Abstract

In this paper the error analysis, construction and experimental assessment of performances of a new high precision six-axis load cell are presented. In a previous companion paper the conceptual design, modelling and embodiment design of the load cell were described. The new load cell is able to measure the three components of respectively a force and a moment acting on the load cell itself. The new six-axis load cell, patented by Politecnico di Milano, performs well in terms of linearity, sensitivity, accuracy and repeatability.

Similar content being viewed by others

Notes

The conditioning of the sensor is the condition number of χ. However, the error propagation on the normalized system can be conveniently considered to show the effects of the main parameters of the sensor on its performances.

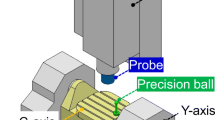

The stiffnesses parameters are referred to the load cell axis (Fig. 1) close to the connection with the structure under test (central part of the load cell).

Abbreviations

- F :

-

vector of the generalized forces acting at the load cell centre

- Ε b :

-

vector of the strains ε i (i=1,..,6)

- C b :

-

load cell calibration matrix

- T :

-

vector of reaction forces at the three joints N i , T i (i=1,2,3)

- ΔV :

-

vector of the output voltages ΔV i (i=1,..,6) at the Wheatstone bridges

- k :

-

gauge factor

- V :

-

excitation voltage at the Wheatstone bridges

- l :

-

spoke length

- M i :

-

calibration matrix

- M tst :

-

calibration matrix (statically determined structure)

- M e :

-

experimental calibration matrix

- M thp :

-

calibration matrix (quasi-statically determined structure)

- k a :

-

joint axial stiffness

- k rx / k ry :

-

joint radial stiffnesses

- k t :

-

joint torsional stiffness

- k bt / k b :

-

joint bending stiffnesses

- k x /k y /k z :

-

load cell interface stiffnesses

- S :

-

vector of the internal forces and moments acting at the spoke tips

- δ i :

-

displacements and rotations at a spoke tip

- R t (α) :

-

rotation matrix

- A(ω) :

-

Inertance—transfer function acceleration/force

- h :

-

distance between a strain gauge and the spoke tip (see Fig. 4)

- h z :

-

distance between a strain gauge and the three spoke structure centre (see Fig. 4)

- ν :

-

vector of the bending moments acting on the six strain gauge bridges

- ν tst :

-

vector of the bending moments—statically determined structure

- ν thp :

-

vector of the bending moments—quasi-statically determined structure

- χ :

-

load cell sensitivity matrix

- χ tst :

-

statically determined structure sensitivity matrix

- χ trj :

-

rigid joints model sensitivity matrix

- χ trs :

-

rigid spokes model sensitivity matrix

- δν :

-

error on the strain (bending) measurements

- δχ :

-

error on the sensitivity matrix

- :

-

Note: bold symbol refers to a vector or a matrix

References

Mastinu G, Gobbi M, Previati G (2010) A new six-axis load cell. Part I: design. Experimental Mechanics, xxx, DOI xxx

Mastinu G, Gobbi M. Dispositivo e metodo per la misura di forze e momenti, Italian Patent MI2003A 001500, 22/07/2003.

Mastinu G, Gobbi M (2005) Device and method for measuring forces and moments, Patent WO2005015146

Mastinu G, Gobbi M. Giunto elastico a cerniera sferica traslante e sensore di forze e momenti perfezionato con tale giunto, Italian Patent, ME.05.025.A, 22/05/2006

Mastinu G, Gobbi M. Elastic joint with translating spherical hinge and force and moment sensor improved by means of the said joint. International Application number PCT/IB2007/001335, 16 May 2007

Bicchi A (1992) A criterion for optimal design of Multiaxis Force Sensors. J Robot Autonom Syst, 10(4)

Golub GH, VanLoan CF (1989) Matrix computations. Johns Hopkins University Press, Baltimore

Gobbi M, Mastinu G, Giorgetta F. Sensors for measuring forces and moments with application to ground vehicle design and engineering. Proceedings ASME IMECE 2005, paper n. IMECE2005-81143

Ewins DJ. Modal testing: theory practice and application (2nd ed.), Research Studies Press LTD., Baldock, Hertfordshire, England, 34–45

ASTM E 74-04, Standard Practice of Calibration of Force-Measuring Instruments for Verifying the Force Indication of Testing Machines, January 2005

Rao SS (1992) Reliability-based design. McGraw-Hill, New York

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

Six-axis load cell matrix M tst [equation (1)]—statically determined structure model:

Six-axis load cell matrix M thp (equation (2))—quasi-statically determined structure.

The expected calibration matrix is

The standard deviations of the elements of the M thp matrix due to the strain gauges position errors only are reported below (the standard deviation matrix is computed by means of bootstrap technique [11]). The standard deviations of the non-zero terms are about 1% of the corresponding expected values.

Experimentally derived calibration matrix M e :

Appendix 2

Sensitivity matrix χ trj for the rigid joint model

Appendix 3

Robustness analysis: numerical data

Geometrical data (all models)

Nominal value | Standard deviation | |

|---|---|---|

Spoke length [mm] | 40.25 | 0.025 |

Strain gauge position h [mm] | 21 | 0.05 |

Spoke section height [mm] | 16 | 0.015 |

Spoke section width [mm] | 16 | 0.015 |

Stiffnesses* (quasi-statically determined structure)

Nominal value | Standard deviation | |

|---|---|---|

k a [N/m] | 9.4 × 106 | 2.5% |

k rx [N/m] | 455 × 106 | 2.5% |

k ry [N/m] | 455 × 106 | 2.5% |

k t [Nm/rad] | 2380 | 2.5% |

k bt [Nm/rad] | 2430 | 2.5% |

k b [Nm/rad] | 3300 | 2.5% |

* estimated by means of the FEM model

Rights and permissions

About this article

Cite this article

Gobbi, M., Previati, G., Guarneri, P. et al. A New Six-Axis Load Cell. Part II: Error Analysis, Construction and Experimental Assessment of Performances. Exp Mech 51, 389–399 (2011). https://doi.org/10.1007/s11340-010-9350-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-010-9350-6