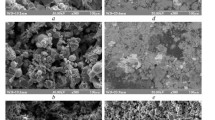

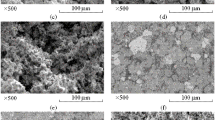

We study the influence of admixtures of CrB2 powder on the mechanical (microhardness H and modulus of elasticity E) and tribological (wear resistance) characteristics of composite materials based on iron, copper, nickel, and tin sintered by the method of cold pressing with subsequent vacuum hot pressing. The source powders have the range of particle sizes 5–50 μm. It is shown that the hardness and elasticity modulus increase with the content of CrB2. At the same time, the wear rate decreases if the CrB2 content remains lower than 2 wt.% but then increases. The values of resistances to the elastic (H/E) and plastic (H3/E2) deformations of the material exhibit good correlation with the level of wear resistance. The causes of changes in the physicomechanical and operating properties of sintered composite materials are discussed.

Similar content being viewed by others

References

V. A. Mechnyk, “Diamond–Fe–Cu–Ni–Sn composite materials with predictable stable characteristics,” Fiz.-Khim. Mekh. Mater., 48, No. 5, 34–42 (2012); English translation: Mater. Sci., 48, No. 5, 591–600 (2013).

A. A. Zaitsev, D. A. Sidorenko, E. A. Levashov, V. V. Kurbatkina, S. I. Rupasov, V. A. Andreev, and P. V. Sevast’yanov, “Development and application of the Cu–Ni–Fe–Sn-based dispersion-hardened bond for cutting tools of superhard materials,” Sverkhtverd. Mater., 34, No. 4, 75–88 (2012); English translation: J. Superhard Mater., 34, No. 4, 270–280 (2012).

E. Gevorkyan, V. Mechnik, N. Bondarenko, R. Vovk, S. Lytovchenko, V. Chishkala, and O. Melnik, “Peculiarities of obtaining diamond–(Fe–Cu–Ni–Sn) composite materials by hot pressing,” Funct. Mater., 24, No. 1, 31–45 (2017).

J. Konstanty, Powder Metallurgy Diamond Tools, Elsevier Science, Oxford (2005).

V. M. Kolodnits’kyi and O. E. Bagirov, “On the structure formation of diamond-containing composites used in drilling and stone-working tools (A review),” Sverkhtverd. Mater., No. 1, 3–26 (2017); English translation: J. Superhard Mater., 39, No. 1, 1–17 (2017).

V. A. Mechnik, N. A. Bondarenko, S. N. Dub, V. M. Kolodnitskyi, Yu. V. Nesterenko, N. O. Kuzin, I. M. Zakiev, and E. S. Gevorkyan, “A study of microstructure of Fe–Cu–Ni–Sn and Fe–Cu–Ni–Sn–VN metal matrix for diamond containing composites,” Mater. Charact., 146, 209–216 (2018).

V. A. Mechnik, N. A. Bondarenko, V. M. Kolodnitskyi, V. I. Zakiev, I. M. Zakiev, M. Storchak, S. N. Dub, and N. O. Kuzin, “Physicomechanical and tribological properties of Fe–Cu–Ni–Sn and Fe–Cu–Ni–Sn–VN nanocomposites obtained by powder metallurgy methods,” Tribol. Ind., 41, No. 2, 188–198 (2019).

V. A. Mechnyk, “Regularities of structure formation in diamond−Fe–Cu–Ni–Sn–CrB2 systems,” Fiz.-Khim. Mekh. Mater., 49, No. 1, 85–92 (2013); English translation: Mater. Sci., 49, No. 1, 93–101 (2013).

A. Leyland and A. Matthews, “On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour,” Wear, 246, Nos. 1–2, 1–11 (2000).

J. Musil, P. Novák, R. Čerstvý, and Z. Soukup, “Tribological and mechanical properties of nanocrystalline-TiC/a-C nanocomposite thin films,” J. Vac. Sci. Technol. A, 28, No. 2, 244–249 (2010).

V. A. Aleksandrov, A. N. Zhukovsky, and V. A. Mechnik, “Temperature field and wear of an inhomogeneous diamond wheel at convective heat exchange,” Tren. Iznos, 15, No. 1, 27–35 (1994).

V. A. Dutka, V. M. Kolodnitskij, O. V. Mel’nychuk, and S. D. Zabolotnyj, “Mathematical model for thermal processes occurring in the interaction between rock destruction elements of drilling bits and rock mass,” Sverkhtverd. Mater., No. 1, 67–77 (2005).

A. N. Zhukovskij, A. L. Majstrenko, V. A. Mechnik, and N. A. Bondarenko, “Stress-strain state of the matrix around the diamond grain exposed to the normal and tangent loading components. Part 2. Analysis,” Tren. Iznos, 23, No. 4, 393–396 (2002).

M. O. Bondarenko, V. A. Mechnik, and M. V. Suprun, “Shrinkage and shrinkage rate behavior in Cdiamond–Fe–Cu–Ni–Sn–CrB2 system during hot pressing of pressureless-sintered compacts,” Sverkhtverd. Mater., No. 4, 29–39 (2009); English translation: J. Superhard Mater., 31, No. 4, 232–240 (2009).

M. Storchak, I. Zakiev, and L. Träris, “Mechanical properties of subsurface layers in the machining of the titanium alloy Ti10V2Fe3Al,” J. Mech. Sci. Technol., 32, 315–322 (2018).

V. A. Mechnik, N. A. Bondarenko, V. M. Kolodnitskyi, V. I. Zakiev, I. M. Zakiev, S. R. Ignatovich, S. N. Dub, and N. O. Kuzin, “Formation of Fe–Cu–Ni–Sn–VN nanocrystalline matrix by vacuum hot pressing for diamond-containing composite. mechanical and tribological properties,” Sverkhtverd. Mater., 41, No. 6, 26–43 (2019); English translation: J. Superhard Mater., 41, No. 6, 388–401 (2019).

S. A. Firstov, V. F. Gorban, N. A. Krapivka, E. P. Pechkovskii, N. I. Danilenko, and M. V. Karpets, “Mechanical properties of multicomponent titanium alloy,” Probl. Prochn., No. 5, 187–198 (2010); English translation: Strength Mater., 42, 622–630 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 56, No. 6, pp. 116–124, November–December, 2020.

Rights and permissions

About this article

Cite this article

Mechnik, V.А., Kolodnitskyi, V.М., Zakiev, І.М. et al. Influence of CrB2 Powder on the Physicomechanical Properties of Fe–Cu–Ni–Sn Composites Sintered By Vacuum Hot Pressing. Mater Sci 56, 852–861 (2021). https://doi.org/10.1007/s11003-021-00504-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-021-00504-7