Abstract

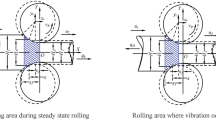

This paper investigates the dynamic behavior of a rolling mill during variable gauge rolling. Considering that the variation of rolling process parameters and the movement of hydraulic cylinder are the remarkable features of the variable gauge rolling process, the dynamic rolling force model and the hydraulic cylinder dynamic model were established respectively, and the rolling mill dynamic model was established based on the structure-process coupling strategy. The Incremental Harmonic Balance Method (IHBM) is used to solve the amplitude–frequency characteristics of the rolling mill system, and the Runge–Kutta method is used to solve the vibration characteristics. The results indicate that as the piston of the hydraulic cylinder is displaced, the stiffness of hydraulic cylinder changes and exhibits nonlinear features. The nonlinear characteristics of the hydraulic cylinder affect the dynamic behavior of the rolling mill, which presents different dynamic behaviors when the piston is in different initial positions for variable gauge rolling. The results provide a theoretical reference for the analysis and control of rolling mill dynamic behavior during variable gauge rolling.

Similar content being viewed by others

References

Liu CY, Barella S, Peng Y, Guo S, Liang SC, Sun JL, Gruttadauria A, Belfi M, Mapelli C (2023) Modeling and characterization of dynamic recrystallization under variable deformation states. Int J Mech Sci 238:107838

Wang JS, Jiang ZY, Tieu AK, Liu XH, Wang GD (2008) A flying gauge change model in tandem cold strip mill. J Mater Process Technol 204(1):152–161

Zhi Y, Wang XG, Wang S, Liu XH (2018) A review on the rolling technology of shape flat products. Int J Adv Manuf Tech 94(9):4507–4518

Yang DY, Bambach M, Cao J, Duflou JR, Groche P, Kuboki T, Sterzing A, Tekkaya AE, Lee CW (2018) Flexibility in metal forming. Cirp Ann-Manuf Techn 67(2):743–765

Liu YM, Wang ZH, Wang T, Sun J, Zheng XG, Zhang DH, Huang QX (2022) Prediction and analysis of the force and shape parameters in variable gauge rolling. Chin J Mech Eeg-EN 35(1):88

Yang YB, Peng Y (2020) Dynamic rolling model based on uniform deformation. J Manuf Process 58:1334–1347

Zhang Y, Tan J (2015) Numerical simulation and vertical motion control of rolls for variable gauge rolling. J Iron Steel Res Int 22(8):703–708

Shafiei E, Dehghani K (2018) Effects of deformation conditions on the rolling force during variable gauge rolling. J Manuf Mater Process 2(3):48

Wang DC, Dong LC, Liu HM, Wang Y (2015) Velocity preset and transitional zone’s shape optimization for tailor rolled blank. J Iron Steel Res Int 22(4):279–287

Zhang GJ, Liu XH, Hu XL, Zhi Y (2013) Horizontal velocity of variable gauge rolling: theory and finite elements simulation. J Iron Steel Res Int 20(10):10–16

Yang YB, Peng Y, Liu Y, Liu CY, Wang J (2021) Dynamic theoretical model of strip hot rolling considering change of roll gap. Iron and Steel 1–15

Yu W, Sun GJ (2014) Forward slip theoretical model and simulation for variable gauge rolling of TRB sheet. J Univ Sci Technol Beijing 36(02):241–245

Gao ZY, Liu Y, Zhang QD, Liao ML, Tian B (2020) Chatter model with structure-process-control coupled and stability analyses in the cold rolling system. Mech Syst Signal Pr 140:106692

Yarita I, Furukawa K, Seino Y, Takimoto T, Nakazato Y, Nakagawa K (1978) An analysis of chattering in cold rolling for ultrathin gauge steel strip. Trans Iron Steel Inst Jpn 18(1):1–10

