Abstract

Background

Stress measurement for thin films is crucial in a variety of fields such as in semiconductor manufacturing, the optoelectronics industry, and biomedical science, among others. However, most measurement methods require surface treatment of the thin film.

Objective

A label-free measurement method for plane stress states in optical isotropic thin films based on spectroscopic ellipsometry analysis is proposed and verified in this paper.

Methods

The proposed method is based on the modulation of the stress-optic effect on reflected spectroscopic ellipsometry. A theoretical model is established to describe the relation between all components of the plane-stress state and the classic ellipsometric parameters (Ψ, Δ). An algorithm is developed to determine all components of a plane-stress state by fitting the model to the experiment data.

Results

In the verification experiment, we determined the plane stress state of a Cu film coated on a PI (polyimide) substrate. The results show a reasonable agreement between the experimental measurements from spectroscopic ellipsometry and the theoretical analysis based on the applied loading.

Conclusion

The results prove that our method can effectively measure the plane stress state of optical isotropic thin films.

Similar content being viewed by others

Data Availability

The data that support the measurement method of this study are available from the corresponding author upon reasonable request.

References

Yu M, Feng X (2019) Thin-Film Electrode-Based Supercapacitors Joule 3:338–360. https://doi.org/10.1016/j.joule.2018.12.012

Wang N, Yang A, Fu Y et al (2019) Functionalized Organic Thin Film Transistors for Biosensing. Acc Chem Res 52:277–287. https://doi.org/10.1021/acs.accounts.8b00448

Martin LW, Rappe AM (2016) Thin-film ferroelectric materials and their applications. Nat Rev Mater 2:16087. https://doi.org/10.1038/natrevmats.2016.87

Abed Zadeh A, Barés J, Brzinski TA et al (2019) Enlightening force chains: a review of photoelasticimetry in granular matter. Granular Matter 21:83. https://doi.org/10.1007/s10035-019-0942-2

Lee YC, Liu TS, Wu CI, Lin WY (2012) Investigation on residual stress and stress-optical coefficient for flexible electronics by photoelasticity. Measurement 45:311–316. https://doi.org/10.1016/j.measurement.2011.11.017

Ajovalasit A, Petrucci G, Scafidi M (2015) Review of RGB photoelasticity. Opt Lasers Eng 68:58–73. https://doi.org/10.1016/j.optlaseng.2014.12.008

Bemporad E, Brisotto M, Depero LE et al (2014) A critical comparison between XRD and FIB residual stress measurement techniques in thin films. Thin Solid Films 572:224–231. https://doi.org/10.1016/j.tsf.2014.09.053

Luo Q, Jones AH (2010) High-precision determination of residual stress of polycrystalline coatings using optimised XRD-sin2ψ technique. Surf Coat Technol 205:1403–1408. https://doi.org/10.1016/j.surfcoat.2010.07.108

Qin M, Ji V, Wu YN et al (2005) Determination of proof stress and strain-hardening exponent for thin film with biaxial residual stresses by in-situ XRD stress analysis combined with tensile test. Surf Coat Technol 192:139–144. https://doi.org/10.1016/j.surfcoat.2004.05.026

Xiong J, Qin W, Cui X et al (2007) High-resolution XRD study of stress-modulated YBCO films with various thicknesses. J Cryst Growth 300:364–367. https://doi.org/10.1016/j.jcrysgro.2006.11.335

Yang F, Jiang JQ, Fang F et al (2008) Rapid determination of residual stress profiles in ferrite phase of cold-drawn wire by XRD and layer removal technique. Mater Sci Eng, A 486:455–460. https://doi.org/10.1016/j.msea.2007.09.025

Chen Y, Sun H, Li Z et al (2020) Strategy of Residual Stress Determination on Selective Laser Melted Al Alloy Using XRD. Materials 13:451. https://doi.org/10.3390/ma13020451

Ma L, Xing H, Li Q et al (2018) Raman stress measurement of crystalline silicon desensitizes shear stress: Only on 001 crystal plane. Jpn J Appl Phys 57:080307. https://doi.org/10.7567/JJAP.57.080307

Qiu W, Kang Y-L (2014) Mechanical behavior study of microdevice and nanomaterials by Raman spectroscopy: a review. Chin Sci Bull 59:2811–2824. https://doi.org/10.1007/s11434-014-0401-8

Zhao P, Ouyang X, Yu J et al (2021) Measurement of Residual Stress in YBa2Cu3O7−x Thin Films by Raman Spectroscopy. J Low Temp Phys 202:382–396. https://doi.org/10.1007/s10909-020-02549-5

Wu X, Yu J, Ren T, Liu L (2007) Micro-Raman spectroscopy measurement of stress in silicon. Microelectron J 38:87–90. https://doi.org/10.1016/j.mejo.2006.09.007

Anné G, Vanmeensel K, Vleugels J, Van Der Biest O (2005) Stress Relaxation on Polished Cross-Sections of Al2O3/ZrO2 FGM Discs Measured by Raman Spectroscopy. MSF 492–493:641–646. https://doi.org/10.4028/www.scientific.net/MSF.492-493.641

Fujiwara H (2007) Spectroscopic ellipsometry: principles and applications. John Wiley & Sons

Kitatani T, Kondow M, Shinoda K et al (1998) Characterization of the Refractive Index of Strained GaInNAs Layers by Spectroscopic Ellipsometry. Jpn J Appl Phys 37:753. https://doi.org/10.1143/JJAP.37.753

Vineis CJ (2005) Complex dielectric function of biaxial tensile strained silicon by spectroscopic ellipsometry. Phys Rev B 71:245205. https://doi.org/10.1103/PhysRevB.71.245205

