Abstract

Background

A challenge for experimental fracture mechanics studies using vision-based methods is the accuracy with which the crack tip can be located in the region of interest for extracting fracture parameters. When using full-field displacement measurement methods such as digital image correlation (DIC), positioning the crack tip coordinate system could greatly influence the accuracy of stress intensity factors for brittle materials.

Objective

The objective of the present work is to develop improved methods of tracking crack tip position for fracture parameter extraction for problems involving moving fracture fronts (e.g. dynamic crack growth).

Methods

An improved image processing-based automated method for identifying the location of a propagating crack tip is proposed here. The primary inputs to the method are two-dimensional displacement fields measured using DIC. An edge detection methodology using a series of partial derivative computations is used to locate the crack tip.

Results

The proposed method’s performance is verified using simulated displacement fields with a sequence of controlled crack tip positions for mode I and mixed-mode examples. The method is used to locate crack tip positions from mixed-mode dynamic fracture experiments and extract instantaneous stress intensity factor histories. Consistency is shown between baseline and automated methods and post-initiation stress intensity factor histories varied by approximately 5% with the maximum variation being under 10% for the mixed-mode experiments.

Conclusions

The automated fracture parameter extraction method produced consistent results with those extracted using traditionally accepted methods, indicating that the proposed automated approach is a marked improvement due to its systematic nature and processing efficiency.

Similar content being viewed by others

References

Lee D, Tippur HV, Bogert P (2009) Experimental study of dynamic crack growth in unidirectional graphite/epoxy composites using digital image correlation method and high-speed photography. J Compos Mater 43(19):2081–2108

Sundaram BM, Tippur HV (2018) Full-field measurement of contact-point and crack-tip. Int J Appl Glas Sci 9:123–136

Dondetti S, Tippur HV (2019) A comparative study of dynamic fracture of soda-lime glass using photoelasticity, digital image correlation and digital gradient sensing techniques. Exp Mech 60:217–233

Redner AS (1977) Experimental determination of stress intensity factors: A review of photoelastic approaches. International Conference on Fracture Mechanics and Technology, Hong Kong

Etheridge JM, Dally JW (1977) A critical review of methods for determining stress-intensity factors from isochromatic patterns. Exp Mech 17(7):248–254

McNeil SR, Peters WH, Sutton MA (1987) Estimation of stress intensity factor by digital image correlation. Eng Fract Mech 28:101–112

Yoneyama S, Takashi M (2001) Automatic determination of stress intensity factor utilizing digitial image correlation. J Jpn Soc Exp Mech 1:202–206

Sanford RJ (1980) Application of the least-squares method to photoelastic analysis. Exp Mech 20:192–197

Pacey MN, James MN, Patterson EA (2005) A new photoelastic model for studying fatigue crack closure. Exp Mech 45(1):42–52

Roux S, Hild F (2006) Stress intensity factor measurements from digital image correlation: post-processing and integrated approaches. Int J Fract 140:141–157

Hamam R, Hild F, Roux S (2007) Stress intensity factor gauging by digital image correlation: Application in cyclic fatigue. Strain 43:181–192

Zanganeh M, Lopez-Crespo P, Tai YH, Yates JR (2013) Locating the crack tip using displacement field data: A comparative study. Strain 49:102–115

Rethore J (2015) Automatic crack tip detection and stress intensity factor estimation of curved cracks from digital images. Int J Numer Meth Eng 103:516–534

Abdel-Qader I, Abdudayyeh O, Kelly ME (2003) Analysis of edge-detection techniques for crack identification in bridges. J Comput Civ Eng 17(4):255–263

Lopez-Crespo P, Shterenlikht A, Patterson EA, Yates JR, Withers PJ (2008) The stress intensity of mixed mode cracks determined by digital image correlation. J Strain Anal 43:769–780

Lopez-Crespo P, Burguete RL, Patterson EA, Shterenlikht A, Withers PJ, Yates JR (2009) Study of a crack at a fastener hole by digital image correlation. Exp Mech 49:551–559

