Abstract

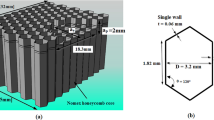

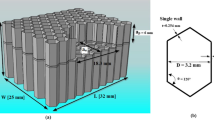

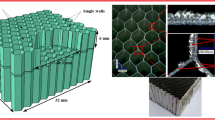

The machining of Nomex honeycomb structures represents a technical and scientific barrier for aeronautical applications. The difficulties encountered during the machining of this type of material are linked to the low density of Nomex paper, and to the low thickness of the walls forming the honeycomb cells of this type of structure. In this work, a finite element calculation code “ABAQUS`- EXPLICIT” was used to optimize and analyze the machining by milling of Nomex honeycomb structures. The main objective of this work is to study the influence of the machining conditions on the cutting forces, and the morphology of the chips.

Similar content being viewed by others

Data availability

Not applicable

References

Ahmad S, Zhang J, Feng P, Yu D, Wu Z, Ma K (2020) Processing Technologies for Nomex Honeycomb Composites (NHCs): a critical review. Compos Struct 250:112545. https://doi.org/10.1016/j.compstruct.2020.112545

Cognard P (2003) Collage des composites. Ed. Techniques Ingénieur.

Davim JP, Reis P, Antonio CC (2004) A study on milling of glass fiber reinforced plastics manufactured by hand-lay up using statistical analysis (ANOVA). Compos Struct 64:493–500. https://doi.org/10.1016/j.compstruct.2003.09.054

Dolatabadi F (2010) Étude de l'influence du mode de lubrification sur les performances d'usinage du composite à matrices d'aluminium, Doctoral dissertation, École Polytechnique de Montréal.

Fang L (2013) Development of ultrasonic milling circular tool made of NOMEX cellular materials.

Fischer S, Drechsler K, Kilchert S, Johnson A (2009) Mechanical tests for foldcore base material properties. Compos Part A 40:1941–1952. https://doi.org/10.1016/j.compositesa.2009.03.005

Foo CC, Chai GB, Seah LK (2007) Mechanical properties of Nomex material and Nomex honeycomb structure. Compos Struct 80:588–594. https://doi.org/10.1016/j.compstruct.2006.07.010

Haddad M (2013) Study of the impact of machining faults in composite structures by trimming on their mechanical behavior, Doctoral dissertation, University of Toulouse III - Paul Sabatier,

Hirayama A (2004) U.S. Patent No. 6,740,268. Washington, DC: U.S. Patent and Trademark Office.

Jaafar M (2018) Étude expérimentale et simulation numérique de l’usinage des matériaux en nids d’abeilles : application au fraisage des structures Nomex® et Aluminium. Doctoral dissertation, Université de Lorraine.

Jaafar M, Atlati S, Makich H, Nouari M, Moufki A, Julliere B (2017) A 3D FE modeling of machining process of Nomex® honeycomb core: influence of the cell structure behaviour and specific tool geometry. Procedia Cirp 58:505–510. https://doi.org/10.1016/j.procir.2017.03.255

Jenarthanan MP, Jeyapaul R (2013) Optimisation of machining parameters on milling of GFRP composites by desirability function analysis using Taguchi method. Int J Eng Sci Technol 5:22–36. https://doi.org/10.4314/ijest.v5i4.3

Karpat Y, Bahtiyar O, Değer B (2012) Mechanistic force modeling for milling of unidirectional carbon fiber reinforced polymer laminates. Int J Mach Tools Manuf 56:79–93. https://doi.org/10.1016/j.ijmachtools.2012.01.001

Kilchert S (2013) Nonlinear finite element modelling of degradation and failure in folded core composite sandwich structures.

Kim G, Sterkenburg R, Tsutsui W (2018) Investigating the effects of fluid intrusion on Nomex® honeycomb sandwich structures with carbon fiber facesheets. Compos Struct 206:535–549. https://doi.org/10.1016/j.compstruct.2018.08.054

Norvillie H.S, Tibor E (1968) U.S. Patent No. 3,413,708. Washington, DC: U.S. Patent and Trademark Office.

Roy R, Park SJ, Kweon JH, Choi JH (2014) Characterization of Nomex honeycomb core constituent material mechanical properties. Compos Struct 117:255–266. https://doi.org/10.1016/j.compstruct.2014.06.033

Seemann R, Krause D (2014) Numerical modelling of nomex honeycomb cores for detailed analyses of sandwich panel joints. In 11th World Congress on Computational Mechanics (WCCM XI).

Sun CT (1996) Comparative evaluation of failure analysis methods for composite laminates (No. DOT/FAA/AR-95/109).

Voß R, Henerichs M, Kuster F, Wegener K (2014) Chip root analysis after machining carbon fiber reinforced plastics (CFRP) at different fiber orientations. Procedia CIRP 14:217–222. https://doi.org/10.1016/j.procir.2014.03.013

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Part I. Int J Mach Tools Manuf 35:1623–1638. https://doi.org/10.1016/0890-6955(95)00014-O

Xiang D, Wu B, Yao Y, Liu Z, Feng H (2019) Ultrasonic longitudinal-torsional vibration-assisted cutting of Nomex® honeycomb-core composites. Int J Adv Manuf Technol 100:1521–1530. https://doi.org/10.1007/s00170-018-2810-3

Xie S, Wang H, Yang C, Zhou H, Feng Z (2020) Mechanical properties of combined structures of stacked multilayer Nomex® honeycombs. Thin-Walled Struct 151:106–729. https://doi.org/10.1016/j.tws.2020.106729

Yaozhi X (2019) Study on cutting tool design and processing technology of ultrasonic-assisted cutting of honeycomb composites. Dissertation, Tsinghua University, Beijing, China,

Zarrouk T, Salhi JE, Atlati S, Nouari M, Salhi M, Salhi (2020) The influence of machining conditions on the milling operations of nomex honeycomb structure. PalArch's J Archaeol of Egypt/Egyptol 17(6):11008–11018

Zarrouk T, Salhi JE, Atlati S, Nouari M, Salhi M, Salhi N (2021) Study on the behavior law when milling the material of the Nomex honeycomb core. Mater Today Proceed. https://doi.org/10.1016/j.matpr.2021.02.110

Author information

Authors and Affiliations

Contributions

TZ performed, analyzed, and interpreted data and results. JES was a major contributor in writing the manuscript. SA analyzed and interpreted data and results. MN was a major contributor in writing the manuscript. MS analyzed and interpreted data and results. NS analyzed and interpreted data and results.

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zarrouk, T., Salhi, JE., Atlati, S. et al. Modeling and numerical simulation of the chip formation process when machining Nomex. Environ Sci Pollut Res 29, 98–105 (2022). https://doi.org/10.1007/s11356-021-13736-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-13736-6