Abstract

This article presents the experiments on the hydroconversion of mixtures of safflower oil (SO) mixed with straight run gas oil (SRGO) in a different ratio as an alternative to obtain biojet. The research was conducted in two stages; the first stage a mixture of SO/SRGO was subjected hydrotreating at 350 °C, 380 °C, 80 bar, LHSV 1 h−1 and 1.5 h−1, over the sulfided NiMo/Al2O3 catalyst, while in the second stage a mixture of SO/SRGO which was already hydrotreated was subjected to a hydroisomerization at 280 °C, LHSV 1 h−1, P = 30 bar, over the sulfided Pt-ZrO2/Al2O3 catalyst. It was studied the influence of SO/SRGO ratio and hydroconversion conditions on the biojet quality produced, compared with characteristics required by standard ASTM D1655. The best condition for obtaining the biojet were 380 °C, 80 bar, LHSV 1 h−1 for hydrotreating followed by hydroisomerization of 20% SO in the mixture at 280 °C, LHSV 1 h−1, P = 30 bar.

Similar content being viewed by others

Introduction

The air transportation industry has officially started its history with the first flight which took place in 1st January 1914, between St. Petersburg and Tampa, Florida. Since then, the air transportation industry has known a rapid evolution, becoming an essential component in the globalization process, facilitating economic and cultural exchange, but it has the disadvantage of being second energy-consuming sector after land transportation [1,2,3].

Because of the rapid evolution of the air transportation, this industry has integrated very quickly in the daily life, mainly because it offers a rapid mode of transportation.

Air transportation industry is responsible for about 2.5% CO2 global emissions, out of which 1.3% represents emissions for domestic flights. Although these are short distance flights, the demand is on the rise: in 2019 the emissions were at 915 million tons CO2, in 2019 they were 905 million tones CO2 and in 2018 they were at 860 million tones CO2 which show there’s a demand from passenger for a short and fast travel mode of transportation [3, 4].

International air transport aviation (IATA) is implementing a program which helps reducing the emissions year after year, with the aim to have the emissions from 2050 at a level of half of those from 2005 [5]. At the same time, International civil aviation organization (ICAO) implemented a resolution in 2020, which requires to increase the fuel efficiency of aircraft by 2% for each year and supports the integration of carbon neutral growth for the aviation sector [6].

The 2050 objective for fuel efficiency can’t be achieved only by improving the performance of the engines and streamlining the aircraft fuselage. For this reason, IATA and ICAO are looking at sustainable aviation fuels (SAF) as means to achieve the 2050 objective. Commercially introduced in 2008, there have been over 300,000 flights done with SAF so far without modifying the aircraft engines in any way. The demand for SAF is increasing year by year, and it was observed even when taking 2020 into account—when although having a lower number of flights due to CoVid-19 restrictions, the demand was with 65% higher than 2019 [7].

This alone explains the interest of researchers and international organizations for using bio-jet fuel as a viable alternative for reducing greenhouse gasses (GHG) emissions [8].

The main fuel utilized in aviation—jet fuel—is made out of a mixture of paraffinic hydrocarbons, naphthenic, aromatics and olefines, with 8–16 carbons. The paraffins have the highest gravimetric energy density due to the high ratio of hydrogen/carbon, they burn without smoke and particle matter. The sub-class of isoparaffins is preferable to be in the composition of jet fuel as besides the already mentioned advantages, isoparaffins also have a lower freezing point than normal paraffins. Naphthenes are also found in the composition of jet fuel because they also possess low freezing points and a gravimetric energy density comparable to the paraffins. With a lower ratio of hydrogen/carbon—which offers a lower volumetric energy density, aromatics have comparable gravimetric energy density with paraffins and naphtenes, but their content is limited to 20–25% volume because their combustion will create higher emissions of particle matter and smoke which will damage in time engine components [9, 10].

Alkylbenzenes have a lower molecular mass and because during the combustion stage they produce less particle matter than aromatics, they are preferred in the composition of SAF [11].

