Abstract

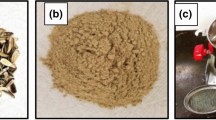

Performance evaluation of drilling fluids is essential for a successful drilling project, as they not only remove drill cuttings but also prevent undesired penetration or outflow of formation fluids by sealing off wellbore walls. However, concerns have been raised about the use of chemical additives in drilling fluids due to their toxicity and non-biodegradability. To this end, agricultural waste materials are recognized as a promising alternative as they are cost-effective, environmentally sustainable, and can be used as a substitute for lost circulation materials. Rice husk ash (RHA) has become popular as an additive due to its renewable characteristics, including its large surface area, silica content, and microporous structure. This research article explores the rheological properties of drilling fluid with RHA as a filter control medium. The results showed that increasing concentrations of RHA in the drilling mud significantly improved its rheology, particularly at higher concentrations (15 and 20 wt.%). The addition of RHA modified the filtration and rheological properties of the drilling mud, resulting in improved plastic viscosity, yield point, density, gel strength, and thixotropy. However, filter loss and mud cake thickness increased at elevated RHA concentrations. Furthermore, the pH test revealed that the mud's properties shifted toward the acidic region as the RHA concentration increased. The results indicate that RHA could be used as a sustainable and cost-effective alternative to conventional chemical additives with a positive environmental impact. This study may also provide valuable insights into the use of RHA in water-based bentonite mud and could serve as a guide for future research in the drilling industry.

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

Abbreviations

- RH:

-

Rice husk

- RHA:

-

Rice husk ash

- Si–O–Si:

-

Silicon dioxide

- TGA:

-

Thermogravimetric analysis

- FTIR:

-

Fourier-transform infrared

- XRD:

-

X-ray diffraction analysis

- SEM:

-

Scanning electron microscope analysis

- EDX:

-

Electron dispersive X-ray

References

Abaide ER, Dotto GL, Tres MV, Zabot GL, Mazutti MA (2019) Adsorption of 2–nitrophenol using rice straw and rice husks hydrolyzed by subcritical water. Bioresource Technol 284:25–35

Adebayo AR, Bageri BS (2020) A simple NMR methodology for evaluating filter cake properties and drilling fluid-induced formation damage. J Pet Explor Prod Technol 10:1643–1655

Agwu OE, Akpabio JU (2018) Using agro-waste materials as possible filter loss control agents in drilling muds:a review. J Pet Sci Eng 163:185–198

Akeke GA, Ephraim ME, Akobo I, Ukpata JO (2013) Structural properties of rice husk ash concrete. Int J Eng 3(3):8269

Al-Hameedi AT, Alkinani HH, Dunn-Norman S, Al-Alwani MA, Alshammari AF, Albazzaz HW, Al-Bazzaz WH (2019a) Proposing a new eco-friendly drilling fluid additive to enhance the filtration properties of water-based drilling fluid systems. Paper presented at the SPE Gas & Oil Technology Showcase and Conference

Al-Hameedi AT, Alkinani HH, Dunn-Norman S, Alashwak NA, Alshammari AF, Alkhamis MM, Ashammarey A (2019b) Evaluation of environmentally friendly drilling fluid additives in water-based drilling mud. Paper presented at the SPE Europec featured at EAGE Conference and Exhibition?

Al-Hameedi AT, Alkinani HH, Dunn-Norman S, Alashwak NA, Alshammari AF, Alkhamis MM, Ashammarey A (2019c) Evaluation of environmentally friendly drilling fluid additives in water-based drilling mud. Paper presented at the SPE Europec featured at 81st EAGE Conference and Exhibition

Al-Hameedi AT, Alkinani HH, Dunn-Norman S, Alashwak NA, Alshammari AF, Alkhamis MM, Alsaba MT (2019d). Environmental friendly drilling fluid additives: can food waste products be used as thinners and fluid loss control agents for drilling fluid? Paper presented at the SPE Symposium: Asia Pacific Health, Safety, Security, Environment and Social Responsibility

Al-Hameedi ATT, Alkinani HH, Dunn-Norman S, Salem E, Knickerbocker MD, Alashwak NF, Al-Bazzaz WH (2020) Laboratory study of environmentally friendly drilling fluid additives banana peel powder for modifying the drilling fluid characteristics in water-based muds. Paper presented at the International Petroleum Technology Conference

