Abstract

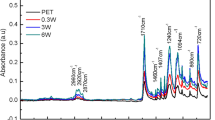

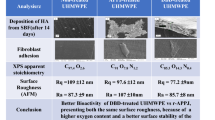

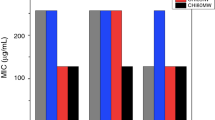

A dielectric barrier discharge (DBD) in helium was used to ameliorate the interface between the blood and the surface of polymeric implants: polyethylene terephthalate (PET) and PET with titanium oxide (PET + TiO2). A higher crystallinity degree was found for the DBD treated samples. The wettability of polymers was improved after the treatment. The chemical composition, analyzed by infrared spectroscopy was preserved during the DBD treatment. The surface modifications have been correlated with polymers hemocompatibility. Concerning the polymer surface–blood interaction, the treatment induced a decrease of the interfacial tension between the blood components and the treated surfaces. The in vitro tests of hemocompatibility showed no perturbation in the blood composition when the polymer samples are present in the blood volume. An interesting result is related to the whole blood clotting time that shows a dramatic increase on the treated surfaces. Moreover, the coagulation kinetics on the treated surfaces is modified.

Similar content being viewed by others

Change history

06 June 2020

The Editor-in-Chief would like to alert readers that due to an administrative error, the article [1] has been republished in the same journal as [2]. The correct citation for this article should be the original publication [1].

References

Mao C, Qiu Y, Sang H, Mei H, Zhu A, Shen J, Lin S (2004) Adv Colloid Interface Sci 110(1–2):5

Chu PK, Chen JY, Wang LP, Huang N (2002) Mater Sci Eng R 36(5–6):143

Huang N, Yang P, Leng YX, Wang J, Sun H, Chen JY, Wan GJ (2004) Surf Coat Technol 186(1–2):218

Fridman G, Peddinghaus M, Balasubramanian M, Ayan H, Fridman A, Gutsol A, Brooks A (2006) Plasma Chem Plasma Process 26(4):425

Schroder K, Meyer-Plath A, Keller D, Besch W, Babucke G, Ohl A (2001) Contrib Plasma Phys 41(6):562

Wang J, Pan CJ, Huang N, Sun H, Yang P, Leng YX, Chen JY, Wan GJ, Chu PK (2005) Surf Coat Technol 196(1–3):307

Okazaki K, Nozaki T (2002) Pure Appl Chem 74(3):447

Dumitrascu N, Topala I, Popa G (2005) IEEE Trans Plasma Sci 33(5):1710

Visser SA, Hergenrother RW, Cooper SL (1996) In: Ratner BD, Hoffman AS, Schoen FS, Lemons JE (eds) Biomaterials science: an introduction to materials in medicine. Academic Press, San Diego, p 50

Pu FR, Williams RL, Markkula TK, Hunt JA (2002) Biomaterials 23(11):2411

Sanders JE, Bale SD, Neumann T (2002) J Biomed Mater Res 62(2):222

Zhang F, Zheng Z, Chen Y, Liu X, Chen A, Jiang Z (1998) J Biomed Mater Res 42(1):128

Strohm H, Sgraja M, Bertling J, Lobmann P (2003) J Mat Sci 38(8):1605

Pena J, Vallet-Regi M, San Roman J (1997) J Biomed Mater Res 35(1):129

Clark DT, Dilks A (1978) J Polym Sci Polym Chem Ed 16:911

Wu S (1982) Polymer interface and adhesion. Marcel Dekker, New York, p 184

Kwok SCH, Wang J, Chu PK (2005) Diamond Relat Mater 14(1):78

Agathopoulos S, Nikolopoulos P (1995) J Biomed Mater Res 29(4):421

Alexander LE (1969) X-ray diffraction methods in polymer science. Wiley Interscience, New York, p 335

Cole KC, Ajji A, Pellerin E (2002) Macromolecules 35(3):770

Koenig JL (1999) Spectroscopy of polymers. Elsevier, New York, p 90

Cenni E, Granchi D, Ciapetti G, Stea S, Verri E, Gamberini S, Gori A, Pizzoferrato A, Zucchelli P (1997) J Mater Sci Mater Med 8:771

Balakrishnan B, Kumar DS, Yoshida Y, Jayakrishnan A (2005) Biomaterials 26(17):3495

Fechine GJM, Souto-Maior RM, Rabello MS (2002) J Mater Sci 37(23):4979

Durell M, Macdonald JE, Trolley D, Wehrum A, Jukes PC, Jones RAL, Walker CJ, Brown S (2002) Europhys Lett 58(6):844

Lippert T (2005) Plasma Proc Polym 2(7):525

Chan CM, Ko TM, Hiraoka H (1996) Surf Sci Rep 24(1–2):1

Ruckenstein E, Gourisankar SV (1986) Biomaterials 7(6):403

Li ZF, Ruckenstein E (2004) J Colloid Interface Sci 269(1):62

Chen JY, Leng YX, Tian XB, Wang LP, Huang N, Chu PK, Yang P (2002) Biomaterials 23(12):2545

Acknowledgments

The authors thank PhD Cristina Morariu, Hematology Laboratory, Military Hospital, Iasi, Romania, for its help with the hemocompatibility tests. This work was supported by the Romanian National University Research Council (CNCSIS) under Grant 1461/2005–2006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Topala, I., Dumitrascu, N. & Pohoata, V. Influence of Plasma Treatments on the Hemocompatibility of PET and PET + TiO2 Films. Plasma Chem Plasma Process 28, 535–551 (2008). https://doi.org/10.1007/s11090-008-9136-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-008-9136-0