Abstract

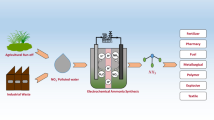

Membrane separation processes are being currently applied to produce drinking water from water contaminated with nitrate. The overall process generates a brine with high nitrate/nitrite concentration that is usually send back to a conventional wastewater treatment plant. Catalytic processes to nitrate reduction are being studied, but the main goal of achieving a high selectivity to nitrogen production is still a matter of research. In this work, a two-step process was evaluated, aiming to verify the best combination of operational parameters to efficiently reduce nitrate to nitrogen. In the first step, the nitrate was reduced to nitrite by electroreduction, applying a copper electrode and different cell potentials. A second step of the process was carried out by reducing the generated nitrite with a catalytic process by hydrogenation. The results showed that the highest nitrate reduction (89%) occurred when a cell potential of 11 V was applied. In this condition, the nitrite ion was generated with all experimental conditions evaluated. Then, to reduce the nitrite ion formed by catalytic reduction, activated carbon fibers (ACF) and powder γ-alumina (γ-Al2O3) were tested as supports for palladium (Pd). With both catalysts, the total nitrite conversion was obtained, being the selectivity to gaseous compounds 94% and 97% for Pd/Al2O3 and Pd/ACF, respectively. Considering the results obtained, a two-stage treatment setup to brine denitrification may be proposed. With electrochemistry, an operating condition was achieved in which ammonium production can be controlled to very low values, but the reduction is predominant to nitrite. With the second step, all nitrite is converted to nitrogen gas and just 3% of ammonium is produced with the most selective catalyst. The main novelty of this work is associated to the use of a two-stage process enabling 89% of nitrate reduction and 100% of nitrite reduction.

Similar content being viewed by others

References

Banasiak LJ, Kruttschnitt TW, Schäfer AI (2007) Desalination using electrodialysis as a function of voltage and salt concentration. Desalination 205:38–46. https://doi.org/10.1016/j.desal.2006.04.038

Barrabés N, Sá J (2011) Catalytic nitrate removal from water, past, present and future perspectives. Appl Catal B 104:1–5. https://doi.org/10.1016/j.apcatb.2011.03.011

Beltrame TF, Coelho V, Marder L, Ferreira JZ, Marchesini FA, Bernardes AM (2017) Effect of operational parameters and Pd/In catalyst in the reduction of nitrate using copper electrode. Environ Technol 39:2835–2847. https://doi.org/10.1080/09593330.2017.1367422

Bernardes AM, Dalla Costa RF, Fallavena VLV, Rodrigues MAS, Trevisan MD, Ferreira JZ (2000) Electrochemistry as a clean technology for the treatment of effluents: the application of electrodialysis. Met Finish 98(52–58):114

Bi J, Peng C, Xu H, Ahmed A-S (2011) Removal of nitrate from groundwater using the technology of electrodialysis and electrodeionization. Desalination and Water Treat 34:394–401. https://doi.org/10.5004/dwt.2011.2891

Bittencourt SD, Marder L, Benvenuti T, Ferreira JZ, Bernardes AM (2017) Analysis of different current density conditions in the electrodialysis of zinc electroplating process solution. Sep Sci Technol 52:2079–2089. https://doi.org/10.1080/01496395.2017.1310896

Bosko ML, Marchesini FA, Cornaglia LM, Miró EE (2011) Controlled Pd deposition on carbon fibers by electroless plating for the reduction of nitrite in water. Catal Commun 16:189–193. https://doi.org/10.1016/j.catcom.2011.09.034

Bosko ML, Rodrigues MAS, Ferreira JZ, Miró EE, Bernardes AM (2014) Nitrate reduction of brines from water desalination plants by membrane electrolysis. J MembrSci 451:276–284. https://doi.org/10.1016/j.memsci.2013.10.004

Bouzek K, Paidar M, Sadilkova A, Bergmann H (2001) Electrochemical reduction of nitrate in weakly alkaline solutions. J Appl Electrochem 31:1185–1193