Although it seems that the aromatics offer a negative impact on the combustion and emission characteristics of jet type fuels, a low content of aromatics is needed in jet fuel as aromatics help maintain the elasticity of gaskets, which will help reduce fuel loss [12, 13].

The chemical composition of the jet type fuel is set by international standards that regulate the main quality requirements of jet fuel for minimum freezing temperature, minimum gravimetric energy density, maximum viscosity, maximum aromatic content, maximum corrosivity, maximum sulfur content, maximum acidity, flash point etc. [10].

The main international standards that govern the quality aspects of jet fuel are: ASTM D1655, IATA Guidance Material, British Standard Def Stan 91-91 and NATO Military Standard Mil-DTL 83133E. There’s a new standard—ASTM D7655—which only applies for SAF and is responsible for imposing standards which will ensure quality and flight safety [10, 14]. The jet fuel—SAF mixture can be used only if it fulfils all the quality standards required by the ASTM D1655 [15].

Table 1 shows a short comparison between Mil-DTL 83133E (also known as JP-8 fuel) with civilian equivalents of Jet A-1 which comprises from ASTM D1655, Def Stan 91-91 and IATA guidance material. Additionally, in this table there is also a comparison with SAF’s ASTM D7566 standard [10, 15].

From Table 1, we can observe that the mentioned standards define the quality and performance of jet fuel and they are very similar to each other, with minimum differences between the characteristics of each standard.

From Table 1, the freezing point—the most important characteristic of jet fuel which ensures a safe flight at high altitude—is identical in all the standards [10, 13].

SAF’s composition consists mainly in normal paraffins and isoparaffins while the aromatic and alkylbenzenes is low or absent. Because of this, SAF content in jet fuel is regulated to a maximum 50%. Even at this percentage, the impact of SAF on environment is great and helps improve air quality [11].

In SAF’s composition it’s advisable to have a limited quantity of normal paraffins because they can have a negative impact on the freezing point. Through hydroisomerization, normal paraffins are transformed into isoparaffins which greatly improve the freezing point characteristics, viscosity and the lubrication of jet fuel [16].

Utilizing an alternative energy source based on biomass is advantageous because the biomass can offer a carbon rich resource which can be employed by the transportation industry. By using biomass-based fuels, some of the polluting effects caused by conventional fuels can be diminished and the global fuel market can stabilize because of preserving the fossil fuels through substitution with the new bio fuel [17].

There are a multitude of technologies which can help convert the biomass in jet fuel substitutes, but most of these technologies are at the research stage while only a few have received actual industrial applicability.

A first technology for obtaining bio-jet is gas-to-jet (GTJ) which uses Fischer–Tropsch synthesis of syngas to obtain liquid hydrocarbons comparable to jet fuel [18, 19].

A second technology for obtaining bio-jet is sugar-to-jet (STJ) which uses bioconversion of sugars into biomass. The result is a 15 carbons terpene with three isoprene monomeric units that is called farnesene. By hydroprocessing the farnesene, the resulted produce is sometimes called synthesized iso-paraffins (SIP). The performances of this bio-jet are comparable with the fossil jet fuel if the farnesene are subjected to hydrocracking and hydroisomerization [20, 21].

A third technology for obtaining bio-jet is alcohol-to-jet (ATJ) which uses in its synthesis process C2–C5 alcohols—mainly ethanol and isobutanol—which are dehydrated to olefins, which are then subjected to an oligomerization process, followed by a hydrogenation process to eliminate the double bonds followed by a final process of separation. To ensure maximum sustainability, the alcohols are obtained from biomass, mainly from sugar beads, sugar cane etc. [13, 21].

