Abstract

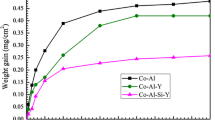

Si–Co–Y diffusion coatings were deposited on TiAl–Nb alloy using pack cementation process. The influence of activators and deposition temperatures on the coating structures was investigated, alongside the coating formation process and hot corrosion performance of the optimized coating in molten salt of 25%NaCl + 75%K2SO4 at 850 °C. The results show that a dense and compact Si–Co–Y diffusion coating can be prepared on TiAl–Nb alloy, with a multi-layered structure including an outmost layer of (Ti, X)Si2 (X represents Co, Al, Nb, Y), an outer layer composed of TiSi2 + Ti5Si4 + Ti5Si3 mixtures, a middle layer of Ti5Si3, and an inner layer of TiAl2. The coating prepared with AlCl3·6H2O and NH4Cl had many pores. Increase in deposition temperature led to a higher coating growth rate within the range of 1050–1100 °C, but temperature exceeding 1100 °C caused the formation of intensive holes in the coating. Hot corrosion tests at high temperatures proved that the Si–Co–Y diffusion coating prepared on TiAl–Nb alloy exhibited excellent hot corrosion resistance in 25%NaCl–75%K2SO4 molten at 850 °C. A protective hot corrosion product scale composed of a TiO2 + Na2SiO3 + Na2TiO3 outer layer and an Al2O3 middle layer, formed on coating after hot corrosion for 50 h. The scale can effectively inhibit the inward diffusion of corrosion medial of O, Cl and S elements.

Similar content being viewed by others

References

H. Wakabayashi, L. J. Signori, A. Shaaban, et al., MRS Advances 4, 1465 (2019).

D. V. Pavlenko, Y. O. Belokon, and D. V. Tkach, Materials Science 55, 908 (2020).

S. Q. Wang, F. Q. Xie, X. Q. Wu, and L. Y. Chen, Journal of Alloys and Compounds 788, 632 (2019).

J. Dai, C. Sun, A. Wang, et al., Corrosion Science 184, 109336 (2021).

Z. K. Wei, X. Li, W. Lv, et al., Journal of Materials Engineering and Performance 32, 4796 (2023).

S. Tian, Y. Zhang, A. He, et al., Surface and Coatings Technology 444, 128687 (2022).

X. Gong, R. R. Chen, Y. Wang, et al., Frontiers in Materials 8, 710431 (2021).

J. J. Wu, H. J. Yan, F. H. Cao, et al., Surface and Coatings Technology 422, 127495 (2021).

S. Wang, F. Xie, X. Wu, et al., Journal of Alloys and Compounds 828, 154271 (2020).

P. Zhang and X. P. Guo, Corrosion Science 71, 10 (2013).

Y. Q. Qiao, Z. Shen, and X. P. Guo, Corrosion Science 93, 126 (2015).

J. Huang, F. Zhao, X. Cui, et al., Applied Surface Science 582, 152444 (2022).

X. Ma, Y. He, J. Lin, et al., Surface and Coatings Technology 206, 2690 (2012).

Y. Qiao, J. Kong, R. Zhou, et al., Vacuum 161, 314 (2019).

M. Qiao and C. Zhou, Corrosion science 75, 454 (2013).

K. L. Wang, Q. B. Zhang, M. L. Sun, et al., Journal of materials processing technology 139, 448 (2003).

A. S. Ramos, C. A. Nunes, and G. C. Coelho, Materials Characterization 56, 107 (2006).

H. Clemens and W. Smarsly, Advanced Materials Research 278, 551 (2011).

Z. Sun, W. Wu, Y. Chen, et al., Corrosion Science 185, 109399 (2021).

Y. Q. Li, J. L. Li, C. Qin, et al., Journal of Central South University 27, 381 (2020).

J. Xiang, F. Xie, X. Wu, and S. Wang, Intermetallics 132, 107151 (2021).

M. K. Marzena and G. Elzbieta, Corrosion Science 115, 18 (2017).

Y. Mishin and Chr Herzig, Acta Materialia 48, 589 (2000).

J. He, X. Guo, and Y. Qiao, Transactions of Nonferrous Metals Society of China 31, 207 (2021).

K. Rubacha, E. Godlewska, and K. Mars, Corrosion Science 118, 158 (2017).

J. Xiang, F. Xie, X. Wu, et al., Surface and Coatings Technology 419, 127282 (2021).

L. K. Wu, J. J. Wu, W. Y. Wu, H. J. Yan, et al., Corrosion Science 174, 108827 (2020).

T. Ishitsuka and K. Nose, Corrosion Science 44, 247 (2002).

Y. Qiao, X. Guo, and X. Li, Corrosion Science 91, 75 (2015).

T. Dudziak, P. Datta, H. Du, et al., Central European Journal of Engineering 3, 722 (2013).

V. Babic, C. Geers, and I. Panas, Oxidation of Metals 93, 229 (2019).

H. Li, M. Qiao, and C. Zhou, Materials Chemistry and Physics 143, 915 (2014).

X. Zhao and C. Zhou, Corrosion Science 86, 223 (2014).

Acknowledgements

This research was financially supported by The National Natural Science Foundation of China (No. 51961003), the Major Project of Science and Technology Department of Sichuan province (No. 22SYSX0141), and the Project of the Key Laboratory of Mechanical Structure Optimization & Material Application Technology of Luzhou (SCHYZSA-2023-01, SCHYZSB-2023-01).

Author information

Authors and Affiliations

Contributions

The authors declare that they have no known competing fnancial interests or personal relationships that could have appeared to influence the work reported in this paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing fnancial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, X., Lv, W., Xie, X. et al. Microstructure and Hot Corrosion Property of a Si–Co–Y Diffusion Coating Deposited on TiAl–Nb Alloy. High Temperature Corrosion of mater. 101, 169–185 (2024). https://doi.org/10.1007/s11085-023-10206-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10206-x