Abstract

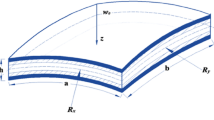

In this study, an analytical procedure for the bending problem of a viscoelastic sandwich plate with a corrugated core is presented. Reissner–Mindlin plate theory and N-termed Prony series are employed to define the elastic and time-dependent contributions of the governing equations, respectively. Three different corrugation patterns, i.e., rectangular, trapezoidal, and triangular, are examined. Moreover, the structure is analyzed under both simply support and clamp boundary conditions. The calibrated material parameters of polymethyl methacrylate (PMMA) for the Generalized Maxwell rheological model are employed to show the viscoelastic response of the structure. A 3D finite element simulation of the problem is also conducted to confirm the accuracy of the analytical formulation. The two well-known creep and stress relaxation phenomena of the viscoelastic materials are examined for the mentioned corrugation cores and both boundary conditions analytically and numerically. The time-dependent dimensionless deflection and resultant von Mises stress distributions are provided. Besides, the variation of the results with various rise-times and applied load are studied in detail. The von Mises stress contours of the upper surface of the structure at the end of the creep test are also presented. The finite element method outcomes verify the analytical results with excellent compatibility. The proposed analytical procedure can be used as an efficient tool to study the effects of various parameters such as material, geometrical constants, and corrugation pattern on bending of viscoelastic sandwich plates with corrugated core problems for design and optimization, which involves a high number of simulations.

Similar content being viewed by others

References

He L, Cheng Y-S, Liu J (2012) Precise bending stress analysis of corrugated-core, honeycomb-core and x-core sandwich panels. Compos Struct 94(5):1656–1668

Plantema FJ (1966) Sandwich construction: the bending and buckling of sandwich beams, plates, and shells

Chang W-S, Ventsel E, Krauthammer T, John J (2005) Bending behavior of corrugated-core sandwich plates. Compos Struct 70(1):81–89

de Vargas Lisbôa T, Marczak RJ (2019) A decomposition method for nonlinear bending of anisotropic thin plates. Eur J Mech-A/Solids 74:202–209

Libove C, Batdorf S (1948) A general small-deflection theory for flat sandwich plates. National aeronautics and space administration washington dc

Libove C, Hubka RE (1951) Elastic constants for corrugated-core sandwich plates

Shaban M, Alibeigloo A (2017) Three-dimensional elasticity solution for sandwich panels with corrugated cores by using energy method. Thin-Walled Struct 119:404–411

Koudzari M, Zakerzadeh M-R, Baghani M (2019) Corrugated structures reinforced by shape memory alloy sheets: analytical modeling and finite element modeling. Proc Inst Mech Eng Part G J Aerosp Eng 233(7):2445–2454

Pydah A, Batra R (2018) Analytical solution for cylindrical bending of two-layered corrugated and webcore sandwich panels. Thin-Wall Struct 123:509–519

Magnucka-Blandzi E, Magnucki K, Wittenbeck L (2015) Mathematical modeling of shearing effect for sandwich beams with sinusoidal corrugated cores. Appl Math Model 39(9):2796–2808

Jamalimehr A, Baghani M, Baniassadi M, Zakerzadeh M (2017) Thermomechanical behavior of shape memory polymer beams reinforced by corrugated polymeric sections. Meccanica 52(8):1947–1962

Akbari-Azar S, Baghani M, Zakerzadeh M-R, Shahsavari H, Sohrabpour S (2019) Analytical investigation of composite sandwich beams filled with shape memory polymer corrugated core. Meccanica 54(10):1647–1661

Dolatabadi R, Mohammadi A, Baghani M (2021) A computational simulation of electromembrane extraction based on poisson-nernst-planck equations. Anal Chim Acta 338414

Bayat MR, Wang K, Baghani M (2020) Visco-hyperelastic swelling and mechanical behavior of tough pH-sensitive hydrogels: theory development and numerical implementation. Int J Eng Sci 152:103294

