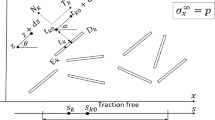

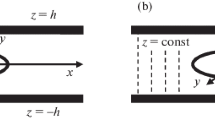

Mode I and mode II stress intensity factors (SIFs) are determined for a material with parallel pore channels of Y-shaped cross-section with centers at nodes of a regular hexagonal grid and arms aligned with the sides of hexagons. Calculations are performed for a unit cell that includes halves of two adjacent pore channels with an arbitrary length ratio of the arms. The finite-element method is used. It is shown that the SIFs for an equal-arm Y-shaped pore channel depend on the fiber cross-sectional radius of curvature. The range of lengths of periodic equal-arm starlike cracks in which they can be regarded as noninteracting is identified.

Similar content being viewed by others

References

G. Richard, Method of Making Porous Bodies, US Patent 2273589, G. Motors Corp., February 17 (1942).

G. A. Meerson, S. S. Kiparisov, and Z. D. Khocholava, “The pressing of tungsten fibers,” Powder Metall. Met. Ceram., 13, No. 4, 262–265 (1974).

M. S. Koval’chenko, Theory of Hot Processing of Porous Materials [in Russian], Naukova Dumka, Kiev (1980).

A. G. Kostornov, Materials Science of Dispersed and Porous Metals and Alloys [in Russian], Vol. 1, Naukova Dumka, Kiev (2002).

W. S. Coblenz, Fibrous Monolithic Ceramic and Method for Production, US Patent 4772524, September 20 (1988).

D. Kovar, B. H. King, and R. W. Trice, “Fibrous monolithic ceramics,” J. Am. Ceram. Soc., 80, No. 10, 2471–2487 (1997).

E. Olevsky, H. J. Dudek, and W. A. Kaysser, “Hipping conditions for processing of metal matrix composites using continuum theory for sintering. II. Application to fiber reinforced titanium alloys,” Acta Mater., 44, No. 2, 715–724 (1996).

M. P. Lisitsa, L. I. Berezhinskii, and M. Ya. Valakh, Fiber Optics [in Russian], Tekhnika, Kiev (1967).

T. Ishikawa, S. Kajii, K. Matsunaga, et al., “Tough, thermally conductive silicon carbide composite with high strength up to 1600°C in air,” Science, 282, No. 5392, 1295–1297 (1998).

Y. Murakami (ed.), Stress Intensity Factors Handbook, Vol. 1, Pergamon, Oxford (1987).

Y. Murakami (ed.), Stress Intensity Factors Handbook, Vol. 2, Pergamon, Oxford (1987).

M. Isida, “Analysis of stress intensity factors of plate with arbitrary array cracks and bent crack,” Trans. Jpn. Soc. Mech. Eng., 44, No. 380, 1122–1133 (1978).

V. G. Borovik, “Modeling the effective elastic properties of materials pressed from a unidirectional hexagonal fiber strand,” Powder Metall. Met. Ceram., 49, No. 1–2, 8–16 (2010).

B. E. Pobedrya, Mechanics of Composite Materials [in Russian], Izd. Mosk. Univ., Moscow (1984).

H. Tada, “A note on the finite width corrections to the stress intensity factor,” Eng. Fract. Mech., 3, No. 3, 345–347 (1971).

R. Kitagawa and R. Yuuki, “Analysis of arbitrarily shaped crack in a finite plate using conformal mapping. I. Construction of analysis procedure and its applicability,” Trans. Jpn. Soc. Mech. Eng., 43, No. 376, 4354–4362 (1977).

A. R. Akisanya, A. C. F. Cocks, and N. A. Fleck, “Hydrostatic compaction of cylindrical particles,” J. Mech. Phys. Solids, 42, No. 7, 1067–1085 (1994).

V. G. Borovik, “Modeling the formation of internal boundaries in a unidirectional fiber strand compacted in plastic state,” Powder Metall. Met. Ceram., 48, No. 7–8, 388–395 (2009).

D. Broek, Elementary Engineering Fracture Mechanics, Noordhoff, Leyden (1974).

V. G. Borovik, “Local stress intensity factors for cracks in a material with parallel channels of various cross-sections,” in: Mathematical Models and Computational Experiment in Materials Science [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kiev (2010), pp. 46–57.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 50, No. 3–4 (478), pp. 10–22, 2011.

Rights and permissions

About this article

Cite this article

Borovik, V.G. Stress intensity factors K I and K II for cracks at the tips of parallel pore channels with starlike cross-sections. Powder Metall Met Ceram 50, 130 (2011). https://doi.org/10.1007/s11106-011-9310-4

Received:

Published:

DOI: https://doi.org/10.1007/s11106-011-9310-4