Abstract

Eradication of established implant-associated and bacterial biofilm-forming infections remains difficult in part because these biofilms remain well-adhered to the implant surface. Few experimental techniques are available to measure macro-scale strength of bacterial biofilm-implant adhesion. We have adapted the laser spallation technique to compare the macro-scale adhesion strength of biofilms formed on titanium. By using a rapid pressure wave (35 ns) to load the interface, we prevent disturbance of the biofilm surface prior to measurement, and preclude the time necessary for the biofilm to respond to and adapt under loading. Biofilms of Streptococcus mutans, a Gram-positive bacterium associated with human dental caries (cavities) were cultured directly on commercially pure titanium within our custom substrate assembly. Growth conditions were varied by adding sucrose to the Todd Hewitt Yeast (THY) broth: THY control, 37.5 mM, 75 mM, 375 mM, and 750 mM sucrose. Multiple locations on each biofilm were loaded using the laser spallation technique. Loading pressure wave amplitude was controlled by adjusting laser fluence, energy per area. Initially, addition of sucrose to the media increased biofilm adhesion to titanium. However, once a saturation concentration of 75 mM sucrose was reached, increasing the sucrose concentration further resulted in a decrease in biofilm adhesion. This study is the first demonstration of the adaptation of the laser spallation technique to measure bacterial biofilm adhesion. Establishment of this macro-scale biofilm adhesion measurement technique opens the door for many biofilm-surface adhesion studies. We anticipate further work in this area towards understanding the complex relationships among bacteria species, environmental factors, surface characteristics, and biofilm adhesion strength.

Similar content being viewed by others

Introduction

Biofilms impact many different industries including food production, water sanitation, nautical, and medical. Deleterious effects of these biofilms range from contamination of food and drinking water, transplantation of invasive species from the bottom of marine vessels, and infections resulting from catheters and implant use [1,2,3,4]. The effects of biofilms are especially prevalent in the medical field considering the need for sterility in treatment and prolific use of implanted devices, which are prone to biofilm formation [5]. One such device that experiences high rate of biofilm formation is the dental implant. Approximately 3 million individuals have dental implants with 500,000 new implants each year. During implantation, implant surfaces are exposed to bacteria present in the oral cavity. The formation of bacterial biofilms on implant surfaces can result in the development of severe infections and necrosis of surrounding tissue [5]. In particular, oral bacteria can attach to dental implants and lead to peri-implantitis, a disease formed by subgingival biofilm between dental implants and surrounding tissue. Peri-implantitis can lead to the decay of the gum surrounding the implant as well as total failure of the implant [1]. Peri-implantitis, along with biofilms in general, is difficult to treat with ordinary antibiotics. The colonization of bacteria and combinations of several different bacteria in biofilms results in an antibiotic resistant organism [6]. Prevention of strong biofilm adhesion could alleviate some of the deleterious effects of biofilm-associated implant infections. An understanding of factors that contribute to strong biofilm adhesion at implant interfaces will guide the development of prevention strategies.

Adhesion techniques have previously been categorized into two groups: counting methods and critical force methods [7]. The first group includes microscopy techniques that describe the presence, amount, activity, and/or type of bacteria. The second group of critical force methods measures quantitatively the strength of the adhesion. Counting methods are ubiquitous as the main identifier of biofilm surface coverage through observation. However, coverage tells us little about the strength of the adhesion making these techniques not suited for quantitative adhesion measurements.

Critical force techniques are divided into microscopic and macroscopic levels. Microscopic critical force techniques refer to probing adhesion mechanisms in reference to individual basis or only a small collection of microorganisms. Predominant microscopic methods to measure bacterial interactions with surfaces include atomic force microscopy (AFM) [8, 9] and optical tweezers [10, 11]. Opto-acoustic techniques have also been used to show adhesion and stiffness of single cells [12]. While these techniques are useful in revealing fundamental molecular mechanisms underlying adhesion [13], extrapolation of nano-scale forces to macroscale adhesion strength erroneously ignores any scale dependence [14]. These nano-scale forces, such as van der Waals forces, do impact adhesion of bacteria onto surfaces, but by measuring forces only associated with a few cells, as opposed to the large colonies of highly integrated bacteria found in fully developed biofilms, the effects of these unmeasured macro-forces associated with extracellular polymeric substances (EPS) development are not measured, thus nano-scaled forces cannot be used solely to determine whole biofilm substrate adhesion [15].

