of the concentrated leachate residue.

Spray irrigation on abutting grassland: The land application technique of spray irrigation, which involves the dispersal of landfill leachate into adjacent grassland, is employed with the objective of effectively managing leachate and facilitating its controlled dispersion. This methodology has the potential to yield advantages such as reducing leachate levels and mitigating the risk of groundwater pollution while concurrently offering an effective method for the disposal of this liquid waste. The leachate is applied onto the grassland, facilitating its absorption and subsequent natural treatment by the soil and plants. This process has the potential to assist in the elimination of certain toxins. Nevertheless, it is important to implement efficient management and monitoring practices in order to prevent the process from surpassing the soil's ability to absorb leachate, which might lead to run-off or excessive pollution. Furthermore, it is important to thoroughly evaluate the potential ecological and agronomic consequences on the grassland and its surrounding ecosystem. This underscores the need to achieve a harmonious equilibrium between waste disposal practices and environmental preservation.

Biodegradation process (biological treatment of leachate)

According to Oller et al. (2011), biological treatment processes have proven to be really effective in getting rid of high concentrations of Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD) from leachate. The two types of treatment processes, aerobic and anaerobic, are classified based on the requirement of oxygen. In the case of aerobic treatment systems, the presence of oxygen plays a crucial role in breaking down the pollutants, resulting in the production of carbon dioxide, solid biological byproducts, and sludge, as explained by Grady et al. in 2011. On the other hand, in an anaerobic process, the organic matter goes through a conversion process that results in the production of biogas, which is mainly made up of carbon dioxide, methane, and biological sludge. The effectiveness of biological processes in removing organic and nitrogenous materials from immature leachate, characterized by its youthfulness, has been well-documented, particularly when the ratio of BOD to COD is relatively high, exceeding 0.5, as observed by Naveen et al. (2018). Nonetheless, it is crucial to acknowledge that the presence of refractory compounds such as humic and fulvic acids can potentially limit the overall effectiveness of the biological treatment process over time, as highlighted by Abbas et al. (2009). Biodegradation occurs when microorganisms break down organic substances into carbon dioxide, sludge, and biogas (a mixture mainly composed of CO2 and CH4) in an aerobic environment (Abdel-Shafy et al. 2014). The removal of leachate laden with high levels of BOD is a widespread application of a biological treatment, primarily distinguished by its excellent cost-effectiveness, dependability, and simplicity. Biological activities successfully treat high BOD/COD ratio values (higher than 0.5) because they help remove nitrogenous and organic materials from young leachate (Tatinclaux et al. 2018). Humic and fulvic acids are examples of refractory substances that may reduce the treatment’s efficacy over time.

Suspended-growth biomass: The term “suspended-growth biomass” describes a population of microorganisms, primarily bacteria and protozoa, that are actively developing and freely floating in a liquid media as part of a wastewater treatment process. These bacteria are essential to biodegradation because they feed on and decompose the organic materials, nutrients, and pollutants that are found in wastewater. The suspended-growth systems used in wastewater treatment facilities, such as activated sludge, create a setting where the biomass may react with the wastewater, resulting in the degradation of pollutants into innocuous by-products (Ahmed and Lan 2012).

Attached-growth: Microorganisms are grown onto a solid surface in a fixed-bed reactor as part of a biological wastewater treatment technique known as attached growth (Mojiri et al. 2013). Microorganisms form a biofilm as wastewater runs over the surface of a medium, such as rocks, gravel, or plastic. Organic materials and contaminants in wastewater are broken down by a microbial population that calls the biofilm home. The bacteria in the biofilm metabolise the organic components in the wastewater as it flows through. Getting rid of organic material and nutrients like nitrogen and phosphorus from wastewater is a speciality of the attached growth method (Aziz et al. 2011). It also has benefits such as being durable, resistant to shock loads, and adaptable to different flow rates. Trickling filters and rotating biological contactors (RBCs) are two examples of attached-growth systems that play an essential role in wastewater treatment by removing pollutants and sustainably protecting water supplies. Furthermore, nitrification is lower, influenced by the low temperatures (Aziz et al. 2011), than that by suspended-growth systems and also by inhibition because of the high nitrogen content (Abdel-Shafy et al. 2023).