Liu ZL, Li P, Jiang JH, Liu B (2021) Research on vibration characteristics of mill rolls based on nonlinear stiffness of the hydraulic cylinder. J Manuf Process 64:1322–1328

Liu ZL, Pan GX, Jiang JH, Liu B (2021) Vibration characteristics of rolling mill system under constraints of the nonlinear spring force and friction force from hydraulic cylinder. Shock Vib 2021:6632714

Xu T, Hou DX, Sun ZN, Guo DW (2020) Vibration characteristics of multi-parametric excitations and multi-frequency external excitations of rolling mill under entry thickness fluctuation of strip. J Iron Steel Res Int 27(5):517–527

Wang X, Yan XQ (2019) Dynamic model of the hot strip rolling mill vibration resulting from entry thickness deviation and its dynamic characteristics. Math Probl Eng 2019:5868740

Patel A, Malik A, Mathews R (2022) Computational method to predict three-dimensional chatter vibration in cold rolling of flat metals. J Manuf Sci E T Asme 145(4):041004

Patel A, Malik A, Mathews R (2021) Efficient three-dimensional model to predict time history of structural dynamics in cold rolling mills. J Manuf Sci E T Asme 144(7):071009

Sun CF, Zhao W, Huang D, Zhang HB (2023) Stability of nonlinear vibrations induced by rolling force in a precise cold mill system. Appl Math Model 119:196–217

Cui JX, Peng Y, Wang J, Hu DK (2022) Study on work roll vertical vibration under periodic spalling of the oxide film. Tribol T 65(5):827–838

Lu X, Sun J, Wei Z, Li GT, Zhang DH (2021) Effect of minimum friction coefficient on vibration stability in cold rolling mill. Tribol Int 159:106958

Gao ZY, Tian B, Liu Y, Zhang LY, Liao ML (2021) Dynamics-based optimization of rolling schedule aiming at dual goals of chatter suppression and speed increase for a 5-stand cold tandem rolling mill. J Iron Steel Res Int 28(2):168–180

Sims RB (1954) The calculation of roll force and torque in hot rolling mills. P I Mech Eng C J Mec 168(1):191–200

Yang YB, Peng Y (2021) Theoretical model and experimental study of dynamic hot rolling. Metals 11(9):1346

Liu HR, Hou DX, Shi PM, Liu F (2011) Vibration characteristics of hysteretic nonlinear vertical vibration system of rolling mill roller. J Mech Eng 47(13):65–71

Snowdon RA, Ryley MD, Temporal J, Crabb GI (1983) The effect of hydraulic stiffness on tunnel boring machine performance. Int J Rock Mech Min Sci Geomech Abstr 20(5):203–214

Zhu Y, Jiang WL, Kong XD, Zheng Z (2015) Study on nonlinear dynamics characteristics of electrohydraulic servo system. Nonlinear Dynam 80(1):723–737

Liu F, Liu B, Shi PM, Hou DX (2014) Vibration behavior of roll system under nonlinear constraints of the hydraulic cylinder. J Mech Eng 50(24):59–65

Cui JX, Peng Y, Wang J (2022) Instability of roll nonlinear system with structural clearance in rolling process. J Iron Steel Res Int 30(1):112–125

Cheung YK, Chen SH, Lau SL (1990) Application of the incremental harmonic balance method to cubic non-linearity systems. J Sound Vib 140(2):273–286

Acknowledgements

This work was supported by Regional Joint Funds of the National Natural Science Foundation of China (Grant No. U20A20289), China Scholarship Council (Grant No. 202208130100), Innovative Research Groups Project of Natural Science Foundation of Hebei Province, China (Grant No. E202103011).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No author has reported a potential conflict of interest relevant to this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Brusa, E., Peng, Y. et al. Dynamics and stability analysis of rolling mill system during variable gauge rolling. Meccanica 58, 2439–2454 (2023). https://doi.org/10.1007/s11012-023-01735-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-023-01735-5