For assessing biofilm adhesion quantitatively on a macroscopic level, few techniques currently exist appropriate for low cohesive films. Common thin film adhesion techniques such as stud pull, and peel tests [16, 17] are less applicable for biofilms because good “grip” is required for measurements which is not possible with the low cohesive strength of biofilms. Fracture techniques have been adapted to account for the deformability of proteinaceous substances [18], but the failure mode is typically cohesive and therefore does not quantify the adhesive strength. Another approach is the use of fluid flow to impose a shear stress across the biofilm [19]. However, during shear loading, and due to the topology of the biofilm surface, the biofilms will break apart cohesively, especially on the outside layer of biofilm, degrading the biofilms before total delamination resulting in inaccurate surface adhesion measurements. This reformation can occur within only a few seconds of shear flow across the biofilm surface [20].

More recently, opto-acoustic techniques have emerged, which describe adhesion based on dissipation of acoustic waves. Changes in dissipation are associated with a change in density or due to the addition or subtraction of mass at a surface [12]. Opto-acoustic methods require specific substrates for testing that limit what surface characterizations can be tested and do not relate adhesion to a stress-to-failure.

A macroscale method for quantifying biofilm adhesion would be a significant advance over previous techniques. Furthermore, a noncontact method (e.g., laser spallation) would circumvent the need for a good “grip” on the material and would avoid harmful disruption of the film prior to measurement.

Laser spallation methods have been used previously to quantitatively express the adhesion of a variety of films with a special focus on polymeric films [21,22,23,24,25] and metallic films [25,26,27,28] with recent exploration of composite bonding [29, 30] and sol-gel film adhesion [31]. Laser spallation methods have also been used when measuring the adhesion of mammalian cells and tissues [32,33,34,35]. The use of the laser spallation technique is optimal as it results in quantified adhesion strength, while using a non-contact high strain rate pressure wave [28, 36]. Generation of the pressure wave on the backside of the substrate opposite to the film prevents disturbance of the biofilm surface prior to measurement and the nanosecond loading precludes the time necessary for the biofilm to break apart under loading, as in shear flow measurements, and instead gives measurements on the whole intact biofilm.

To establish the method for biofilm-adhesion measurement, we have chosen a single-species biofilm of Streptococcus mutans. S. mutans, a Gram-positive bacterium, is a major etiological agent of human dental caries that colonizes the oral cavity and also forms bacterial biofilms [37]. Moreover it has been shown to stimulate the growth and adhesion of other bacteria to form biofilms [38]. S. mutans biofilms are highly dynamic three-dimensional structures which consists of bacteria enmeshed in EPS [39, 40]. The major component of the EPS is exopolysaccharide which is produced by secreted glucosyltransferases [41]. These enzymes catalyze synthesis of glucans from sucrose [42]. Here, varying concentrations of sucrose were added to media in which the biofilms were grown in order to assess the relationship between sucrose concentration and adhesion strength of the S. mutans biofilms to titanium. Titanium is the current standard in the dental implant industry for many reasons such as its biocompatibility with bone and surrounding gum, high corrosion resistance, and its modulus of elasticity is comparable to that of bone [43, 44]. Thus, commercially pure titanium was used to mimic the surface of a dental implant [45] though there has been an increase in research of a number of titanium alloys or zirconia implant materials [46].

Materials & Methods

Substrate Assembly

Glass slides with one side coated with commercially pure titanium, composed of 99.995% titanium, (100 nm thick) and one side coated with aluminum (300 nm) were purchased from Deposition Research Laboratory Inc. (DRLI). The aluminum side of the sample is used as an absorbing layer for the Nd:YAG laser. Using a diamond-tip scribe, the slides were cut into 1″×1″ squares. A layer of sodium silicate (waterglass) is spun cast at 3000 rpm for 5 min on the aluminum side. Holes of 13/16 in were cut into the bottom of Petri dishes (VWR 35 × 10 mm) using a spade bit and a lathe. DRLI slides were adhered using room temperature vulcanizing silicone (Dow Corning 732 RTV Sealant) to the bottoms of the Petri dishes shown in Fig. 1. Importantly, the adhesive does not interfere with biofilm growth. With the slides attached to the bottom of the Petri dishes, the dishes are ready for sterilization and biofilm culture. A second Petri dish is used to encapsulate the backside of the substrate assembly to prevent disturbance of the sodium silicate layer prior to testing.

