Abstract

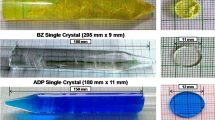

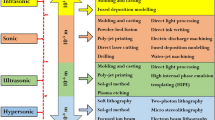

In this study, a technique is developed for fabricating high-temperature solute-solvent separation soft lithography (HSS-SL) grating for metallic materials. Using this technique, a 150 lines/mm crossing-type grating is directly fabricated on the surface of a miniaturized single edge notch tension (SENT) specimen. Further, the microstructure of the grating is analyzed using scanning electron microscope (SEM) and atom force microscope. The grating is found to be highly suited for forming high-contrast SEM moiré fringes. In addition, the chemical composition of the grating is characterized using energy dispersive X-ray spectroscope (EDS), whose results indicate that the grating exhibits good resistance to high-temperature oxidation owing to the high heat endurance of its constituent materials, SiO and SiO2. With respect to high-temperature applications, the HSS-SL grating is employed successfully for measuring the linear thermal expansion coefficient of GH2036 alloy at temperatures of 25-600 °C. Moreover, the high-temperature displacement and strain fields around the semicircular notch of the SENT specimen are determined based on the SEM moiré. These results confirm that thus-fabricated HSS-SL gratings show high potential for use in high-temperature in situ deformation measurements using the SEM moiré method.

Similar content being viewed by others

References

Kishimoto S, Egashira M, Shinya N (1993) Microcreep Deformation Measurements by a moiré Method Using Electron-Beam Lithography and Electron-Beam Scan. Opt Eng 32(2):522–526

Dally JW, Read DT (1993) Electron-Beam Moiré. Exp Mech 33(4):270–277

Read DT, Dally JW, Szanto M (1993) Scanning moiré at High Magnification Using Optical Methods. Exp Mech 33(2):110–116

Tanaka Y, Naito K, Kakisawa H (2017) Measurement method of multi scale thermal deformation inhomogeneity in CFRP using in situ FE-SEM observations. Compos A: Appl Sci Manuf 102:178–183

Berger JR, Drexler ES, Read DT (1998) Error analysis and thermal expansion measurement with electron-beam moire. Exp Mech 38(3):167–171

Li CW, Liu ZW, Xie HM, Wu D (2014) Statistics-based electron Moiré technique: a novel method applied to the characterization of mesoporous structures. Nanoscale 6(22):13409–13415

Wang QH, Kishimoto S, Jiang XF, Yamauchi Y (2013) Formation of secondary Moiré patterns for characterization of nanoporous alumina structures in multiple domains with different orientations. Nanoscale 5(6):2285–2289

Hu ZX, Xie HM, Lu JA, Liu ZW, Wang QH (2010) A new method for the reconstruction of micro- and nanoscale planar periodic structures. Ultramicroscopy 110(9):1223–1230

Yamauchi Y, Nagaura T, Takai K, Suzuki N, Sato K, Fukata N, Inoue S, Kishimoto S (2009) Generation of Electron Moiré Fringes on Designed Nanoporous Anodic Alumina Films and Their Replicated Ni Cone Arrays: Exploration of Domain Sizes and Nanopore Arrangements. J Phys Chem C 113(22):9632–9637

Li CW, Liu ZW, Xie HM, Wu D (2013) Novel 3D SEM Moiré method for micro height measurement. Opt Express 21(13):15734–15746

Xing YM, Tanaka Y, Kishimoto S, Shinya N (2003) Determining interfacial thermal residual stress in SiC/Ti-15-3 composites. Scr Mater 48(6):701–706

Lee OS, Read DT (1995) Micro-Strain Distribution around a Crack-Tip by Electron-Beam Moiré Methods. KSME Int J 9(3):298–311

Li YJ, Xie HM, Tang MJ, Zhu JG, Luo Q, Gu CZ (2012) The study on microscopic mechanical property of polycrystalline with SEM moiré method. Opt Lasers Eng 50(12):1757–1764

Kishimoto S, Shinya N, Mathew MD (1997) Application of electron beam lithography to study microcreep deformation and grain boundary sliding. J Mater Sci 32(13):3411–3417

Lang FC, Zhao YR, Xing YM, Liu F, Hou XH, Zhu J, Li JJ, Yang ST (2016) A novel raster-scanning method to fabricate ultra-fine cross-gratings for the generation of electron beam moiré fringe patterns. Opt Lasers Eng 86:281–290

Zhao YR, Lei ZK, Xing YM, Hou XH, Bai PC (2014) Fabricating Parameters Optimization of High Frequency Grating by Multi-scanning Electron Beam Method. Exp Mech 54(1):45–55

Du H, Xie HM, Guo ZL, Pan B, Luo Q, Gu CZ, Jiang HC, Rong LJ (2007) Large-deformation analysis in microscopic area using micro-moiré methods with a focused ion beam milling grating. Opt Lasers Eng 45(12):1157–1169

Wang QH, Kishimoto S (2012) Simultaneous analysis of residual stress and stress intensity factor in a resist after UV-nanoimprint lithography based on electron moiré fringes. J Micromech Microeng 22(10):105021

Xia YN, Whitesides GM (1998) Soft lithography. Annu Rev Mater Sci 28:153–184

Dai XL, Xie HM, Wang HX (2014) Deformation grating fabrication technique based on the solvent-assisted microcontact molding. Appl Opt 53(30):7037–7044

Fan B, Xie HM (2018) Fabrication of high temperature grating on thermal barrier coatings based on solute-solvent separation soft lithography. Theor Appl Mech Lett 8:12–17

Dai XL, Xie HM (2016) Versatile specimen-grating fabrication technique for moiré method based on solute-solvent separation soft lithography. Opt Mater Express 6(5):1530–1544

Dai XL, Xie HM (2015) A simple and residual-layer-free solute-solvent separation soft lithography method. J Micromech Microeng 25(9):095013

Acknowledgments

This research was financially supported by the National Natural Science Foundation of China (Grant Nos. 11672153 and 11232008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, B., Li, J., Xie, H. et al. Development of Solute-solvent Separation Soft Lithography Grating for Measuring High-temperature In situ Deformation Using Scanning Electron Microscope Moiré Method. Exp Mech 59, 29–39 (2019). https://doi.org/10.1007/s11340-018-00436-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-018-00436-5