A fourth technology to obtain bio-jet is oil-to-jet which sometimes is also called hydroprocessed renewable jet (HRJ) or hydroprocessed esters and fatty acids (HEFA). The resulted biofuel is called “green jet” and uses as feedstock vegetable oils and animal fats which are subjected to hydrotreatment, which through the hydrogenation, hydrodeoxygenation, hydrodecarboxylation and hydroisomerization of triglycerides are transformed in mostly paraffinic hydrocarbons. By using a SAF based on OTJ technology, the polluting emissions are greatly diminished and the sulfur and aromatic content are noticeably lower than the fossil jet fuel. In 2011, ASTM has allowed through the D7655 standard the usage of SAF based on OTJ technology with a 50-50 ratio with fossil fuel. A great advantage of this technology is the fact that it can be easily integrated into refineries, the above mention technologies and processes being already present and technologically matured, making the cost of integration into a refinery much lower than any other technology [14, 21, 22].

Protecting the environment, improving the quality of air and reducing the GHG emissions are the main topics which the air transport industry wishes to improve upon. Anthropogenic studies have showed that air transport industry is responsible for 2% of the CO2 emissions and also for emissions of water vapors, nitrogen oxides, emissions of substances which create aerosol particles or clouds [23, 24].

Life cycle assessment (LCA) takes into account all the emissions created, starting with the agriculture land where the crops are cultivated, the harvesting process, de conversion (well-to-bank analysis) and final emissions created by the fuel combustion by the jet engine (well-to-wake analysis), can identify the GHG emissions from biofuel combustion. These types of analysis—well-to-tank and tank-to-wake are necessary in order to offer a clearer picture on the GHG emissions caused by biofuels and fossil fuels. The GHG emissions resulted from jet fuel combustion show us that through well-to-wake analysis it results 14.3 CO2 eq. g/MJ, while through well-to-wake it results 73.2 CO2 eq. g/MJ, resulting a total of 87.5 CO2 eq. g/MJ. By utilizing SAF, the CO2 emissions can be reduced by 90%, GHG emissions being directly influenced by the raw material and its conversion process [14].

A viable alternative for the future is using a SAF based on renewables which are plants with limited use or not used for food as Jatropha curcas, Brassica carinata, Camelina sativa, etc. The oils extracted from these plants and their seeds can be used for SAF production by blending with jet fuel. Another plant is safflower (Carthamus tinctorius), an herbaceous plant well adapted to arid areas, low rainfall and it has a long history of usage in agriculture. Its seeds have a high content of unsaturated fatty acids, a high oleic content that reaches up to 40% weight. Although the SO doesn’t fulfil the oxidation stability requirements imposed by EN 14214, in the future the SO could become a viable alternative for biofuel production, its properties being easily adjusted with the help of correction additives [25, 26].

The current paper evaluates the possibility of using SAF obtained through hydroconversion of SO 100% or in blending with straight run gas oil (SRGO), followed by distillation of a fraction with distillation temperature 180–300 °C which is used by jet engines. In this paper, it’s investigated the effect of different ratio of SO/SRGO and the reaction conditions on the SAF characteristics. Also, the aim of the paper was to study the improvement of cold flow properties of SAF though sequential coprocessing of SO/SRGO mixture through hydrotreating followed by hydroisomerization.

In previous research we studied the obtaining of the biojet by hydrotreating mixtures of Camelina with SRGO over the sulfided NiMo/Al2O3 catalyst [27]. As a novelty in this paper, we obtained SAF with better properties than before, the freezing point exceeding the requirements of the ASTM D1655 standard. The processing was done in two stages, hydrotreating followed by the hydroisomerization of the hydrotreated product over sulfided Pt-ZrO2/Al2O3 catalyst using safflower oil and SRGO mixtures as a feedstock.

Experimental

Feedstocks and catalysts

SO was used as during the experiment as feed which was mixed with SRGO in different quantities: 10, 15 and 20% volume of SO.

The main physicochemical properties of SRGO and SO are presented in Tables 2 and 3, while in Table 4 it’s presented the composition in fatty acids of SO.

For the hydroconversion reactions, an industrial catalyst sulfided NiMo/Al2O3 was used, with a specific surface of 232.4 m2/g, the pore volume of 1.294 cm3/g and the average pore dimension of 3.52 mm. Table 5, shows the main properties of the catalyst used during the experimental stage.

