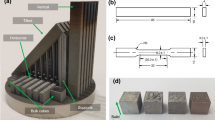

Features of the effect of sintering temperature, pressure and duration of isothermal exposure during spark plasma sintering on the structure of Al2O3 ceramics without activating additives are determined. The correlation revealed makes it possible to determine the direction for finding optimum parameters of a sintering regime and to formulate the production recommendations for sintering ingots for small end milling cutters.

Similar content being viewed by others

References

V. V. Kuzin, “Study of high-speed cutting with ceramic tools,” Russian Engineering Research, 24(3), 40 – 46 (2004).

M. A. Volosova and V. V. Kuzin, “Regular features of wear of cutting plates from oxide and nitride ceramics,” Metal Sci. Heat Treat., 54(1/2), 41 – 46 (2012).

V. V. Kuzin, “Increasing the operational stability of nitride-ceramic cutters by optimizing their grinding conditions,” Russian Engineering Research, 23(12), 32 – 36 (2003).

S. N. Grigor’ev, V. V. Kuzin, M. N. Morgan, and A. D. Batako, “Influence of loads on the stress-strain state of aluminum-oxide ceramic cutting plates,” Russian Engineering Research, 32(1), 61 – 67 (2012).

S. N. Grigor’ev, V. V. Kuzin, M. N. Morgan, and A. D. Batako, “Influence of thermal loads on the stress–strain state of aluminum-oxide ceramic cutting plates,” Russian Engineering Research, 32(5), 473 – 477 (2012).

M. Tokita, “Development of advanced spark plasma sintering (SPS) systems and its applications,” Ceram. Trans., 194, 51 – 60 (2006).

E. K. Papypov, O. O. Shichalin, V. Yu. Maiorov, et al., “Spar plasma sintering technology as a promising solution for creating functional nanostructured ceramic,” Vestn, DVO RAN. Perspekt. Material Metody, No. 6, 15 – 30 (2016).

Z. A. Munir, D. V. Quach, and M. Ohyanagi, “Electric current activation of sintering: a review of the pulsed electric current sintering process,” J. Am. Ceram. Soc., 94, 1 – 19 (2011).

M. S. Boldin, N. V. Sakharaov, S. V. Shotin, et al., “Composite ceramics base on aluminum oxide prepared by electro-impulse plasma sintering for tribological application,” Vestn. Nizhegorod N. I. Lobachevskii University, No. 6, 32 – 37 (2012).

Z. A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi, “The effect of electric plasma sintering method,” J. Mater. Sci., 41, 763 – 777 (2006).

M. Tokita, “The potential of spark plasma sintering (SPS) method for the fabrication on an industrial scale of functionally graded materials,” Adv. Sci. Technol., 63, 322 – 331 (2010).

O. Yu. Sorokin, S. S. Solntsev, S. A. Evdokimov, et al., “method of hybrid spark plasma sintering: principle, potential, and application prospects,” Aviats. Metr. Tekhnol., No. S6, 11 – 16 (2014).

Zhijian Shen, Mats Johnsson, Zhe Zhao, et al., “Spark plasma sintering of alumina,” J. Am. Ceram. Soc., 85, 1921 – 1927 (2002).

A. G. Anisimov and V. I. Mali, “Study of the possibility of electro-impulse sintering of nanostructured powder materials,” Fiz. Goren. Vzryva, No. 2, 135 – 139 (2010).

I. Álvarez, R. Torrecillas, W. Solisand, et al., “Microstructural design of Al2O3–SiC nanocomposites by spark plasma sintering,” Ceram. Int., 42, 17248 – 17253 (2016).

Jae Hong Chae, Kyung Hun Kim, Yong Ho Choa, et al., “Microstructural evolution of Al2O3–SiC nanocomposites during spark plasma sintering,” J. Alloys Compd., 413, 259 – 264 (2006).

C. F. Gutiérrez-González, M. Suarez, S. Pozhidaev, et al., “Effect of TiC addition on the mechanical behaviour of Al2O3–SiC whiskers composites obtained by SPS,” J. Eur. Ceram. Soc., 36, 2149 – 2152 (2016).

É. Alvarez, K. Guttierrez, R Torresilyas, et al., “Properties of nanocomposite materials based on oxide ceramic prepared by a spark-plasma method,” Perspekt. Materialy., No. 4, 43 – 50 (2014).

V. N. Chuvil’deev, M. S. Boldin, Ya. D. Shyamlova, et al., Comparative study of hot compaction and spark plasma sintering of Al2O3–ZrO2–Ti(C, N) powder,” Neorgan. Materialy, No. 10, 1128 – 1134 (2015).

Yoshihiro Tamura, Eugenio Zapata-Solvas, Bibi Malmal Moshtaghioun, et al., “Grain-boundary diffusion coefficient in α-Al2O3 from spark plasma sintering tests,” Ceram. Int., 44, 19044 – 19048 (2018).

Wang CaoWang, XinWang, and Zhe Zhao, “Microstructure homogeneity control in spark plasma sintering of Al2O3 ceramics, J. Eur. Ceram. Soc., 31, 231 – 235 (2011).

E. V. Petrova, A. F. Fresvyannikov, and V. N. Doronin, “Synthesis of nanostructured material based on aluminum oxide by means of spark plasma sintering,” Vestn. Kazan. Tekhnol. Univ., No. 11, 256 – 259 (2011).

I. P. Shapiro, R. I. Todd, J. M. Titchmarsh, et al., “Effects of Y2O3 additives and powder purity on the densification and grain boundary composition of Al2O3/SiC nanocomposites,” J. Eur. Ceram. Soc., 29, 1613 – 1624 (2009).

E. Tõldsepp, F. Schoenstein, M. Amamra, et al., “Spark plasma sintering of ultra-porous γ-Al2O3,” Ceram. Int. 42, 11709 – 11715 (2016).

Jinling Liu, Yiguang Wang, Fuqian Yang, et al., “Grain refining in spark plasma sintering Al2O3 ceramics,” J. Alloys Compd., 622, 596 – 600 (2015).

S. W. Wang, L. D. Chen, T. Hirai, et al., “Formation of Al2O3 grains with different sizes and morphologies during the pulse electric current sintering process,” Mater. Res. 16, 3514 – 3517 (2001).

Research was carried out due to a grant of the Russian Scientific Fund No. 18-19-00599.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Grigor’ev, N., Fedorov, S.Y. et al. Spark Plasma Sintering of Al2O3-Ceramic Workpieces for Small End Milling Cutters. Refract Ind Ceram 59, 623–627 (2019). https://doi.org/10.1007/s11148-019-00285-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-019-00285-2