Abstract

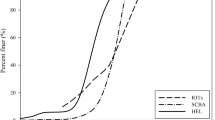

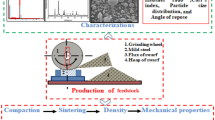

The main chemical component of high-silicon iron tailings (HSITs) is SiO2; HSITs also include some oxides such as Al2O3 and CaO. Mechanical activation can reduce the particle size of HSITs and enhance their pozzolanic activity such that they can be used as a type of mineral admixture for cement-based materials (CBMs). This study aims to investigate the mechanical activation (ultrafine grinding) effects of HSITs, including physical and crystallization structure effects. The particle distribution, specific surface area, density, and solubility of HSITs were tested using laser particle size analysis and other routine physical testing methods. Their crystal structures were analyzed using X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), and differential scanning calorimetry-thermogravimetry (DSC-TG). Grinding reduced the particle size of HSIT particles and increased their specific surface area, wherein the minimum D50 was 5.75 μm, the maximum specific surface area was 7608 m2/kg, and the corresponding grinding time was 3.5 h. With an increase in grinding time, the solubility showed an increasing trend; however, the density showed a decreasing trend. The change was fast before 3.5 h or 4 h and then slowed down, but the final solubility was still higher than its initial level, while the final density was still lower than its initial level. Grinding reduced the degree of crystallization of the minerals in HSITs and increased the microscopic strain and disorder of its crystal structure. These changes were significant for a grinding time of 0–3.5 h, after which the changes tended to be slow. The symmetry and integrity of the SiO2 structure decreased with grinding. The activity index of the HSIT powder was higher than 0.6. Ultrafine grinding improves the particle size distribution of HSITs and reduces the crystallinity of their main minerals, which in turn increases their chemical reactivity. It can be said that ultra-finely ground HSIT powder is pozzolanic and can be used as a mineral admixture for CBMs, and its grinding limit can be inferred to be 3.5 h.

Similar content being viewed by others

Data Availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- HSITs:

-

high-silicon iron tailings

- CBMs:

-

cement-based materials

- DPI:

-

diffraction peak intensity

- FWHM:

-

full width at half maximum

- XRD:

-

X-ray diffraction

- FTIR:

-

Fourier transform infrared spectroscopy

- DSC-TG:

-

differential scanning calorimetry-thermogravimetry

References

Akinyemi BA, Alabab PA, Rashedi A (2022) Selected performance of alkali-activated mine tailings as cementitious composites: a review. Journal of Building. Engineering 50

Alex TC, Rakesh Kumar SK, Roy SPM (2014) Mechanically induced reactivity of gibbsite: part 1. Planetary milling. Powder Technol 264:105–113

Allahverdi A, Mahinroosta M (2013) Mechanical activation of chemically activated high phosphorous slag content cement. Powder Technol 245:182–188

Boldyrev VV (2006) Mechanochemistry and mechanical activation of solids. Russian Chem Rev 75(3):177–189

Chen Z, Shengyong L, Tang M, Ding J, Buekens A, Yang J, Qiu Q, Yan J (2019) Mechanical activation of fly ash from MSWI for utilization in cementitious materials. Waste Manage 88:182–190

Chen B, Pang L, Zhou Z, Chang Q, Peng F (2022) Study on the activation mechanism and hydration properties of gold tailings activated by mechanical-chemical-thermal coupling. J Build Eng 48

Chen X, Zhang D, Cheng S, Xiong X, Zhao C, Wang X, Qiaoyun W, Bai X (2022) Sustainable reuse of ceramic waste powder as a supplementary cementitious material in recycled aggregate concrete: mechanical properties, durability and microstructure assessment. J Build Eng 52

Cheng Y, Huang F, Li R, Li G, Wei J (2016) Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete. Construct Build Mater 118:164–170

Cheng Y, Huang F, Qi S, Li W, Li R, Li G (2020) Durability of concrete incorporated with siliceous iron tailings. Construct Build Mater 242

Cheng Y-h, Yang S-h, Zang J-y, Sun X-h (2022) Test research on hydration process of cement-iron tailings powder composite cementitious materials. Powder Technol 399

de Magalhaes LF, França S, dos Santos Oliveira a M, Peixoto RAF, Bessa c SAL, da Silva Bezerra AC (2020) Iron ore tailings as a supplementary cementitious material in the production of pigmented cements. J Clean Prod 274:123260