The activation of the catalyst has been done through sulfurization with dimethyl disulfide (DMDS) which was solubilized in SRGO with a 5 wt% concentration. This process took place at a temperature of 280 °C and a pressure of 20 bar, in a rich hydrogen environment—20 L\h. The catalyst has been activated when following the formation of H2S in the reaction gases, we obtained a yellow pigment in the indicator solution of cadmium acetate—aqueous solution 5%.

Micropilot plant

A micropilot plant (Fig. 1) was used for conducting the hydroconversion experiments. The microplant used a fixed bed reactor which has a volume of catalyst of 60 cm3.

The hydroconversion micropilot plant. 1—Filling layer; 2—Catalyst; A—Hydrogen tank, B—Pressure regulator with safety valve, C—Pressure dial, D—Temperature register and control Panel, E—Metering pump, F—Feedstock burette, F—Reactor, G—Thermocouple, H—Water cooler, I—High pressure separator, J—Safety valve, K—collecting vessel, L—Flowmeter, M—Flowmeter dial, N—Electrical heater

The hydroconversion conditions used during the laboratory are as follow: temperature of 350 and 380 °C pressure 80 bar, LHSV 1 and 1.5 h−1; 650 cm3/cm3 H2/feedstock ratio.

All the water was eliminated using CaCl2 after the hydroconversion process, water which could have resulted during the deoxygenation process of fatty acids found in the SO composition.

In order to determine the yields of the hydroprocessing liquid, a thorough weighing has been done.

The final product is left for 1 h in order to dry, after which it’s separated through a TBP distillation into 3 phases: gasoline (IBP—160 °C); jet fuel (180–300 °C) and a heavier phase (> 300 °C).

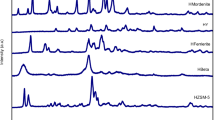

For the characterization of the SAF resulted from hydroconversion process, the following standards have been utilized for determining the values of: Density (EN ISO 12185); the freezing point (SR 13552); flash point (SR 5489). To determine the chemical composition of the SO SAF, chromatography, mass spectrometry analysis was used. For this, we employed a GC–MS/MS CP-3800 triple quad agilent technologies machine.

The technical parameters of the GC–MS/MS equipment, parameters that were used to analyze the reaction mixtures from the NIST library are presented in Table 6.

Results and discussion

Following the SO 100% hydroconversion, we obtain mostly hydrocarbons with 17 and 18 carbons. These long chains are resulted due to triglycerides being hydrocracking and the reactions of hydrodeoxygenation, hydrodecarbonylation and hydrodecarboxylation of fatty acids.

By hydroconversion of 100% SO, it is obtained mostly n-paraffinic hydrocarbons with 17 and 18 carbons, which are the result of the hydrocracking reactions of triglycerides followed by reactions of hydrodeoxygenation, hydrodecarbonylation, hydrodecarboxylation of the fatty acids.

Resulting the hydrocracking reactions is a small quantity of hydrocarbons with smaller chains of carbons, between 10 and 16 per molecule. The chemical composition of the hydrotreated products from SO 100% which is presented in Table 7 (LHSV = 1 h−1, pressure = 50 bar).

The paraffinic hydrocarbons over 17 carbons have a boiling point in excess of 300 °C are found in the diesel fraction while the hydrocarbons with under 16 carbons are found in the jet fraction.

Based on the data from Table 7 and correlating it with the boiling points of obtained hydrocarbons, we observed that we obtain a higher fraction of diesel and a smaller fraction of jet fuel as of result of the SO hydrotreating process. The hydrotreatment at 350 °C results in a yield of 28.67% hydrocarbons with greater than 17 carbons, which are all found in the diesel fraction, while for 380 °C we obtained a yield of 26.42%.

The heptadecane fraction finds itself just over the separation limit—with a boiling point of 302 °C. If it’s included into the jet fuel fraction, the yield of jet fuel increases to 84.78% for 350 °C and 86.29% for 380 °C.

