Abstract

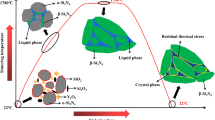

Ti3SiC2 was thermally oxidized (TO) at 1,000 °C for 10 h. An oxide scale of ca. 25 μm was composed of rutile TiO2 and Al2O3 for the outer sub-layer and mixtures of TiO2 and SiO2 for the inner sub-layer. The tribological behavior of Ti3SiC2 and TO–Ti3SiC2 sliding against Si3N4 at 25 and 600 °C was investigated. Results indicated that at both 25 and 600 °C, the oxide scale significantly improved the tribological performance of Ti3SiC2. The wear mechanisms of Ti3SiC2 and TO–Ti3SiC2 sliding against Si3N4 at 25 and 600 °C are briefly discussed.

Similar content being viewed by others

References

Barsoum, M.W.: The Mn+1AXn phases: a new class of solids; thermodynamically stable nanolaminates. Prog. Solid State Chem. 28, 201–281 (2000)

Barsoum, M.W., El-Raghy, T.: Synthesis and characterization of a remarkable ceramic: Ti3SiC2. J. Am. Ceram. Soc. 79, 1953–1956 (1996)

Barsoum, M.W., Brodkin, D., El-Raghy, T.: Layered machinable ceramics for high temperature applications. Scripta Mater. 36, 535–541 (1997)

Myhra, S., Summers, J.W.B., Kisi, E.H.: Ti3SiC2—a layered ceramic exhibiting ultra-low friction. Mater. Lett. 39, 6–11 (1999)

El-Raghy, T., Blau, P., Barsoum, M.W.: Effect of grain size on friction and wear behavior of Ti3SiC2. Wear 238, 125–130 (2000)

Souchet, A., Fontaine, J., Belin, M., Le Mogne, T., Loubet, J.-L., Barsoum, M.W.: Tribological duality of Ti3SiC2. Tribol. Lett. 18(3), 314–352 (2005)

Sun, Z., Zhou, Y.: Tribological behavior of Ti3SiC2-based material. J. Mater. Sci. Technol. 18(2), 142–145 (2002)

Zhang, Y., Ding, G., Zhou, Y., Cai, B.: Ti3SiC2—a self-lubricating ceramic. Mater. Lett. 55, 285–289 (2002)

Hu, C., Zhou, Y., Bao, Y., Wan, D.: Tribological properties of polycrystalline Ti3SiC2 and Al2O3-reinforced Ti3SiC2 composites. J. Am. Ceram. Soc. 89(1), 3456–3461 (2006)

Sarkar, D., Manoj Kumar, B.V., Basu, B.: Understanding the fretting wear of Ti3SiC2. J. Eur. Ceram. Soc. 26, 2441–2452 (2006)

Hibi, Y., Miyake, K., Murakami, T., Sasaki, S.: Tribological behavior of SiC-reinforced Ti3SiC2-based composites under dry condition and under lubricated condition with water and ethanol. J. Am. Ceram. Soc. 89(9), 2983–2985 (2006)

Ren, S., Meng, J., Lu, J., Yang, S.: Tribological behavior of Ti3SiC2 sliding against Ni-based alloys at elevated temperatures. Tribol. Lett. 31, 129–137 (2008)

Huang, Z., Zhai, H., Zhou, W., Zhang, Z., Wang, Y., Ai, M., Zhang, Z., Li, S.: High-speed friction and wear behaviors of bulk Ti3SiC2. Trans. Nonferrous Met. Soc. China 15(2), 266–269 (2005)

Zhai, H., Hang, Z., Zhou, Y., Zhang, Z., Wang, Y., Ai, M.: Oxidation layer in sliding friction surface of high-purity Ti3SiC2. J. Mater. Sci. 39, 6635–6637 (2004)

Gupta, S., Filimonov, D., Zaitsev, V., Palanisamy, T., Barsoum, M.W.: Ambient and 550 °C tribological behavior of select MAX phases against Ni-based superalloys. Wear 264, 270–278 (2008)