(A) Schematic of custom substrate assembly made from 35 mm Petri dishes for biofilm growth. The thicknesses of each layer in the assembly are given. (B). Optical image of assembly dish where the titanium layer is visible. The growth region is approximately 1″ in diameter. (C). Optical image from underneath the substrate assembly where the aluminum layer on the backside is visible. The substrate assembly is prepared for waterglass application followed by biofilm growth. Scale bar is 10 mm

Bacterial Growth and Biofilm Formation

Streptococcus mutans (ATCC 25175) were suspended in Todd Hewitt Yeast broth (THY) with 20% glycerol and kept as a frozen stock in a − 80 °C freezer. Frozen bacteria stock was thawed gently then a small amount was removed with a sterile inoculating loop and placed into 5 mL of THY within a 15 mL centrifuge tube. The centrifuge tube was then placed into a warming bath at 37 °C. After 24 h, the optical density (OD) at 600 nm was measured using a GE Ultrospec 8000. By growing the bacteria from stock, a desired OD600 was kept constant to inoculate all substrate assemblies. Substrate assemblies were sterilized using 70% ethanol in DI water followed by UV irradiation for 30 min. To each substrate assembly, 3 mL of THY (or THY + sucrose) was added followed by 1 mL of THY that contained an OD600 of 0.7 of S. mutans. Because of the dilution, the final OD600 at inoculation was 0.175. Final concentration of THY + sucrose was: THY control, 37.5 mM, 75 mM, 375 mM and 750 mM sucrose. Inoculated substrate assemblies were then placed in an incubator at 37 °C with 5% CO2 and cultured for 24 H. media was then removed and the biofilms were gently rinsed with phosphate buffered saline (PBS) in order to remove any bacteria not colonized within the biofilm.

Laser Spallation Method

Substrate assemblies with biofilms were placed into a laser spallation set up as shown in Fig. 2. An Nd:YAG laser (Spectra Physics Quanta-Ray), which emits an infrared light pulse of 10 ns with a wavelength of 1064 nm, travels through a motorized attenuator (Newport VA-BB Series) in order to attenuate the pulse energy. Once the laser is attenuated, it passes through a focusing lens to decrease the beam diameter to our desired diameter, 2.2 mm. Then the focused and attenuated beam is reflected, using a 1064 nm YAG mirror, to arrive at the backside of the substrate assembly. Once the infrared light wave contacts the aluminum energy absorbing layer on the back surface of the substrate assembly, the light wave is converted into a compressive acoustic wave which propagates through the substrate. The wave then reflects at the thin film free surface resulting in a tensile load onto the biofilm-titanium interface. If the magnitude of the tensile load is greater than the biofilm-titanium adhesion strength, the biofilm will be ejected from the surface in a process called spallation. Each substrate assembly can be loaded at multiple locations by adjusting appropriate translation stages. Multiple biofilms (3–5 dishes, average of 12 tests per dish) were grown under the varying growth conditions and loaded over a range of fluences. Multiple biofilms were grown in order to account for the inherent variability found when culturing bacteria, including variability in thickness and adhesion strength. Variability of these parameters were captured by the sigmoidal spallation statistics that demonstrate that spallation can occur over a tight group of fluence values.

Schematic of laser spallation set-up including where Nd:YAG pulse energy is modulated using a motorized attenuator, passes through a focusing lens to control the spot size, reflects from a YAG-specific mirror and is incident on the backside of the substrate assembly. If the amplitude of the stress wave generated from impingement of the Nd:YAG pulse is greater than the strength of adhesion, biofilm within the loaded region will be ejected from the surface

Interferometric Calibration Protocol

Due to the unreflective nature of bacterial biofilms, a set of calibration experiments is necessary because in situ interferometry measurements could not be performed. Instead, calibration experiments were performed directly with unmodified substrate assemblies used for spallation experiments following previously described protocols [22, 32]. Briefly, titanium surface displacements are measured with a Michelson interferometer that includes a 532 nm continuous wave laser (CrystaLaser CL-2000). A high rate oscilloscope (LeCroy WaveRunner 8404 M) captures the temporal voltage trace from a silicon photodetector (Electo Optics ET 2030). The voltage trace can be expressed with the equation,

where Vmax and Vmin are the voltage maximum and voltage minimum of each interference fringe. The interference fringe number, n(t), is unwrapped and then converted to displacement using [47],

where λ0 is the wavelength of the interferometric laser, 532 nm. For a simple bi-material interface, the evolution of the substrate stress can easily be determined from the displacement history using the principles of one-dimensional wave mechanics [47]. When the thickness of the test film is sufficiently small, the following analytic thin film equation for the substrate stress, σsub, is valid,

where ρ and Cd respectively denote the density and dilatational wave speed of the substrate. From this equation a peak substrate stress can be measured.