Al-Saba M, Al Fadhli A, Marafi A, Hussain A, Bander F, Al Dushaishi M (2018a) Application of nanoparticles in improving rheological properties of water based drilling fluids. Paper presented at the SPE Kingdom of Saudi Arabia Annual technical symposium and exhibition

Al-Saba M, Amadi K, Al-Hadramy K, Dushaishi M, Al-Hameedi A, Alkinani H (2018b) Experimental investigation of bio-degradable environmental friendly drilling fluid additives generated from waste. Paper presented at the SPE International Conference and Exhibition on Health, Safety, Security, Environment, and Social Responsibility

Alhazzaa M, Nutskova M (n.d.) The effect of environmentally friendly additives on the rate of lluid loss and the theological properties of the drilling fluid

Ali I, Ahmad M, Ganat TA-A (2022) Experimental study on water-based mud: investigate rheological and filtration properties using cupressus cones powder. J Pet Explor Prod Technol 1–11

Annudeep SJ (2012) Rheological properties and corrosion characteristics of drilling mud additives. Dalhousie University, Halifax, Nova Scotia, PDF

Azizi A, Ibrahim MSN, Hamid KHK, Sauki A, Ghazali NA, Mohd TAT (2013) Agarwood waste as a new fluid loss control agent in water-based drilling fluid. Int J Sci Eng 5(2):101–105

Barreno-Avila E, Moya-Moya E, Pérez-Salinas C (2022) Rice-husk fiber reinforced composite (RFRC) drilling parameters optimization using RSM based desirability function approach. Mater Today Proc 49:167–174

Biltayib BM, Rashidi M, Balhasan S, Alothman R, Kabuli MS (2018) Experimental analysis on rheological and fluid loss control of water-based mud using new additives. J Pet Gas Eng 9(3):23–31

Biwott TC, Kiprop AK, Akaranta O, Oriji B (2019) Improving the rheological properties of water based mud with moringa oleifera leaves

Chen X-G, Lv S-S, Liu S-T, Zhang P-P, Zhang A-B, Sun J, Ye Y (2012) Adsorption of methylene blue by rice hull ash. Sep Sci Technol 47(1):147–156

Culver G (1998) Drilling and well construction

Feng Y, Li X, Gray K (2018) Mudcake effects on wellbore stress and fracture initiation pressure and implications for wellbore strengthening. Pet Sci 15:319–334

Feng Z, Hongming T, Yingfeng M, Gao L, Xijin X (2009) Damage evaluation for water-based underbalanced drilling in low-permeability and tight sandstone gas reservoirs. Pet Explor Dev 36(1):113–119

Hadipramana J, Riza F, Rahman I, Loon L, Adnan S, Zaidi A (2016) Pozzolanic characterization of waste Rice husk ash (RHA) from Muar, Malaysia. Paper presented at the IOP Conference Series: Materials Science and Engineering

Henry LC, Wadsworth JA, Hansen B (2017) Visualizing a sub-salt field with image logs: image facies, mass transport complexes, and reservoir implications from Thunder Horse, Mississippi canyon, Gulf of Mexico. Search and Discovery Article 90291

Hossain SS, Roy P, Bae C-J (2021) Utilization of waste rice husk ash for sustainable geopolymer: a review. Constr Build Mater 310:125218

Igwilo KC, Okoro EE, Agwu O, Onedibe C, Ibeneme SI, Okoli N (2019) Experimental analysis of Persea Americana as filtration loss control additive for non-aqueous drilling fluid. Paper presented at the International Journal of Engineering Research in Africa

Kelvin VK, Dune K (n.d.) The effect of cassava starch and coconut fibre on rheological properties and fluid loss control of water-based drilling fluid

Loy ACM, Yusup S, Lam MK, Chin BLF, Shahbaz M, Yamamoto A (2018) The effect of industrial waste coal bottom ash as catalyst in catalytic pyrolysis of rice husk for syngas production. Energy Convers Manag 165:541–554

Luke K, Taylor H, Kalousek G (1981) Some factors affecting formation of truscottite and xonotlite at 300–350 C. Cem Concr Res 11(2):197–203

Malhotra V (1993) Fly ash, slag, silica fume, and rice husk ash in concrete: a review. Concr Int 15(4):23–28

McCosh K, Getliff J (2004) Effect of drilling fluid components on composting and the consequences for mud formulation. AADE Drilling Fluid Conference, Radisson Astrodome, Houston

Mozgawa W, Król M, Dyczek J, Deja J (2014) Investigation of the coal fly ashes using IR spectroscopy. Spectrochim Acta A Mol Biomol Spectrosc 132:889–894