Cheikh A, Grib H, Drouiche N, Abdi N, Lounici H, Mameri N (2013) Water denitrification by a hybrid process combining a new bioreactor and conventional electrodialysis. Chem Eng Process 63:1–6

Cheng H, Scott K, Christensen PA (2005) Application of a solid polymer electrolyte reactor to remove nitrate ions from wastewater. J Appl Electrochem 35:551–560

Chinthaginjala JK, Lefferts L (2010) Support effect on selectivity of nitrite reduction in water. Appl Catal B 101:144–149. https://doi.org/10.1016/j.apcatb.2010.09.023

Choi E, Park K, Lee H, Cho M, Ahn S (2013) Formic acid as an alternative reducing agent for the catalytic nitrate reduction in aqueous media. J Environ Sci 25:1696–1702. https://doi.org/10.1016/S1001-0742(12)60226-5

Cobo M, Quintero A, de Correa CM (2008) Liquid phase dioxin hydrodechlorination over Pd/γ–Al2O3. Catal Today 133–135:509–519. https://doi.org/10.1016/j.cattod.2007.12.020

de Groot M, Koper MT (2004) The influence of nitrate concentration and acidity on the electrocatalytic reduction of nitrate on platinum. J Electroanal Chem 562:81–94. https://doi.org/10.1016/j.jelechem.2003.08.011

De Lucas A, Rodríguez L, Villaseñor J, Fernández FJ (2005) Denitrification potential of industrial wastewaters. Water Res 39:3715–3726. https://doi.org/10.1016/j.watres.2005.06.024

Deganello F, Liotta L, Macaluso A, Venezia A, Deganello G (2000) Catalytic reduction of nitrates and nitrites in water solution on pumice-supported Pd–Cu catalysts. Appl Catal B 24:265–273. https://doi.org/10.1016/S0926-3373(99)00109-5

Devard A, Ulla MA, Marchesini FA (2013) Synthesis of Pd/Al2O3 coating onto a cordierite monolith and its application to nitrite reduction in water. Catal Commun 34:26–29. https://doi.org/10.1016/j.catcom.2013.01.005

Ding J, Li W, Zhao Q-L, Wang K, Zheng Z, Gao Y-Z (2015) Electroreduction of nitrate in water: role of cathode and cell configuration. Chem Eng J 271:252–259. https://doi.org/10.1016/j.cej.2015.03.001

Gao Z, Zhang Y, Li D, Werth CJ, Zhang Y, Zhou X (2015) Highly active Pd–In/mesoporous alumina catalyst for nitrate reduction. J Hazard Mater 286:425–431. https://doi.org/10.1016/j.jhazmat.2015.01.005

Garcia-Segura S, Lanzarini-Lopes M, Hristovski K, Westerhoff P (2018) Electrocatalytic reduction of nitrate: fundamentals to full-scale water treatment applications. Appl Catal B 236:546–568. https://doi.org/10.1016/j.apcatb.2018.05.041

Guo L, Lv T, He K, Wu S, Dong X, Dong R (2017) Removal of organic matter, nitrogen and faecal indicators from diluted anaerobically digested slurry using tidal flow constructed wetlands. Environ Sci Pollut Res 24:5486–5496. https://doi.org/10.1007/s11356-016-8297-2

Hell F, Lahnsteiner J, Frischherz H, Baumgartner G (1998) Experience with full-scale electrodialysis for nitrate and hardness removal. Desalination 117:173–180

Jaworski MA, Lick ID, Siri GJ, Casella ML (2014) ZrO2-modified Al2O3-supported PdCu catalysts for the water denitrification reaction. Appl Catal B 156–157:53–61. https://doi.org/10.1016/j.apcatb.2014.02.048

Jaworski MA, Vetere V, Bideberripe HP, Siri GJ, Casella ML (2013) Structural aspects of PtSn/γ-Al2O3 catalysts prepared through surface-controlled reactions: Behavior in the water denitrification reaction. Appl Catal A 453:227–234. https://doi.org/10.1016/j.apcata.2012.12.034