Results

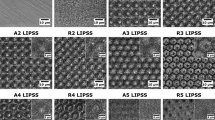

Microscopy of Loaded Biofilms

The laser spallation technique was used to load biofilm-titanium interfaces at a range of laser fluence values (energy per area). After loading, specimens were investigated using a stereo microscope (Olympus SZ61). The onset of failure of the biofilm-titanium interface was marked by spallation of the biofilm from the surface of the titanium resulting in a dark spallation region. For example, Fig. 3 shows optical images of before and after loading at a range of laser fluences on a biofilm cultured in 37.5 mM sucrose. As laser fluence increased, the spallation region also increased.

(A) Optical image of a test biofilm grown in 75 mM sucrose media prior to loading. (B) Optical image of biofilm after loading. Dashed circles indicate the approximate location of a loaded region. The size of the circle is exaggerated to not obstruct loaded regions. Each dish is loaded at 10–15 locations with a range of laser fluences. For example, location ① was loaded at 39.7 mJ/mm2, location ② 47.7 mJ/mm2, location ③ 55.6 mJ/mm2 location ④ 63.5 mJ/mm2, and location ⑤ 79.4 mJ/mm2, respectively. There is an increase in visible damage to the biofilm with increasing laser fluence. Scale bar is 3 mm

Magnification of the spallation region illustrates the relationship between fluence and the size of the spallation region. Figure 4 shows optical images for THY control and 75 mM sucrose biofilms at increasing laser fluence. At lower fluences, the biofilms did not spall from the substrate as shown in Fig. 4(A) for a THY control biofilm loaded at a fluence of 23.8 mJ/mm2 and Fig. 4 (E) and (F), a 75 mM biofilm loaded at a fluence of 23.8 mJ/mm2 and 31.8 mJ/mm2, respectively. At increasing fluence, the size of the spalled region also increased. For example, THY control biofilms at fluences of 31.8 mJ/mm2, 39.7 mJ/mm2, and 55.6 mJ/mm2 (Fig. 4(B), (C), and (D), respectively) had spallation regions of 0.26 mm2, 1.2 mm2, and 1.8 mm2, respectively. For 75 mM biofilms, the onset of spallation occurred at a higher fluence shown in Fig. 4(G) and (H), which had spallation regions of 0.5 mm2, and 1.5 mm2, for fluences of 39.7 mJ/mm2 and 55.6 mJ/mm2, respectively. All spallation regions were measured using ImageJ image processing software.

Optical images of loaded biofilms at increasing laser fluence for THY control (A.-D.) and 75 mM sucrose biofilms (E.-H.), respectively. Fluence values increase from left to right and each column includes the same loading fluence of 23.8 mJ/mm2(A., E.), 31.8 mJ/mm2(B., F.), 39.7 mJ/mm2(C., G.), and 55.6 mJ/mm2(D., H.). Scale bar is 500 μm

Scanning Electron Microscopy (SEM) was used to investigate spalled regions to confirm that the titanium film was undisturbed by the loading. Titanium-glass adhesion is substantially greater than biofilm-titanium adhesion and we saw no evidence for disturbance of the titanium film underneath. An SEM image of a spalled region with the EDS (Energy Dispersive Spectroscopy) information is included in Fig. 5. EDS signals were captured particularly isolating the binding energies of carbon and titanium. As shown in Fig. 5, the titanium spectra within the spalled region is extremely high indicating the presence of the titanium film. The carbon spectra is extremely high in the unloaded region compared to the loaded region indicating the biofilm has been spalled from the titanium in the loaded region.

(A) SEM image of a spalled biofilm cultured in 75 mM sucrose loaded to a fluence value of 79.5 mJ/mm2. (B) Signal from EDS of Carbon (green). (C) Signal from EDS of Titanium (red). (D) Overlay of signal from EDS onto the SEM image. The relative amounts of carbon and titanium indicate the loading event ejected the biofilm from the titanium surface. Scale bar is 500 μm

Substrate Stress Calibration Experiments

Each fluence value used during laser spallation experiments was calibrated using the substrate stress calibration procedure described in Section 2.4. Representative calibration curves at a loading fluence of 79.4 mJ/mm2 appear in Fig. 6, which include a raw voltage trace, temporal displacement obtained by Eq. 2, and subsequent substrate stress loading wave from Eq. 3 with ρ = 2500 g/cm3 and Cd = 5378 m/s, the density and dilatational wave speed of glass, respectively [48].