Okon AN, Akpabio JU, Tugwell KW (2020) Evaluating the locally sourced materials as fluid loss control additives in water-based drilling fluid. Heliyon 6(5):e04091

Okon AN, Udoh FD, Bassey PG (2014) Evaluation of rice husk as fluid loss control additive in water-based drilling mud. Paper presented at the SPE Nigeria Annual International Conference and Exhibition

Patidar AK, Ghosh S, Thakur NK, Sharma A, Baliyan A (2021) A review and comparative analysis of effectively functionalized eco-friendly and biodegradable nanoparticle based additives for drilling muds. Mater Today Proc 57(4):1598–1604

Prasara-A J, Gheewala SH (2017) Sustainable utilization of rice husk ash from power plants: a review. J Clean Prod 167:1020–1028

Rabia H (1985) A unified prediction model for percussive and rotary drilling. Min Sci Technol 2(3):207–216

Ricky E, Mpelwa M, Wang C, Hamad B, Xu X (2022) Modified corn starch as an environmentally friendly rheology enhancer and fluid loss reducer for water-based drilling mud. SPE J 27:1064–1080. https://doi.org/10.2118/209195-PA

Silva RR, Garnica AI, Leal GL, Viana LR, Freitas JC, Barros AN (2022) Evaluation of novel microemulsion-based (O/W) drilling fluid with nonionic surfactant and shale interaction mechanisms. J Pet Sci Eng 213:110327

Torres-Carrasco M, Reinosa J, de la Rubia M, Reyes E, Peralta FA, Fernández JF (2019) Critical aspects in the handling of reactive silica in cementitious materials: Effectiveness of rice husk ash vs nano-silica in mortar dosage. Constr Build Mater 223:360–367

Vidal AV, Araujo RG, Freitas JC (2018) Sustainable cement slurry using rice husk ash for high temperature oil well. J Clean Prod 204:292–297

Wibowo WA, Cahyono RB, Budiman A (2022) Thermogravimetric analysis and kinetic study on catalytic pyrolysis of rice husk pellet using its ash as a low-cost in-situ catalyst. Int J Renew Energy Dev 11(1):207–219. https://doi.org/10.14710/ijred.2022.41887

Xie S, Jiang G, Chen M, Deng H, Xu Y (2012) Study and application of green throwing drilling fluid. Pet Sci Technol 30(5):443–452

Yalman E, Depci T, Federer-Kovacs G, Al Khalaf H (2021) A new eco-friendly and low cost additive in water-based drilling fluids. Rud-Geološko-Naft Zb 36(5):1–12

Yalman E, Federer-Kovacs G, Depci T, Al Khalaf H, Aylikci V, Aydin MG (2022) Development of novel inhibitive water-based drilling muds for oil and gas field applications. J Pet Sci Eng 210:109907

Zhang L, Wu X, Sun Y, Cai J, Lyu S (2020) Experimental study of the pomelo peel powder as novel shale inhibitor in water-based drilling fluids. Energy Explor Exploit 38(2):569–588

Acknowledgements

The authors would like to acknowledge the Coal and Sustainable Energy Research Center at NFC-IET, Multan.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Ali Raza: writing—original draft, conceptualization, writing—review and editing, and validation. Maham Hussain: conceptualization, supervision, visualization, writing—original draft, resources, validation, and funding acquisition. Nadeem Raza: writing—original draft, data curation, formal analysis, investigation, methodology, and review. Waqas Aleem: writing—original draft, data curation, formal analysis, investigation, methodology, and software. Sheraz Ahmad: conceptualization, data curation, visualization, writing—original draft, investigation, validation, and methodology. Sabih Qamar: writing—original draft, data curation, formal analysis, investigation, methodology, and software.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate and publish

Not applicable. The research does not report on or involve the use of any animal or human data or tissue.

Conflict of interest

The authors declare no conflict of interest.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Exploitation of rice husk as a fluid loss control additive in water-based drilling mud.

• Characterization of rice husk ash using SEM, EDX, BET, FTIR, and XRD.

• Evaluation of water-based bentonite drilling mud’s rheological and filtration properties.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Raza, A., Hussain, M., Raza, N. et al. Rice husk ash as a sustainable and economical alternative to chemical additives for enhanced rheology in drilling fluids. Environ Sci Pollut Res 30, 105614–105626 (2023). https://doi.org/10.1007/s11356-023-29856-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-29856-0