Strohmann T, Starostin-Penner D, Breitbarth E, Requena G (2021) Automatic detection of fatigue crack paths using digital image correlation and convolutional neural networks. Fatigue Fract Eng Mater Struct 44:1336–1348

Miao S, Pan P, Li S, Chen J, Konicek P (2021) Quantitative fracture analysis of hard rock containing double infilling flaws with a novel DIC-based method. Eng Fract Mech 252:107846

Peters W, Ranson W (1982) Digital Imaging Techniques in Experimental Stress Analysis. Opt Eng 21(3):427–432

Sutton MA, Wolters WJ, Peters WJ, Peters WH, Ranson WF, McNeill SR (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1(3):133–139

Peters WH, Ranson WF, Sutton MA, Chu T, Anderson J (1983) Applications of Digital Correlation Methods to Rigid Body Mechanics. Opt Eng 22(6):738–742

Chu TC, Ranson MA, Sutton MA (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25(3):232–244

Schreier H, Orteu J-J, Sutton MA (2009) Image Correlation for Shape, Motion and Deformation Measurements. Springer, New York, NY

Canny J (1986) A computational approach to edge detection. IEEE Trans Pattern Anal Mach Intell 8(6):679–698

McIlhagga W (2011) The Canny edge detector revisited. Int J Comput Vision 91:251–261

Sobel I, Feldman G (1968) A 3X3 isotropic gradient operator for image processing. Stanford Artificial Intelligence Project

Rong W, Li Z, Zhang W, Sun L (2014) An improved Canny edge detection algorithm. 2014 IEEE international conference on mechatronics and automation. IEEE, pp 577–582

Shih CF, Moran B, Nakamura T (1986) Energy release rate along a three-dimensional crack front in a thermally stressed body. Int J Fract 30:79–102

Shih CF, Asaro R (1988) Elastic-plastic analysis of cracks on bimaterial interfaces: Part I: Small scale yielding. J Appl Mech 55(2):299–316

Owens AT, Tippur HV (2021) Measurement of mixed-mode fracture characteristics of an epoxy-based adhesive using a hybrid Digital Image Correlation (DIC) and Finite Elements (FE) approach. Opt Lasers Eng 140:106544

Isaac JP, Dondeti S, Tippur HV (2020) Crack initiation and growth in additively printed ABS: Effect of print architecture studied using DIC. Addit Manuf 36:101536

Chong KP, Kuruppu MD (1984) New specimen for fracture toughness determination for rock and other materials. Int J Fract 26:R49–R62

Chong KP, Kuruppu MD, Kuszmaul JS (1987) Fracture toughness determination of rocks with core-based specimens. SEM/RILEM International Conference on Fracture of Concrete and Rocks, Texas

Lim IL, Johnston IW, Choi SK (1993) Stress intensity factors for semi-circular specimens under three-point bending. Eng Fract Mech 44(3):363–382

Samareh J (2007) Discrete data transfer technique for fluid-structure interaction. 18th AIAA Computational Fluid Dynamics Conference

Silva GHC, Le Riche R, Molimard J, Vautrin A (2009) Exact and efficient interpolation using finite elements shape functions. Eur J Comput Mech 18(3–4):307–331

Blaber J, Adair B, Antoniou A (2015) Ncorr: Open-source 2D digital image correlation Matlab software. Exp Mech 55(6):1105–1122

Owens AT, Tippur HV (2022) Mixed-mode dynamic fracture behavior of an epoxy adhesive under stress wave loading. Eng Fract Mech 276, Part A, 108833

Westergaard HM (1939) Bearing pressure and cracks. J Appl Mech 6:49–53

Hua C (1990) An inverse transformation for quadrilateral isoparametric elements: Analysis and application. Finite Elem Anal Des 7:159–166

Acknowledgements

Partial support for this work under US Army Research Office grant W911NF-22-1-0015 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Dr. Hareesh Tippur currently serves as the Chair of the International Advisory Board of Experimental Mechanics.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

Non-maximum Suppression Procedure

A simple example with an edge running in the horizontal or vertical direction can be used to illustrate the concept of non-maximum suppression. A 5 × 5 excerpt from a random magnitude intensity field with an edge oriented in the vertical direction is shown in Fig. 18 with resulting simple gradient computations.