Calibration substrates were loaded at each fluence value 10 times, and the peak substrate stress for each substrate stress pulse was averaged for the corresponding laser fluence shown in Fig. 7. Lowest fluence value of 15.9 mJ/mm2 results in an average substrate stress of 1.69 ± 0.11 GPa. Average substrate stress increases monotonically with increasing laser fluence reaching 3.54 ± 0.13 GPa at a fluence of 79.4 mJ/mm2. From these calibration experiments, we demonstrate increasing laser fluence results in a higher magnitude substrate loading pulse imparted to the biofilm.

Biofilm Spallation Statistics

Each loading location across all biofilm conditions was inspected for spallation of the biofilm from the titanium surface and results are presented in Figs. 8 and 9. For example, control biofilms grown in THY only showed no spallation at a loading laser fluence of 15.9 mJ/mm2 for 10 loading sites, however, increasing the fluence to 23.8 mJ/mm2, 12 out of 18 or 67% of loading sites exhibited a spalled biofilm. Further increasing the laser fluence to 32 mJ/mm2 and beyond resulted in spallation at 100% of loading sites. By adding 37.5 mM sucrose to the media a delay in the onset of biofilm spallation was observed. No biofilm spallation occurred at a fluence of 23.8 mJ/mm2 for biofilms grown in 37.5 mM sucrose concentration, which showed a 67% spallation rate for THY control, demonstrating an increase in adhesion. For biofilms grown in 75 mM sucrose the onset of biofilm spallation required even higher fluence value, no spallation occurred at a fluence of 47.7 mJ/mm2, and 100% spallation rate was not reached until a laser fluence of 79.4 mJ/mm2. This fluence value is 2.5 times the fluence needed for 100% spallation rate when compared to the THY control, and 2 times the fluence needed for 100% spallation rate when compared to 37.5 mM + THY. This increase in laser fluence required for spallation leads to the conclusion that adhesion of S. mutans is greatly enhanced by the addition of 75 mM sucrose.

Fraction of loading locations that showed delamination for biofilms on titanium surfaces as a function of laser fluence for biofilms cultured in Todd Hewitt Yeast broth control (THY control, solid black line), THY+ 37.5 mM sucrose (dark blue dashed line), and THY + 75 mM sucrose (cyan blue solid line). Increasing sucrose molarity from zero (control) to 75 mM increased the laser fluence necessary to spall the biofilm

Fraction of loading locations that showed delamination for biofilms on titanium surfaces as a function of laser fluence for biofilms cultured in THY + 75 mM sucrose (cyan blue solid line), THY + 375 mM sucrose (red long dash line), THY + 750 mM sucrose (red short dash line). After 75 mM, increasing sucrose molarity decreased the laser fluence necessary to spall the biofilm

Increasing the sucrose concentration further did not result in enhanced adhesion, but instead a decrease in adhesion, and thus the 75 mM sucrose concentration was deemed the adhesion saturation point. Therefore, there exists an optimal sucrose concentration that will result in the strongest adhering biofilm. If more sucrose is added, the media will become saturated and the bacteria will not as strongly colonize to the surface. Figure 9 includes spallation rate at each fluence for 375 mM sucrose, 750 mM sucrose, and the saturation point 75 mM sucrose for reference. The onset of spallation occurred at lower fluences for 375 mM sucrose and 750 mM sucrose than the lower concentration of 75 mM sucrose. For example, at a fluence of 39.7 mJ/mm2, biofilms cultured in 375 mM sucrose exhibited a spallation rate of 25% while biofilms cultured in 750 mM sucrose exhibited a spallation rate of 78% and 75 mM sucrose exhibited no spallation at that fluence value. Number of test sites at each fluence are included in Table 1.

Critical fluence of failure was determined by the fluence at which the majority, greater than 50%, of tests resulted in spallation occurrence. Critical laser fluence was calculated for each sucrose concentration, THY only, 37.5 mM, 75 mM, 375 mM, and 750 mM and were 23.8 mJ/mm2, 31.8 mJ/mm2, 55.6 mJ/mm2, 47.7 mJ/mm2, and 39.7 mJ/mm2, respectively. Because an increase in fluence is directly calibrated to an increase in substrate stress (Fig. 7), and assuming identical stress wave transmission at the biofilm-substrate interface regardless of culture conditions, critical fluence values provide a valid trend for biofilm adhesion strength onto the substrate. Figure 10 shows the trend for average peak substrate stress vs sucrose concentration for all biofilms in this study. Peak substrate stress profiles have been shown to correlate to a unique interface stress using finite element analysis for mammalian cell monolayers [32] but has yet to be applied to thicker biofilms. Development of a finite element analysis for thicker bacterial biofilms is an active area of research.

