Abstract

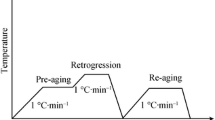

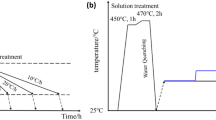

The study investigated the effect of retrogression and re-aging (RRA) on the structure and properties of the new Al–3.5Zn–3.5Mg–3.5Cu–1.6Er–0.2Zr–0.2Cr alloy through the use of scanning electron microscopy, thermodynamic calculations, hardness tests, current density, and corrosion potential. During the crystallization process, chromium is distributed between primary intermetallic compounds with an approximate composition of (Al,Zn)79.8Mg4.7Cu3Cr5.5(Er,Ti)7, with a size of approximately 10 μm and an aluminum solid solution. Following two-stage homogenization heat treatment, the Al8Cu4Er and Mg2Si phases exhibit minimal morphological changes, with the θ‑phase (Al2Cu) being completely dissolved and the T‑phase (Al,Zn,Mg,Cu) transformed into the S‑phase (Al2CuMg). Thermodynamic calculations indicate that the alloy should also contain the Al3Zr and Al45Cr7 phases, which precipitate from the supersaturated solid solution during homogenization. Age hardening in the temperature range of 150–210 °C occurs due to the release of metastable modifications of the T‑phase. The combination of hardness (140 HV) and corrosion resistance (minimum corrosion current density 1 μA/cm2) is optimized by retrogression and re-aging.

Similar content being viewed by others

References

Krasilnikov GL (1978) Development and Study of High-Strength Casting Alloy Based on Aluminum–Zinc–Magnesium System. Dissertation, Moscow, MISiS

Postnikov NS (1983) Strengthening of Aluminum Alloys and Castings. Metallurgiya, Moscow

Gotsev IS (1989) Structural-Phase Analysis of Al–Cu–Si–Mn System and Development of High-Strength and Heat-Resistant Alloy. Dissertation, Moscow, VIAM

Zavarsin A (1981) Research and Development of Secondary Casting Alloys Based on Al–Mg–Zn–Cu System. Cand. Sci (Engineering) Dissertation, Moscow: MISiS

Zolotorevsky VS, Ratner AD, Belov NA, Aksenov AA, Alekseev VF, Baev VA (1992) Structure of new high-strength casting aluminum alloys based on technical aluminum,” Sb. “Metallovedenie i Obrabotka Tsvetnykh Splavov. Nauka, Moscow, pp 142–157

Belov NA (1985) nfluence of Composition and Structure on Fracture Toughness of Casting Alloys of Al–Mg–Zn–Cu System and Development of High-Strength Alloy Based on This System with Increased Impurity Content. Dissertation, Moscow, MISiS

Belov NA, Zolotorevsky VS (2003) New high-strength casting alloys based on aluminum-nickel eutectic (nicalines),” Nauch.-Tekhnolog. Obesp. Deyatel. Predpr. Instit. Firm Mater. Sem. MGIU, Moscow, pp 584–593

Belov NA, Zolotorevsky VS (2003) Casting alloys based on aluminum-nickel eutectic (nicalines) as a possible alternative to silumins. Tsvetnye Met 2:99–105

Cheverikin VV (2007) nfluence of Eutectic-Forming Elements on the Structure and Properties of High-Strength Alloys of Al–Zn–Mg system. Dissertation, Moscow, MISiS

Gerchikova NS, Fridlyander IN, Zaitseva NI, Kirkina NN (1972) Change in the structure and properties of Al–Zn–Mg alloys. Met Sci Heat Treat 14(3):233–236

Zolotorevsky VS (1978) Microstructure and Mechanical Properties of Cast Aluminum Alloys. Dissertation, Moscow, MISiS

Zou Y, Wu X, Tang S, Zhu Q, Song H, Guo M, Cao L (2021) Investigation on microstructure and mechanical properties of Al–Zn–Mg–Cu alloys with various Zn/Mg ratios. J Mater Sci Technol 85:106–117

Novikov II (1966) Hot Brittleness of Non-Ferrous Metals and Alloys. Nauka, Moscow, p 300

Pan Y, Zhang D, Liu H, Zhuang L, Zhang J (2021) Precipitation hardening and intergranular corrosion behavior of novel Al–Mg–Zn(–Cu) alloys. J Alloys Compd 853:157199

Zolotorevskiy VS, Pozdniakov AV, Yu. Churyumov A (2014) Search for promising compositions for developing new multiphase casting alloys based on Al–Zn–Mg matrix using thermodynamic calculations and mathematical modeling. Phys Met Met 115(3):286–294

Pozdniakov AV, Zolotorevskiy VS, Mamzurina OI (2015) Determining the hot cracking index of Al–Mg–Zn casting alloys calculated using the effective solidification range. Int J Cast Met Res 28(5):318–321