Increasing the temperature during the hydrotreating process results in an increase in jet yield due to hydrocracking reactions. In order to increase the yield of jet fuel fraction, a more acidic catalyst specific to hydrocracking would be a better fit for this process. This would allow more intense cracking and isomerization reactions, which will allow the creation of shorter chain carbons, with a branched structure, which will have an optimal distillation temperature specific to jet fuel.

The yields obtained have been calculated based on mass balance after each experiment, knowing the quantity of feedstock and weighting each fraction of distilled liquid that resulted from the hydrotreating process. All distilled fluids have been dehydrated with CaCl2. The difference between the initial feedstock and the resulted dehydrated liquid consists of gases, water and coke deposited on the catalyst.

The yields in products obtained at the hydroconversion of SO, SRGO and mixtures of SO/SRGO at different reaction conditions are presented in (Table 8, Fig. 2) for 350 and 380 °C LHSV = 1 h−1, pressure = 80 bar.

Following our experiments, the data shows a higher yield in diesel fraction and a smaller yield in jet fuel for each experiment temperature, regardless of the reaction conditions, justified by the formation of hydrocarbons with 17–21 carbons in the molecule from hydrotreating the SO.

The hydrotreated SRGO mixture offers a better yield of jet fuel because SRGO has a better distribution of 10 to 16 carbons in its composition—TBP distillation curve, Table 3—which shows around 50% of the diesel fraction is formed from components with a boiling point that is in the range of jet fuel limit. After the hydrotreating process, most of these components will retain the same number of carbons or they will hydrocrack and form lighter components.

The yields in products obtained at the hydroconversion of SO, SRGO and mixtures of SO/SRGO at different reaction conditions are presented in Table 9 and Fig. 3.

Increasing the LHSV has a negative effect on the yield of jet fuel even if the SO-SRGO ratio and the temperature remains the same, because the reaction time gets shorter which doesn’t allow all the hydrocracking reactions to fully take place see Figs. 2 and 3.

The experimental data obtained shows the SO hydrotreatment will result in higher yields of diesel and smaller ones in jet fuel, no matter the experimental conditions subjected to the feedstock, which is justified by the formation of C17-C21 in the molecule.

The highest yields of jet fuel are obtained from hydroconversion of SRGO and this is mainly due to the distribution of C10-C16 in the composition of the SRGO, which stands out from the TBP distillation curve which shows that approximately 50% of the diesel components are formed from components which are within the jet fuel limit—Table 3. Following the hydrotreating reactions, most of these components keep the same number of carbons or more, they hydrocrack and then form lighter components.

At the same LHSV and temperature, increasing the SO ratio in the SO-SRGO mixture will result in a drop in jet fuel yield, because the hydroconversion of SO will result in a higher ratio of diesel than jet fuel. If the temperature increases but the SO ratio and LHSV remains the same, the jet fuel yield will increase, because of more intense hydrocracking reactions, which will lead to creating lighter components see Figs. 2 and 3.

From the hydrotreating reactions of SO-SRGO, SO and SRGO, we also obtain small quantities of light fractions (gasoline) with a maximum boiling point of 180 °C. These light fractions are resulted from the hydrocracking reactions of both SO and SRGO. Increasing the SO ratio into the mixture results in a drop in gasoline yield. Increasing the temperature while retaining the same SO content and increasing the LHSV will result in a decrease of gasoline yield due to a shorter time of hydrocracking reactions.

We also obtain water, gases and a small quantity of coke which was deposited on the catalyst. These are all associated with losses. These gases resulted during the hydrotreatment are mostly propane, which is resulted from the hydrocracking, hydrodeoxygenation and hydrodecarbonilation of triglycerides found in SO. Hydrocracking of SRGO also results in small quantities of gases and coke.

Figs. 2 and 3 show that the yield of losses increases with the decreasing of LHSV and with the increase of the SO ratio and the temperature.