El-Raghy, T., Barsoum, M.W.: Diffusion kinetics of the carburization and silicidation of Ti3SiC2. J. Appl. Phys. 83(1), 112–119 (1998)

Li, C., Li, M., Zhou, Y.: Improving the surface hardness and wear resistance of Ti3SiC2 by boronizing treatment. Surf. Coat. Technol. 201, 6005–6011 (2007)

Low, I.M.: Depth profiling of phase composition in a novel Ti3SiC2–TiC system with graded interfaces. Mater. Lett. 58, 927–932 (2004)

Yang, S., Yang, Q., Sun, Z.: Nucleation and growth of diamond on titanium silicon carbide by microwave plasma-enhanced chemical vapor deposition. J. Cryst. Growth 294, 452–458 (2006)

Guo, H., Zhang, J., Li, F., Liu, Y., Yin, J., Zhou, Y.: Surface strengthening of Ti3SiC2 through magnetron sputtering Cu and subsequent annealing. J. Eur. Ceram. Soc. 28, 2099–2107 (2008)

Gardos, M.N.: Magnéli phases of anion-deficient rutile as lubricious oxides. Part I. Tribological behavior of single-crystal and polycrystalline rutile (Ti n O2n−1). Tribol. Lett. 8, 65–78 (2000)

Gardos, M.N., Hong, H.-S., Winer, W.O.: The effect of anion vacancies on the tribological properties of rutile (TiO2-x), Part II: experimental evidence. Tribol. Trans. 22(2), 209–220 (1990)

Gardos, M.N.: The effect of anion vacancies on the tribological properties of rutile (TiO2−x ). Tribol. Trans. 31(4), 427–436 (1988)

Gardos, M.N.: The effect of anion vacancies on the tribological properties of rutile (TiO2−x ). Tribol. Trans. 32, 30–31 (1989)

Woydt, M.: Tribological characteristics of polycrystalline Magnéli-type titanium dioxides. Tribol. Lett. 8, 117–130 (2000)

Król, S., Ptacek, L., Zalisz, Z., Hepner, M.: Friction and wear properties of titanium and oxidised titanium in dry sliding against hardened C45 steel. J. Mater. Process. Technol. 157–158, 364–369 (2004)

Rama Krishna, D.S., Brama, Y.L., Sun, Y.: Thick rutile layer on titanium for tribological applications. Tribol. Int. 40, 329–334 (2007)

Barsoum, M.W., El-Raghy, T., Ogbuji, L.U.J.T.: Oxidation of Ti3SiC2 in Air. J. Electrochem. Soc. 144(7), 2508–2516 (1997)

Sun, Z., Zhou, Y., Li, M.: High temperature oxidation behavior of Ti3SiC2-based material in air. Acta Mater. 49, 4347–4353 (2001)

Chen, T., Green, P.M., Jordan, J.L., Hampikian, J.M., Thadhani, N.N.: Oxidation of Ti3SiC2 composites in air. Metall. Mater. Trans. A 33, 1737–1742 (2002)

Sun, Z., Zhou, Y., Li, M.: Oxidation behaviour of Ti3SiC2-based ceramic at 900–1300 °C in air. Corros. Sci. 43, 1095–1109 (2001)

Sun, Z., Zhou, Y., Li, M.: Cyclic-oxidation behavior of Ti3SiC2-base material at 1100 °C. Oxid. Met. 57, 379–394 (2002)

Lee, D.B., Park, S.W.: Oxidation of Ti3SiC2 between 900 and 1200 °C in air. Oxid. Met. 67, 51–66 (2006)

Acknowledgments

The authors acknowledge the financial support from the National Natural Science Foundation of China (50675216), the West Doctor Program and the Knowledge Innovation Program of the Chinese Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, S., Meng, J., Wang, J. et al. Friction and Wear of Thermal Oxidation-Treated Ti3SiC2 . Tribol Lett 37, 59–67 (2010). https://doi.org/10.1007/s11249-009-9490-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9490-y