Abstract

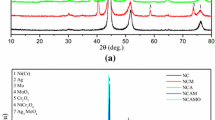

The novel Ta2AlC–20 vol.% Ag (TaAg) and Cr2AlC–20 vol.% Ag (CrAg) composites were tribologically tested versus a Ni-based superalloy Inc718 (SA) by dry sliding at a sliding speed of 1 m/s at room temperature in air at loads from 3 N to 18 N. The TaAg composites were also tested at 8 and 18 N at 550 °C, and at a 3 N load against the SA with different surface roughnesses at 26 °C and 550 °C. At room temperatures, the coefficients of friction, μ’s, decreased from ~0.8–0.9 to ~0.3–0.4 for both the TaAg and CrAg composites as the applied normal force increased from 3 N to 8 N. Further increases in load to 18 N did not change the μ’s. The specific wear rates, sWR, increased with increased loads for the TaAg composite; they remained almost unchanged for the CrAg composite. This behavior was attributed to the formation of glaze tribofilms—similar to ones observed previously in these tribocouples at elevated temperatures and 3 N—promoted by the increased loads. Preconditioning of the SA surface by sliding against the TaAg composite at 550 °C and 8 N resulted in μ’s of <0.2 and sWR < 10−6 mm3/N-m in subsequent room temperature sliding at 3 N. Somewhat higher, but stable room temperature μ’s of ~0.3 and sWR of ~3 × 10−5 mm3/N-m were observed when the TaAg composites were slid versus a sandblasted SA surface at 500 °C and 3 N. It follows that in situ preconditioning of the tribo-surfaces is a powerful tool for improving the properties of the MAX/Ag-SA tribocouples. The relationship between sliding conditions, chemistries of tribofilms, and their properties are discussed.

Similar content being viewed by others

References

Erdemir, A.: Modern Tribology Handbook, Ch. 22. CRC Press LLC, Boca Raton, Florida (2003)

Peterson, M.B., Calabrese, S.J., Li, S., Jiang, X.: Friction of alloys at high temperature. J. Mater. Sci. Technol. 10, 313–320 (1994)

Dellacorte, C., Sliney, H.E.: Tribological Properties of PM212: A High-Temperature, Self-Lubricating, Powder Metallurgy Composite, p. 102355, NASA TM (1990)

Wang, W.: Application of a high temperature self-lubricating composite coating on steam turbine components. Surf. Coat. Tech. 177, 12–17 (2004). doi:10.1016/j.surfcoat.2003.06.025

Barsoum, M.W.: The Mn+1AXn phases: a new class of solids; thermo-dynamically stable nanolaminates. Prog. Solid State Chem. 28, 201–281 (2000). doi:10.1016/S0079-6786(00)00006-6

Gupta, S., Filimonov, D., Palanisamy, T., El-Raghy, T., Barsoum, M.W.: Ta2AlC and Cr2AlC Ag-based composites—new solid lubricant materials for use over a wide temperature range against Ni-based superalloys and alumina. Wear 262, 1479–1489 (2007). doi:10.1016/j.wear.2007.01.028

Gupta, S.: Tribology of MAX Phases and Its Composites, Ph.D. Thesis, Drexel University, Philadelphia (2006)

Inman, I.A., Datta, S., Du, H.L., Burnell-Gray, J.S., Luo, Q.: Microscopy of glazed layers formed during high temperature sliding wear at 750 degrees C. Wear 254, 461–467 (2003)

Jiang, J.R., Stott, F.H., Stack, M.M.: A generic model for dry sliding wear of metals at elevated temperatures. Wear 256, 973–985 (2004). doi:10.1016/j.wear.2003.09.005

Stott, F.H.: The role of oxidation in the wear of alloys. Tribol. Int. 31, 61–71 (1998). doi:10.1016/S0301-679X(98)00008-5

Li, X.Y., Tandon, K.N.: Microstructural characterization of mechanically mixed layer and wear debris in sliding wear of an Al alloy and an Al based composite. Wear 245, 148–161 (2000). doi:10.1016/S0043-1648(00)00475-0

Gupta, S., Filimonov, D., Zaitsev, V., Palanisamy, T., Barsoum, M.W.: Study of tribofilms formed during dry sliding of Ta2AlC/Ag or Cr2AlC/Ag composites against Ni based superalloys and Al2O3. Wear (submitted)

Archard, J.F., Rowntree, R.A.: The temperature of rubbing bodies; part 2, the distribution of temperatures. Wear 128, 1–17 (1988). doi:10.1016/0043-1648(88)90249-9

Kumar, B.V.M., Basu, B., Kalin, M., Vizintin, J.: Load-dependent transition in sliding wear properties of TiCN-WC-Ni cermets. J. Am. Ceram. Soc. 90, 1534–1540 (2007). doi:10.1111/j.1551-2916.2007.01630.x

So, H., Yu, D.S., Chuang, C.Y.: Formation and wear mechanism of tribo-oxides and the regime of oxidational wear of steel. Wear 253, 1004–1015 (2002). doi:10.1016/S0043-1648(02)00230-2

Gonzalez, C., Martin, A., Llorca, J., Garrido, M.A., Gomez, M.T., Rico, A., et al.: Numerical analysis of pin on disc tests on Al-Li/SiC composites. Wear 259, 609–612 (2005). doi:10.1016/j.wear.2005.02.107

Gao, J.Q., Lee, S.C., Ai, X.L., Nixon, H.: An FFT-based transient flash temperature model for general three-dimensional rough surface contacts. J. Tribol. Trans. Asme 122, 519–523 (2000). doi:10.1115/1.555395

Gong, Z.Q., Komvopoulos, K.: Thermomechanical analysis of semi-infinite solid in sliding contact with a fractal surface. J. Tribol. Trans. Asme 127, 331–342 (2005). doi:10.1115/1.1792691

Guha, D., Chowdhuri, S.K.R.: The effect of surface roughness on the temperature at the contact between sliding bodies. Wear 197, 63–73 (1996). doi:10.1016/0043-1648(95)06833-3

Kalin, M.: Influence of flash temperatures on the tribological behaviour in low-speed sliding: a review. Mater Sci Eng A 374, 390–397 (2004)

Gupta, S., Filimonov, D., Palanisamy, T., Barsoum, M.W.: Tribological behavior of select MAX phases against Al2O3 at elevated temperatures. Wear 265, 560–565 (2008). doi:10.1016/j.wear.2007.11.018

Lin, Z.J., Li, M.S., Wang, J.Y., Zhou, Y.C.: High-temperature oxidation and hot corrosion of Cr2AlC. Acta Mater. 55, 6182–6191 (2007). doi:10.1016/j.actamat.2007.07.024

Gupta, S., Filimonov, D., Zaitsev, V., Palanisamy, T, Barsoum, M.W.: Ambient and 550°C tribological behavior of select MAX phases against Ni-based superalloys. Wear 264, 270–278 (2008). doi:10.1016/j.wear.2007.03.011

Rozman, G., Urbakh, M., Klafter, J.: Stick-slip dynamics of interfacial friction. Physica A 249, 184–189 (1998). doi:10.1016/S0378-4371(97)00462-7

Acknowledgments

This work was supported by Office of Naval Research (N00421-03-C-0085).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Filimonov, D., Gupta, S., Palanisamy, T. et al. Effect of Applied Load and Surface Roughness on the Tribological Properties of Ni-Based Superalloys Versus Ta2AlC/Ag or Cr2AlC/Ag Composites. Tribol Lett 33, 9–20 (2009). https://doi.org/10.1007/s11249-008-9384-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-008-9384-4