Jung S, Bae S, Lee W (2014) Development of Pd-Cu/Hematite catalyst for selective nitrate reduction. Environ Sci Technol 48:9651–9658

Kapoor A, Viraraghavan T (1997) Nitrate removal from drinking water. J Environ Eng 123:371–380

Katsounaros I, Ipsakis D, Polatides C, Kyriacou G (2006) Efficient electrochemical reduction of nitrate to nitrogen on tin cathode at very high cathodic potentials. Electrochim Acta 52:1329–1338. https://doi.org/10.1016/j.electacta.2006.07.034

Kim J, Kelly MJ, Lamb HH, Roberts GW, Kiserow DJ (2008) Characterization of palladium (Pd) on alumina catalysts prepared using liquid carbon dioxide. The J Phys Chem C 112:10446–10452. https://doi.org/10.1021/jp711495n

Kim YJ, Lee K, Cha HY, Yoo KM, Jeon CS, Kim HJ, Kim D, Park KY (2015) Electrolytic denitrification with an ion-exchange membrane in groundwater. Water Sci Technol 15:1320–1325. https://doi.org/10.2166/ws.2015.079

Kizito S, Lv T, Wua S, Ajmal Z, Luo H, Dong R (2017) Treatment of anaerobic digested effluent in biochar-packed vertical flow constructed wetland columns: Role of media and tidal operation. Sci Total Environ 592:197–205. https://doi.org/10.1016/j.scitotenv.2017.03.125

Lan H, Mao R, Tong Y, Liu Y, Liu H, An X, Liu R (2016) Enhanced electroreductive removal of bromate by a supported Pd–In Bimetallic catalyst: kinetics and mechanism investigation. Environ Sci Technol 50(21):11872–11878. https://doi.org/10.1021/acs.est.6b02822

Liedtke A-K, Bornette F, Philippe R, de Bellefon C (2016) External liquid solid mass transfer for solid particles transported in a milli-channel within a gas–liquid segmented flow. Chem Eng J 287:92–102. https://doi.org/10.1016/j.cej.2015.10.109

Mahmoud MHH, Abdel-Aal EA, Abdel-hamed RM, Kandil AT (2015) Denitration of Coke plant wastewater using a bench-scale electrodialysis unit via statistical design. Int. J Electrochem Sci 10:1478–1493

Marchesini FA, Gutierrez LB, Querini CA, Miró EE (2010) Pt,In and Pd,In catalysts for the hydrogenation of nitrates and nitrites in water. FTIR characterization and reaction studies. Chem Eng J 159:203–211. https://doi.org/10.1016/j.cej.2010.02.056

Marchesini FA, Irusta S, Querini C, Miró E (2008a) Spectroscopic and catalytic characterization of Pd–In and Pt–In supported on Al2O3 and SiO2, active catalysts for nitrate hydrogenation. Appl Catal A 348:60–70. https://doi.org/10.1016/j.apcata.2008.06.026

Marchesini FA, Irusta S, Querini C, Miró E (2008b) Nitrate hydrogenation over Pt,In/Al2O3 and Pt,In/SiO2. Effect of aqueous media and catalyst surface properties upon the catalytic activity. Catal Commun 9:1021–1026. https://doi.org/10.1016/j.catcom.2007.09.037

Martínez J, Ortíz A, Ortíz I (2017) State-of-the-art and perspectives of the catalytic and electrocatalytic reduction of aqueous nitrates. Appl Catal B 207:42–59. https://doi.org/10.1016/j.apcatb.2017.02.016

Matějŭ V, Čižinská S, Krejčí J, Janoch T (1992) Biological water denitrification—a review. Enzyme Microb Tech 14:170–183

Mattarozzi L, Cattarin S, Comisso N, Guerriero P, Musiani M, Vázquez-Gómez L, Verlato E (2013) Electrochemical reduction of nitrate and nitrite in alkaline media at CuNi alloy electrodes. Electrochim Acta 89:488–496. https://doi.org/10.1016/j.electacta.2012.11.074