Aerobic treatment: Aerobic biological treatments are a type of wastewater treatment that uses oxygen-dependent bacteria to decompose organic materials and contaminants. These techniques are widely utilised in municipal and industrial wastewater treatment plants because they effectively remove organic compounds, nutrients, and other impurities. The efficient and highly effective technique employed for the treatment of landfill leachate involves the utilization of the traditional biological process, specifically the aerobic process. This process facilitates the elimination of biodegradable organic pollutants while simultaneously converting ammoniacal nitrogen into nitrite through the process of nitrification. Consequently, this results in the degradation of organic material in a highly efficient manner, thus enabling the convenient removal of nitrogenous compounds. It is important to note that this approach has been extensively studied and researched by Ilmasari et al. (2022) as well as Luo et al. (2020), who have provided valuable insights into its effectiveness and potential applications. Aerobic biological processes rely on suspended growing biomass in conventional activated sludge processes, sequencing batch reactors (SBRs), and aerated lagoons (Aziz et al. 2011). There are several varieties of attached-growth systems, such as the bio-filters and the moving-bed biofilm reactor (MBBR). Aerobic treatment can help remove the biodegradable organic contaminants and move the ammonium-nitrogen nitrification process along. The membrane bioreactor, which combines membrane separation with aerobic bioreactors, has recently garnered much interest (Ahmed and Lan 2012; Abdel-Shafy et al. 2023).

Activated sludge: Activated sludge is a popular and efficient biological wastewater treatment method that uses a microbial suspension in a liquid media to decompose organic matter and contaminants in wastewater. Wastewater is treated with this technique by combining it with a colony of microorganisms called activated sludge in aeration tanks. Bacteria and other microbes break down organic chemicals into harmless by-products like carbon dioxide and water (Kamaruddin et al. 2017). What is left of the mixture after the aeration phase settles in secondary clarifiers? This is the sludge that is returned to the aeration tank and used to keep the microbial population stable. Effluent treated in this way is more likely to be free of organic material, nutrients, and pollutants, making it compliant with discharge or reuse regulations. The flexibility, efficiency, and resilience of activated sludge make it an indispensable component of worldwide municipal and industrial wastewater treatment facilities. The treatment of leachate has been explored through the implementation of the Activated Sludge Process (ASP), which has showcased its viability by effectively removing organic carbon, ammonia, inorganic nutrients, and phenolic compounds (Ilmasari et al. 2022). However, it has been proven inadequate for treating landfill leachate (Abdel-Shafy et al. 2014). Despite being beneficial in the removal of nutrients, organic carbon, and ammonia contents, however, there are some other difficulties to consider: Municipal landfill leachate, anaerobically pre-treated, was nitrified at different temperatures (5–10°C) in an activated sludge reactor and the presence of plastic carrier material (Kamaruddin et al. 2017; Abdel-Shafy et al. 2023). Some of the disadvantages associated with this approach include the necessity for longer aeration periods, lasting approximately 20 h, and the inadequate capability of the sludge to settle properly (Wanner et al. 2014). Additionally, there is an overproduction of sludge and a high energy demand (Pant et al. 2010). The growth of microbes is hindered due to the elevated nitrogen content found in most leachates. Furthermore, the resulting sludge fails to meet established standards, necessitating an additional treatment technique to ensure compliance (Ilmasari et al. 2022). Aerobic post-treatment yielded an effluent of 150–500 mg COD L−1, lesser than 7 mg BOD L−1and lesser than 13 mg L−1.

Aerated lagoons: ‘Lagooning’ stops biomass growth. Aerated lagoons like the one in are cost-effective for removing organic and inorganic matter, as well as pathogens, in wastewater treatment, especially in developing countries where specialized skills are scarce (Frascari et al. 2004). Aerated lagoons, vast basins that use biological oxidation with a constant air supply, are a cost-effective way to remove microbial and organic load. Operators and decision-makers in developing countries choose these basins to treat landfill leachate because of their efficient operation and low maintenance and operational costs (Maia et al. 2015). Landfill-diluted leachate treated with artificial wetlands and anaerobic-aerobic lagoons removed over 70% N, P, and Fe (Ahmed and Lan 2012). Frascari et al. (2004) found that lagooning phenolic and organic debris reduced COD and phenol concentrations by 55–64% and 80–88%, respectively. Due to its reliance on microbial activity, this technique is susceptible to temperature changes. Temperatures below 15–20°C inhibit bacterial growth, slowing therapy (Abbas et al. 2009). Treatment effectiveness also depends on retention length. This is because it controls microorganisms’ lagoon stays and organic matter breakdown Frascari et al. (2004). Temperature greatly affects microbial activity, limiting lagoons.

