Abstract

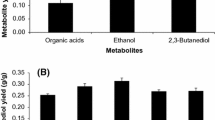

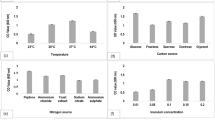

2,3-Butanediol (2,3-BD) can be produced by fermentation of natural resources like Miscanthus. Bacillus licheniformis mutants, WX-02ΔbudC and WX-02ΔgldA, were elucidated for the potential to use Miscanthus as a cost-effective biomass to produce optically pure 2,3-BD. Both WX-02ΔbudC and WX-02ΔgldA could efficiently use xylose as well as mixed sugars of glucose and xylose to produce optically pure 2,3-BD. Batch fermentation of M. floridulus hydrolysate could produce 21.6 g/L d-2,3-BD and 23.9 g/L meso-2,3-BD in flask, and 13.8 g/L d-2,3-BD and 13.2 g/L meso-2,3-BD in bioreactor for WX-02ΔbudC and WX-02ΔgldA, respectively. Further fed-batch fermentation of hydrolysate in bioreactor showed both of two strains could produce optically pure 2,3-BD, with 32.2 g/L d-2,3-BD for WX-02ΔbudC and 48.5 g/L meso-2,3-BD for WX-02ΔgldA, respectively. Collectively, WX-02ΔbudC and WX-02ΔgldA can efficiently produce optically pure 2,3-BD with M. floridulus hydrolysate, and these two strains are candidates for industrial production of optical purity of 2,3-BD with M. floridulus hydrolysate.

Similar content being viewed by others

References

Biswas R, Yamaoka M, Nakayama H, Kondo T, Yoshida K, Bisaria VS, Kondo A (2012) Enhanced production of 2,3-butanediol by engineered Bacillus subtilis. Appl Microbiol Biotechnol 94, 651–658

Chen T, Liu WX, Fu J, Zhang B, Tang YJ (2013) Engineering Bacillus subtilis for acetoin production from glucose and xylose mixtures. J Biotechnol 168:499–505

Chirino-Valle I, Kandula D, Littlejohn C, Hill R, Walker M, Shields M, Cummings N, Hettiarachchi D, Wratten S (2016) Potential of the beneficial fungus Trichoderma to enhance ecosystem-service provision in the biofuel grass Miscanthus × giganteus in agriculture. Sci Rep 6:25109

Chu H, Xin B, Liu P, Wang Y, Li L, Liu X, Zhang X, Ma C, Ping Xu, Gao C (2015) Metabolic engineering of Escherichia coli for production of (2S, 3S)-2,3-butanediol from glucose. Biotechnol Biofuels 8:143–154

Fu J, Wang Z, Chen T, Liu W, Shi T, Wang G, Tang YJ, Zhao X (2014) NADH plays the vital role for chiral pure d-2,3-butanediol production in Bacillus subtilis under limited oxygen conditions. Biotechnol Bioeng 111:2126–2131

Fu J, Hu G, Feng L, Mao Y, Wang Z, Ma H, Chen T, Zhao X (2016) Metabolic engineering of Bacillus subtilis for chiral pure meso-2,3-butanediol production. Biotechnol Biofuels 9:90–104

Huang CF, Jiang YF, Guo GL, Hwang WS (2013) Method of 2,3-butanediol production from glycerol and acid-pretreated rice straw hydrolysate by newly isolated strains: pre-evaluation as an integrated biorefinery process. Bioresour Technol 135:446–453

Ji XJ, Liu LG, Shen MQ, Nie ZK, Tong YJ, Huang H (2015) Constructing a synthetic metabolic pathway in Escherichia coli to produce the enantiomerically pure (R,R)-2,3-butanediol. Biotechnol Bioeng 112:1056–1059

Jiang LQ, Fang Z, Guo F, Yang LB (2012) Production of 2,3-butanediol from acid hydrolysates of Jatropha hulls with Klebsiella oxytoca. Bioresour Technol 107:405–410

Jurchescu IM, Hamann J, Zhou X, Ortmann T, Kuenz A, Prüße U, Lang S (2013) Enhanced 2,3-butanediol production in fed-batch cultures of free and immobilized Bacillus licheniformis DSM 8785. Appl Microbiol Biotechnol 97:6715–6723

Lee WC, Kuan WC (2015) Miscanthus as cellulosic biomass for bioethanol production. Biotechnol J 10:840–854

Lee S, Kim B, Park K, Um Y, Lee J (2012) Synthesis of pure meso-2,3-butanediol from crude glycerol using an engineered metabolic pathway in Escherichia coli. Appl Biochem Biotechnol 166:1801–1813

Lewandowska M, Szymańska K, Kordala N, Dąbrowska A, Bednarski W, Juszczuk A (2016) Evaluation of Mucor indicus and Saccharomyces cerevisiae capability to ferment hydrolysates of rape straw and Miscanthus giganteus as affected by the pretreatment method. Bioresour Technol 212:262 – 70

Li L, Wang Y, Zhang L, Ma C, Wang A, Tao F, Xu P (2012) Biocatalytic production of (2S,3S)-2,3-butanediol from diacetyl using whole cells of engineered Escherichia coli. Bioresour Technol 115:111–116

Li J, Wang W, Ma Y, Zeng AP (2013a) Medium optimization and proteome analysis of (R,R)-2,3-butanediol production by Paenibacillus polymyxa ATCC 12321. Appl Microbiol Biotechnol 97:585–597