Ermolovich EA, Ermolovich OV (2016) Effects of mechanical activation on the structural changes and microstructural characteristics of the components of ferruginous quartzite beneficiation tailings. Intl J Mining Sci Technol 26:1043–1049

Ferreiro S, Frías M, Vigil de la Villa R, Sánchez de Rojas MI (2013) The influence of thermal activation of art paper sludge on the technical properties of blended Portland cements. Cement Concrete Compos 37:136–142

Han F, Luo A, Liu J, Zhang Z (2020) Properties of high-volume iron tailing powder concrete under different curing conditions. Construct Build Mater 241

Han F, Zhang H, Liu J, Song S (2022) Influence of iron tailing powder on properties of concrete with fly ash. Powder Technol 398

Hao B-h (2001) IR analysis of the chemical bond changes in quartz powder during superfine milling. Mining Metall Eng 21(2001-04):64–66 (in Chinese)

Jiang S, Chen T, Zhang J, Duan LX, Yan B (2022) Roasted modified lead-zinc tailings using alkali as activator and its mitigation of Cd contaminated: characteristics and mechanisms. Chemosphere 297:134029

Kitamura M, Senna M (2001) Electrorheological properties of mechanically activated gibbsite. Intl J Inorg Mater 3:563–567

Kiventera J, Lancellotti I, Catauro M, Poggetto FD, Leonelli C, Illikainen M (2018) Alkali activation as new option for gold mine tailings inertization. J Clean Prod 187:76e84

Li J, Hitch M (2017) Structural and chemical changes in mine waste mechanically-activated in various milling environments. Powder Technol 308:13–19

Li J, Ni W, Wang X, Zhu S, Wei X, Jiang F, Zeng H, Hitch M (2022) Mechanical activation of medium basicity steel slag under dry condition for carbonation curing. J Build Eng 50

Lv X, Lin Y, Chen X, Shi Y, Liang R, Wang R, Peng Z (2021) Environmental impact, durability performance, and interfacial transition zone of iron ore tailings utilized as dam concrete aggregates. J Clean Prod 292

Lv Z, Jiang A, Liang B (2022) Development of eco-efficiency concrete containing diatomite and iron ore tailings: mechanical properties and strength prediction using deep learning. Construct Build Mater 327

Perumal P, Niu H, Kiventera J, Kinnunen P, Illikainen M (2020) Upcycling of mechanically treated silicate mine tailings as alkali activated binders. Minerals Eng 158

Perumal P, Kiventerä J, Illikainen M (2021) Influence of alkali source on properties of alkali activated silicate tailings. Mater Chem Phys 271:12493213

Pourghahramani P, Pålson B, Forssberg E (2008) Multivariate projection and analysis of microstructural characteristics of mechanically activated hematite in different grinding mills. Intl J Mineral Process 87:73–82

Purushotham E, Gopi N (2014) Krishna. Effect of particle size and lattice strain on Debye–Waller factors of Fe3C nanoparticles. Bull Mater Sci 37:773–778

Purushotham E, Krishna NG (2015) X-Ray Determination of crystallite size and effect of lattice strain on the Debye-Waller Factors of Ni nano powders using high energy ball mill. Chemistry and Materials Research 7(2015-02) 1-6

Saedi A, Jamshidi-Zanjani A, Darban AK (2020) A review on different methods of activating tailings to improve their cementitious property as cemented paste and reusability. J Environ Manage 270

Sahraoui T, Belhouchet H, Heraiz M, Brihi N, Guermat A (2016) The effects of mechanical activation on the sintering of mullite produced from kaolin and aluminum powder. Ceram Intl 42:12185–12193

Sajedi F (2012) Mechanical activation of cement–slag mortars. Construct Build Mater 26:41–48

Sajedi F, Razak HA (2011) Effects of thermal and mechanical activation methods on compressive strength of ordinary Portland cement–slag mortar. Mater Design 32:984–995

Sasikumar C, Srikanth S, Mukhopadhyay NK, Mehrotra SP (2009) Energetics of mechanical activation–application to ilmenite. Minerals Eng 22:572–574

Souri A, Golestani-Fard F, Naghizadeh R, Veiseh S (2015) An investigation on pozzolanic activity of Iranian kaolins obtained by thermal treatment. Appl Clay Sci 103:34–39

Tõnsuaadu K, Kaljuvee T, Petkova V, Traksmaa R, Bender V, Kirsimäe K (2011) Intl J Mineral Process 100:104–109

