Abstract

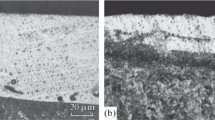

A study has been made on the adhesion of the new composite ceramic AlN - Ti(Zr)B2 -Ti(Zr)Si2 with steel 45 and alloy AL9 in relation to the mass-transfer kinetics in spark working. There is a three-stage mass-transfer mechanism. The materials in the electrode and the substrate affect the electrical erosion of the electrode.

Similar content being viewed by others

REFERENCES

A. D. Verkhoturov, I. A. Podchernyaeva, and L. N. Kurilenko, “Reverse mass transfer kinetics in electrospark alloying and the formation of a secondary structure in the anode,” Fiz.-Khim. Obrab. Materialov, No. 4, 65–68 (1986).

I. A. Podchernyaeva, A. D. Panasyuk, V. A. Lavrenko, et al., “Structure and properties of composite electrospark laser and magnetron coatings of AlN-TiB2 material,” Poroshk. Metall., Nos. 9–10, 69–77 (2001).

M. A. Teplenko, I. A. Podchernyaeva, A. D. Panasyuk, et al., “Structure and wear resistance of coatings on titanium alloy and steel obtained by electrospark alloying with AlN-ZrB2 material,” Poroshk. Metall., Nos. 3–4, 48–57 (2002).

Yu. V. Naidich, “Interphase surface energies and wetting angles for solid bodies by liquid in equilibrium and nonequilibrium systems,” Surface Phenomena in Melts [in Russian], Nauk. Dumka, Kiev (1968), pp. 337–344.

A. D. Verkhoturov, I. A. Podchernyaeva, Yu. A. Gorbunov, and F. F. Egorov, “Choice of electrode material and mass transfer in electrospark alloying,” Poroshk. Metall., No. 2, 36–40 (1985).

A. D. Verkhoturov, Formation of a Surface Layer of Metals in Spark Alloying [in Russian], Dal’nauka, Vladivostok (1995).

A. D. Verkhoturov, Yu. I. Mulin, and A. N. Vishnevskii, “Reduction and hardening of dies for pressing aluminum profiles by electrospark alloying,” Fiz.-Khim. Obrab. Materialov, No. 4, 82–89 (2002).

T. V. Samsonov, L. Ya. Markovskii, A. F. Zhigach, and M. G. Valyashko, Boron: Its Compounds and Alloys [in Russian], Izd. AN Ukr. SSR, Kiev (1960).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, Nos. 9–10(439), pp. 43–50, September–October, 2004.

Rights and permissions

About this article

Cite this article

Podchernyaeva, I.A., Yurechko, D.V., Panasyuk, A.D. et al. Mass transfer and adhesion in electrospark alloying of AL9 alloy with AlN - Ti(Zr)B2 - Ti(Zr)Si2 ceramic electrodes. Powder Metall Met Ceram 43, 473–479 (2004). https://doi.org/10.1007/s11106-005-0008-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-005-0008-3