Membrane bioreactors (MBRs): MBRs are advanced wastewater treatment systems that combine biological treatment with membrane filtration. They are widely used in various industrial and municipal applications to treat wastewater efficiently and produce high-quality effluent. Membrane technology combines the use of ASP and membrane units for efficient treatment, mainly applied to highly loaded leachates that are difficult to treat using other technologies (Gu et al. 2023). Moreover, membrane technology has proved to be efficient for the treatment of mature landfill leachates with recalcitrant pollutants (Zhang et al. 2020) and offers a stable process with low sludge production (Iorhemen et al. 2016a, b). MBRs provide an effective means of removing organic pollutants, suspended solids, and pathogens from wastewater. In addition, the membrane bioreactor (MBR) is a system that combines a bioreactor with membrane separation technology to provide a small footprint while producing high-quality effluent (Ahmed and Lan 2012; Teng et al. 2021). Biodegradation, adsorption, and membrane filtration are all combined in the Ultrafiltration-biologically active carbon (UF-BAC) hybrid membrane bioreactor system (Mansoorian et al. 2020). Overall, the procedure was between 95 and 98% effective at reducing organic carbon.

On top of that, in contrast to standard practices, the organisms responsible for the gradual degradation of biodegradable materials, such as nitrifiers, are probably not rinsed out of the process (Lu et al. 2021). Nevertheless, the most challenging aspect of membrane technology is the fouling occurrence due to the use of high organic strength leachate, excessive formation of biosolids, or excessive microbial growth, among other reasons. These challenging aspects substantially increase the operating cost (Abuabdou et al. 2020; Remmas et al. 2018).

Constructed wetlands (CWs): Constructed wetlands (CWs) mirror natural wetland ecosystems by incorporating essential features that clean leachates and wastewater of hazardous chemicals. Hydric soils with various microorganisms, aquatic flora, and a sand and gravel filtration system are essential (Stottmeister et al. 2003; Wdowczyk et al. 2022). Synthetic ecosystems filter and reuse urban, industrial, and agricultural water (Wu et al. 2014; Zhang et al. 2020). A built wetland can also remediate leachate biologically. Plants, media, and microbes are purposely included. Long, stringy-rooted water plants clean leachate well. Scirpus validus, Limnocharis flava, and Ipomoaea aquatica eliminate ammonia nitrogen. CW systems can recover biodegradable organic carbon and ammonia from landfill leachate (Dan et al. 2017). There are numerous ways to reduce nitrogen pollution, according to Mojiri et al. (2016). Adsorption on substrates, plant root absorption, ammonia volatilisation, biological breakdown, and biochemical translation into N2 (Badejo et al. 2020; Zhang et al. 2020). Free-water surface flow CWs flow on basin surfaces, while subsurface flow CWs flow below them. Based on subsurface water flow, the latter might be vertical or horizontal. Vertical subsurface flow CWs are utilized more than horizontal ones. Selecting vegetation in built wetlands (CWs) is crucial to leachate treatment. Their vital function in absorbing nutrients and heavy metals affects removal efforts (Klomjek and Nitisoravut 2005; Mbuligwe 2005). Thus, the inlet’s organic material and pollutants, temperature, and hydrology must be considered before selecting CW vegetation. Cost reduction, habitat creation, and aesthetics are all benefits of adopting CWs. They require a lot of space and may be weather-sensitive. CWs handle leachate sustainably and ecologically, improving water quality and the environment.

Moving beds biofilm reactors (MBBR): MBBR is a method of treating wastewater that uses biofilm technology to eliminate organic debris, nutrients, and pollutants. High-surface-area media carriers made of plastic are used in MBBR systems. These transport mediums are ideal for microbial biofilm formation (Saxena 2022). The media carriers are free to move around as the wastewater flows through the reactor, producing a dynamic environment in which the biofilm is continually exposed to clean water. This motion brings biofilm microbes into more direct and constant contact with organic and nutritional contaminants in the wastewater. A biofilm of the active biomass forms on the surfaces while porous polymer-carriers are hung and move continuously inside the aeration tank. In addition to rejecting organic matter and large quantities of ammonia in a single cycle, the process has several other benefits, including increased biomass production and shorter sludge-settling times (Abdel-Shafy et al. 2021). High ammonia concentrations did not prevent nitrification (Aziz et al. 2011). In contrast, it has been reported that granular activated carbon (GAC) can function as a porous surface adsorbing organic matter and furnish acceptable conditions for enhanced biodegradation (Aziz et al. 2011; Abdel-Shafy et al. 2023), so a steady equilibrium can be achieved between the processes of adsorption and biodegradation. A very effective biological AC fluidised bed might remove as much as 70% of the refractory organics present. Ammonia levels were observed to be reduced by 85–87%, and COD levels by 61–82% (Aziz et al. 2011; Abdel-Shafy et al. 2023)