Shurkin PK, Akopyan TK, Galkin SP, Aleshchenko AS (2019) Effect of radial shear rolling on the structure and mechanical properties of a new-generation high-strength aluminum alloy based on the Al–Zn–Mg–Ni–Fe system. Met Sci Heat Treat 60:764–769

Knipling KE, Dunand DC, Seidman DN (2007) Nucleation and precipitation strengthening in dilute Al-Ti and Al-Zr alloys. Met Mater Trans A 38:2552–2563

Belov NA, Alabin AN, Yu A (2009) Prokhorov, “Effect of zirconium additive on strength and electrical resistance of cold-rolled aluminum sheets,”. Izv Vuzov Tsvetnaya Met 4:42–47

Belov NA, Alabin AN, Yu. Prokhorov A (2009) “Influence of annealing on electrical resistance and mechanical properties of cold-formed alloys Al–0,6% (mas.) Zr. Tsvet Met 10:65–68

Souza PHL, de Oliveira CAS, do Vale Quaresma JM (2018) Precipitation hardening in dilute Al–Zr alloys. J Mater Res Technol 7:66–72

Zakharov VV, Fisenko IA (2018) Effect of homogenization on the structure and properties of alloy of the Al–Zn–Mg–Sc–Zr system. Met Sci Heat Treat 60:354–359

Amer SM, Barkov RY, Yakovtseva OA, Pozdniakov AV (2020) Comparative analysis of structure and properties of quasibinary Al–6.5Cu–2.3Y and Al–6Cu–4.05Er alloys. Phys Met Met 121(5):476–482

Pozdnyakov AV, Yu. Barkov R, Sarsenbaev Z, Amer SM, Prosviryakov AM (2019) Evolution of microstructure and mechanical properties of a new Al–Cu–Er wrought alloy. Phys Met Met 120(6):614–619

Amer SM, Yu. Barkov R, Yakovtseva OA, Loginova IS, Pozdniakov AV (2020) Effect of Zr on microstructure and mechanical properties of the Al–Cu–Er alloy. Mater Sci Technol 36(4):453–459

Amer SM, Mikhaylovskaya AV, Yu. Barkov R, Kotov AD, Mochugovskiy AG, Yakovtseva OA, Glavatskikh MV, Loginova IS, Medvedeva SV, Pozdniakov AV (2021) Effect of homogenization treatment regime on microstructure, recrystallization behavior, mechanical properties, and superplasticity of Al–Cu–Er–Zr alloy. JOM 73(10):3092–3101

Amer S, Yakovtseva O, Loginova I, Medvedeva S, Prosviryakov A, Bazlov A, Barkov R, Pozdniakov A (2020) The phase composition and mechanical properties of the novel precipitation-strengthening Al–Cu–Er–Mn–Zr alloy. Appl Sci 10:5345

Amer SM, Yu. Barkov R, Prosviryakov AS, Pozdniakov AV (2021) tructure and properties of new heat-resistant cast alloys based on the Al–Cu–Y and Al–Cu–Er systems. Phys Met Met 122:908–914

Amer SM, Yu. Barkov R, Prosviryakov AS, Pozdniakov AV (2021) Structure and properties of new wrought Al–Cu–Y and Al–Cu–Er based alloys. Phys Met Met 122:915–922

Glavatskikh MV, Yu. Barkov R, Khomutov MG, Pozdniakov AV (2022) The effects of yttrium and erbium on the phase composition and aging of the Al–Zn–Mg–Cu–Zr alloy with a high copper content. Phys Met Met 123:617–623

Zhang Z, Li D, Li S, Deng H, Zhang S, Fang J, Yuan H, Deng B, Qi L (2022) Effect of direct aging treatment on microstructure, mechanical and corrosion properties of a Si–Zr–Er modified Al–Zn–Mg–Cu alloy prepared by selective laser melting technology. Mater Charact 194:112459

Wang Y, Wu X, Cao L, Tong X, Couper MJ, Liu Q (2020) Effect of trace Er on the microstructure and properties of Al–Zn–Mg–Cu–Zr alloys during heat treatments. Mater Sci Eng A 792:139807

Lu JT, Huang H, Wu H, Wen SP, Gao KY, Wu XL, Nie ZR (2023) Mechanical properties and corrosion behavior of a new RRA-treated Al–Zn–Mg–Cu–Er–Zr alloy. Rare Met 42:672–679

An Z, Yang W, Zhan H, Hu B, Wang Q, Matsumura S, Sha G (2020) On the strengthening effect of Al–Cr–Si dispersoid in an Al–Si–Mg–Cu casting alloy with Cr addition. Mater Charact 166:110457

