Abstract

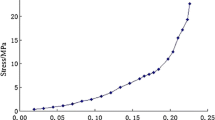

Management of solid waste and protecting the ecological balance of the region are key challenges that the coal mining industry has to face. This study evaluated the effect of solid waste backfilling mining on the overlying strata movement and surface deformation variation pattern in slice mining. The mechanical characteristics of different cemented paste backfills (CPB) were compared. The CPB specimens were made of coal gangue and cement with or without the addition of fly ash. The experiments showed that the mechanical strength of the CPBs made of coal gangue and cement increased dramatically. A numerical simulation was then performed to analyze the variation patterns of the overlying strata displacement and surrounding rock stress distribution before and after filling the 3lower and 3upper coal seams with CPB. The CPBs reduced the movement of the surface by 95.1% and 95% during the mining of the 3lower and 3upper coal seams, respectively. Finally, we used a mining-induced subsidence prediction and analysis system to predict the influence of the 3lower and 3upper coal seams on the ground surface subsidence. It was found that the ground surface subsidence induced by CPB mining was 1/20 that of the cumulative ground surface subsidence caused by caving mining. CPB mining could effectively control the ground surface subsidence caused by multi-slice mining of the thick coal seam, offering protection for buildings above the ground. Our research provides theoretical and technical support for coal mining under buildings subjected to similar conditions.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Change history

07 February 2024

A Correction to this paper has been published: https://doi.org/10.1007/s11356-024-32002-z

References

Adibee N, Osanloo M, Rahmanpour M (2013) Adverse effects of coal mine waste dumps on the environment and their management. Environ Earth Sci 70:1581–1592

Behera SK, Mishra DP, Prashant S, Mishra K, Mandal Sujit K, Ghosh CN, Ritesh K, Mandal Phanil K (2021) Utilization of mill tailings, fly ash and slag as mine paste backfill material: review and future perspective. (309):125120

Bian ZF, Miao XX, Lei SG, Chen SE, Wang WF (2012) The challenges of reusing mining and mineral processing wastes. Science 337(6095):702–703

BP (2020) Statistical review of world energy. British Petroleum (BP), London

Cavusoglu I, Yilmaz E, Yilmaz AO (2021) Sodium silicate effect on setting properties, strength behavior and microstructure of cemented coal fly ash backfill. Powder Technol 384:17–28

Deng XJ, Zhang JX, Zhou N, de Wit B, Wang CT (2017) Upward slicing longwall-roadway cemented backfilling technology for mining an extra-thick coal seam located under aquifers: a case study. Environ Earth Sci 23(76):789

Dong SC, Samsonov S, Yin HW, Yao SP, Xu C (2015) Spatio-temporal analysis of ground subsidence due to underground coal mining in Huainan coalfield China. Environ Earth Sci 73(9):5523–5534

Fang K, Fall M (2020) Shear behavior of the interface between rock and cemented backfill: effect of curing stress, drainage condition and backfilling rate. Rock Mech Rock Eng 1(53):325–336

Hu B, Guo W (2018) Mining subsidence area status, syntheses governance model and governance recommendation. Coal Min Technol 23(02):1–4

Jiang HQ, Han J, Li Y, Yilmaz E, Sun Q, Liu J (2020) Relationship between ultrasonic pulse velocity and uniaxial compressive strength for cemented paste backfill with alkali-activated slag. Nondestruc Test Eval 35(4):359–377

Ju Y, Zhu Y, Xie HP, Nie XD, Zhang Y, Lu C, Gao F (2019) Fluidized mining and in-situ transformation of deep underground coal resources: a novel approach to ensuring safe, environmentally friendly, low-carbon, and clean utilization. Int J Coal Sci Technol 6:184–196

Kou YP, Jiang HQ, Ren L, Yilmaz E, Li YH (2020) Rheological properties of cemented paste backfill with alkali-activated slag. Minerals 10(3):288

Lin BQ, Liu JH (2010) Estimating coal production peak and trends of coal imports in China. Energy Policy 38(1):512–519

Lin H, Yang R, Bin Lu, Li YL, Fang SZ, Fan ZY, Li ZZ (2021) Overlying strata movement law of continuous mining and continuous backfilling cemented-fill mining. Environ Earth Sci 20(80):688

Liu L, Xin J, Qi C, Jia H, Song KI (2020a) Experimental investigation of mechanical, hydration, microstructure and electrical properties of cemented paste backfill Constr. Build Mater 263:120137

Liu JG, Li XW, He T et al (2020b) Application status and development of backfilling mining in coal mines in china. J China Coal Soc 45(01):141–150

Lu B, Li YL, Fang SZ, Lin Hai, Zhu Y (2021) Cemented backfilling mining technology for gently inclined coal seams using a continuous mining and continuous backfilling method. Shock Vibration 6652309

Ma D, Duan HY, Liu JF, Li XB, Zhou ZL (2019) The role of gangue on the mitigation of mining-induced hazards and environmental pollution: an experimental investigation. Sci Total Environ 664:436–448