Sequencing batch reactor (SBR): Batch-operated activated sludge Sequencing Batch Reactors (SBRs) treat leachate and other effluent. Dynamic, flexible, suspended-growth biological therapy (SBR) technology has no steady-state condition. This process uses fill and decant-ASP with or without a clarifier. Al-Rekabi et al. (2007) and Mahvi et al. (2008) characterize the traditional SBR process as fill, react, settle, draw, and idle. Intermittently aerating the system allows all metabolic processes and solids-liquid separation to occur in a single tank, carefully regulated by a timed sequence (Alattabi et al. 2017). Duan et al. (2020) noted that the conventional SBR method uses a single reactor, leachate, aeration, settling, decanting, and waste collection to nitrify, denitrify, and phosphorous simultaneously. Leachate is effectively filtered of organic pollutants and suspended particles, improving operational adaptability and environmental impact. SBR also removes nutrients as well. SBR requires constant sludge control. According to Deng et al. (2018), aerobic leachate treatment in SBR can remove 75% COD and 99% -N in 20–40 days. Sequential anaerobic-aerobic reactor batch reactors remove 62% COD, 31% -N, and 19% with solid capture and less organics after 21 h. By efficiently abating organic waste, methanogenesis and denitrification may enhance early landfill nitrification (Deng et al. 2018). High-rate reactors shorten digestion time.

Phytoremediation system: Phytoremediation removes pollutants from soil and water using plants. A sustainable, cost-effective, and environmentally friendly repair approach (Kafle et al. 2022). Plants remove pollutants from landfill leachate by phytoextraction and phytovolatilization. Plants that accumulate heavy metals in their tissues are used for phytoextraction from leachate. Metals are collected from harvested plants. However, phytovolatilization uses plants that release pollutant gases. This method removes volatile pollutants from landfill effluent. While eliminating toxins, phytoremediation can also lower landfill discharge volume. Leachate water and nutrients help plants develop (Kafle et al. 2022). In landfill leachate treatment, phytoremediation is promising. It removes various pollutants from leachate in a sustainable, cost-effective, and ecologically friendly manner. Like CWs, phytoremediation depends on plant type. Abbas et al. (2009) used aquatic plants to remove COD, BOD, and heavy metals from landfill leachate with little migration from roots to aboveground portions. Lavagnolo et al. (2016) observed that leachate-irrigated oleaginous plants exhibited higher plant mass and COD, total nitrogen, and total phosphorous removal efficiency than control systems, with soil type also affecting plant growth. Phytoremediation reduces landfill leachate levels by evapotranspiration and recovers water and nutrients (Lavagnolo et al. 2016; Nagendran et al. 2006). Ponding systems: Ponding systems are an efficient and straightforward technique for treating landfill leachate (Adhikari and Fedler 2020). They rely on natural processes such as sedimentation, flocculation, and biodegradation to remove pollutants from leachate. The leachate is initially poured into a large pond, where it settles, then the denser solids sink to the bottom of the pond while the lighter solids flocculate and float to the surface and the settled solids are extracted from the reservoir, while the flocculated solids are skimmed off the surface (Adhikari and Fedler 2020). The clarified leachate is then circulated through an array of aerobic and anaerobic basins. In aerobic ponds, microorganisms utilize oxygen to decompose the organic matter in effluent.