Tushar Q, Bhuiyan MA, Zhang G, Maqsood T (2022) Tamina Tasmin. Application of a harmonized life cycle assessment method for supplementary cementitious materials in structural concrete. Construct Build Mater 316

Vargas F, Lopez M (2018) Development of a new supplementary cementitious material from the activation of copper tailings: mechanical performance and analysis of factors. J Clean Prod 182:427–436

Wang Z, Chu H, Wang J, Feng E, Zhang Y, Lyu X (2022) Mechanical activation of siliceous tailings and its application as cement admixtures. Minerals Eng 177

Wei B, Zhang Y, Bao S (2017) Preparation of geopolymers from vanadium tailings by mechanical activation. Construct Build Mater 145:236–242

Wen B-J, Lu L (2006) Study of mechanochemistry activate the steel slag. Bull Chin Ceram Soc 25(2006-04):89-92+136 (in Chinese)

Wu R, Liu J (2018). Experimental study on the concrete with compound. Admixture of iron tailings and slag powder under low cement clinker system. Adv Mater Sci Eng 9816923

Wu C-R, Hong Z-Q, Yin Y-H, Kou S-C (2020) Mechanical activated waste magnetite tailing as pozzolanic material substitute for cement in the preparation of cement products. Construct Build Mater 252

Xu Y, Jiang T, Zhoua M, Wen J, Chen W, Xue X (2017) Effects of mechanical activation on physicochemical properties and alkaline leaching of boron concentrate. Hydrometallurgy 173:32–34

Yang H, Zhao S, Wang G, Zhang Q, Jin Z, Tong L, Chen G, Qiu X (2022) Mechanical activation modes of chalcopyrite concentrate and relationship between microstructure and leaching efficiency. Hydrometallurgy 207

Yao G, Wang Q, Wang Z, Wang J, Lyu X (2020) Activation of hydration properties of iron ore tailings and their application as supplementary cementitious materials in cement. Powder Technol 360:863–871

Yu R, Dong E, Shui Z, Qian D, Fan D, Wang J, Leng Y, Liu K, Chen Z (2022) Advanced utilization of molybdenum tailings in producing ultra high-performance composites based on a green activation strategy. Construct Build Mater 330

Zhang W, Gu X, Qiu J, Liu J, Zhao Y, Li X (2020) Effects of iron ore tailings on the compressive strength and permeability of ultra-high performance concrete. Construct Build Mater 260

Zhang Z, Zhang Z, Yin S, Linwen Y (2020) Utilization of iron tailings sand as an environmentally friendly alternative to natural river sand in high-strength concrete: shrinkage characterization and mitigation strategies. Materials 13:5614

Zhang N, Tang B, Liu X (2021) Cementitious activity of iron ore tailing and its utilization in cementitious materials, bricks and concrete. Construct Build Mater 288

Zhang M, Li K, Ni W, Zhang S, Liu Z, Wang K, Wei X, Yang Y (2022) Preparation of mine backfilling from steel slag-based non-clinker combined with ultra-fine tailing. Construct Build Mater 320

Zhang N, Hedayat A, Figuero L, Steirer KX, Li H, Sosa HGB, Bernal RPH, Tupa N, Morales IY, Loza RSC (2022) Experimental studies on the durability and leaching properties of alkali-activated tailings subjected to different environmental conditions. Cement Concrete Compos 130:104531

Zielinski PA, Van Neste A, Akolekar DB, Kaliaguine S (1995) Effect of high-energy ball milling on the structural stability, surface and catalytic properties of small-, medium- and large-pore zeolites. Microporous Mater 5:123–133

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 51874076)

Author information

Authors and Affiliations

Contributions

Conceptualization, Yun-hong Cheng; methodology, Yun-hong Cheng and Bai-qiang Tong; formal analysis and investigation, Yun-hong Cheng, Bai-qiang Tong, Xiao-hui Sun, and Jing-yu Zhang; writing — original draft preparation, Yun-hong Cheng; writing — review and editing, Yun-hong Cheng; funding acquisition, Yun-hong Cheng; resources, Bai-qiang Tong, Xiao-hui Sun, Jing-yu Zhang; supervision, Yun-hong Cheng.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: George Z. Kyzas

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, Yh., Tong, Bq., Sun, Xh. et al. On the grinding effects of high-silicon iron tailings. Environ Sci Pollut Res 29, 73326–73340 (2022). https://doi.org/10.1007/s11356-022-20964-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-20964-x