Abstract

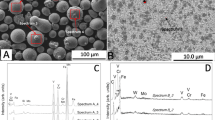

The use of nickel- and iron-based alloy coatings containing Cr, Al, and Y (NiCrAlY and FeCrAlY) were evaluated as potential oxidation barriers for low-alloy steels for the next generation of high-output diesel engines. Rapid oxidation at temperatures above 500 °C currently limits the use of the 4140 steels used to manufacture pistons crowns in this application. Isothermal furnace testing, a novel highly transient combustion-based laboratory test, and direct high temperature engine exposure were used to assess the efficacy of the coating-substrate systems. Both NiCrAlY and FeCrAlY coatings appear to protect the substrate from oxidation at isothermal temperatures up to 677 °C. On direct exposure to combustion, through Impulse Cyclic Heating Tests, the NiCrAlY coatings themselves also appear resistant to degradation at very high temperatures, while the FeCrAlY coatings degrade more rapidly for equivalent thermal loading. Engine tests further validated the efficacy of NiCrAlY coatings, with neither coatings nor 4140 steel pistons showing degradation at temperatures estimated to be more than 500 °C. From this work NiCrAlY coatings are estimated to have a potential upper limit of 677 °C, at which interdiffusion between the coating and substrate will likely complicate their use.

Similar content being viewed by others

References

J. Saputo, F.Caliari , E.Gingrich , M. Tess , S. Sampath, Oxidation of Metals. (in press).

D. Pierce, J. Haynes, J. Hughes, et al., High Temperature Materials for Heavy Duty Diesel Engines: Historical and Future Trends. Progress in Materials Science 103, 109 (2019).

E. Gingrich, D. Pierce, M. Tess et al., SAE Technical Paper. 2022–01–0599 (2022)

H. J. Williams and W. E. Ballard, Journal of the Institution of Production Engineers 16, 251 (1937).

E. Cady, Scientific American 176, 201 (1947).

F. J. Centolanzi , NASA Technical Memorandum X-620, 15 (1971)

S. Kaminaka, Journal of Medical Instrument 16, 1 (1938).

J. Sannier, R. Dominget, and R. Darras, J. Nuclear Materials 3, 212 (1959).

E. Gulbransen and K. F. Andre, Journal of the Electrochemical Society, 106, 941 (1959).

S.Grisaffe, Protective Coatings for Superalloys. Aerospace Structural Materials Proceedings, 305–316 (1969).

F. P. Talboom, R. C. Elam , L. W. Wilson, Evaluation of Advanced Superalloy Protection Systems. Final report. No. NASA-CR-72813. 1970.

R. C. Tucker, Summary of the Seventeenth Refractory Composites Working Group, Williamsburg, VA, (1970).

G. W. Goward, Surf Coat Technol. 108, 73 (1998).

F. J. Hermanke, All About “Emcrawlees.” J Therm Spray Technol. 9, 315 (2000).

E. Bodmann, D. Diehl , I. Blume-Firla, H. Demus, In: Proceedings of A Specialists Meeting Organized by the International Atomic Energy Agency. Cracow, Poland, (1988).

M. G. Hocking, Surf Coat Tehcnol. 62, 460 (1993).

I. A. Kvernes and P. Fartum, Thin Solid Films. 53, 259 (1978).

D Zhu, R. A. Miller, Evaluation of Oxidation Damage in Thermal Barrier Coating Systems. NASA Technical Memorandum, 107360 (1996).

M. B. Beardsley, Thick Thermal Barrier Coatings (TTBCs) for Low Emission, High Efficiency Diesel Engine Components. USDOE Report 22580–1, Caterpillar Inc., Peoria (2006).

D. Dickey , S. Vinyard , R. Keribar, The Effect of Insulated Combustion Chamber Surfaces on Direct-Injected Diesel Engine Performance, Emissions and Combustion. NASA Technical Memorandum, CR-182204 (1988).

W. Lineton , M. Azevedo, Thermal Oxidation Protective Surface for Steel Pistons. US Patent # 7458358 (2008).

N. Uchida, . International Journal of Engine Research 23 (2020).

E. Gingrich, M. Tess , G. J. Korivi, International Journal of Engine Research (2021).

D. R. Tree, P. Wiczynski, and T. M. Yonushonis, SAE Transactions 105, 112 (1996 ).

E. Gingrich, M. Tess, V. Korivi, P. Schihl, J. Saputo, G. Smith, S. Sampath, and J. Ghandhi, The Impact of Piston Thermal Barrier Coating Roughness on High-load Diesel Operation. International Journal of Engine Research 22, 1239 (2021).

J. Schindelin, I. Arganda-Carreras, E. Frise, et al., Fiji: Nature Methods 9, 676 (2012).

Standard Procedure for Measuring and Compensating for Emissivity Using Infrared Imaging Radiometers. E1933–14, Annual Book of ASTM Standards, Part 0.3.03, (2018)

Y. C. Chen , J. Worden, Evaluation of Microalloyed Steel for Articulated Piston Applications in Heavy Duty Diesel Engines. SAE Technical Paper: 200–01–1232m, (2000).

K. Hirano, M. Cohen, and B. L. Averbach, Acta Metallurgica 9, 440 (1961).

A. W. Bowen and G. M. Leak, Metallurgical Transactions, 1, 2767 (1970).

B. Chattopadhyay and G. C. Wood, J. Electrochem. Soc. 117, 1163 (1970).

N. Otsuka, Y. Shida, and H. Fujikawa, Oxidation of Metals 32, 13 (1989).

M. Auinger, V. G. Praig, B. Linder, and H. Danninger, Grain boundary oxidation in iron-based alloys, investigated by 18O enriched water vapor—The effect of mixed oxides in binary and ternary Fe-{Al, Cr, Mn, Si} systems. Corrosion Science 96, 133 (2015).

J. Ruzickova and B. Million, Materials Science and Engineering 50, 59 (1981).

Acknowledgements

This work was funded by Army In-House Laboratory Independent Research (ILIR) basic research funds in coordination with the Office of Naval Research grant N00014-20-1-2700 to Stony Brook University. The authors would like to thank Mr. Carl Schmidt for his assistance in the preparation of coatings, Mr. Steven Stoll for his mechanical expertise in acquiring engine data, Dr. James Quinn for his assistance in EDAX collection and data processing, and all other individuals in GVSC’s propulsion laboratory and the CTSR that made this work possible.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Caliari, F., Saputo, J., Gingrich, E. et al. Oxidation of Ferrous Alloys and Coatings Under Isothermal, Impulse Heating, and Diesel Engine Operation: Part II—MCrAlY Coatings for Protection of 4140 Steel. Oxid Met 98, 471–488 (2022). https://doi.org/10.1007/s11085-022-10132-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-022-10132-4