Rotating Biological contactors: A Rotating Biological contactor (RBC) is a secondary treatment method where rotating disks with fixed media filters are used to remove organic material and ammonia from wastewater and leachates by submerging the disks partially in the wastewater and allowing their rotation to degrade the organic material, while specific microorganisms grow on the disk's surface and are later removed along with excess sludge (Miao et al. 2019). RBCs are well-suited for purifying landfill leachate, which is a highly concentrated wastewater that may contain high levels of organic matter, ammonia, and heavy metals. The treatment efficiencies of RBC systems for leachate treatment have varied across different studies due to different operational conditions; Wang et al. (2021) found complete ammonia oxidation but low COD removal of 38% when treating high-strength ammonia leachate with low BOD using RBCs with low substrate loading rates to promote nitrification. RBCs have a number of advantages over other forms of biological wastewater treatment systems for the treatment of landfill leachate. They are comparatively compact and simple to install in confined spaces. They are also exceptionally effective at removing organic matter and ammonia from effluent. Moreover, RBCs are comparatively simple to operate and maintain. RBC systems for leachate treatment, which have been extensively researched and analyzed by various studies, including Maheepala et al. (2022), have proven to possess an exceptional ability in nitrification. The effectiveness of these systems in removing nitrogen compounds from wastewater has been well-documented. However, like any technology, RBC systems come with their limitations, and the primary drawback lies in their vulnerability to extreme weather conditions. In order to maintain optimal performance and prevent any potential damage, these systems must be adequately shielded from excessive sunlight, wind, rain, and even snow, as highlighted by Wang et al. (2021) in their research. The need for protection against these environmental factors is crucial to ensure the longevity and efficiency of RBC systems in wastewater treatment applications.

Anaerobic treatment of leachate: The oldest wastewater treatment method is the anaerobic process, from the late nineteenth century. This therapy uses microbes to convert organic materials. Anaerobic organisms live without molecular oxygen using nitrogen, phosphorus, sulfur, potassium, calcium, and magnesium; these anaerobes can promote microorganism development. Anaerobes may acidogenize and methanogenize leachate (Tawfik and ElBatrawy 2012). Organic trash and pollutants in landfill leachate are broken down by anaerobic microorganisms without oxygen. Anaerobic digestion produces biogas and carbon dioxide from microbes, simplifying leachate organic components (Deng et al. 2018). In a closed reactor or digester, leachate is fed to anaerobic bacteria. Anaerobic treatment reduces organic load, eliminates odours, and generates energy-generating biogas (Maillacheruvu and Fayyaz 2007). The treated leachate may need aerobic or physicochemical treatment before discharge. Anaerobic landfill leachate treatment can generate renewable energy and reduce greenhouse gas emissions. Anaerobic digestion produces fewer solids and conserves energy due to its delayed reaction rates (Maia et al. 2015). With CH4, the digester may be heated to a pleasant 35°C.

Anaerobic ammonium oxidation (Anammox): The process of anaerobic ammonium oxidation (Anammox) transforms ammonium (\({NH}_4^{+}\)) to dinitrogen (N2) gas in anoxic environments (Strous et al. 1999). A consortia of bacteria oxidizes ammonium without oxygen. Anammox is a novel landfill leachate treatment that shows potential. Organic debris, ammonium, and other contaminants are concentrated in landfill leachate. Leachate with high ammonium levels can cause eutrophication and other water quality concerns. Anammox removes ammonium from leachate efficiently and sustainably (Heijnen et al. 1998). Anammox is usually done in a reactor at 20–30°C and 7–8 pH (Strous et al. 1999). After seeding the reactor with Anammox bacteria, leachate is pumped in. Leachate ammonium provides electrons for bacteria, which generate dinitrogen gas. Anammox removes ammonium up to 90% efficiently. This yields far greater removal efficiencies than aerobic oxidation or chemical precipitation (Hu and Deng 2011). Anammox’s energy efficiency makes landfill leachate treatment cost-effective. Several variables can alter Anammox’s performance. These include leachate pH, content, and temperature. Organic substances can also inhibit Anammox (Hu and Deng 2011). These elements may be modified to optimize the Anammox process.

Nitrification and denitrification: Nitrification and denitrification are frequently combined in landfill leachate treatment in a two-step process known as “nitrogen removal” or “nitrification-denitrification.” Alternating aerobic and anoxic conditions are provided to maintain both nitrifying and denitrifying microorganisms. Nitrification takes place during the aerobic phase as ammonia is transformed into nitrate. Denitrification happens in the anoxic phase as nitrate is converted to nitrogen gas. This two-step procedure successfully eliminates nitrogen compounds from leachate, decreasing its environmental impact and allowing it to be safely discharged or reused. To achieve optimal performance of the bacteria participating in the nitrification and denitrification processes in landfill leachate treatment, operational variables such as pH, dissolved oxygen levels, and organic carbon availability must be carefully controlled.

Furthermore, enough mixing and aeration are required to keep the required aerobic and anoxic conditions inside the treatment system. Nitrification and denitrification, when properly built and managed, serve a critical role in minimising the nitrogen-related environmental hazards connected with landfill leachate wastewater. Nitrification and denitrification are critical stages in lowering ammonia and nitrate concentrations prior to discharge or reuse of treated leachate (Zhang et al. 2020).