This is explained by the fact that propane and water are formed during the hydroconversion of triglycerides from the SO and also due to the intensification of the hydrocracking reactions from the increase of temperature and the decrease in LHSV.

For the SAF we have obtained through hydrotreatment of SO-SRGO mixture, the main characteristics have been determined by following the ASTM D1655 standard (Figs. 4, 5, 6, 7, 8).

The density of the obtained SAF through hydrotreatment falls between the values of 0.788 and 0.809 g/cm3, which is within the requirements of ASTM D1655 standard for Jet A1 fuel (density between 0.775 and 0.840 g/cm3). Due to hydrotreating, the density drops significantly, from the initial 0.921 g/cm3 of SO and 0.8596 g/cm3 of SRGO due to hydrocracking, hydrotreating and hydrodeoxygenation reactions of the triglycerides from the SO, reactions which eliminate the oxygen groups and partially eliminate the paraffinic molecules over C17 which are resulted from the hydrotreating process. The hydrocracking process determines a drop in density due to aromatic hydrocarbons being saturated and forming hydrocarbons with a smaller molecular mass than the ones found in the SRGO. If the SO ratio and LHSV remains the same, the increase in temperature will lead to a drop in density (Figs. 4, 5) due to deoxygenation reaction, hydrocracking and saturation of aromatics in the diesel fraction. The density of the jet fuel fraction obtained from hydroconversion of SO-SRGO mixture is slightly increasing with the increase of SO ratio (as seen in Figs. 4, 5) due to the formation of paraffinic hydrocarbons (C18–C21) which have a higher density.

At the same SO content and temperature, an increase in LHSV will lead to an increase in density due to a reduction in the reaction time which won’t allow the hydrocracking and hydrodeoxygenation reactions to fully take place (Figs. 4, 5).

The freezing temperatures of the SAF resulted from hydrotreating the SO-SRGO mixtures are between − 14 and − 28 °C (Tables 10, 11). These temperatures do not meet the minimum requirement imposed by ASTM D1655 (− 47 °C) and are justified due to the higher content of n-paraffins resulted from the hydrogenation of triglycerides found in SO. Because of this, when the SO content increases but LHSV remains constant, the freezing temperature of the resulted SAF is increasing as well. If the reaction temperature increases, the secondary reactions of hydrocracking and hydroisomerization start to be more intense and lead to formation of isoparaffins that will slightly decrease the freezing temperature (Fig. 6). If the SO content and the temperature remains the same but the LHSV increases, the freezing temperature will not improve at all, because it decreases the conversion by hydrocracking due to the decrease in reaction time (Fig. 6).

In the case of hydroconversion of 100% SRGO, we observe that the ASTM D1655 standard is mostly met when the reaction temperature is at 380 °C, while at 350 °C it is found with 1 degree under the minimum temperature requirement. The low freezing temperatures are due to a more favorable chemical composition of the hydrotreated SRGO, which is composed mostly from naphthenes resulted from the saturation of aromatics, and from isoparaffins with C10–C17 which are resulted from hydrocracking.

Throughout the hydroconversion experiments, we obtained an important decrease in sulfur content, from 2256 ppm of SRGO to values between 14 and 26 ppm. These values are under the limit imposed by ASTM D1655 of maximum 30 ppm sulfur. With the increase of SO content into the mixture, the sulfur value drops in the composition of SAF because SO does not have sulfur in its composition. If LHSV remains the same, the increase of temperature will lead to a drop in sulfur content due to intensification of the hydrogenolysis reactions of the sulfur components from the mixture (Figs. 7, 8). If the LHSV increases, the sulfur content in SAF will increase due to a decrease in the conversion in the hydrogenolysis reaction of the sulfur components from the mixture due to a decrease in reaction time (Figs. 7, 8).

Hydroisomerization

In order to improve the physicochemical of SAF, we decided to use as feedstock the 380 °C hydrotreated fraction LHSV = 1 h−1 with 10, 15 and 20% SO because these three fractions showed the best characteristics.

