Abstract

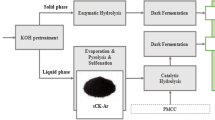

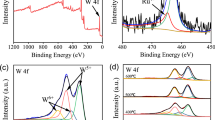

In order to maximize the utilization of biomass waste, a Cu/C-P biochar catalyst prepared by supporting copper on the pyrolysis char derived from wheat straw was used in the hydrothermal conversion of wheat straw to prepare lactic acid and acetic acid. The catalyst was characterized using scanning electron microscopy, X-ray diffraction, Fourier transform infrared spectroscopy, and X-ray photoelectron spectroscopy methods. The effects of Cu loading, reaction time, reaction temperature, and catalyst dosage on the yield of lactic acid and acetic acid were studied to optimize the reaction conditions. Results showed that Cu/C-P had a noticeable catalytic effect on the hydrothermal catalytic conversion of wheat straw, with the yield of lactic acid increasing by 37.68% and the yield of acetic acid increasing by 30.58%. CuO was generated and loaded on the biochar acting as the active site of the catalyst and interacted with soluble oligomers and glucose in solution to form lactic acid and acetic acid. The interaction of oxygen-containing functional groups on the surface of the biochar with active sites Cu0 and Cu2O, which played the role of co-catalyst, improved the catalytic activity and effectively promoted the generation of lactic acid and acetic acid.

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Should any raw data files be needed in another format they are available from the corresponding author upon reasonable request. Source data are provided with this paper.

References

Sansaniwal SK, Rosen MA, Tyagi SK (2017) Global challenges in the sustainable development of biomass gasification: an overview. Renew Sustain Energy Rev 80:23–43. https://doi.org/10.1016/j.rser.2017.05.215

Pang S (2019) Advances in thermochemical conversion of woody biomass to energy, fuels and chemicals. Biotechnol Adv 37:589–597

Kumar A, Kumar J, Bhaskar T (2020) Utilization of lignin: a sustainable and eco-friendly approach. J Energy Inst 93:235–271. https://doi.org/10.1016/j.joei.2019.03.005

Shaikh WA, Kumar A, Chakraborty S et al (2022) Removal of toxic dye from dye-laden wastewater using a new nanocomposite material: isotherm, kinetics and adsorption mechanism. Chemosphere 308:136413

Aragaw TA, Bogale FM (2021) Biomass-based adsorbents for removal of dyes from wastewater: a review. Front Environ Sci. https://doi.org/10.3389/fenvs.2021.764958

Kumar A, Bhattacharya T, Shaikh WA, Chakraborty S, Owens G, Naushad M (2022) Valorization of fruit waste-based biochar for arsenic removal in soils. Environ Res 213:113710

Kumar A, Bhattacharya T, Mozammil Hasnain SM, Kumar Nayak A, Hasnain MS (2020) Applications of biomass-derived materials for energy production, conversion, and storage. Mater Sci Energy Technol 3:905–920

Shan R, Han J, Gu J, Yuan H, Luo B, Chen Y (2020) A review of recent developments in catalytic applications of biochar-based materials. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2020.105036

Kostić MD, Bazargan A, Stamenković OS, Veljković VB, McKay G (2016) Optimization and kinetics of sunflower oil methanolysis catalyzed by calcium oxide-based catalyst derived from palm kernel shell biochar. Fuel 163:304–313. https://doi.org/10.1016/j.fuel.2015.09.042

Cao X, Sun S, Sun R (2017) Application of biochar-based catalysts in biomass upgrading: a review. RSC Adv 7:48793–48805. https://doi.org/10.1039/c7ra09307a

Wei Y, Shen C, Xie J, Bu Q (2020) Study on reaction mechanism of superior bamboo biochar catalyst production by molten alkali carbonates pyrolysis and its application for cellulose hydrolysis. Sci Total Environ 712:136435. https://doi.org/10.1016/j.scitotenv.2019.136435

Liu Y, Nie Y, Lu X et al (2019) Cascade utilization of lignocellulosic biomass to high-value products. Green Chem 21:3499–3535. https://doi.org/10.1039/C9GC00473D