The gradient magnitude is calculated from the individual directional gradient values using equation (5) and the directions of the gradient vector can be computed using equation (6).

With the magnitude and direction of the partial derivatives known, the edge points can next be separated from the non-edge points. This information is used to adjudicate points within the field of gradient values that may be an actual edge, with the objective being to arrive at an edge that is exactly 1 data point wide. The first step here is to organize the partial derivative values according to direction, such that they are grouped into bins, [0°, 45°, 90°, 135°]. For the example problem illustrated here, the angles are tabulated in Fig. 19. For this example, since the values are primarily dominated by the vertically oriented edge, all of the directions round to 0°.

With the directions known, each value can then be compared to the eight data points that surround it. More specifically, each point is compared to its neighboring points only in the direction of the angle of the gradient. For instance, if the direction is determined to be closest to the 45° direction, the data point is compared to the point to its upper right and lower left. The value at the given data point is then taken as the maximum of the 3 points along that direction. In the current example, the direction values are all 0°, thus each gradient value is only compared to its left or right neighbor as illustrated in Fig. 20.

Appendix B

Stress Intensity Factor Extraction Using Over-deterministic Least-squares Approach

For the displacement field around the crack tip prior to crack initiation, the over-deterministic least-squares results can be computed using the equations reported in [39] for the crack sliding (ux) and crack opening displacements (uy):

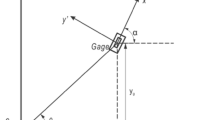

In the preceding equations, µ is the material shear modulus, and r and θ are the polar coordinates with crack tip as the origin and \(\kappa =\frac{3-\upsilon }{1+\upsilon }\) for plane stress. The coefficients KI and KII, when n = 1, are the mode I and mode II stress intensity factors. For digital image correlation experiments, the ux and uy fields are known for a set of points in the polar coordinates r and θ.

By selecting a group of points in the vicinity of the crack, a set of equations can be formed to determine coefficients \({\left({K}_{I}\right)}_{n}\) and \({\left({K}_{II}\right)}_{n}\). Using an over-deterministic approach, the experimental crack opening displacement can be used for extracting mode I fracture components whereas the crack sliding displacements can be used for mode II fracture components. However, it has been shown that by transforming experimentally measured in-plane Cartesian displacements into radial (ur) and angular (uθ) components, more accurate SIFs can be found in mixed mode problems [7]. That is, the Cartesian displacement components can be transformed into polar components as shown in equation (14).

For the analyses presented in the present work, the radial (ur) components are utilized for computing the SIFs. Using this technique, these equations can be expanded out to any number of higher order terms. For the present work, the equations were expanded for up to 10 terms and stress intensity factors were taken once KI and KII were determined to have converged. Measured displacement data was extracted for \(0.5\le {^r}/{_B} \le 1.5\) and \(-120^\circ \le \theta \le 120^\circ\). The over-determined equation set was formed and solved for minimizing the least-squares error to compute values of KI, KII for the crack up to the point of initiation at a range of values of n.

Once the crack begins to propagate, the opening and sliding displacements can instead be written as:

In the above equations, µ is the material shear modulus, and r and θ are the polar coordinates with crack tip as the origin as before and \(\kappa =\frac{3-\upsilon }{1+\upsilon }\) for plane stress. The longitudinal and shear wave speeds are defined as \({C}_{L}=\sqrt{\frac{\left(\kappa +1\right)\mu }{\left(\kappa -1\right)\rho }}\) and \({C}_{S}=\sqrt{\frac{\mu }{\rho }}\), respectively. The non-dimensional quantities, \({\beta }_{1}=\sqrt{1-{\left(\frac{c}{{C}_{L}}\right)}^{2}}\) and \({\beta }_{2}=\sqrt{1-{\left(\frac{c}{{C}_{S}}\right)}^{2}}\) are used to compute the spatial variations of \({r}_{m}=\sqrt{{X}^{2}+{\beta }_{m}^{2}{Y}^{2}}\) and \({\theta }_{m}={\mathrm{tan}}^{-1}\left(\frac{{\beta }_{m}Y}{X}\right)\) based on the crack speed, c. Also, BI, BII, D, and h are defined in equation (17).

