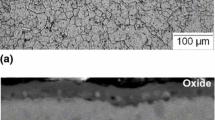

Structure is studied for diffusion layers of heat-resistant steel 16Kh2N3MFBAYu-Sh prepared by ion-plasma nitriding, and their phase composition is established represented by ultra-finely dispersed incoherent chromium nitride particles in a solid solution matrix. Contact fatigue strength of the nitrided layer prepared by an optimized regime is determined by experiment. A feature is established for the effect of nitride layer thickness on contact fatigue strength for heat-resistant steel alloyed with nickel. Nitriding regimes are recommended for treating low modulus gear wheels and other similar components whose performance is governed by contact fatigue strength.

Similar content being viewed by others

References

Yu. S. Eliseev, V. V. Krymov, I. P. Nezhurin, et al., Production of Gas Turbine Engine Gear Wheels, Vysshaya Shkola, Moscow (2001).

A. G. Bratukhin, G. K. Yazov, and B. E. Karasev (eds.), Contemporary Technology in the Production of Gas Turbine Engines, Mashinostoenie, Moscow (1997).

A. A. Babad-Zakhryapin and G. D. Kuznetsov, Chemical Heat Treatment in a Glow Discharge, Atomizdat, Moscow (1975).

S. D. Karpukhin, Study of the Effect of Nitrided Steel Structure on Contact Fatigue and Development of Prior Heat Treatment Technology and Ion-Nitriding of Gear Wheels Made of Steel 16Kh2N3MFBAYu-Sh: Auth. Abstr. Diss. Cand. Tech. Sci., Moscow (1992).

E. A. Eliseev, Development of Ion-Nitriding with Plastic Deformation Preceding It for Improving Contact Endurance of Nickel-Containing Low-Carbon Steels of the Martensitic Class: Auth. Abstr. Diss. Cand. Tech. Sci., Moscow (1995).

S. A. Gerasimov, L. I. Kuksenova, and V. G. Lapteva, Structure and Wear Resistance of Nitrided Structural Steels and Alloys, Izd. MGTU Baumana, Moscow (2014).

GOST 25.501–78, Contact Fatigue Test Methods, Izd. Standartov, Moscow (1979).

M. Yu. Semenov, A. E. Smirnov, R. S. Fakhurtdinov, et al., “Optimization of process regimes for vacuum carburization of gear wheels made of heat-resistant steel VKS-7 based on a calculated planning method,” MiTOM, No. 1(715), 27–30 (2015).

N. M. Ryzhov, “Processing provision of contact fatigue resistance for gear wheels made of heat-resistant steels,” MiTOM, No. 7(661), 39–45 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 4, pp. 77–81, April, 2016.

Rights and permissions

About this article

Cite this article

Gerasimov, S.A., Kuksenova, L.I., Semenov, M.Y. et al. Structure and Contact Fatigue Strength of Heat-Resistant Steel VKS-7 Hardened Layers After Ion-Plasma Nitriding. Metallurgist 60, 428–433 (2016). https://doi.org/10.1007/s11015-016-0309-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0309-4