Glavatskikh MV, Yu. Barkov R, Khomutov MG, Pozdniakov AV (2023) Influence of manganese on phase composition and mechanical properties of alloys Al–Zn–Mg–Cu–Zr–Y(Er). Metallurg 12:47–53

Glavatskikh MV, Gorlov LE, Yu. Barkov R, Khomutov MG, Pozdniakov AV (2023) Microstructure, mechanical and corrosion properties of new foundry heat-resistant alloys Al–4Zn–4Mg–4Cu–Zr–Y(Er). Metallurg 9:39–41

Wang X, Ma P‑K, Meng Z‑Y, Zhang S‑Y, Liu X, Wang C, Wang H‑Y (2021) Effect of trace Cr alloying on centerline segregations in sub-rapid solidified Al–Mg–Si (AA6061) alloys fabricated by twin-roll casting. Mater Sci Eng A 825:141896

Trudonoshyn O, Prach O, Randelzhofer P, Durst K, Körner C (2021) Heat treatment of the new high-strength high-ductility Al–Mg–Si–Mn alloys with Sc, Zr and Cr additions. Materialia 15:100981

Wen L, Liu W, Wu G, Wu H, Zhang L, Sun J, Zhang J, Xu S, Shi C, Wang Y, Lu Y (2022) Microstructure and stress corrosion cracking resistance of Al–6.5Zn–2Cu–1.5Mg–0.05Ti alloy modified by Cr addition. Mater Charact 183:111621

Amer SM, Glavatskikh MV, Yu. Churyumov A, Loginova IS, Yu. Barkov R, Khomutov MG, Pozdniakov AV (2023) Comprehensive analysis of microstructure and hot deformation behavior of Al–Cu–Y–Mg–Cr–Zr–Ti–Fe–Si alloy. Metals 13:1853

Park JK (1988) Influence of retrogression and reaging treatments on the strength and stress corrosion resistance of aluminium alloy 7075-T6. Mater Sci Eng A 103:223–231

Peng G, Chen K, Chen S, Fang H (2012) Influence of dual retrogression and re-aging temper on microstructure, strength and exfoliation corrosion behavior of Al–Zn–Mg–Cu alloy. Trans Nonferrous Met Soc China 22(4):803–809

Wang YL, Pan QL, Wei LL, Li B, Wang Y (2014) Effect of retrogression and reaging treatment on the microstructure and fatigue crack growth behavior of 7050 aluminum alloy thick plate. Mater Des 55:857–863

He B, Cao L, Wu X, Tang S, Lin X, Zou Y (2024) Effect of continuous retrogression and re-ageing treatment on mechanical properties, corrosion behavior and microstructure of an Al–Zn–Mg–Cu alloy. J Alloys Compd 970:172592

Zhong H, Li S, Wu J, Deng H, Chen J, Yan N, Chen Z, Duan L (2022) Effects of retrogression and re-aging treatment on precipitation behavior, mechanical and corrosion properties of a Zr+Er modified Al–Zn–Mg–Cu alloy. Mater Charact 183:111617

Knipling K (2008) Precipitation evolution in Al–Zr and Al–Zr–Ti alloys during aging at 450–600 °C. Acta Mater 56:1182–1195

Wei C, Zhan Y (2019) Phase-equilibrium investigation of the Al–Cr–Er ternary system at 773 K (500 °C). Met Mater Trans A 50A:2956–2970

Raghavan V (2012) Al–Cr–Cu (Aluminum–Chromium–Copper). J -ph Equilib Diffus 33:53–54

Raghavan V (2007) Al–Er–Mg (Aluminum–Erbium–Magnesium). J -ph Equilib Diffus 28:461–463

Rogl P, Stiltz S, Hayes FH (1992) The Al–Cr–Mg system (aluminum–chromium–magnesium). J -ph Equilib 13:317–323

Zou Y, Wu X, Tang S, Zhu Q, Song H, Cao L (2020) Co-precipitation of T′ and η′ phase in Al–Zn–Mg–Cu alloys. Mater Charact 169:110610

Hou S, Liu P, Zhang D, Zhang J, Zhuang L (2018) Precipitation hardening behavior and microstructure evolution of Al–5.1Mg–0.15Cu alloy with 3.0Zn (wt.%) addition. J Mater Sci 53(5):3846–3861

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 5, pp. 62–67, May, 2024. Russian DOI: https://doi.org/10.52351/00260827_2024_5_62.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Glavatskikh, M.V., Gorlov, L.E., Barkov, R.Y. et al. Effect of retrograssion and re-aging on microstructure and properties of Al–Zn–Mg–Cu–Zr–Er alloy. Metallurgist 68, 702–710 (2024). https://doi.org/10.1007/s11015-024-01776-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01776-5