Appendix C

Mapping from FE-space to Uniformly Gridded Space

As previously stated, the FE model is comprised of a variety of element shapes due to geometry around the crack, and therefore, does not create output on a uniformly spaced grid of points. A mapping procedure is thus necessary to create a uniformly spaced grid of displacement data for testing the algorithm. To that end, an inverse FE mapping technique was created to generate displacement fields. In the mapper developed for the current effort, the input file for the source finite element model contains all of the node numbers, nodal coordinates, and element connectivity. For each of the 4-noded elements in the finite element model, the mapper locates the grid points that reside within its boundaries using a polygon search algorithm coded in MATLAB®. Since the element shape could be in the form of any four-sided polygon, potentially distorted, a numerical routine was then used to determine the parametric coordinates of each of the destination grid points within the space of their parent source element in the original model. An example of the dissimilarity between the two data point locations is shown in Fig. 21. A set of x- and y-coordinates on a uniform grid was created at the desired “output” point locations, as shown in red. The source model elements and nodes are shown in black. The relationship between the global space and the parametric space is also illustrated in Fig. 21 with an example map-to point shown by the dark-shaded point, xp.

The global coordinate of any point within the boundary of the element is a function of the parametric equation, N, and the global coordinates of the nodes that define the boundary of the polygon. For a 4-noded quadrilateral element, the global coordinate of a point, xp and yp,, is defined in equation (18).

where i is the node number, xi and yi are the global coordinates of the i-th node and ξ and η are the parametric coordinates.

The parametric equations, N, for a quadrilateral element are [40]:

The parametric coordinates, ξ and η, for the target output point can be located using an iterative procedure. For a given iteration, the parametric space is split up into a 5 × 5 grid of points. The values of ξ and η, are used to calculate the resulting global coordinates at each of these points on the 5 × 5 grid. The point within the grid that results in coordinates that have the shortest Euclidean distance to the actual point of interest is used as the initial guess of the next iteration. That initial guess becomes the center point of a smaller 5 × 5 grid that is part of a subdivision of the grid in the previous iteration. This iterative process continues to subdivide the parametric space into smaller and smaller 5 × 5 grids until a result is found that matches the coordinates of the desired point within an acceptable tolerance. For the present work, the algorithm was required to determine the values of ξ and η that resulted in an error between the calculated coordinates and the actual coordinates of less than 1e-6. While there are more efficient numerical techniques for this part of the process, this approach converges reasonably quickly, usually within 6–8 iterations and is relatively inexpensive computationally. The approach can suffer some difficulty when the elements are significantly distorted. However, for the present work, the mesh was controlled sufficiently upfront and significant element distortions were avoided.

For a given point of interest in the grid that is being mapped to, once the parametric coordinates are known with an acceptable accuracy, any desirable field quantities can then be calculated. For this work, the field quantities of interest namely, displacements in the vertical and horizontal directions, the following relationships are used to compute those values:

This method is particularly advantageous because it avoids issues with averaging or smoothing around the crack tip or across the crack faces in the source data. This is because the target grid points are associated with elements from the output data. The nodal connectivity for the source elements is inherited from the source finite element model. Since the original mesh is created without elements spanning the crack tip or bridging across the crack faces, no averaging occurs due to target nodes on one side of the crack face being influenced by displacements of nodes on the opposing side of the crack. It should be noted that in the case of a set of points that are arranged in a rectangular fashion, this general method simplifies to bilinear interpolation.

Rights and permissions

About this article

Cite this article

Taylor Owens, A., Tippur, H.V. An Image Processing Technique to Identify Crack Tip Position and Automate Fracture Parameter Extraction Using DIC: Application to Dynamic Fracture. Exp Mech 63, 445–466 (2023). https://doi.org/10.1007/s11340-022-00925-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-022-00925-8