Menkouchi Sahli MA, Annouar S, Mountadar M, Soufiane A, Elmidaoui A (2008) Nitrate removal of brackish underground water by chemical adsorption and by electrodialysis. Desalination 227:327–333. https://doi.org/10.1016/j.desal.2007.07.021

Mirabi M, Ghaderi E, Rasouli Sadabad H (2017) Nitrate reduction using hybrid system consisting of zero valent magnesium powder/activated carbon (Mg 0 /AC) from water. Process Saf Environ Prot 111:627–634. https://doi.org/10.1016/j.psep.2017.08.035

Naumkin AV, Kraut-Vass A, Gaarenstroom SW, Powell CJ (2014) NIST X-ray Photoelectron Spectroscopy Database. National Institute of Standards and Technology

Palin G (1969) Electrochemistry for Technologists. Pergamon Press Oxford, England

Pérez-Gallent E, Figueiredo MC, Katsounaros I, Koper MTM (2017) Electrocatalytic reduction of nitrate on copper single crystals in acidic and alkaline solutions. Electrochim Acta 227:77–84. https://doi.org/10.1016/j.electacta.2016.12.147

Pourbaix M (1963) Atlas D’equilibres Electrochimiques. Gauthier-Villars, Paris

Puckett LJ (1995) Identifying the major sources of nutrient water pollution. Environ Sci Technol 29:408A–414A

Reyter D, Bélanger D, Roué L (2008) Study of the electroreduction of nitrate on copper in alkaline solution. Electrochim Acta 53:5977–5984. https://doi.org/10.1016/j.electacta.2008.03.048

Reyter D, Bélanger D, Roué L (2009) Elaboration of Cu − Pd films by coelectrodeposition: application to nitrate electroreduction. J Phys Chem C 113:290–297. https://doi.org/10.1021/jp805484t

Reyter D, Bélanger D, Roué L (2010) Nitrate removal by a paired electrolysis on copper and Ti/IrO2 coupled electrodes – Influence of the anode/cathode surface area ratio. Water Res 44:1918–1926. https://doi.org/10.1016/j.watres.2009.11.037

Reyter D, Bélanger D, Roué L, (2011) Optimization of the cathode material for nitrate removal by a paired electrolysis process. J Hazard Mater 192:507–513. https://doi.org/10.1016/j.jhazmat.2011.05.054

Schoeman JJ, Steyn A (2003) Nitrate removal with reverse osmosis in a rural area in South Africa. Desalination 155:15–26

Shrimali M, Singh KP (2001) New methods of nitrate removal from water. Environ Pollut 112:351–359

Sinha X (2005) The electrochemical reduction of nitrate in low conductivity aqueous solutions [master’s thesis]. San Jose State University

Subba Rao AN, Venkatarangaiah VT (2014) Metal oxide-coated anodes in wastewater treatment. Environ Sci Pollut Res 21:3197–3217. https://doi.org/10.1007/s11356-013-2313-6

Tong S, Liu H, Feng C, Chen N, Zhao Y, Xu B, Zhao J, Zhu M (2019) Stimulation impact of electric currents on heterotrophic denitrifying microbial viability and denitrification performance in high concentration nitrate-contaminated wastewater. J Environ Sci 77:363–371. https://doi.org/10.1016/j.jes.2018.09.014

Treybal RE (1987) Mass- Transfer Operations. McGraw-Hill

Wang L, Yao Y, Zhang Z, Sun L, Lu W, Chen W, Chen H (2014) Activated carbon fibers as an excellent partner of Fenton catalyst for dyes decolorization by combination of adsorption and oxidation. Chem Eng J 251:348–354. https://doi.org/10.1016/j.cej.2014.04.088

Wang Y, Qu J, Liu H, Hu C (2007) Adsorption and reduction of nitrate in water on hydrotalcite-supported Pd-Cu catalyst. Catal Today 126:476–482. https://doi.org/10.1016/j.cattod.2007.06.024