Dunn MG, Silver FH (1983) Viscoelastic behavior of human connective tissues: relative contribution of viscous and elastic components. Connect Tissue Res 12(1):59–70

Testu J, McGarry M, Dittmann F, Weaver J, Paulsen K, Sack I, Van Houten E (2017) Viscoelastic power law parameters of in vivo human brain estimated by MR elastography. J Mech Behav Biomed Mater 74:333–341

Kazempour M, Baniassadi M, Shahsavari H, Remond Y, Baghani M (2019) Homogenization of heterogeneous brain tissue under quasi-static loading: a visco-hyperelastic model of a 3D RVE. Biomech Model Mechanobiol 18(4):969–981

Johnson A, Quigley C (1992) A viscohyperelastic Maxwell model for rubber viscoelasticity. Rubber Chem Technol 65(1):137–153

Khajehsaeid H, Baghani M, Naghdabadi R (2013) Finite strain numerical analysis of elastomeric bushings under multi-axial loadings: a compressible visco-hyperelastic approach. Int J Mech Mater Des 9(4):385–399

Fahimi S, Baghani M, Zakerzadeh M-R, Eskandari A (2018) Developing a visco-hyperelastic material model for 3D finite deformation of elastomers. Finite Elem Anal Des 140:1–10

Naghdabadi R, Baghani M, Arghavani J (2012) A viscoelastic constitutive model for compressible polymers based on logarithmic strain and its finite element implementation. Finite Elem Anal Des 62:18–27

Ansari M, Golzar M, Baghani M, Abbasishirsavar M, Taghavimehr M (2019) Force recovery evaluation of thermo-induced shape-memory polymer stent: material, process and thermo-viscoelastic characterization. Smart Mater Struct 28(9):095022

Yarali E, Taheri A, Baghani M (2020) A comprehensive review on thermomechanical constitutive models for shape memory polymers. J Intell Mater Syst Struct:1045389X20916795

Di Lorenzo S, Di Paola M, La Mantia FP, Pirrotta A (2017) Non-linear viscoelastic behavior of polymer melts interpreted by fractional viscoelastic model. Meccanica 52(8):1843–1850

Goh S, Charalambides M, Williams J (2003) Large strain time dependent behavior of cheese. J Rheol 47(3):701–716

Charalambides MN, Wanigasooriya L, Williams JG, Goh SM, Chakrabarti S (2006) Large deformation extensional rheology of bread dough. Rheol Acta 46(2):239–248

Shojaeifard M, Sheikhi S, Baniassadi M, Baghani M (2020) On finite bending of visco-hyperelastic materials: a novel analytical solution and FEM. Acta Mech: 1–16

Goh S, Charalambides M, Williams J (2004) Determination of the constitutive constants of non-linear viscoelastic materials. Mech Time-Dependent Mater 8(3):255–268

Yarali E, Baniasadi M, Bodaghi M, Baghani M (2020) 3D constitutive modelling of electro-magneto-visco-hyperelastic elastomers: a semi-analytical solution for cylinders under large torsion-extension deformation. Smart Mater Struct

Baniasadi M, Fareghi P, Darijani F, Baghani M (2020) Finite strain relaxation and creep in coupled axial and torsional deformation. Mech Des Struct Mach: 1–17

Baniasadi M, Maleki-Bigdeli M-A, Baghani M (2020) Force and multiple-shape-recovery in shape-memory-polymers under finite deformation torsion-extension. Smart Mater Struct 29(5):055011

Garekani HA, Dolatabadi R, Akhgari A, Abbaspour MR, Sadeghi F (2017) Evaluation of ethylcellulose and its pseudolatex (Surelease) in preparation of matrix pellets of theophylline using extrusion-spheronization. Iran J Basic Med Sci 20(1):9–16

Shojaeifard M, Baghani M, Shahsavari H (2018) Rutting investigation of asphalt pavement subjected to moving cyclic loads: an implicit viscoelastic–viscoplastic–viscodamage FE framework. Int J Pavement Eng: 1–15