Discussion

Differences in critical fluence required to spall S. mutans biofilms from titanium revealed a non-monotonic relationship between sucrose molarity and peak substrate stress. Absolute values of peak substrate stress are not equal to adhesion strength, however, an increase in peak substrate stress is correlated to increased adhesion strength for thin films of the same material and thickness. For our experiments, this correlation is predicated upon similar mechanical properties of biofilms across culture conditions, which includes identical transmission and reflection coefficients of stress waves at the substrate-biofilm interface. Therefore, increased laser fluence of spallation calibrated to measured increases in peak substrate stress correlates to increased adhesion strength. Initially, as sucrose concentration increased, critical laser fluence increased, which demonstrates an increasing relationship between sucrose molarity and adhesion strength. Eventually, however, the media becomes over saturated with sucrose at higher concentrations and the laser fluence of spallation decreases, resulting in decreased adhesion strength. One possible explanation is the increased formation of acid end-products during fermentation of dietary sugars [49]. Normally this production of acids is a driving force in the generation of cariogenic dental biofilms, however, as more sucrose is added, the generated acidic environment could have an impact on the adhesion strength of the extracellular matrix. This trend corresponds to previous studies of the effect of sucrose levels on oral bacteria development performed by Cai et al. [50], who used a change in biofilm volume as a measurement for adhesion strength. While the measurement of biofilm volume corresponds to how much the biofilm has grown, it will not yield a quantitative measurement of adhesive forces. In the previous study mentioned they determined, using a polynomial regression fit to adhesion vs sucrose molarity measurements, that 0.45% (w/v) sucrose was the optimal concentration for adhesion, which corresponds to approximately 13 mM. While this concentration is less than our optimal adhesive strength tested, the data obtained from Cai et al. show that adhesion strength does initially increase with sucrose concentration, holds relatively constant over a range of concentrations, until the adhesion decreases at a very high concentration. The plateau for maximum adhesion strength occurs from 0.1% to 20% (w/v), or approximately 3 mM to 590 mM, a relatively large range of values. The peak sucrose value found in our study of 75 mM does lie within this range.

There are limitations when applying the laser spallation technique to interfaces involving biological constituents. Cell membranes (e.g., sarcoma cells) in PBS have been shown to be altered by stress waves, though these changes are complicated by the possibility of microcavitation [51]. In our system, PBS is removed prior to laser-induced spallation loading reducing the likelihood of cavitation. An additional consideration for stress wave loading, is that the same stress wave amplitude must be generated at the same fluence for a direct comparison. For thin film on substrate systems, this assumption is satisfied when the films being loaded have the same material parameters such as wave speed, density, and thickness. For biological materials, there may be more variability in these parameters which will affect the stress wave amplitude as well as the stress wave velocity. Our assumption in this study is that these variations are small, self-consistent, and will be included in the failure statistics for our large sample size.

Conclusions

We have demonstrated the use of laser-induced spallation as a technique to measure the adhesion strengths of bacterial biofilms on surfaces using S. mutans biofilms grown on titanium. The influence of sucrose on biofilm adhesion was probed by adding different concentrations to the growth media during inoculation. After 24 h of growth on custom titanium substrate assemblies, biofilms were loaded using the laser spallation technique. The relationship between sucrose concentration and biofilm-titanium adhesion strength was increasing for lower sucrose concentrations 0 to 75 mM, after which the adhesion strength became decreasing for higher sucrose concentrations 75 mM to 750 mM. This trend follows a similar relationship found between growth characteristics of S. mutans biofilms and sucrose [50].

This technique can be applied further to different biofilm-surface combinations. Our custom substrate assemblies allow for easy substitution of substrates with different surface treatments, patterns, and composition as well as the study of varied single and multi-species biofilms. By extending the range of material interfaces probed by the laser spallation technique to include biofilms, our aim is to identify factors that significantly alter macro-scale adhesion strength of biofilms on implant surfaces. Once factors are identified, they will lead directly to the development of implant surfaces that reduce adhesion strength of colonizing bacteria perhaps reducing the likelihood of the onset of biofilm-associated infections.

In order to achieve the goals of studying biofilm-associated infection at implant-tissue interfaces, more complex biofilm models need to be characterized. Future work in this area includes development of finite element analysis for determining interface stress with thick biofilms, and broadening adhesion tests to multi-species biofilms as well as modifications of the titanium surface. The increase in biofilm complexity with the inclusion of several different oral bacteria will better mimic in vivo conditions and allow for an accurate representation of oral biofilms. This application could be extended to clinical applications by examining human saliva samples and determining the bacteria which are highest risk for certain groups and recommending specific surfaces for specific patients.