Pezoldt J, Förster C, Cimalla V et al (2007) FTIR Ellipsometry Analysis of the Internal Stress in SiC/Si MEMS. Mater Sci Forum 556–557:363–366. https://doi.org/10.4028/www.scientific.net/MSF.556-557.363

Zhou Z, Jiang H, Gu H et al (2019) Strain-optical behavior of polyethylene terephthalate film during uniaxial stretching investigated by Mueller matrix ellipsometry. Polymer 182:121842. https://doi.org/10.1016/j.polymer.2019.121842

Kaya H, Ngo D, Hahn SH et al (2021) Estimating Internal Stress of an Alteration Layer Formed on Corroded Boroaluminosilicate Glass through Spectroscopic Ellipsometry Analysis. ACS Appl Mater Interfaces 13:50470–50480. https://doi.org/10.1021/acsami.1c10134

Sun X, Wang S, Li L et al (2023) Measurement of stress-optic coefficients for metals in the visible to near-infrared spectrum with spectroscopic ellipsometry. Opt Lasers Eng 161:107362. https://doi.org/10.1016/j.optlaseng.2022.107362

Nye JF (1984) Physical properties of crystals: their representation by tensors and matrices, 1st published in pbk. with corrections, 1984. Clarendon Press ; Oxford University Press, Oxford [Oxfordshire] : New York

Pan B (2018) Digital image correlation for surface deformation measurement: historical developments, recent advances and future goals. Meas Sci Technol 29:082001. https://doi.org/10.1088/1361-6501/aac55b

Acknowledgements

This work was supported by the National Natural Science Foundation of China (12041201, 12172251 and 12021002).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of Interest

The authors declare that there are no conflicts of interest related to this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Theoretical Analysis

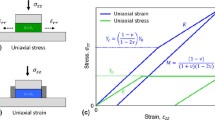

In this section, a theoretical analysis supporting the conclusions drawn in "Determination of Principal Stress Direction" section is provided. As depicted in Fig. 1(d), the rotation angle \(\varphi\) represents the orientation of the optical principal axis relative to the incident plane. When \(\varphi =0\), the optical principal axis is parallel to the incident plane, and in such an orientation, the refractive index tensor can be expressed as

where \({n}_{1}\) and \({n}_{2}\) are the refractive indices parallel and perpendicular to the incident plane, respectively. The corresponding dielectric tensor should be

where \({\varepsilon }_{1}={{n}_{1}}^{2}\), \({\varepsilon }_{2}={{n}_{2}}^{2}\).

As \(\varphi\) changes, the dielectric tensor also changes. To determine the instantaneous dielectric tensor during rotation, the rotation tensor \(B\) is introduced as

Thus, the instantaneous dielectric tensor during rotation is obtained by

Since the difference of \({n}_{1}\) and \({n}_{2}\) is small, i.e., \({n}_{1}-{n}_{2}\approx 0\), we can get

So, in equation (11), the non-diagonal elements can be ignored compared with diagonal element, and it can be degenerated into

It can be deduced that if the optical anisotropy of the specimen is induced by stress, the dielectric tensor can always be approximated as a diagonal tensor. As outlined in Ref. [18], when the dielectric tensor is diagonal, the ellipsometric parameters \(\Psi\) and \(\Delta\) can be calculated directly by

where \({n}_{i}\) is the refractive index of air, which is equal to 1, and \(\theta\) is the incident angle. Substituting equation (13) into equation (14), we can obtain

Subsequently, the partial derivative of equation (15) with respect to rotation angle \(\varphi\) is

where \(f({\varepsilon }_{1},{\varepsilon }_{2},\theta ,\varphi )\) is a complicated function, which is too long to be presented here. It can be found from equation (16) that when \(\varphi\) is an integral multiple of \({}^{\pi}/_{2}\), \(\frac{\partial \rho }{\partial \varphi }=0\) and \(\frac{{\partial }^{2}\rho }{\partial {\varphi }^{2}}=0\), which indicates that \(\rho\) attain the extreme values. Since the ellipsometric parameters Ψ and Δ are monotone functions of \(\rho\) according to equation (14), they will attain extreme values, too. Therefore, we have demonstrated that when the ellipsometric parameters attain their extreme values, the incident plane aligns with the optical principal axis, which corresponds to the stress principal axis.

DIC Measurement

The experiment employs a high-speed camera, as depicted in Fig. 13(a), provided by Beijing Daheng Image Vision Co., Ltd. The dimensions of each pixel are 1.4 \(\mu m \times 1.4 \mu m\), and the frame rate is 13 frames per second (\(fps\)). Speckles are applied onto the masking tape using a black marking pen. As the ellipsometer requires a smooth, reflective surface for measurement, for the uniaxial stress state, speckles are applied to both edges of the Cu film, as illustrated in Fig. 13(b), but not on the measurement point itself. Under uniaxial stress, the area covered by the Cu film experiences uniform stress. This allows for the stress values at the measurement point to be determined by calculating the relative displacement between speckles using 1D-DIC. In the case of biaxial stress condition, this method is inapplicable due to the non-uniform strain field. To measure the strain at the measurement point (the center of the specimen), speckles were sprayed as shown in Fig. 13(c). Utilizing the Finite Element Method, the stress values at the measurement point can be ascertained based on the strain in the areas with speckles using 1D-DIC.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, X., Wang, S., Xing, W. et al. A Label-Free Measurement Method for Plane Stress States in Optical Isotropic Films with Spectroscopic Ellipsometry. Exp Mech 64, 341–352 (2024). https://doi.org/10.1007/s11340-023-01026-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-01026-w