Anaerobic digestion: Leachate treatment often employs the biological process of anaerobic digestion, which includes the degradation of organic materials by anaerobic microbes in the absence of oxygen. The organic load and hazardous chemicals in leachate may be greatly reduced by anaerobic digestion, a procedure that is both efficient and ecologically benign. The organic chemicals in leachate are decomposed by bacteria during the anaerobic digestion process into molecules like methane, carbon dioxide, and water (Strous et al. 1999). The utilization of digesters or bioreactors, which provide a closed, oxygen-free environment, is commonplace during this microbial activity. Biogas, which is comprised primarily of methane, is produced as a byproduct of anaerobic digestion and may be collected and used as a sustainable energy source (Kumar et al. 2021). There are several upsides to adopting anaerobic digestion for leachate cleanup. First, it aids in reducing the negative effects of leachate on the environment by keeping potentially hazardous contaminants from seeping into the ground and water. Second, producing biogas as an alternative energy source helps the environment and cuts down on fossil fuel use, both of which are important for long-term sustainability. The resource efficiency is increased since the treated leachate may be safely released or reused. However, the composition of the leachate, temperature, pH, and retention duration in the digester are only a few of the elements that might affect the efficacy of anaerobic digestion in leachate treatment. To increase microbial activity and waste elimination, ideal conditions must be preserved.

Anaerobic filters: Anaerobic filtration is a prominent leachate treatment. Anaerobic digestion involves microorganisms breaking down organic materials without oxygen. Anaerobic filters clean landfill leachate well due to their high concentrations of organic pollutants and other impurities (Weiland 1987). Leachate-treating anaerobic filters employ a packed-bed reactor containing pebbles, plastic, or other support materials. Anaerobic microorganisms degrade leachate organic molecules on the medium’s surface. The reactor’s biofilm of anaerobic bacteria digests organic waste as leachate runs through, creating methane, carbon dioxide, and water. This biological process reduces organic load and removes harmful compounds from leachate. Anaerobic filters can handle leachate’s strong and complex organic waste, making them ideal for treatment. The reactor’s medium keeps the anaerobic microbial community stable, ensuring effective treatment independent of leachate composition (Pal et al. 2010). Kumar et al. (2021) used an up-flow anaerobic filter to remove organic materials from landfill leachates. The filter considerably reduced COD in landfill leachate, with biogas generation and methane levels within defined parameters. Anaerobic filters also use less electricity and are easier to maintain. They also produce biogas, which may be harvested and utilized as renewable energy, reducing greenhouse gas emissions. Anaerobic filters, like every therapeutic device, have limits. Maintenance and monitoring may be needed to maintain microbial activity and discover and correct blockages before they cause issues. Temperature, pH, and leachate contaminants can also impact method efficacy.

Anaerobic sequencing batch reactors: Anaerobic sequencing batch reactors (ASBRs) can treat leachate. The ASBR works like the aerobic sequencing batch reactor but without aeration. Batch-operated ASBRs are multi-stage treatment systems. They have garnered recognition for their ability to handle difficult organic waste like landfill leachate. Because they recycle leachate through numerous phases in the same reactor, ASBRs handle it well (Jiraprasertwong et al. 2018). Therapy plans usually have four phases: The reactor is filled with leachate to a target volume during filling. In the react phase, reactor anaerobic bacteria degrade leachate’s organic components, creating biogas (mainly methane) and stable organic compounds.

Let the treated leachate settle and separate particles after the react phase when biogas generation diminishes. Decanting the filtered effluent leaves solids at the reactor’s base (Jiraprasertwong et al. 2018). Timur and Ozturk (1999) found that a lab-scale ASBR could treat municipal landfill leachate, removing 64 to 85% of COD depending on loading rates and converting 83% of COD into biomethane. The batch operation gives ASBRs leachate treatment advantages. Process control and leachate property adaptation are improved. ASBRs are also more resistant to influent flow and composition, making them effective for leachate with different organic loads (Yong et al. 2018). Another benefit of ASBRs is organic waste diversion and biogas production. Leachate treatment biogas may be utilized as renewable energy, boosting the operation's long-term profitability. ASBRs have severe limitations, but so does any technology (Yong et al. 2018). Due to its intricacy, the system may require more advanced operation and maintenance than simpler treatment systems. Inhibitory chemicals or dangerous substances in leachate, which anaerobic bacteria would normally thrive on, may also hamper treatment.