Sherwood J (2020) The significance of biomass in a circular economy. Bioresour Technol 300:122755. https://doi.org/10.1016/j.biortech.2020.122755

Din NAS, Lim SJ, Maskat MY, Mohd Zaini NA (2022) Microbial D-lactic acid production, in situ separation and recovery from mature and young coconut husk hydrolysate fermentation broth. Biochem Eng J 188:108680

Tufail T, Saeed F, Afzaal M et al (2021) Wheat straw: a natural remedy against different maladies. Food Sci Nutr 9:2335–2344. https://doi.org/10.1002/fsn3.2030

Chang C, Deng L, Xu G (2018) Efficient conversion of wheat straw into methyl levulinate catalyzed by cheap metal sulfate in a biorefinery concept. Ind Crops Prod 117:197–204. https://doi.org/10.1016/j.indcrop.2018.03.009

Xu S, Pan D, Wu Y et al (2019) Direct conversion of wheat straw components into furan compounds using a highly efficient and reusable SnCl2-PTA/β zeolite catalyst. Ind Eng Chem Res 58:9276–9285. https://doi.org/10.1021/acs.iecr.9b00984

Heda J, Niphadkar P, Mudliar S, Bokade V (2020) Highly efficient micro-meso acidic H-USY catalyst for one step conversion of wheat straw to ethyl levulinate (biofuel additive). Microporous Mesoporous Mater 306:110474. https://doi.org/10.1016/j.micromeso.2020.110474

Xu S, Pan D, Wu Y et al (2018) Efficient production of furfural from xylose and wheat straw by bifunctional chromium phosphate catalyst in biphasic systems. Fuel Process Technol 175:90–96. https://doi.org/10.1016/j.fuproc.2018.04.005

Nkosi DV, Bekker JL, Hoffman LC (2021) The use of organic acids (lactic and acetic) as a microbial decontaminant during the slaughter of meat animal species: a review. Foods. https://doi.org/10.3390/foods10102293

Kwan TH, Hu Y, Lin CSK (2018) Techno-economic analysis of a food waste valorisation process for lactic acid, lactide and poly (lactic acid) production. J Clean Prod 181:72–87. https://doi.org/10.1016/j.jclepro.2018.01.179

Németh Á, Vidra A (2017) Bio-produced acetic acid: a review. Periodica Polytech, Chem Eng 62:245–256. https://doi.org/10.3311/PPch.11004

Van Wouwe P, Dusselier M, Vanleeuw E, Sels B (2016) Lactide synthesis and chirality control for polylactic acid production. Chemsuschem 9:907–921. https://doi.org/10.1002/cssc.201501695

Iglesias J, Moreno J, Morales G et al (2019) Sn–Al-USY for the valorization of glucose to methyl lactate: switching from hydrolytic to retro-aldol activity by alkaline ion exchange. Green Chem 21:5876–5885. https://doi.org/10.1039/c9gc02609f

Komesu A, Maciel M, Filho R (2017) Separation and purification technologies for lactic acid – a brief review. BioResources 12:6885–6901. https://doi.org/10.15376/biores.12.3.6885-6901

Nayak J, Pal P (2013) Transforming waste cheese-whey into acetic acid through a continuous membrane-integrated hybrid process. Ind Eng Chem Res 52:2977–2984. https://doi.org/10.1021/ie3033729

Alper K, Tekin K, Karagöz S, Ragauskas AJ (2020) Sustainable energy and fuels from biomass: a review focusing on hydrothermal biomass processing. Sustain Energy Fuels 4:4390–4414. https://doi.org/10.1039/d0se00784f

Younas R, Zhang S, Zhang L et al (2016) Lactic acid production from rice straw in alkaline hydrothermal conditions in presence of NiO nanoplates. Catal Today 274:40–48. https://doi.org/10.1016/j.cattod.2016.03.052

Jin F, Zhou Z, Kishita A, Enomoto H, Kishida H, Moriya T (2007) A New hydrothermal process for producing acetic acid from biomass waste. Chem Eng Res Des 85:201–206. https://doi.org/10.1205/cherd06020

