Abstract

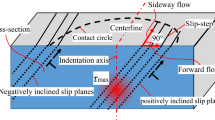

Background: Surface topography of pile-up and sink-in is an issue of strain-hardening behavior around pyramidal and spherical indentations. The relationship between the surface profile and the activated dislocations is not clearly understood. Objective: This study combined electron channeling contrast imaging (ECCI), electron backscatter diffraction-based (EBSD) techniques and 3D laser microscopy to visualize the stress field and understand the influence of activated dislocations on the surface topography around an indent. Methods: The dislocation structures were identified using ECCI and geometrically necessary dislocation (GND) analysis. The stresses and GND densities were calculated to characterize the plastic deformation in terms of activated dislocations. The 3D laser microscopy was applied to reveal the surface topography. Results: The activated slip systems were identified as screw-type on \( \left(1\overline{1}\overline{1}\right)\left[110\right] \), \( \left(1\overline{1}\overline{1}\right)\left[101\right] \), \( \left(\overline{1}1\overline{1}\right)\left[011\right] \), \( (111)\left[\overline{1}10\right] \) and \( (111)\left[10\overline{1}\right] \) slip systems, and edge-type on \( \left(1\overline{1}\overline{1}\right)\left[101\right] \), \( \left(\overline{1}1\overline{1}\right)\left[\overline{1}01\right] \) and \( \left(\overline{1}\overline{1}1\right)\left[\overline{1}0\overline{1}\right] \) slip systems by combining ECCI and GND techniques. Furthermore, the surface morphology reveals a combination of pile-up and sink-in patterns around the indent, as observed by 3D laser microscopy. According to GND analysis, pile-up is generated from the \( \left(1\overline{1}\overline{1}\right)\left[\overline{1}\overline{1}0\right] \), \( (111)\left[1\overline{1}0\right] \), \( \left(1\overline{1}\overline{1}\right)\left[101\right] \) and \( \left(\overline{1}\overline{1}1\right)\left[101\right] \) slip systems, and sink-in is caused by the \( \left(\overline{1}1\overline{1}\right)\left[0\overline{1}\overline{1}\right] \), \( \left(1\overline{1}\overline{1}\right)\left[\overline{1}0\overline{1}\right] \), and \( \left(\overline{1}1\overline{1}\right)\left[10\overline{1}\right] \). Conclusions: The surface profile reveals a combination of pile-up and sink-in patterns resulting in the activated dislocations, where the deformation around the indent is dominated by screw-type dislocations.

Similar content being viewed by others

References

Mott BW (1956) Micro-indentation hardness testing. Butterworths, London

Tabor D (1951) Hardness of metals. Clarendon Press, Oxford

Fischer-Cripps AC (2004) Nanoindentation. Springer, New York

Alcalá J, Barone AC, Anglada M (2000) The influence of plastic hardening on surface deformation modes around Vickers and spherical indents. Acta Mater 48:3451–3464

Petryk H, Stupkiewicz S, Kucharski S (2017) On direct estimation of hardening exponent in crystal plasticity from the spherical indentation test. Int J Solids Struct 112:209–221

Dyer LD (1965) Actual dislocation distribution around a ball indentation on cube face of capper. ASM Trans Q 58:620–644

Bernhard E (2011) Crystal plasticity finite-element analysis versus experimental results of pyramidal indentation into (001) fcc single. Acta Mater 59:1761–1771

Kova’cs Z, Chinh NQ, Lendvai J (2001) Orientation dependence of Portevin–Le Chaˆtelier plastic instabilities in depth-sensing microindentation. J Mater Res 16:1171–1177

Stelmashenko NA, Walls MG, Brown LM, Milman YV (1993) Microindentations on W and Mo oriented single crystals: an STM study. Acat Metall Mater 41:2855–2865

Wang Y, Raabe D, Klueber C, Rosters F (2004) Orientation dependence of nanoindentation pile-up patterns and of nanoindentation microtextures in copper single crystals. Acta Mater 52:2229–2238

Liu Y, Varghese S, Ma J, Yoshino M, Lua H, Komanduri R (2008) Orientation effects in nanoindentation of single crystal copper. Int J Plasticity 24:1990–2015

Lee WB, To S, Cheung CF (2000) Effect of crystallographic orientation in diamond turning of copper single crystals. Scripta Mater. 42:937–945

Weidner A, Beyerb R, Blochwitz C, Holste C, Schwab A, Tirschler W (2006) Slip activity of persistent slip bands in polycrystalline nickel. Mat Sci Eng A 435–436:540–546