References

Busscher HJ, Rinastiti M, Siswomihardjo W, van der Mei HC (2010) Biofilm Formation on Dental Restorative and Implant Materials. Crit Rev Oral Biol Med

Van Houdt R, Michiels CW (2010) Biofilm formation and the food industry, a focus on the bacterial outer surface. J Appl Microbiol 109(4):1117–1131

Cathryn CM et al (2014) Spatial distribution of marine invasive species: environmental, demographic and vector drivers. Divers Distrib 20(7):824–836

Donlan RM (2011) Biofilm Elimination on Intravascular Catheters: Important Considerations for the Infectious Disease Practitioner. Clin Infect Dis 52(8):1038–1045

Dhir S (2012) Biofilm and dental implant: The microbial link. Society of Periodontology

Rajiv Saini SS, Sharma S (2011) Biofilm: A dental microbial infection. Journal of Natural Science, Biology and Medicine

Garrett TR, Bhakoo M, Zhang ZB (2008) Bacterial adhesion and biofilms on surfaces. Progress in Natural Science-Materials International 18(9):1049–1056

Fang HH, Chan K-Y, Xu L-C (2000) Quantification of bacterial adhesion forces using atomic force microscopy (AFM). J Microbiol Methods 40(1):89–97

Boyd RD et al (2002) Use of the atomic force microscope to determine the effect of substratum surface topography on bacterial adhesion. Langmuir 18(6):2343–2346

Zhang H, Liu KK (2008) Optical tweezers for single cells. J R Soc Interface 5(24):671–690

Fallman E et al (2004) Optical tweezers based force measurement system for quantitating binding interactions: system design and application for the study of bacterial adhesion. Biosens Bioelectron 19(11):1429–1437

Ghanem MA et al (2018) Opto-acoustic microscopy reveals adhesion mechanics of single cells. Rev Sci Instrum 89(1):014901

Hinterdorfer P, Dufrene YF (2006) Detection and localization of single molecular recognition events using atomic force microscopy. Nat Methods 3(5):347–355

Nikhil ST, Bharat B (2004) Scale dependence of micro/nano-friction and adhesion of MEMS/NEMS materials, coatings and lubricants. Nanotechnology 15(11):1561

Burks GA et al (2003) Macroscopic and Nanoscale Measurements of the Adhesion of Bacteria with Varying Outer Layer Surface Composition. Langmuir 19(6):2366–2371

Mittal KL (1975) Adhesion measurement of thin films. Electrocompon Sci Technol 3:21–42

Hull TR, Colligon JS, Hill AE (1987) Measurement of thin film adhesion. Vacuum 37(3):327–330

Dastjerdi AK et al (2012) Cohesive behavior of soft biological adhesives: experiments and modeling. Acta Biomater 8(9):3349–3359

Busscher HJ, van der Mei HC (2006) Microbial adhesion in flow displacement systems. Clin Microbiol Rev 19(1):127–141

Paul E et al (2012) Effect of shear stress and growth conditions on detachment and physical properties of biofilms. Water Res 46(17):5499–5508

Gupta V, Hernandez R, Charconnet P (2001) Effect of humidity and temperature on the tensile strength of polyimide/silicon nitride interface and its implications for electronic device reliability. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing 317(1–2):249–256

Grady ME, Geubelle PH, Sottos NR (2014) Interfacial adhesion of photodefinable polyimide films on passivated silicon. Thin Solid Films 552:116–123

Kandula SSV et al (2008) Adhesion strength measurement of polymer dielectric interfaces using laser spallation technique. Thin Solid Films 516(21):7627–7635

Grady ME et al (2014) Shockwave Loading of Mechanochemically Active Polymer Coatings. ACS Appl Mater Interfaces 6(8):5350–5355

Gupta V (1999) Surface science-based adhesion enhancement using a laser spallation technique. Surface Engineering: Science and Technology I 9–20

Grady ME et al (2014) Molecular Tailoring of Interfacial Failure. Langmuir 30(37):11096–11102

Kingstedt OT, Lambros J (2015) Ultra-high Speed Imaging of Laser-Induced Spallation. Exp Mech 55(3):587–598

Wang JL, Weaver RL, Sottos NR (2002) A parametric study of laser induced thin film spallation. Exp Mech 42(1):74–83