The experimental conditions used were: 280 °C, P = 30 bar with LHSV = 1 h−1. The isomerization catalyst used was an industrial use sulfided Pt-ZrO2 /Al2O3 with 750 cm3/cm3 H2/feedstock ratio.

By hydroisomerizing the 10, 15 and 20% fractions that were previously hydrotreated at 380 °C, we obtained data that shows a decrease in yield in the product obtained, which is explained by the hydrocracking reactions of n-paraffins from each fraction. Each increase of SO in the fraction will reduce the yield of final product.

By hydroisomerizing the hydrotreated mixtures, we obtained fractions with a considerable improved property, as it can be seen in Table 12, where the viscosity and freezing point have been significantly improved over previous experiments. The obtained viscosity can be explained by the fact that hydroisomerization helps convert the n-paraffins into isoparaffins which have superior properties. The freezing point knows the biggest improvement by the hydroisomerization process, increasing the values with almost 40 °C and exceeding the requirements of ASTM D1655 of − 47 °C (Fig. 9). This can be explained by the hydrocracking reactions that generate branched hydrocarbons but with a small number of carbons. Since the hydroisomerization process is performed at a relatively high temperature, the isomerization process and hydrocracking are more intense than usual. By increasing the SO ratio into the SO-SRGO mixture, the freezing point increases because the ratio of isoparaffins increases into the final product.

Conclusions

The present study highlights the possibility of obtaining SAF, meeting the requirement imposed by the ASTM D1655 standard, by hydrotreating followed by hydroisomerization of a SO mixture with SRGO.

It is found that the hydrotreating process, at temperature of 380 °C, P = 80 bar and LHSV = 1 h−1 on industrial sulfided NiMo/Al2O3 catalyst, ensures the best freezing temperature, in any SO-SRGO mixture ratio (10, 15 and 20%), but the value imposed by the standard is not yet obtained.

The previously hydrotreated SO-SRGO mixture, subjected to the process of hydroisomerization on the sulfided Pt-ZrO2/Al2O3 catalyst, at 280 °C, LHSV 1 h−1, P = 30 bar and 20% SO in the mixture, leads to a biojet whose characteristics meet and even exceed the requirements of the standard, the freezing point value reach − 70 °C. There is observed an improvement of the viscosity as well.

The hydroisomerization process generates higher yields in loses due to the catalyst used, which promotes cracking reactions on its acidic sites.

Hydroconversion of a SO and SRGO mixture, can use the technologies already available in the industry and it is cost effective.

References

Fischer J, Casto G, Hamlin G (2014) Commercial aviation soars into its second century. Aerial views of a rapidly developing history—and outlook. 295: 14–16

Eliminating CO2 emissions from industry and transport in line with the 1.5 °C climate goal (2020). Accessed from https://www.irena.org/publications/2020/Sep/Reaching-Zero-with-Renewables

Eurostat (2020) Energy data. Accessed from https://ec.europa.eu/eurostat/documents/3217494/11099022/KS-HB-20-001-EN-N.pdf/bf891880-1e3e-b4ba-0061-19810ebf2c64?t=1594715608000

Benito A, Alonso G (2018) Energy efficiency in air transportation. Butterworth-Heinemann Elsevier, Amsterdam, pp 1–236

IATA (International Air Transport Association) (2021) Aviation & climate change. Accessed from https://www.iata.org/en/programs/environment/climate-change/

Fleming GG, De Lepinay I (2019) Environmental trends in aviation to 2050. Aviation and Environmental Outlook, 17–23

IATA (International Air Transport Association) (2021) Realizing the potential of sustainable aviation fuel. Accessed from https://airlines.iata.org/analysis/realizing-the-potential-of-sustainable-aviation-fuel

Miller P, Kumar A (2013) Development of emission parameter and net energy ratio for renewable diesel from Canola and Camelina. Energy 58:426–437

Liu G, Yan B, Chang G (2013) Technical review on a jet fuel production. Renew Sustain Energy Rev 25:59–70