Ma D, Zhang JX, Duan HY, Huang YL, Li M, Sun Q, Zhou N (2021) Reutilization of gangue wastes in underground backfilling mining: overburden aquifer protection. Chemosphere 264:128400

Marschalko M, Bednárik M, Yilmaz I, Bouchal T, Kubečka K (2012) Evaluation of subsidence due to underground coal mining: an example from the czech republic. Bull Eng Geol Environ 71:105–111

Helinski M, Martin F, Andy F (2010) Coupled two-dimensional finite element modelling of mine backfilling with cemented tailings. Can Geotech J 11(47):1187–1200

Miao XX, Ju F, Huang YL et al (2015) New progress and prospect of backfilling mining theory and technology. J China Univ Min Technol 44(03):391–399

National Bureau of Statistics (2021) Statistical bulletin on national economic and social development 2021. 410A04–0402–202202–0006

Ouattara D, Yahia A, Mbonimpa M, Belem T (2017) Effects of superplasticizer on rheological properties of cemented paste backfills Int. J Miner Process 161:28–40

Rošer J, Potočnik D, Vulić M (2018) Analysis of dynamic surface subsidence at the underground coal mining site in velenje slovenia through modified sigmoidal function. Minerals 8(2):74

Shi J, Huang W, Han H, Xu C (2021) Pollution control of wastewater from the coal chemical industry in China: environmental management policy and technical standards. Renew Sustain Energy Rev 143 (4)

Tong Q, Che YL (2014) Design and application of gangue vertical feeding system in mine backfilling mining. Coal Sci Technol 42(08):19–21

Tu SH, Hao DY, Li WL et al (2020) Construction of selective mining theory and technical system of “mining, dressing and charging + X” integrated mine. J Min Saf Eng 37(01):81–92

Wang FT, Ma Q, Li G, Wu CG, Guo GL (2018) Overlying strata movement laws induced by longwall mining of deep buried coal seam with superhigh-water material backfilling technology. Adv Civ Eng 2018:4306239

Wang A, Cao S, Yilmaz E (2022) Influence of types and contents of nano cellulose materials as reinforcement on stability performance of cementitious tailings backfill. Constr Build Mater 344:128179

Xue GL, Yilmaz E (2022) Strength, acoustic, and fractal behavior of fiber reinforced cemented tailings backfill subjected to triaxial compression loads. Constr Build Mater 338:127667

Zhang JX, Zhang Q, Sun Q, Gao R, Germain D, Abro S (2015) Surface subsidence control theory and application to backfill coal mining technology. Environ Earth Sci 74(2):1439–1448

Zhang JX, Zhang Q, Spearing AJS, Miao XX, Guo S, Sun Q (2017) Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int J Min Sci Technol 27(1):17–27

Zhang JX, Zhang Q, Ju F et al (2018) Theory and technology of green mining of deep coal resources. J China Coal Soc 43(02):377–389

Zhang JX, Zhang Q, Ju F et al (2019) Green mining technology system and engineering practice of “mining, dressing and charging + X” in coal mine. J China Coal Soc 44(01):64–73

Zhang S, Yang L, Ren F, Qiu J, Ding H (2020) Rheological and mechanical properties of cemented foam backfill: effect of mineral admixture type and dosage. Cem Concr Compos 112:103689

Zhang J, Zhang A, Huang C, Yu H, Zhou C (2021) Characterising the resilient behaviour of pavement subgrade with construction and demolition waste under freeze-thaw cycles. J Clean Prod 300:126702

Zhang H, Cao S, Yilmaz E (2022) Influence of 3D-printed polymer structures on dynamic splitting and crack propagation behavior of cementitious tailings backfill. Constr Build Mater 343:128137

Zhou N, Yao YN, Song WJ et al (2020) Present situation and prospect of coal gangue treatment technology. J Mining Safety Eng 37(01):136–146

Zhu XJ, Zha F, Guo GL, Zhang PF, Cheng H, Liu H, Yang XY (2021) Subsidence control design method and application to backfill-strip mining technology. Adv Civ Eng 2021:5177174

Zhu CL, Zhang JX, Li M, He ZW, Wang YY (2022) Lan YW (2022) Effect mechanism of strata breakage evolution on stope deformation in extra-thick coal seams. Alex Eng J 61:5003–5020

Funding

This research were funded by the National Natural Science Foundation of China [grant number 51725403].

Author information

Authors and Affiliations

Contributions

Cunli Zhu: methodology, visualization, formal analysis, investigation, and writing—original draft. Jixiong Zhang: supervision. Taheri, Abbas: writing—review and editing. Nan Zhou: writing—review and editing. Zejun Li and Meng Li: reviewed the final paper and made important suggestions and recommendations for paper.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Shimin Liu

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: The correct presentation of the 3rd Author name is Abbas Taheri.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, C., Zhang, J., Taheri, A. et al. Control effect of coal mining solid-waste backfill for ground surface movement in slice mining: a case study of the Nantun Coal Mine. Environ Sci Pollut Res 30, 27270–27288 (2023). https://doi.org/10.1007/s11356-022-24164-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-24164-5