Hybrid filters: Hybrid filters are a type of leachate treatment that combines many treatment methods into a single system to improve overall performance. Because of the complex nature of landfill leachate, innovative hybrid solutions have been developed to handle it (Kececioglu et al. 2016). Hybrid filters are a method of treating a problem by combining multiple treatment methods, usually in a sequential or parallel fashion. The synergistic benefits of each process are amplified when several technologies are used in tandem, leading to more efficient pollution reduction and a greater treatment level than would be possible with any technology used alone. Hybrid filters like this are often used in leachate treatment (Kececioglu et al. 2016). A hybrid of biological (such as anaerobic or aerobic digestion) and physical (such as filtration or sedimentation) treatment procedures. This method can purge leachate of both organic and inorganic contaminants efficiently.

Thermal treatment processes: Due to the pervasive and difficult-to-treat nature of certain of the contaminants found in landfill leachate, thermal treatment techniques play a vital role in leachate treatment (Wang et al. 2022). These procedures make use of heat to hasten several chemical and physical reactions, ultimately resulting in the breakdown, volatilization, or destruction of organic and inorganic pollutants in the leachate. When treating leachate, thermal treatment methods such as:

-

1)

Leachate can be incinerated in an oxygen-rich atmosphere by a controlled burning process called incineration. Carbon dioxide and water vapour are produced from organic molecules as the heat does its work, while inorganic substances become ash. To remediate high-strength leachate and lessen the amount of trash that has to be disposed of, incineration is a viable option. However, it needs to be closely monitored and managed so that dangerous air pollutants aren't produced (Wang et al. 2022).

-

2)

Thermal treatment and oxidation in one step using high-pressure steam characterize the process known as wet air oxidation (WAO). Organic pollutants in leachate are degraded by heating in the presence of oxygen. When opposed to incineration, WAO has less air emissions and can efficiently remove refractory organic contaminants (Schnell et al. 2020).

-

3)

High-temperature anaerobic digestion (HTAD) is a method of decomposing organic materials by microorganisms that involves heating leachate to higher temperatures than is typical for anaerobic digestion. Faster digestion and biogas generation can be achieved due to the increased activity of anaerobic microbes as a result of the higher temperature (Candelier et al. 2016).

-

4)

Through a process called pyrolysis, organic compounds in leachate are broken down into their parts—char, liquid oils, and gaseous products like syngas and volatiles—when the liquid is heated to high enough temperatures without the presence of oxygen. Energy recovery and trash minimization are two of the many applications of pyrolysis.

-

5)

When organic components in leachate undergo gasification, a thermal process, the resulting gases are a combination of carbon monoxide, hydrogen, and methane. Synthesis gas (syngas) is the name given to the byproduct gas, which has potential as a clean energy source.

-

6)

Thermal treatment technologies are helpful for dealing with stubborn and complicated contaminants that are difficult to remove using more conventional biological or physical approaches. They offer benefits, but they also have problems, including high energy demands and possible air pollutants. Effective emission control and waste disposal are just two aspects of process management that are crucial to the long-term viability of these operations (Candelier et al. 2016).

Up-flow anaerobic sludge blanket (UASB): Process development and high-rate treatment technologies have advanced greatly with the UASB module. A unique design allows the UASB to separate liquid, gas, and solid phases in one container. UASB reactors are being explored for leachate treatment due to their energy efficiency, user-friendliness, and low sludge generation. Methane and hydrogen are created during operations and can be used as fuel. Pre-treatment of landfill leachate to remove particulates may increase reactor performance. Post-treatment with the UASB reactor is necessary to meet discharge requirements (Tawfik et al. 2012). Volumetric organic loading ratios between 20 and 35 benefit from this method’s better treatment and shorter hydraulic retention duration. At 20–23° Celsius, COD was decreased by over 70%, and at 35° Celsius, by over 80%. COD was reduced by 92% due to low to moderate organic loading ratios (Kurniawan et al. 2006). Maintaining a temperature between 15 and 35° Celsius before high-rate treatment reduces heat consumption (Miao et al. 2019). Anaerobic lab-scale suspended-growth digesters removed 80–90% and 55% of COD at 35°C and ambient temperature (Noerfitriyani et al. 2018). The extraordinary results shown by UASB suggest that a high-rate treatment at lower temperatures might minimize leachate heating, presenting an exciting and economically viable option. Note that this treatment approach is prone to harmful substances, including ammonia and heavy metals (Timur Özturk 1997). Noxious substances are not allowed (Kuusik et al. 2014).