Bayat MR, Dolatabadi R, Baghani M (2020) Transient swelling response of pH-sensitive hydrogels: A monophasic constitutive model and numerical implementation. Int J Pharm 577:119030

Yamaguchi T, Fujii Y, Fukushima T, Kanai T, Nagai N, Maruyama S (2010) Applied mechanics and materials. Trans Tech Publ

Shahsavari H, Naghdabadi R, Baghani M, Sohrabpour S (2016) A finite deformation viscoelastic–viscoplastic constitutive model for self-healing materials. Smart Mater Struct 25(12):125027

Baghani M, Dolatabadi R, Baniassadi M (2017) Developing a finite element beam theory for nanocomposite shape memory polymers with application to sustained release of drugs. Scientia Iranica 24(1):249–259

Bacca M, McMeeking RM (2017) A viscoelastic constitutive law for hydrogels. Meccanica 52(14):3345–3355

Altenbach H, Eremeyev VA (2009) On the bending of viscoelastic plates made of polymer foams. Acta Mech 204(3–4):137

Hilton HH, Kubair D, Beldica CE (2001) Piezoelectric bending control of nonlinear viscoelastic plates: probabilities of failure and survival times. ASME Appl Mech Div-Publ-AMD 249:81–94

Kadıoğlu F, Tekin G. Analysis of Plates under Point Load Using Zener Material Model

Salehi M, Safi DA (2010) Non-Linear analysis of viscoelastic rectangular plates subjected to in-plane compression

Amabili M (2018) Nonlinear mechanics of shells and plates in composite, soft and biological materials. Cambridge University Press

Mohammadsalehi M, Zargar O, Baghani M (2017) Study of non-uniform viscoelastic nanoplates vibration based on nonlocal first-order shear deformation theory. Meccanica 52(4–5):1063–1077

Zhou YF, Wang ZM (2014) Application of the differential quadrature method to free vibration of viscoelastic thin plate with linear thickness variation. Meccanica 49(12):2817–2828

Amabili M (2016) Nonlinear vibrations of viscoelastic rectangular plates. J Sound Vib 362:142–156

Amabili M (2018) Nonlinear damping in nonlinear vibrations of rectangular plates: derivation from viscoelasticity and experimental validation. J Mech Phys Solids 118:275–292

Balasubramanian P, Ferrari G, Amabili M (2018) Identification of the viscoelastic response and nonlinear damping of a rubber plate in nonlinear vibration regime. Mech Syst Signal Process 111:376–398

Ebrahimi F, Hosseini S (2016) Thermal effects on nonlinear vibration behavior of viscoelastic nanosize plates. J Therm Stresses 39(5):606–625

Gupta A, Kumar L (2008) Thermal effect on vibration of non-homogenous visco-elastic rectangular plate of linearly varying thickness. Meccanica 43(1):47–54

Allam M, Zenkour A, El-Mekawy H (2010) Bending response of inhomogeneous fiber-reinforced viscoelastic sandwich plates. Acta Mech 209(3–4):231–248

Yang X-D, Yu T-J, Zhang W, Qian Y-J, Yao M-H (2016) Damping effect on supersonic panel flutter of composite plate with viscoelastic mid-layer. Compos Struct 137:105–113

Wu P, Zhou D, Liu W, Lu W, Fang H (2017) 3-D exact solution of two-layer plate bonded by a viscoelastic interlayer with memory effect. Compos Struct 164:291–303

Reissner E (1947) On bending of elastic plates. Q Appl Math 5(1):55–68

Chang W-S (2004) Elasto-plastic analysis of corrugated sandwich steel panels

Park S, Schapery R (1999) Methods of interconversion between linear viscoelastic material functions: part I—A numerical method based on Prony series. Int J Solids Struct 36(11):1653–1675

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maleki-Bigdeli, MA., Sheikhi, S. & Baghani, M. Development of an analytical framework for viscoelastic corrugated-core sandwich plates and validation against FEM. Meccanica 56, 2103–2120 (2021). https://doi.org/10.1007/s11012-021-01350-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-021-01350-2