Abstract

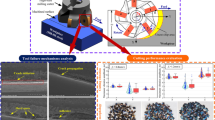

The application of controlled, low-frequency modulation superimposed onto the cutting process—modulation-assisted machining (MAM)—is shown to be quite effective in reducing the wear of cubic boron nitride (CBN) tools when machining compacted graphite iron (CGI) at high machining speeds (>500 m/min). The tool life is at least one order of magnitude greater than that in conventional machining. The improvement in wear performance is a consequence of a reduction in the severity of the tool–work contact conditions in MAM: reduction in intimacy of the contact, formation of discrete chips, enhanced fluid action, and lower cutting temperatures. The propensity for thermochemical wear of CBN, the principal wear mode at high speeds in CGI machining, is thus reduced. The MAM configuration employing feed-direction modulation appears feasible for implementation at high speeds and offers a potential solution to this challenging class of industrial machining applications.

Similar content being viewed by others

References

Dawson, S.: Compacted graphite iron: mechanical and physical properties for engine design. Paper presented at Materials in Powertrain VDI, Dresden, Germany. SinterCast Tech. Publication (1999)

Dawson, S., Hollinger, I., Robbins, M., Daeth, J., Reuter, U., Schulz, H.: The effect of metallurgical variables on the machinability of compacted graphite iron. SAE Tech. Pap. Ser. 2001-01-0409 (2009)

Abele, E., Sahm, A., Schultz, H.: Wear mechanism when machining compacted graphite iron. Ann. CIRP 51, 53–56 (2002)

Zelinski, P.: Surpassing the speed limit in CGI. Mod. Mach. Shop 76, 102–103 (2003)

Gastel, M., Konetschny, C., Reuter, U., Fasel, C., Schulz, H., Riedel, R., Ortner, H.M.: Investigation of the wear mechanism of cubic boron nitride tools used for the machining of compacted graphite iron and grey cast iron. Int. J. Refract. Met. Hard Mater. 18, 287–296 (2000)

Heck, M., Ortner, H.M., Flege, S., Reuter, U., Ensinger, W.: Analytical investigations concerning the wear behavior of cutting tools used for the machining of compacted graphite iron and grey cast iron. Int. J. Refract. Met. Hard Mater. 26, 192–206 (2008)

Tasdelen, B., Escursell, M., Grenmyr, G., Nyborg, L.: Machining of gray cast irons and compacted graphite iron. In: Swedish Production Symposium. pp. 1–6 (2007)

Shaw, M.C.: Metal cutting principles. Clarendon Press, Oxford (1984)

Moscoso, W., Olgun, E., Compton, W.D., Chandrasekar, S.: Effect of low-frequency modulation on lubrication of chip-tool interface in machining. J. Tribol. 127, 238–244 (2005)

Mann, J.B., Saldana, C., Moscoso, W., Compton, W.D., Chandrasekar, S.: Effects of controlled modulation on interface tribology and deformation in machining. Tribol. Lett. 35, 221–227 (2009)

Huang, C., Lee, S., Sullivan, J.P., Chandrasekar, S.: In situ measurement of fluid film thickness in machining. Tribol. Lett. 28, 39–44 (2007)

Moriwaki, T., Shamoto, E.: Ultraprecision diamond turning of stainless steel by applying ultrasonic vibration. Ann. CIRP 40, 559–562 (1991)

Brehl, D.E., Dow, T.A.: Review of vibration-assisted machining. Precis. Eng. 32, 153–172 (2008)

Kumabe, J.: Vibration cutting—basic principle and application. Jikkyo Shuppan Books, Japan (1979)

Mann, J.B., Saldana, C., Chandrasekar, S., Compton, W.D., Trumble, K.P.: Metal particulate production by modulation-assisted machining. Scr. Mater. 57, 909–912 (2007)

Mann, J.B., Guo, Y., Saldana, C., Compton, W.D., Chandrasekar, S.: Enhancing material removal processes using modulation-assisted machining. Tribol. Int. 44, 1225–1235 (2011)

Boothroyd, G.: Fundamentals of metal machining and machine tools. McGraw-Hill, New York (1975)

Hutchings, I.M.: Tribology: friction and wear of engineering materials. Arnold, London (1992)

Kountanya, R.: Cutting tool temperatures in interrupted cutting—the effect of feed direction modulation. J. Manuf. Process 10, 47–55 (2008)

Acknowledgments

This study was supported in part by Diamond Innovations, Inc. (Columbus, Ohio, USA) and a Bilsland fellowship to Yang Guo. We thank M4 Sciences LLC for providing the prototype large-scale MAM system used in the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Y., Mann, J.B., Yeung, H. et al. Enhancing Tool Life in High-Speed Machining of Compacted Graphite Iron (CGI) Using Controlled Modulation. Tribol Lett 47, 103–111 (2012). https://doi.org/10.1007/s11249-012-9966-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-9966-z