Fluidised bed reactor: A fluidised bed reactor (FBR) is a reactor utilised in various industrial processes and applications, such as chemical reactions, catalytic processes, and wastewater treatment. Solid particles floating in a fluid (typically a gas or liquid) behave like a fluidised mass in a fluidised bed reactor. This happens when there is enough upward movement of fluid, causing the solid particles to become buoyant and appear to be boiling. It has been demonstrated that combining biodegradation and adsorption techniques enables excellent removal of different organic chemicals (Castilhos et al. 2009). The biological AC fluidised bed was discovered to be far more effective than conventional methods, such as fixed film and activated sludge, in treating leachate from prehistoric landfills.

Chemical and physical treatment

Chemical and physical processes are often used to remove different pollutants and toxins from landfill leachate efficiently. The objective is to minimise the adverse effects of waste disposal on the surrounding environment while producing effluent of the appropriate quality for safe discharge or potential reuse. The processes include the reduction of toxic compounds, floating material, colloidal particles, suspended solids and colour via chemical oxidation, adsorption, flotation, air stripping or coagulation/flocculation. Chemical and physical approaches to treating landfill leachate are summarised here (Abdel-Shafy et al. 2023).

Floatation: Dissolved air flotation (DAF) physically removes suspended sediments and other tiny pollutants from wastewater. It is utilized in municipal and industrial wastewater treatment because it filters out non-settling particles. As air or gas enters the wastewater system under pressure, small bubbles adhere to particles and raise them to the top for removal. The sludge or foam is skimmed off and removed from the wastewater system. Flotation removes macromolecules, germs, fibres, colloids, humic acids, and ions from solutions, according to several studies. Combining FeCl3 coagulation with DAF was tested for treating semi-aerobic liquid-landfill leachate. RSM and CCD helped the researchers identify optimal values for all variables. All turbidity, colour, chemical oxygen requirement, and ammonia nitrogen (-N) were eliminated to maximum values. We achieved 50% turbidity reduction, 75% COD removal, 93% colour retention, and 41% (-N) retention. Overall, flow rate and pressure removed fewer pollutants. The DAF system under study’s performance and efficiency depend on these two components. These novel discoveries have already been included in commercial DAF landfill leachate treatment (Mohd et al. 2011). Post-treatment with column flotation extracted residual humic acids and non-biodegradable compounds from simulated landfill leachate (Abdel-Shafy et al. 2020). Ideally, 60% of humic acids could be removed (Dabaghian et al. 2018).

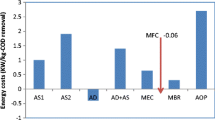

Chemical Coagulation–flocculation: The use of chemical coagulants and then flocculants to destabilise and aggregate suspended particles and colloidal debris in leachate wastewater is the chemical coagulation-flocculation process, and it is commonly used for treating wastewater. This method successfully eliminates small particles, organic compounds, and certain dissolved pollutants, making it a vital stage in water and wastewater treatment facilities. Chemical coagulation and flocculation are extensively utilised in leachate wastewater treatment and the treatment of old and stabilised landfill leachates (Assou et al. 2016). It has been used successfully as a pre-treatment to remove non-biodegradable organic contaminants or before the reverse osmosis phase. Coagulants commonly employed include ferrous sulfate, ferric chloride sulfate, ferric chloride, lime, and aluminium sulfate (Ghafari et al. 2009). It was discovered that bio-flocculants are a feasible alternative to typical inorganic coagulants, with a dose of 20 mg L−1 eliminating more than 85% of humic acid and 90% of heavy metals (Abdel-Shafy et al. 2015; Abdel-Shafy et al. 2023). Process optimisation was investigated, including assessing the pH effect and selecting the most appropriate coagulant (Abdel-Shafy et al. 2015). and the best experimental circumstances. Iron salts offered sufficient COD reductions of up to 5%, whereas aluminium salts or lime gave moderate comparable values ranging between 10 and 40% (Mojiri et al. 2013). COD reduction of up to 50% might be accomplished by increasing the floc-settling rate with either a coagulant combination or the coexistence of flocculants and coagulants (Aziz et al. 2011). Nonetheless, several drawbacks may be observed: constant sludge volume generation and increased aluminium or iron content in the liquid phase (Mojiri et al. 2013).