Ehrhart B et al (2014) Development of a laser shock adhesion test for the assessment of weak adhesive bonded CFRP structures. Int J Adhes Adhes 52:57–65

Ecault R et al (2016) Numerical modeling of laser-induced shock experiments for the development of the adhesion test for bonded composite materials. Compos Struct 152:382–394

Berfield TA, Kitey R, Kandula SS (2016) Adhesion strength of lead zirconate titanate sol-gel thin films. Thin Solid Films 598:230–235

Lili Hu, Zhang X, Miller P, Ozkan M, Ozkan C, Wang J (2006) Cell adhesion measurement by laser-induced stress waves. Journal of Applies Physics 100

Hagerman E et al (2007) Evaluation of laser spallation as a technique for measurement of cell adhesion strength. J Biomed Mater Res A 82A(4):852–860

Miller P, Hu L, Wang J (2010) Finite element simulation of cell-substrate decohesion by laser-induced stress waves. J Mech Behav Biomed Mater 3(3):268–277

Nakamura H et al (2006) Glycosaminoglycan degradation reduces mineralized tissue-titanium interfacial strength. J Biomed Mater Res A 77(3):478–486

Sherman B, Liou H-C, Balogun O (2015) Thin film interface stresses produced by high amplitude laser generated surface acoustic waves. J Appl Phys 118(13):135303

Krzyściak W et al (2014) The virulence of Streptococcus mutans and the ability to form biofilms. Eur J Clin Microbiol Infect Dis 33(4):499–515

Barbosa JO et al (2016) Streptococcus mutans Can Modulate Biofilm Formation and Attenuate the Virulence of Candida albicans. PLoS One 11(3):e0150457

Flemming H-C, Wingender J (2010) The biofilm matrix. Nat Rev Microbiol 8(9):623–633

Zijnge V et al (2010) Oral Biofilm Architecture on Natural Teeth. PLoS One 5(2):e9321

Bowen WH, Koo H (2011) Biology of Streptococcus mutans-Derived Glucosyltransferases: Role in Extracellular Matrix Formation of Cariogenic Biofilms. Caries Res 45(1):69–86

Moye ZD, Zeng L, Burne RA (2014) Fueling the caries process: carbohydrate metabolism and gene regulation by Streptococcus mutans. J Oral Microbiol 6:24878

Barfeie A, Wilson J, Rees J (2015) Implant surface characteristics and their effect on osseointegration. Br Dent J 218(5):E9–E9

Oshida Y (2013) Bioscience and bioengineering of titanium material Elsevier. 2nd Edition

Atieh MA, Alasbeeha NHM, Faggion CM Jr., Duncan WJ (2012) The frequency of peri-implant diseases: A systematic review and meta-analysis. Periodontal

Shen JZ, Kosmač T (2014) Advanced ceramics for dentistry. Butterworth-Heinemann, Waltham

Barker LM (1972) Laser Interferometry in Shock-Wave Research. Exp Mech 12(5):209

Gupta V et al (1990) Measurement of interface strength by laser-pulse-induced spallation. Mater Sci Eng A 126(1):105–117

Paes Leme AF, Bellato CM, Bedi G, Del Bel Cury AA, Koo H, Cury JA (2008) Effects of Sucrose on the Extracellular Matrix of Plaque-Like Biofilm Formed in vivo, Studied by Proteomic Analysis. Caries Res 42(6):435–443

Cai J-N et al (2016) Functional Relationship between Sucrose and a Cariogenic Biofilm Formation. PLoS One 11(6):e0157184

Lee S et al (1996) Alteration of cell membrane by stress waves in vitro. Ultrasound Med Biol 22(9):1285–1293

Acknowledgements

We would like to acknowledge NIH COBRE Phase III pilot funding under number 5P30GM110788-04 to carry out these experiments. SEM images were taken within the Electron Microscopy Center at the University of Kentucky by staff associate Azin Akbari. We thank the Center for Pharmaceutical Research and Innovation (CPRI) for use of bacterial culture equipment. CPRI is supported, in part, by the University of Kentucky College of Pharmacy and Center for Clinical and Translational Science (UL1TR001998). We thank Dr. Larissa Ponomareva for sharing her bacterial culture expertise. We would also like to thank Drs. Craig Miller, Lina Sharab, and Ahmad Kutkut from the University of Kentucky College of Dentistry for their guidance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boyd, J.D., Korotkova, N. & Grady, M.E. Adhesion of Biofilms on Titanium Measured by Laser-Induced Spallation. Exp Mech 59, 1275–1284 (2019). https://doi.org/10.1007/s11340-018-00458-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-018-00458-z