Genée J, Signor L, Villechaise P (2017) Slip transfer across grain/twin boundaries in polycrystalline Ni-based superalloys. Mat Sci Eng A 701:24–33

Nibur KA, Bahr DF (2003) Identifying slip systems around indentations in FCC metals, Scripta Mater 49:1055–1060

Kaboli S, Goldbaum D, Chromik RR, Gauvin R (2013) Electron channeling contrast imaging of plastic deformation induced by indentation in polycrystalline nickel. Microsc Microanal 19:1620–1631

Nye JF (1953) Some geometrical relations in dislocated crystals. Acta Metall Mater 1:153-162

Troost KZ, van der Sluis P, Gravesteijn DJ (1993) Microscale elastic-strain determination by backscatter kikuchi diffraction in the scanning electron microscope. Appl Phys Lett 62:1110-1112

Wilkinson AJ, Meaden G, Dingley DJ (2006) High-resolution elastic strain measurement from electron backscatter diffraction patterns: new levels of sensitivity. Ultramicroscopy 106:307-313

Wilkinson AJ, Meaden G, Dingley DJ (2006) High resolution mapping of strains and rotations using electron back scatter diffraction. Mater Sci Technol 22:1-11

Kacher J, Landon C, Adams BL, Fullwood D (2009) Braggs law diffraction simulations for electron backscatter diffraction analysis. Ultramicroscopy 109:1148-1156

Ruggles TJ, Fullwood DT, Kysar JW (2016) Resolving geometrically necessary dislocation density onto individual dislocation types using EBSD-based continuum dislocation microscopy. Int J Plasticity 76:231-243

Wilkinson AJ, Randman D (2010) Determination of elastic strain fields and geometrically necessary dislocation distributions near nanoindents using electron back scatter diffraction. Philos Mag 90:1159–1177

Crimp MA, Simkin BA, Ng BC (2001) Demonstration of the g · b x u = 0 edge dislocation invisibility criterion for electron channeling contrast imaging. Phil Mag Lett 81:833-837

Mansour H, Crimp MA, Gey N, Maloufi N (2015) Accurate electron channeling contrast analysis of a low angle sub-grain boundary. Scripta Mater 109:76–79

Zhang J, Zaefferer S, Raabe D (2015) A study on the geometry of dislocation patterns in the surrounding of nanoindents in a TWIP steel using electron channeling contrast imaging and discrete dislocation dynamics simulations. Mat Sci Eng A 636:231-242

Xia W, Dehm G, Brinckmann S (2019) Unraveling indentation-induced slip steps in austenitic stainless steel. Mater Des 183:108169

Shetty MN (2013) Dislocations and mechanical behavior of materials. PHI learning private limited, Delhi

Sun S, Adams BL, Shet C, Saigal S, King W (1998) Mesoscale investigation of the deformation field of an aluminum bicrystal. Scripta Mater 39:501-508

Ma A, Roters F, Raabe D (2006) On the consideration of interactions between dislocations and grain boundaries in crystal plasticity finite element modeling –Theory, experiments, and simulations. Acta Mater 54:2181-2194

Zaafarani N, Raabe D, Singh RN, Roters F, Zaefferer S (2006) Three-dimensional investigation of the texture and microstructure below a nanoindent in a Cu single crystal using 3D EBSD and crystal plasticity finite element simulations. Acta Mater 54:1863-1876

Zeng K, Rowcliffe DJ (1995) Vickers indentations in glass – I. residual stress fields and iso-stress contour maps. Acta Metall Mater 43: 1935-1943

Kucharski S, Stupkiewicz S, Petryk H (2014) Surface Pile-Up Patterns in Indentation Testing of Cu Single Crystals. Exp Mech 54:957–969

Nibur KA, Akasheh F, Bahr DF (2007) Analysis of dislocation mechanisms around indentations through slip step observations. J Mater Sci 42:889–900

Acknowledgments

The authors would gratefully like to thank the Ministry of Science and Technology for funding the project under MOST 106-2221-E-006-071, MOST 107-2221-E-006-018 and MOST 108-2221-E-006-135, and Professor Tzu-Yao Tai at Southern Taiwan University of Science and Technology for providing 3D laser scanning microscopy to characterize the surface topography.

Funding

This study was funded by the Ministry of Science and Technology under grant number MOST 106–2221-E-006-071, 107–2221-E-006-018 and 108–2221-E-006-135.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, F., Kuo, J. On the Pile-Up and Sink-in Behavior of Indented Nickel Considering Dislocation Structures. Exp Mech 60, 1055–1066 (2020). https://doi.org/10.1007/s11340-020-00624-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00624-2