Lin J-C, Mariuzza D, Volpe M, Fiori L, Ceylan S, Goldfarb JL (2021) Integrated thermochemical conversion process for valorizing mixed agricultural and dairy waste to nutrient-enriched biochars and biofuels. Bioresour Technol 328:124765

Guo X, Li H, Yan H et al (2019) Production of organic carboxylic acids by hydrothermal conversion of electron beam irradiation pretreated wheat straw. Biomass Convers Biorefinery 10:997–1006. https://doi.org/10.1007/s13399-019-00471-9

Wu S, Chen Y, Chen Z, Wang J, Cai M, Gao J (2021) Shape-stabilized phase change material with highly thermal conductive matrix developed by one-step pyrolysis method. Sci Rep 11:822. https://doi.org/10.1038/s41598-021-80964-8

Chen Z, Shan F, Cao L, Fang G (2012) Synthesis and thermal properties of shape-stabilized lauric acid/activated carbon composites as phase change materials for thermal energy storage. Sol Energy Mater Sol Cells 102:131–136. https://doi.org/10.1016/j.solmat.2012.03.013

Zhu Y, Chi Y, Liang S et al (2018) Novel metal coated nanoencapsulated phase change materials with high thermal conductivity for thermal energy storage. Sol Energy Mater Sol Cells 176:212–221. https://doi.org/10.1016/j.solmat.2017.12.006

Meghana S, Kabra P, Chakraborty S, Padmavathy N (2015) Understanding the pathway of antibacterial activity of copper oxide nanoparticles. RSC Adv 5:12293–12299. https://doi.org/10.1039/c4ra12163e

Vinod Kumar V, Dharani A, Mariappan M, Anthony SP (2016) Synthesis of CuO and Cu2O nano/microparticles from a single precursor: effect of temperature on CuO/Cu2O formation and morphology dependent nitroarene reduction. RSC Adv 6:85083–85090. https://doi.org/10.1039/c6ra16553b

Xiong L, Xiao H, Chen S et al (2014) Fast and simplified synthesis of cuprous oxide nanoparticles: annealing studies and photocatalytic activity. RSC Adv 4:62115–62122. https://doi.org/10.1039/c4ra12406e

Prajapati JP, Das D, Katlakunta S, Maramu N, Ranjan V, Mallick S (2021) Synthesis and characterization of ultrasmall Cu2O nanoparticles on silica nanoparticles surface. Inorg Chim Acta. https://doi.org/10.1016/j.ica.2020.120069

Hu H, Sun L, Jiang B, Wu H, Huang Q, Chen X (2018) Low concentration Re(VII) recovery from acidic solution by Cu-biochar composite prepared from bamboo (Acidosasa longiligula) shoot shell. Miner Eng 124:123–136. https://doi.org/10.1016/j.mineng.2018.05.021

Fang S, Cui Z, Zhu Y et al (2019) In situ synthesis of biomass-derived Ni/C catalyst by self-reduction for the hydrogenation of levulinic acid to γ-valerolactone. J Energy Chem 37:204–214. https://doi.org/10.1016/j.jechem.2019.03.021

Deng L, Chang C, An R, Qi X, Xu G (2017) Metal sulfates-catalyzed butanolysis of cellulose: butyl levulinate production and optimization. Cellulose 24:5403–5415. https://doi.org/10.1007/s10570-017-1530-4

Deng, L. (2018) Study on the alcoholysis of wheat straw to methyl levulinate catalyzed by copper sulfateed^eds, Zhengzhou: Zhengzhou University. https://kns.cnki.net

Moulder, J.F., Stickle, W.F., Sobol, W.M., Bomben, K.D. (1992) Handbook of X-Ray Photoelectron Spectroscopy.

NIST X-ray Photoelectron Spectroscopy Database, (2000) NIST Standard Reference Database Number 20, National Institute of Standards and Technology, Gaithersburg MD, 20899. https://doi.org/10.18434/T4T88K.