Li L, Zhang L, Li K, Wang Y, Gao C, Han B, Ma C, Xu P (2013b) A newly isolated Bacillus licheniformis strain thermophilically produces 2,3-butanediol, a platform and fuel bio-chemical. Biotechnol Biofuels 6:123

Li L, Li K, Wang K, Chen C, Gao C, Ma C, Xu P (2014) Efficient production of 2,3-butanediol from corn stover hydrolysate by using a thermophilic Bacillus licheniformis strain. Bioresour Technol 170:256–261

Liu Z, Qin J, Gao C, Hua D, Ma C, Li L, Wang Y, Xu P (2011) Production of (2S,3S)-2,3-butanediol and (3S)-acetoin from glucose using resting cells of Klebsiella pneumonia and Bacillus subtilis. Bioresour Technol 102:10741–10744

Mazumdar S, Lee J, Oh MK (2013) Microbial production of 2,3 butanediol from seaweed hydrolysate using metabolically engineered Escherichia coli. Bioresour Technol 136:329–336

Qi G, Kang Y, Li L, Xiao A, Zhang S, Wen Z, Xu D, Chen S (2014) Deletion of meso-2,3-butanediol dehydrogenase gene budC for enhanced d-2,3-butanediol production in Bacillus licheniformis. Biotechnol Biofuels 7:16

Qiu Y, Zhang J, Li L, Wen Z, Nomura CT, Wu S, Chen S (2016) Engineering Bacillus licheniformis for the production of meso-2,3-butanediol. Biotechnol Biofuels 9:117

Roberts SB, Gowen CM, Brooks JP, Fong SS (2010) Genome-scale metabolic analysis of Clostridium thermocellum for bioethanol production. BMC systems Biology 4:31

Siemerink MAJ, Kuit W, Contreras AML, van der Oost EGJ, Kenge SWM (2011) d-2,3-butanediol production due to heterologous expression of an acetoin reductase in Clostridium acetobutylicum. Appl Environ Microbiol 77:2582–2588

Świątek K, Lewandowska M, Świątek M, Bednarski W, Brzozowski B (2014) The improvement of enzymatic hydrolysis efficiency of rape straw and Miscanthus giganteus polysaccharides. Bioresour Technol 151:323–331

Tong YJ, Ji XJ, Shen MQ, Liu LG, Nie ZK, Huang H (2016) Constructing a synthetic constitutive metabolic pathway in Escherichia coli for (R, R)-2,3-butanediol production. Appl Microbiol Biotechnol 100:637 – 47

Wang A, Wang Y, Jiang T, Li L, Ma C, Xu P (2010) Production of 2,3-butanediol from corncob molasses, a waste by-product in xylitol production. Appl Microbiol Biotechnol 87:965–970

Wang Q, Chen T, Zhao X, Chamu J (2012) Metabolic engineering of thermophilic Bacillus licheniformis for chiral pure d-2,3-butanediol production. Biotechnol Bioeng 109:1610–1621

Wu G, Yan Q, Jones JA, Tang YJ, Fong SS, Koffas MAG (2016) Metabolic burden: cornerstones in synthetic biology and metabolic engineering applications. Trends Biotechnol 34:652–664

Xu Y, Chu H, Gao C, Tao F, Zhou Z, Li K, Li L, Ma C, Xu P (2014) Systematic metabolic engineering of Escherichia coli for high-yield production of fuel bio-chemical 2,3-butanediol. Metab Eng 23:22–33

Yan Q, Hong E, Fong SS (2017) Study of ChiR function in Serratia marcescens and its application for improving 2,3-butanediol from crystal chitin. Appl Microbiol Biotechnol 101(19):1–12

Yang T, Rao Z, Zhang X, Lin Q, Xia H, Xu Z, Yang S (2011a) Production of 2,3-butanediol from glucose by GRAS microorganism Bacillus amyloliquefaciens. J Basic Microbiol 51:650–658

Yang T, Zhang X, Rao Z, Gu S, Xia H, Xu Z (2011b) Optimization and scale-up of 2,3-butanediol production by Bacillus amyloliquefaciens B10-127. World J Microb Biotechnol 28:1563–1574

Yang T, Rao Z, Zhang X, Xu M, Xu Z, Yang ST (2013a) Improved production of 2,3-Butanediol in Bacillus amyloliquefaciens by over-expression of glyceraldehyde-3-phosphate dehydrogenase and 2,3-butanediol dehydrogenase. PLoS ONE 8:e76149

Yang TW, Rao ZM, Zhang X, Xu MJ, Xu ZH, Yang ST (2013b) Effects of corn steep liquor on production of 2,3-butanediol and acetoin by Bacillus subtilis. Process Biochem 48:1610–1617

Yang TW, Rao ZM, Zhang X, Xu MJ, Xu ZH, Yang ST (2013c) Fermentation of biodiesel-derived glycerol by Bacillus amyloliquefaciens: effects of co-substrates on 2,3-butanediol production. Appl Microbiol Biotechnol 97:7651–7658

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, Y., Huang, H., Chen, S. et al. Production of optically pure 2,3-butanediol from Miscanthus floridulus hydrolysate using engineered Bacillus licheniformis strains. World J Microbiol Biotechnol 34, 66 (2018). https://doi.org/10.1007/s11274-018-2450-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-018-2450-7