Wang WC, Tao L, Markham J, Zhang Y, Tan E, Batan L, Warner E, Biddy M (2016) Review of biojet conversion technologies. National Renewable Energy Laboratory, Golden, pp 1–106

Cheng F, Brewer CE (2017) Producing jet fuel from biomass lignin: potential pathways to alkyl-benzenes and cycloalkanes. Renew Sustain Energy Rev 72:673–722

Corporan E, Edwards T, Shafer L, DeWitt MJ, Klingshirn C, Zabarnick S, West Z, Striebich R, Graham J, Klein J (2011) Chemical, thermal stability, seal swell, and emissions studies of alternative jet fuels. Energy Fuels 25:955–966

Chuck CJ (2016) Biofuels for aviation. Elsevier, Amsterdam, pp 1–392

Energy Efficiency and Renewable Energy US Department of Energy (2016) Alternative aviation fuels: overview of challenges, opportunities, and next steps. Accessed from https://www.energy.gov/sites/prod/files/2017/03/f34/alternative_aviation_fuels_report.pdf

Rumizen M (2016) Sustainable alternative jet fuel certification and qualification. Commercial Aviation Alternative Fuel Initiative, Washington DC, pp 1–13

Perez W, Marin J, del Rio J, Pena J, Rios L (2007) Upgrading of palm oil renewable diesel through hydroisomerization and formulation of an optimal blend. Fuel 209:442–448

Al-Muhtaseb AH, Jamil F, Al-Haj L, Myint MTZ, Mahmoud E, Ahmad MNM, Hasan AO, Rafiq S (2018) Biodiesel production over a catalyst prepared from biomass-derived waste data pits. Biotechnol Rep 20:1–8

Dagaut P, Dievart P (2017) Combustion of synthetic jet fuels: naphtenic cut and blend with a gas-to-liquied (GtL) jet fuel. Proc Combust Inst 36:433–440

Hu J, Yu F, Lu Y (2012) Application of fisher tropsch synthesis in biomass to liquid conversion. Catalysts 2:303–326

Santos CI, Silva CC, Mussatto SI, Osseweijer P, van der Wielen P, Posada JA (2018) Integrated 1st and 2nd generation sugarcane bio-refinery for jet fuel production in Brazil: techno-economic and greenhouse gas emissions assessment. Renew Energy 129:733–747

Yang J, Xin Z, He Q, Corscadden NH (2019) An overview on performance characteristics of bio-jet fuels. Fuel 237:916–936

Doukeh R, Bombos M, Trifoi A, Pasare M, Banu I, Bolocan I (2017) Dimethyldisulphide hydrodesuphurization on NiCoMo/Al2O3 Catalyst. Rev Chim 68:1496–1500

Sridhar B, Chen NY, Ng HK (2014) Aircraft trajectory design based on reducing the combined effects of carbon-dioxide, oxides of nitrogen and contrails. American Institute of Aeronautics and Astronautics, Reston, pp 1–10

Oleson C, Wuebbles DJ, Owen B (2013) Comparison of global 3-D aviation emissions datasets. Atmos Chem Phys 13:429–441

Rathore MS, Tiwari JK, Mishra S (2017) Performance and experimental analysis of safflower biodiesel and diesel blends on C.I. engine. Int Res J Eng Technol 4:1–7

Patrascoiu M, Rathbauer J, Negrea M, Zeller R (2013) Perspective of SO as biodiesel source for South Eastern Europe (comparative study: Safflower, soybean and rapeseed). Fuel 111:114–119

Tepelus A, Rosca P, Dragomir R (2019) Biojet from hydroconversion of camelina oil mixed with straight run gas oil. Rev Chim 9:3284–3291

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tepelus, A., Dragomir, R.E. & Rosca, P. Sustainable aviation fuel from hydroconversion of safflower oil over NiMo/Al2O3 and Pt-ZrO2/Al2O3 catalysts. Reac Kinet Mech Cat 135, 1503–1522 (2022). https://doi.org/10.1007/s11144-022-02197-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02197-8