Wei N, Cui H, Wang X, Xie X, Wang M, Zhang L, Tian J (2017) Hierarchical assembly of In2O3 nanoparticles on ZnO hollow nanotubes using carbon fibers as templates: enhanced photocatalytic and gas-sensing properties. J Colloid Interface Sci 498:263–270. https://doi.org/10.1016/j.jcis.2017.03.072

Wisniewski C, Persin F, Cherif T, Sandeaux R, Grasmick A, Gavach C (2002) Use of a membrane bioreactor for denitrification of brine from an electrodialysis process. Desalination 149:331–336

Wisniewski C, Persin F, Cherif T, Sandeaux R, Grasmick A, Gavach C (2001) Denitrification of drinking water by the association of an electrodialysis process and a membrane bioreactor: feasibility and application. Desalination 139:199–205

Yang S, Xiao T, Zhang J, Chen Y, Li L (2015) Activated carbon fiber as heterogeneous catalyst of peroxymonosulfate activation for efficient degradation of Acid Orange 7 in aqueous solution. Sep Purif Technol 143:19–26. https://doi.org/10.1016/j.seppur.2015.01.022

Yang Q, Yao F, Zhong Y, Chen F, Shu X, Sun J, He L, Wu B, Hou K, Wang D, Li X (2019) Metal–organic framework supported palladium nanoparticles: applications and mechanisms Part. Part Syst Charact 1800557:1–19. https://doi.org/10.1002/ppsc.201800557

Yao F, Yang Q, Zhong Y, Shu X, Chen F, Sun J, Ma Y, Fu Z, Wang D, Li X (2019) Indirect electrochemical reduction of nitrate in water using zero-valent titanium anode: factors, kinetics, and mechanism. Water Res 157:191–200. https://doi.org/10.1016/j.watres.2019.03.078

Ye T, Durkin DP, Hu M, Wang X, Banek NA, Wagner MJ, Shuai D (2016) Enhancement of nitrite reduction kinetics on electrospun Pd-carbon nanomaterial catalysts for water purification. ACS Appl Mater Interfaces 8(28):17739–17744. https://doi.org/10.1021/acsami.6b03635

Yoshinaga Y, Akita T, Mikami I, Okuhara T (2002) Hydrogenation of nitrate in water to nitrogen over Pd–Cu supported on active carbon. J Catal 207:37–45. https://doi.org/10.1006/jcat.2002.3529

Zoppas FM, Marchesini FA, Devard A, Bernardes AM, Miró EE (2016) Controlled deposition of Pd and in on carbon fibers by sequential electroless plating for the catalytic reduction of nitrate in water. Catal Commun 78:59–63. https://doi.org/10.1016/j.catcom.2016.02.012

Zoppas FM, Bernardes AM, Miró EE, Marchesini FA (2018a) Nitrate reduction of brines from water desalination plants employing a low metallic charge Pd In Catalyst and formic acid as reducing agent. Catal Lett 148:2572–2584. https://doi.org/10.1007/s10562-018-2429-x

Zoppas FM, Bernardes AM, Miró E, Marchesini FA (2018b) Improving selectivity to dinitrogen using palladium-indium coated on activated carbon fibers: Preparation, characterization and application in water-phase nitrate reduction using formic acid as an alternative reductant source. J Environ Chem Eng 6:4764–4772. https://doi.org/10.1016/j.jece.2018.07.015

Acknowledgments

The authors wish to acknowledge the financial support received from ANPCyT (PICT) (2014-1379, 2014-2408), UNL, the Project CAPES-MERCOSUR (CAPG-BA), CYTED and the Brazilian financial support from FINEP, FAPERGS, CNPq, and CAPES. Thanks also to Florencia Agustina Sosa for the revision of the English usage.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Bingcai Pan

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beltrame, T.F., Zoppas, F.M., Marder, L. et al. Use of a two-step process to denitrification of synthetic brines: electroreduction in a dual-chamber cell and catalytic reduction. Environ Sci Pollut Res 27, 1956–1968 (2020). https://doi.org/10.1007/s11356-019-06763-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-06763-x