Abstract

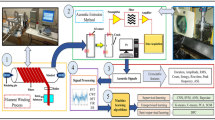

In this study, acoustic emissions (AE) signal processing using wavelet packet transform technique was used to identify damage mechanisms during sheet metal forming simulation experiments. Current investigation was carried out based on decomposing the recorded AE signals into different wavelet levels. Following decomposition process, the energy distribution criteria were used to characterize dominant components, which are considered to be related to dominant damage mechanisms. Results revealed that the energy of AE signals was distributed dominantly on four components, which can be correlated by 3 specific damage mechanisms occurred during simulation experiments. After comparison with previous works, results were validated by surface observations in order to establish a meaningful relation between dominant wavelet components and surface damage mechanisms.

Similar content being viewed by others

References

Schedin, E.: Galling mechanisms in sheet metal forming operations. Wear 179, 123–128 (1994)

Gåård, A., Krakhmalev, P., Bergström, J.: Wear mechanisms in deep drawing of carbon steel- correlation to laboratory testing. Tribotest 14, 1–9 (2008)

Van der Heide, E., Huis Veld, A.J., Schipper, D.J.: The effect of lubricant selection on galling in a model wear test. Wear 251, 971–979 (2001)

Podgornik, B., Hogmarkb, S., Pezdirnik, J.: Comparison between different test methods for evaluation of galling properties of surface engineered tool surfaces. Wear 257, 843–851 (2004)

Wang, L., Wood, R.J.K.: Acoustic emissions from lubricated hybrid contacts. Tribol. Int. 42, 1629–1637 (2009)

Skare, T., Thilderkvist, P., Stahl, J.E.: Monitoring of friction processes by the means of acoustic emission measurements—deep drawing of sheet metal. J. Mater. Proc. Technol. 80–81, 263–272 (1998)

Satoshi, I., Masayuki, S., Tatsuhiro, J., Hideki, A.: The relationship between AE and dissipation energy for fretting wear. Tribol. Int. 42, 236–242 (2009)

Yang, M., Manabea, K., Hayashi, K., Miyazaki, M., Aikawa, N.: Data fusion of distributed AE sensors for the detection of friction sources during press forming. J. Mater. Proc. Technol. 139, 368–372 (2003)

Ni, Q.Q., Iwamoto, M.: Wavelet transform of acoustic emission signals in failure of model composites. Eng. Fract. Mech. 69, 717–728 (2002)

Qi, G., Barhorst, A., Hashemi, J., Kamala, G.: Discrete wavelet decomposition of acoustic emission signals from carbon-fiber-reinforced composites. Compos. Sci. Technol. 57, 389–403 (1997)

Qi, G.: Wavelet-based AE characterization of composite materials. NDT & E Int. 33, 133–144 (2000)

Loutas, T.H., Kostopoulos, V., Ramirez-Jimenez, C., Pharaoh, M.: Damage evolution in center-holed glass/polyester composites under quasi-static loading using time/frequency analysis of acoustic emission monitored waveforms. Compos. Sci. Technol. 66, 1366–1375 (2006)

Velayudham, A., Krishnamurthy, R., Soundarapandian, T.: Acoustic emission based drill condition monitoring during drilling of glass/phenolic polymeric composite using wavelet packet transform. Mater. Sci. Eng. A 412, 141–145 (2005)

Rao, R.M., Bopardikar, A.S.: Wavelet Transforms: Introduction to Theory and Applications. Addison-Wesley, Boston (1998)

Soman, K.P., Ramachandran, K.I.: Insight into Wavelets from Theory to Practice. Prentice-Hall, New Delhi (2004)

Wojtaszczyk, P.: A Mathematical Introduction to Wavelets. Cambridge University Press, Cambridge (1997)

Walnut, D.F.: An Introduction to Wavelet Analysis. Birkhäuser, Boston (2002)

Schedin, E., Lehtinen, B.: Galling mechanisms in lubricated systems: a study of sheet metal forming. Wear 170, 119–130 (1993)

Rooij, M.B., Rooij, M.B., de Schipper, D.J.: Analysis of material transfer from a soft workpiece to a hard tool: Part I—Lump growth model. J. Tribol. 123(3), 469–473 (2000)

Woska, R.: Influence of selected surface layers on the friction and wear behavior in deep drawing. Ph.D. Thesis, TU Darmstadt (1982)

Coifman, R.R., Wickerhauser, M.V.: Entropy-based algorithms for best basis selection. IEEE Trans. Info. Theory 38, 713–718 (1992)

Mukhopadhyay, C.K., Ray, K.K., Jayakumar, T., Raj, B.: Acoustic emission from tensile deformation of unnotched and notched specimens of AISI type 304 stainless steels. Mater. Sci. Eng. A 255, 98–106 (1998)

Sindi, T.C., Ahmadi, N.M., Salehi, M.: Investigation of surface damages during sheet metal forming using acoustic emission. Proc. IMechE Part J: J Eng. Tribol. 227, 286–296 (2013)

Curtis, G.: Spectral analysis of acoustic emission. Non-Destruct. Test. 7, 82–91 (1974)

Raj, B., Jha, B.B., Rodriguez, P.: Frequency spectrum analysis of acoustic emission signal obtained during tensile deformation and fracture of an AISI 316 type stainless steel. Acta Metall. 37, 2211–2215 (1989)

Bruchy, W.J.: Technical Report BRL TR-2774, US Army Ballastic Res. Lab., Maryland (91986)

Hertzberg, R.W.: Deformation and Fracture Mechanics of Engineering Materials. Wiley, New York (1996)

Ki, W.N., Chang, Y.K., Jae, Y.D., Seok, H.A., Sang, K.L.: Fatigue crack propagation of super duplex stainless steel with dispersed structure and time-frequency analysis of acoustic emission. Met. Mater. Int. 7, 227–231 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teymuri Sindi, C., Ahmadi Najafabadi, M. & Salehi, M. Tribological Behavior of Sheet Metal Forming Process Using Acoustic Emission Characteristics. Tribol Lett 52, 67–79 (2013). https://doi.org/10.1007/s11249-013-0193-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0193-z