Biesinger MC (2017) Advanced analysis of copper X-ray photoelectron spectra. Surf Interface Anal 49:1325–1334. https://doi.org/10.1002/sia.6239

Zhang P, Song T, Wang T, Zeng H (2017) In-situ synthesis of Cu nanoparticles hybridized with carbon quantum dots as a broad spectrum photocatalyst for improvement of photocatalytic H2 evolution. Appl Catal B 206:328–335. https://doi.org/10.1016/j.apcatb.2017.01.051

Zhang P, Wang T, Zeng H (2017) Design of Cu-Cu 2 O/g-C 3 N 4 nanocomponent photocatalysts for hydrogen evolution under visible light irradiation using water-soluble erythrosin B dye sensitization. Appl Surf Sci 391:404–414. https://doi.org/10.1016/j.apsusc.2016.05.162

Sun G, Jia S, Zhang X et al (2021) Anchoring core-shell Cu@Cu2O nanoparticles to two-dimensional carbon nanosheets for bacterial disinfection. ACS Appl Nano Mater 4:9831–9841. https://doi.org/10.1021/acsanm.1c02233

Platzman I, Brener R, Haick H, Tannenbaum R (2008) Oxidation of polycrystalline copper thin films at ambient conditions. J Phys Chem C 112:1101–1108. https://doi.org/10.1021/jp076981k

Liu P, Hensen EJM (2013) Highly efficient and robust Au/MgCuCr2O4 catalyst for gas-phase oxidation of ethanol to acetaldehyde. J Am Chem Soc 135:14032–14035. https://doi.org/10.1021/ja406820f

Zhang P, Song T, Wang T, Zeng H (2018) Plasmonic Cu nanoparticle on reduced graphene oxide nanosheet support: an efficient photocatalyst for improvement of near-infrared photocatalytic H2 evolution. Appl Catal B 225:172–179. https://doi.org/10.1016/j.apcatb.2017.11.076

Wijayanti K, Xie K, Kumar A, Kamasamudram K, Olsson L (2017) Effect of gas compositions on SO2 poisoning over Cu/SSZ-13 used for NH3-SCR. Appl Catal B 219:142–154. https://doi.org/10.1016/j.apcatb.2017.07.017

Li W, Wang Z, Liao H et al (2021) Enhanced degradation of 2,4,6-trichlorophenol by activated peroxymonosulfate with sulfur doped copper manganese bimetallic oxides. Chem Eng J. https://doi.org/10.1016/j.cej.2020.128121

Poreddy R, Engelbrekt C, Riisager A (2015) Copper oxide as efficient catalyst for oxidative dehydrogenation of alcohols with air. Catal Sci Technol 5(4):2467–2477. https://doi.org/10.1039/C4CY01622J

Jin Y, Lai C, Li Y, Cheng X (2020) Preparation and catalytic performance of biomass-based solid acid catalyst from Pennisetum sinense for cellulose hydrolysis. Int J Biol Macromol 165:1149–1155. https://doi.org/10.1016/j.ijbiomac.2020.09.256

Guo H, Qi X, Li L, Smith RL Jr (2012) Hydrolysis of cellulose over functionalized glucose-derived carbon catalyst in ionic liquid. Biores Technol 116:355–359. https://doi.org/10.1016/j.biortech.2012.03.098

Guo H, Lian Y, Yan L, Qi X, Smith RL (2013) Cellulose-derived superparamagnetic carbonaceous solid acid catalyst for cellulose hydrolysis in an ionic liquid or aqueous reaction system. Green Chem. https://doi.org/10.1039/c3gc40433a

Wattanapaphawong P, Reubroycharoen P, Yamaguchi A (2017) Conversion of cellulose into lactic acid using zirconium oxide catalysts. RSC Adv 7:18561–18568. https://doi.org/10.1039/c6ra28568f

Zhang S-P, Jin F, Hu J, Zhang W (2017) Role of metallic Zn, Ni and activated carbon additives in improving the hydrothermal conversion of glucose into lactic acid. J Chem Technol Biotechnol 92:1046–1052. https://doi.org/10.1002/jctb.5080

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, X., Chen, Y., Wang, S. et al. Preparation of lactic acid and acetic acid via hydrothermal conversion of wheat straw with Cu/C-P biochar catalyst. Reac Kinet Mech Cat 136, 1437–1453 (2023). https://doi.org/10.1007/s11144-023-02418-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-023-02418-8